Whole-value grain biological feed for fattening cattle

A technology of biological feed and fattening cattle, which is applied in the field of full-price pellets for fattening cattle, can solve problems such as waste, achieve convenient feeding, reduce the occurrence of hoof diseases, and meet the growth needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

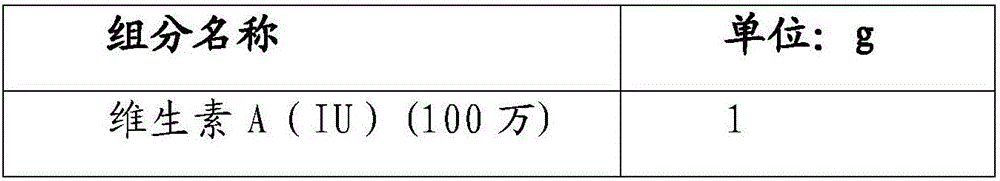

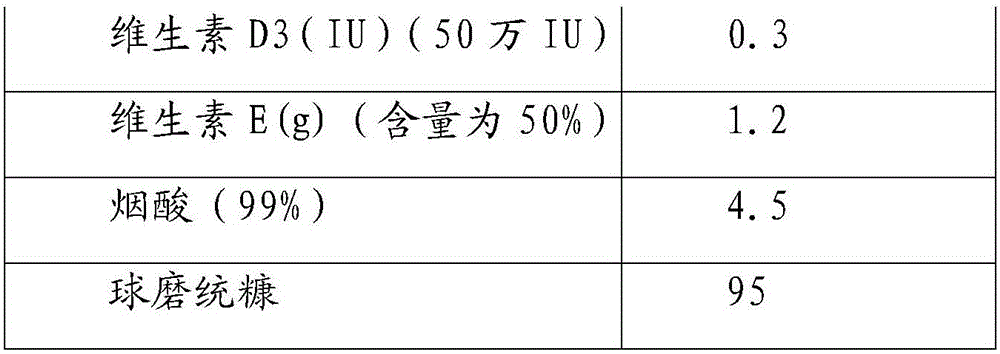

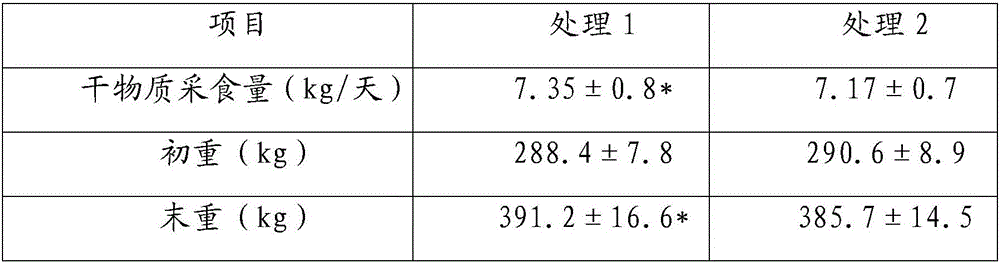

[0039] Full-price pellets for fattening cattle, including the following raw materials: 22.8g corn, 4g soybean meal (43%), 5g barley root, 5g biological feed, 3g cotton meal (42%), 10g corn distiller's grains, 5g corn straw, 15g wheat straw , brewer's grains 6g, dry white distiller's grains 6g, apple pomace 12g, sucrose 2g, salt 0.1g, calcium hydrogen phosphate 0.5g, calcium powder 1.1g, baking soda 1.2g, magnesium oxide 0.45g, rumen-passing lysine (60% ) 0.06, rumen-passed methionine 0.2g, brewer’s yeast culture 0.3g, sweetener 0.02g, multivitamin 0.1g, trace element additive 0.15g, monensin 0.02g.

Embodiment 2

[0041] Full-price pellets for fattening cattle, including the following raw materials: 20g corn, 4g soybean meal (43%), 5.5g barley root, 6g biological feed, 2.5g cotton meal (42%), 10g corn distiller's grains, 5.5g corn stalks, wheat Straw 15.3g, brewer's grains 7g, distiller's grains 6g, apple pomace 12g, sucrose 2g, salt 0.1g, calcium hydrogen phosphate 0.5g, calcium powder 1.1g, baking soda 1.2g, magnesium oxide 0.45g, rumen-passing lysine (60%) 0.06, rumen-passed methionine 0.2g, brewer's yeast culture 0.3g, sweetener 0.02g, multivitamin 0.1g, trace element additive 0.15g, monensin 0.02g.

Embodiment 3

[0043] Full-price pellets for fattening cattle, including the following raw materials: 22g corn, 3g soybean meal (43%), 4g barley root, 8g biological feed, 3g cotton meal (42%), 10g corn distiller's grains, 5g corn straw, 14g wheat straw, Brewer's grains 6g, dry distiller's grains 6g, apple pomace 12.8g, sucrose 2g, salt 0.1g, calcium hydrogen phosphate 0.5g, calcium powder 1.1g, baking soda 1.2g, magnesium oxide 0.45g, rumen-passing lysine (60% ) 0.06, rumen-passed methionine 0.2g, brewer’s yeast culture 0.3g, sweetener 0.02g, multivitamin 0.1g, trace element additive 0.15g, monensin 0.02g.

[0044] The raw materials are sieved and pulverized, each component is weighed according to the weight ratio, and added into the mixer in order of the ratio from large to small, mixed evenly and then granulated.

[0045] Wherein, the parameters of the double-deck initial cleaning sieve are: the upper sieve is 10.0mm, and the lower sieve is 3 mesh; the parameters of the double-drum initial c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com