Energy-saving aluminum alloy door and window with high compression resistance and corrosion resistance

A kind of aluminum alloy doors and windows, corrosion-resistant technology, applied in the direction of window/door frame, window/door improvement, parallel glass structure, etc., can solve the problem of friction and rainwater entering at the connecting profile, doors and windows can not effectively buffer shock absorption, corrosion resistance It can improve the effect of wind pressure resistance, improve wind pressure resistance ability, and prevent corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

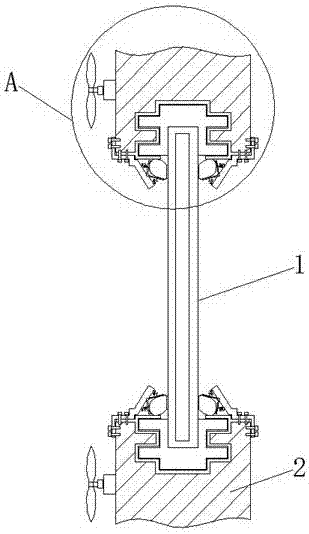

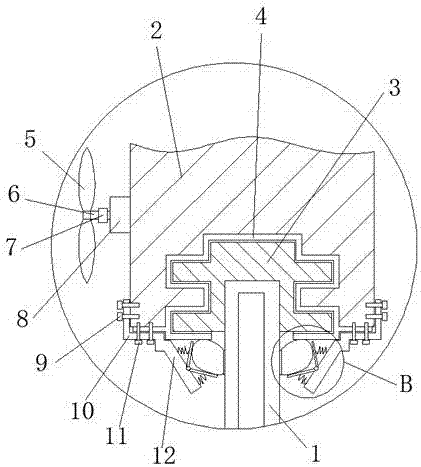

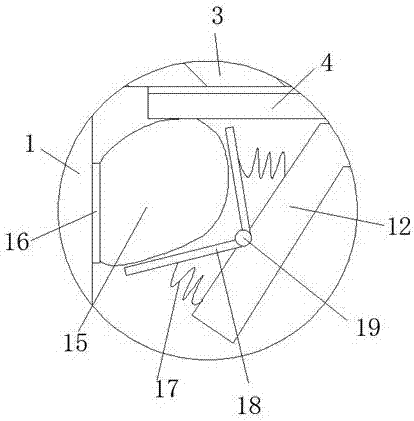

[0020] see Figure 1-4 , a high-pressure-resistant, corrosion-resistant, energy-saving aluminum alloy door and window, comprising a vacuum window 1, the vacuum window 1 is connected to a wall 2, the surrounding of the vacuum window 1 is fixedly connected with a connection profile 3, and the wall 2 is provided with a connection profile 3 corresponds to the connecting groove, the connecting profile 3 is provided with a plurality of clamping blocks, and the inner wall of the connecting groove is provided with a corresponding clamping groove, and the inner wall of the connecting groove is fixed with a corrosion-resistant rubber pad 4, and the corrosion-resistant rubber pad 4 Pasted in the card slot, the wall 2 is fixedly connected with the L-shaped stabilizing plate 10 through the first fixing screw 9 and the second fixing screw 11, and the lower end of the corrosion-resistant rubber pad 4 is located between the wall 2 and the L-shaped stabilizing plate 10 , and the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com