Polyvinyl chloride (PVC) magnetic-plastic blending door gasket and manufacture method thereof

A door seal and blending technology is applied in the field of PVC magnetic-plastic blended door seal and its preparation, which can solve the problems of many production steps, excessively long magnetic strips, unfavorable production management, etc., so as to improve the sealing performance and use deadlines, eliminate quality and product waste, and reduce labor and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

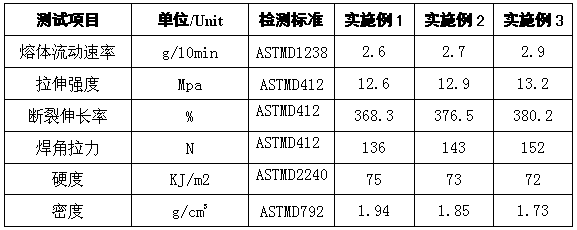

Embodiment 1

[0040] Weigh 68 parts of PVC, 32 parts of CPE, 30 parts of environmental plasticizer, 70 parts of magnetic powder, 4.5 parts of stabilizer, 0.75 parts of dispersant, CaCO 3 After mixing 5 parts and 2 parts of pigment, then carry out high-speed mixing and oil filling at 70°C for 12 minutes, then unload the material and put it in a cold mixing pot and stir for 15 minutes; finally put the material into a twin-screw extrusion with L / D≥24 Machine granulation, the granulation temperature is 130-150 ℃, to make PVC magnetic-plastic blended pellets; then extrude the door seal rubber sleeve through a single screw machine, and apply voltage and magnetization to it after cooling and setting, so that the door seal rubber sleeve After passing through the electric plate, the magnetic powder forms a directional arrangement to show magnetism; finally, the magnetized door seal rubber sleeve is cut and cut at a 45-degree angle, stored for at least 12 hours, and then melted or bonded to make PVC...

Embodiment 2

[0050] Weigh respectively 71 parts of PVC, 28 parts of CPE, 35 parts of environmental plasticizer, 62 parts of magnetic powder, 4 parts of stabilizer, 0.6 part of dispersant, 10 parts of hydrotalcite, 2.2 parts of pigment and mix them, then mix them at 120 After 20 minutes of high-speed mixing and oil filling at ℃, unload the material and put it in a cold mixing pot and stir for 15 minutes; finally put the material into a twin-screw extruder with L / D≥24 for granulation, and the granulation temperature is 130-150 ℃. PVC magnetic-plastic blended pellets; then extrude the door seal rubber sleeve through a single screw machine, and apply voltage and magnetization to it after cooling and shaping, so that the magnetic powder of the door seal rubber sleeve passes through the electric plate to form a directional arrangement and show magnetism ;Finally, the magnetized door seal rubber sleeve is cut and cut at 45 degrees, stored for 15 hours, and then melted, welded or bonded to make a P...

Embodiment 3

[0052] Weigh 75 parts of PVC, 25 parts of CPE, 38 parts of environmental plasticizer, 55 parts of magnetic powder, 3.5 parts of stabilizer, 0.8 parts of dispersant, CaCO 3 After mixing 15 parts and 2.5 parts of pigment, then carry out high-speed mixing and oil filling at 100°C for 18 minutes, unload the materials and put them in a cold mixing pot and stir for 15 minutes; finally put the materials into a twin-screw extrusion with L / D≥24 Machine granulation, the granulation temperature is 130-150 ℃, to make PVC magnetic-plastic blended pellets; then extrude the door seal rubber sleeve through a single-screw machine, and apply a magnetic field to it after cooling and shaping, so that the door seal rubber sleeve The magnetic powder forms a directional arrangement in the magnetic field to show magnetism; finally, the magnetized door seal rubber sleeve is cut and cut at a 45-degree angle, stored for at least 12 hours, and then melted, welded or bonded to make a PVC magnetic plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com