Stackable hinge connection

a hinge connection and fixing technology, applied in the field of hinge connection, can solve the problems of inability to stabilize the hinge connection, disadvantage, and backlash, and achieve the effect of increasing the ease of use without losing the stability of the hinge connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

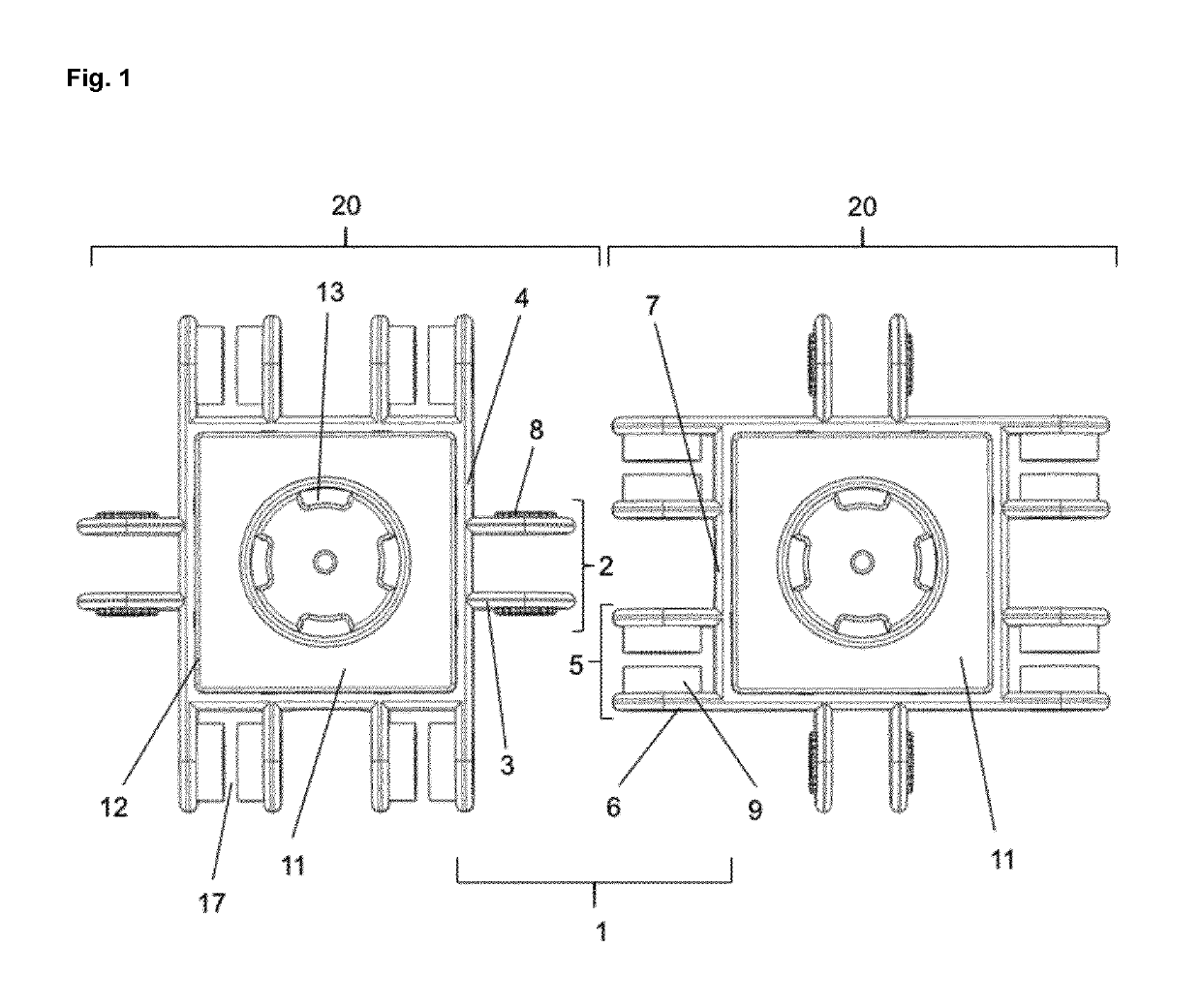

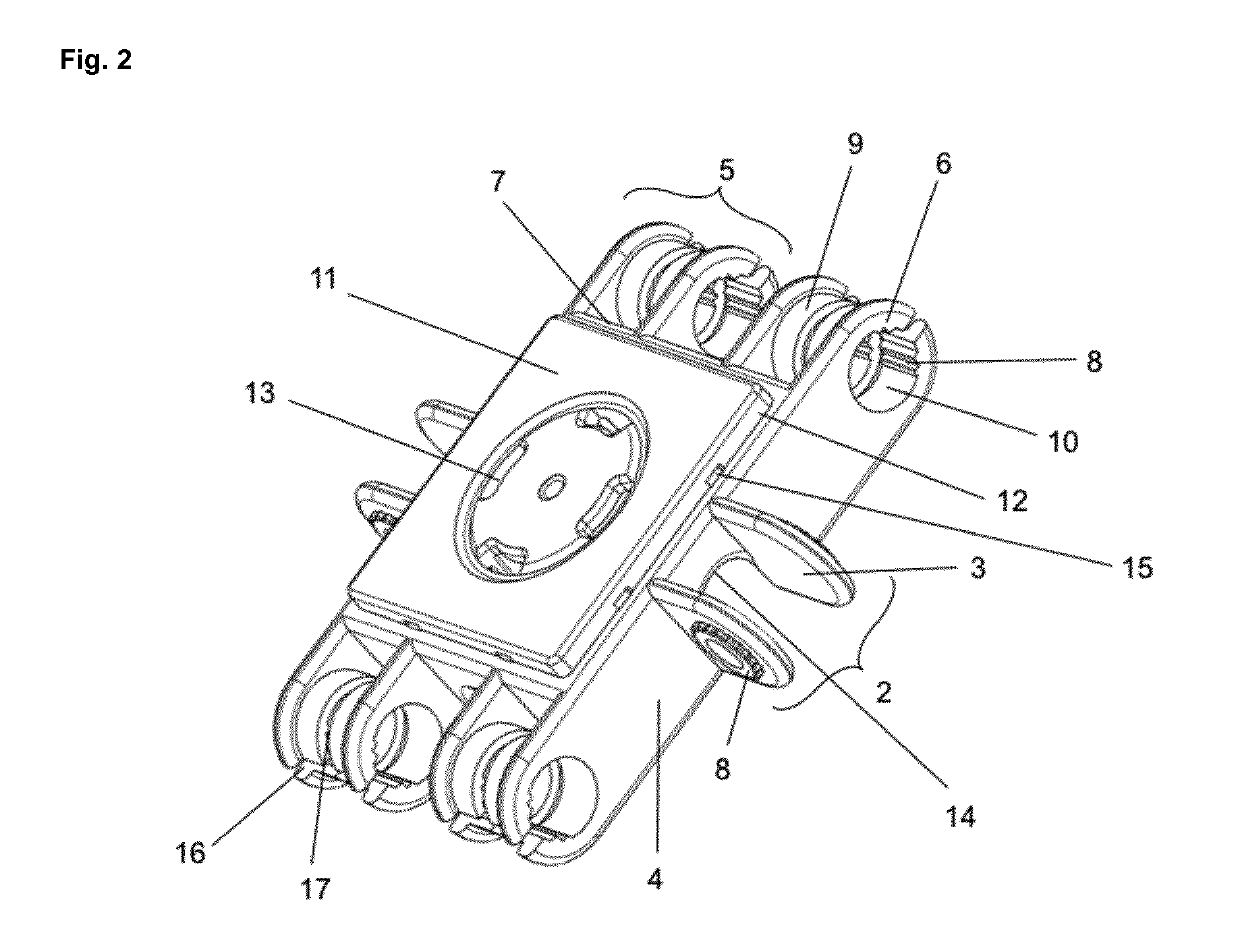

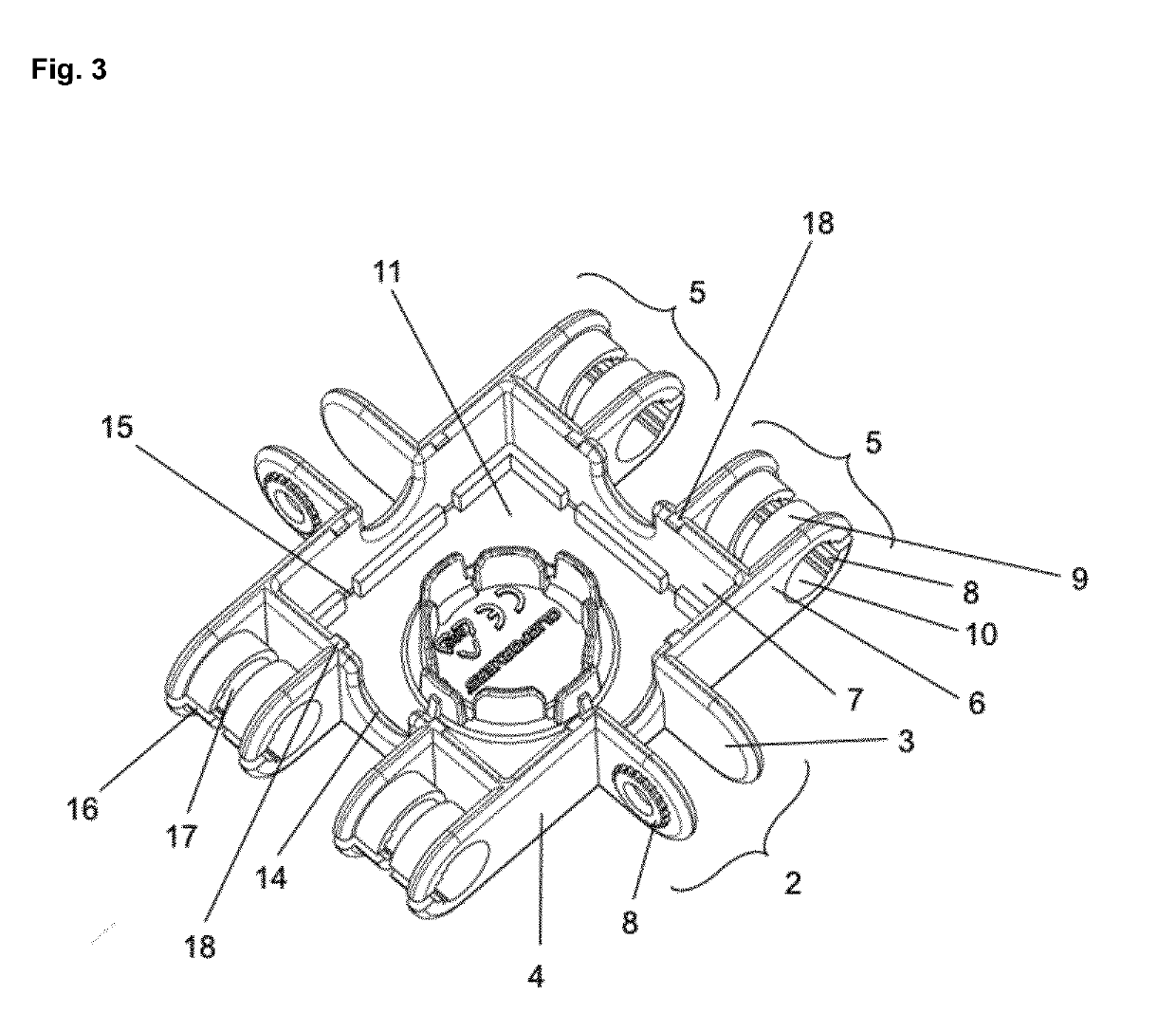

embodiment 1

[0026]2. The hinge connection (1) , wherein the intermediary piece (9) of the female member (5) is mounted offset from the further base plate (7).

[0027]3. The hinge connection (1) according to embodiment 1 or 2, wherein the intermediary piece and the female legs (6) of the female member (5) are interrupted in the longitudinal direction (16).

[0028]4. The hinge connection (1) according to any one of the preceding embodiments, wherein the intermediary piece (9) of the female member (5) is interrupted in the transverse direction (17).

[0029]5. The hinge connection (1) according to any one of the preceding embodiments, wherein the intermediary piece (9) is cylindrical.

[0030]6. The hinge connection (1) according to any one of the preceding embodiments, wherein the male (2) and female (5) members are provided with rounded free ends.

[0031]7. The hinge connection (1) according to any one of the preceding embodiments, wherein the male (3) and female (6) legs comprise rounded borders.

[0032]8. A...

embodiment 9

[0036]12. A construction element (20) further comprising two linking members (21) applied on a base plate provided to be resiliently fitted on two female members, said female members formed by two parallel female legs and comprising a through hole and wherein the two parallel female legs are connected by an intermediary piece and wherein said through hole extends through said female legs and said intermediary piece, characterized in that the linking member (21) comprises a C-shaped curved leg (22).

[0037]13. A construction element (20) according to anyone of embodiments 8 to 12, comprising a connection plate (11) that connects the base plates (4) and / or the further base plates (7) and extends in a plane perpendicular to said base plates.

embodiment 13

[0038]14. A construction element (20) further comprising a connection plate (11) that connects the two base plates (4) and the two further base plates (7) and extends in a plane perpendicular to said base plates.

[0039]15. The construction element (20) according to embodiment 13 or 14, wherein the connection plate (11) comprises a ridge (12) at the connections between the connection plate (11) and the base plates (4) and further base plates (7).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com