Stope structure for upward slicing whole tailing cemented filling method

A cemented filling, full tailings technology, applied in the fields of fillings, safety devices, surface mining, etc., can solve the problems of inability to achieve continuous mining in two steps, high stope support costs, and large mining engineering volume, etc. The effect of stope support engineering volume, improving filling efficiency and mine production efficiency, and high recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

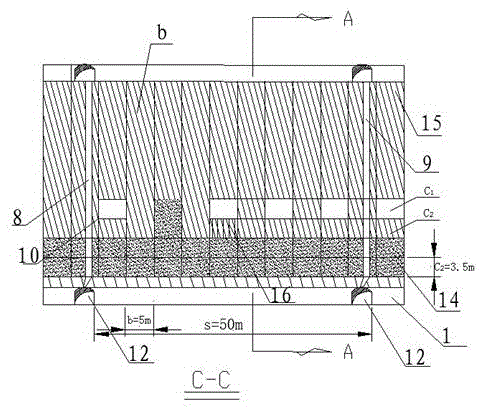

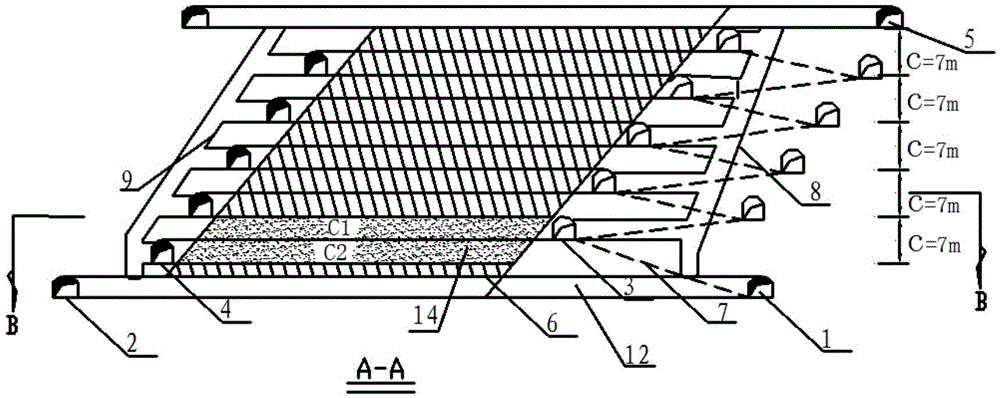

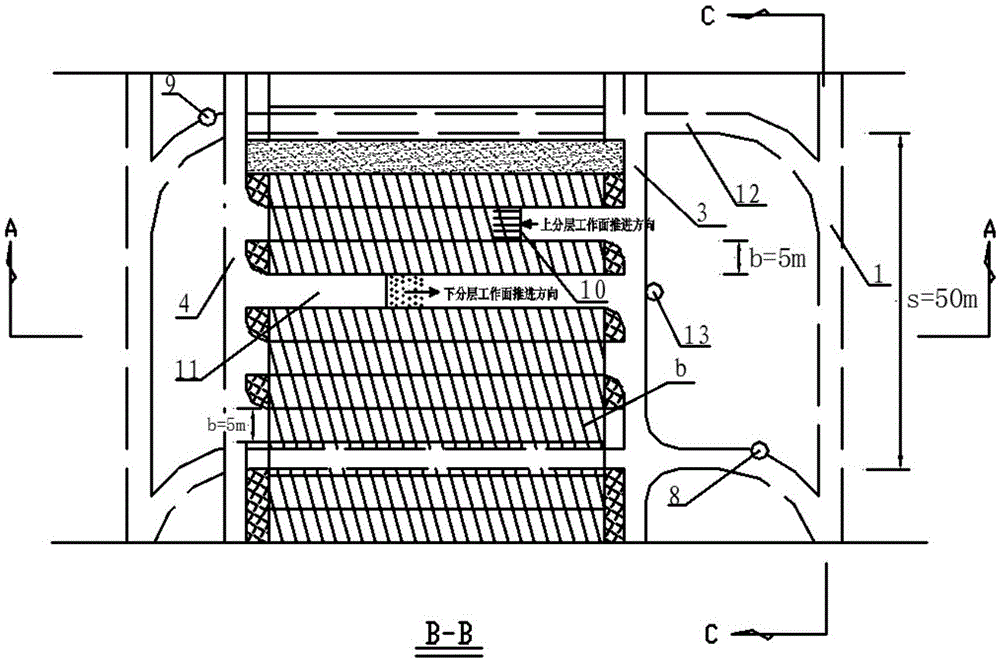

[0030] In order to further describe the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] A volcanic sedimentary metamorphic iron deposit in central my country has complex mine engineering geology, low ore grade, ore body is gently inclined, inclined distribution, and there are many ore interlayers, the stability of the ore body directly contacting the roof and floor surrounding rock is poor, and the hanging wall is more serious. , and the surrounding areas of the mining area are mostly villages and farmland, and the surrounding environment is complex.

[0032] In the early stage of the mine, the upward approach layered filling method was used for mining, two-step recovery, and each layered approach was mined one by one. The production capacity was about 3000t / d. Due to the influence of the stope layout and the limitation of operating conditions, it could not be realized. Larg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com