Mounting structure of die-cast cap mouth shell and method of die-casting pouring

A technology of installation structure and cap mouth, which is applied in the field of metal casting, can solve the problems of reducing yield, cracks, and easy damage, etc., and achieve the effects of increasing filling time, slowing down thermal shock, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Cr12MoV steel, cast ingot 3.2t; Embodiment follows:

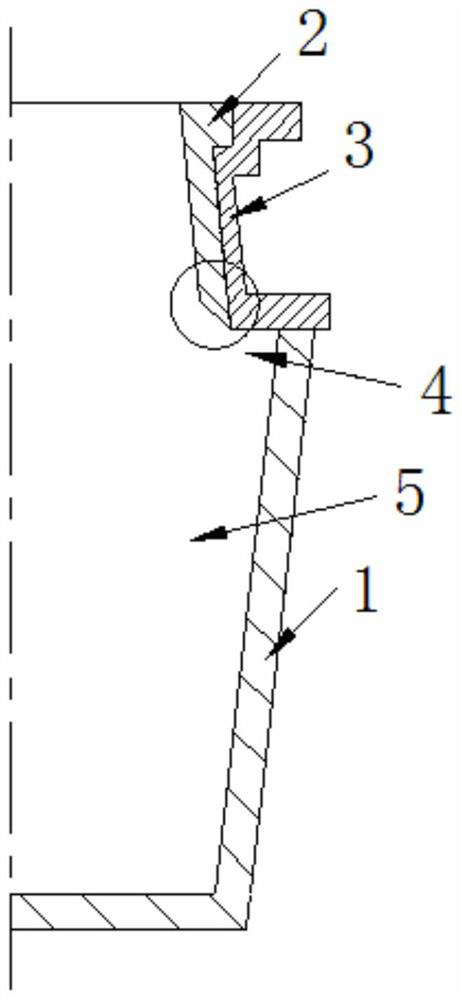

[0029] 3 the lower end of the cap lumen port are provided in a housing arranged in a first annular protrusion. A first projection size parameters as follows: L1 is the value of 60mm, the value of L2 of 60mm, the lower surface of the first chamfer or rounded protrusions, α angle of 45 °, the first projection tip a small chamfer is formed with a lumen surface of the heat insulating plate 2 is flush with the inclined surface, trimming length 20mm (i.e. the length of the first linear projection at its tip end face is oblique direction 20mm). Port 3 and the cap housing is a first protrusion cast iron unitary structure.

[0030] 1 the mold has a rectangular cross section of the lumen, the lumen cross section of the cap shell port 3 is also mounted to lumen rectangular mouth of the cap 3 of the four shell heat insulating plate 2, one on each side, the bottom plate 2 is placed on the first insulating convex upper surf...

Embodiment 2

[0032] Example 2: For 4Cr13 steel, pouring 3T ingots, the embodiment is as follows:

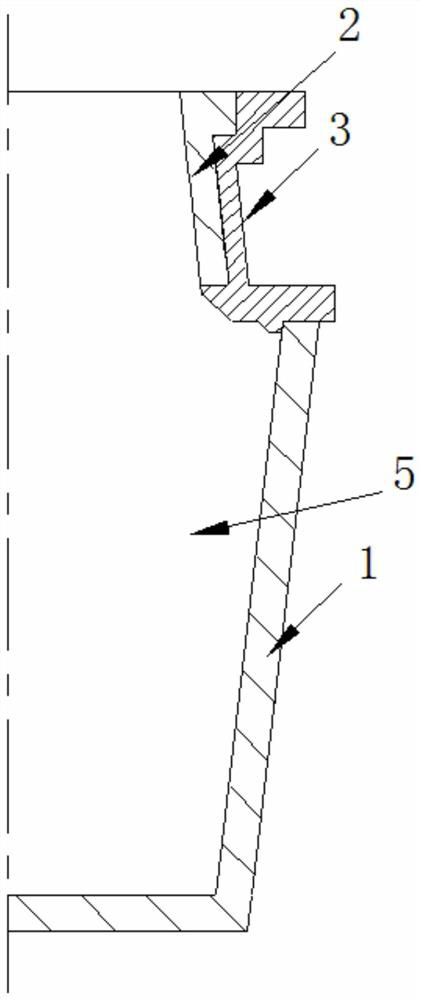

[0033] The lower end of the cap housing 3 is provided with an annular arrangement of a first projection. The first protrusions are as follows: L1 is from 35 mm, and the value of L2 is 40 mm. The lower surface of the first protrusion is inverted or filled, and the angle of the α is 40 °, the first protrusions of the tip For a small cut angle, a slope of flushing with the insulation plate 2 is flushed, and the cutting edge length is 25 mm (i.e., the linear length of the first projection is 25 mm in its inclination direction).

[0034] The lower surface of the mounting base of the cap housing 3 is provided with a second projection of the annular arrangement, and the second protrusion is disposed in the metal mold 1 lumen, and one of the second projections is fitted with the metal mold 1 lumen. The longitudinal section of the second projection is a trapezoid, and the size parameters are as follows: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com