PLC (Programmable Logic Controller) type optical splitter testing method

A test method and optical splitter technology, which is applied in the direction of testing optical performance, etc., can solve the problems of low test efficiency and long test time, and achieve the effects of reducing artificial test errors, saving labor costs, and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

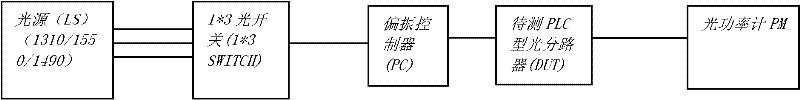

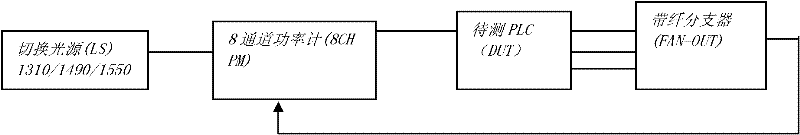

[0013] see image 3 , the embodiment of the present invention is an 8-channel optical power meter (8CH PM), which integrates 3 light sources of traditional test equipment, for example, the wavelength is 1310, 1550, 1490 nanometers (nm), and 1 3-way switching light source A switch, a polarization controller and 8 single-channel optical power meters are connected to a computer (not shown in the figure), and the test data can be selected according to actual needs after the test.

[0014] The method provided by the present invention is as follows: the above-mentioned 3-way switching optical switch is integrated into the above-mentioned 3-wavelength light source and connected through the above-mentioned 8-channel power meter, and the polarization controller is integrated into the 8-channel power meter, which is uniformly controlled by a computer. The light source is output by a light source line, and the output light source line is respectively calibrated by the 8 detection ports o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com