Insulation roof slab and method for making same

A technology of thermal insulation roof panel and production method, which is applied in the direction of roof, roof using flat/curved panel, roof covering layer, etc., can solve the problem of thermal insulation, sound insulation, waterproof, anti-seepage, durability, and can not meet the needs of large-scale roof panel structure. Force requirements, waste of materials and other problems, to achieve the effect of eliminating the plastering process, ensuring anti-fatigue effect, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

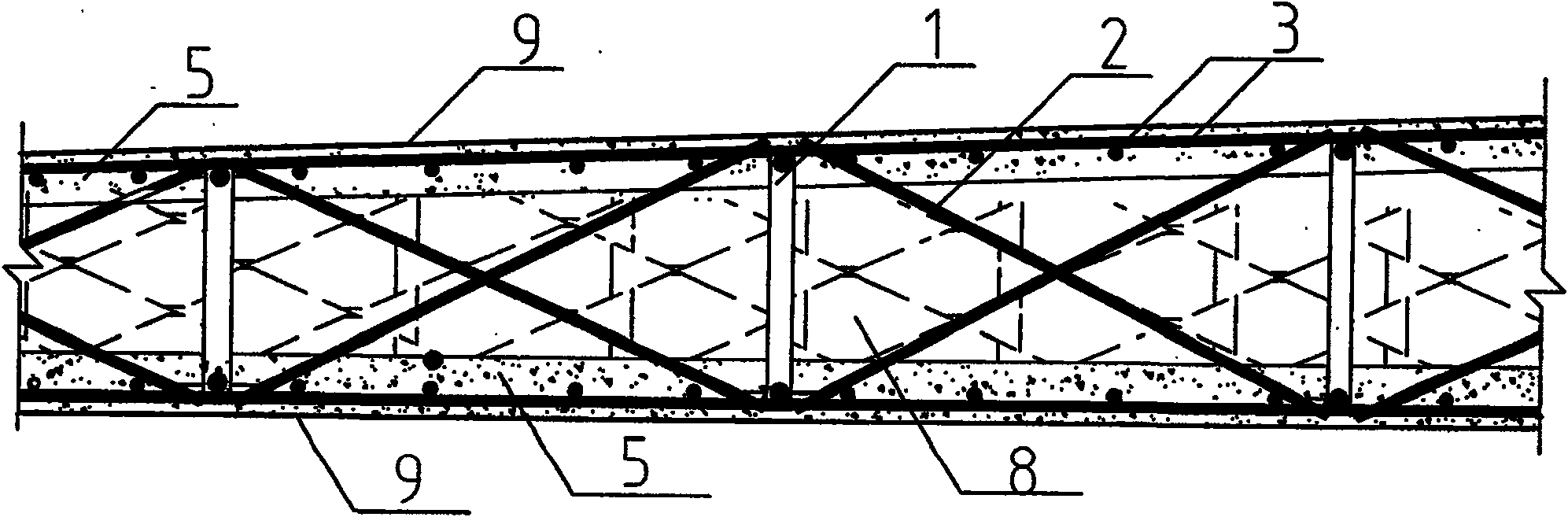

[0021] Concrete (5) is fixedly connected to both sides of the steel wire grid skeleton, so that an empty stomach is formed between the concrete (5), and the insulating material is filled in the empty stomach to form an insulating layer (8), so that it is closely connected with the inner walls of the concrete on both sides, and the concrete (5) The outer side is fixedly connected with an alkali-resistant glass fiber mesh cloth (9). Its production specifically includes the following steps:

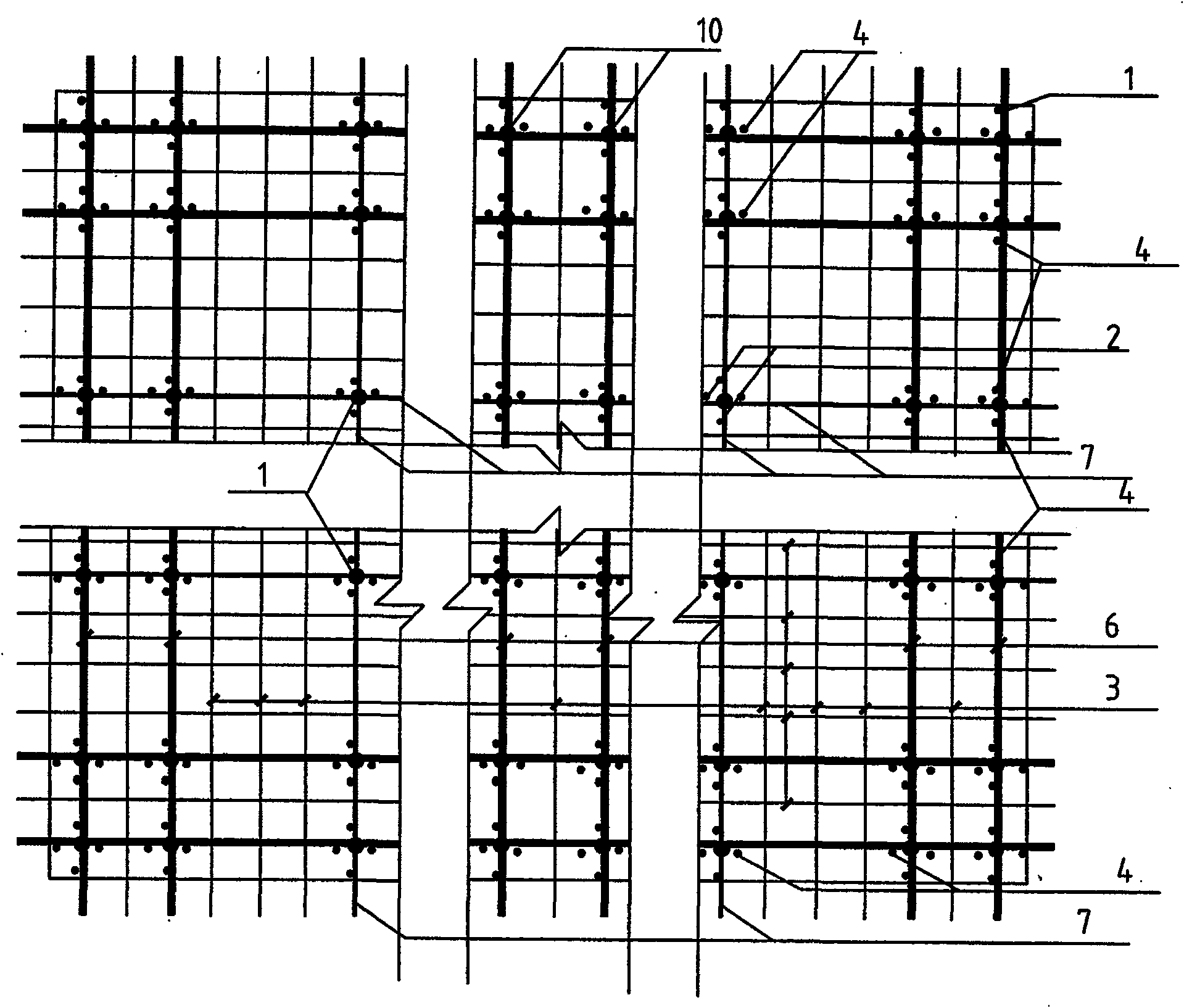

[0022] (1) To make the steel wire grid skeleton, ① make the mesh, use galvanized steel bars, cold-drawn weldable galvanized steel wires, and use a CNC welding machine to connect the vertical and horizontal intersections according to the material, diameter and spacing required by the design. Carry out welding to form the mesh, the making of the mesh is to set up two roads to strengthen the main ribs (6) at the required distance along the length direction of the mesh around it and at the cente...

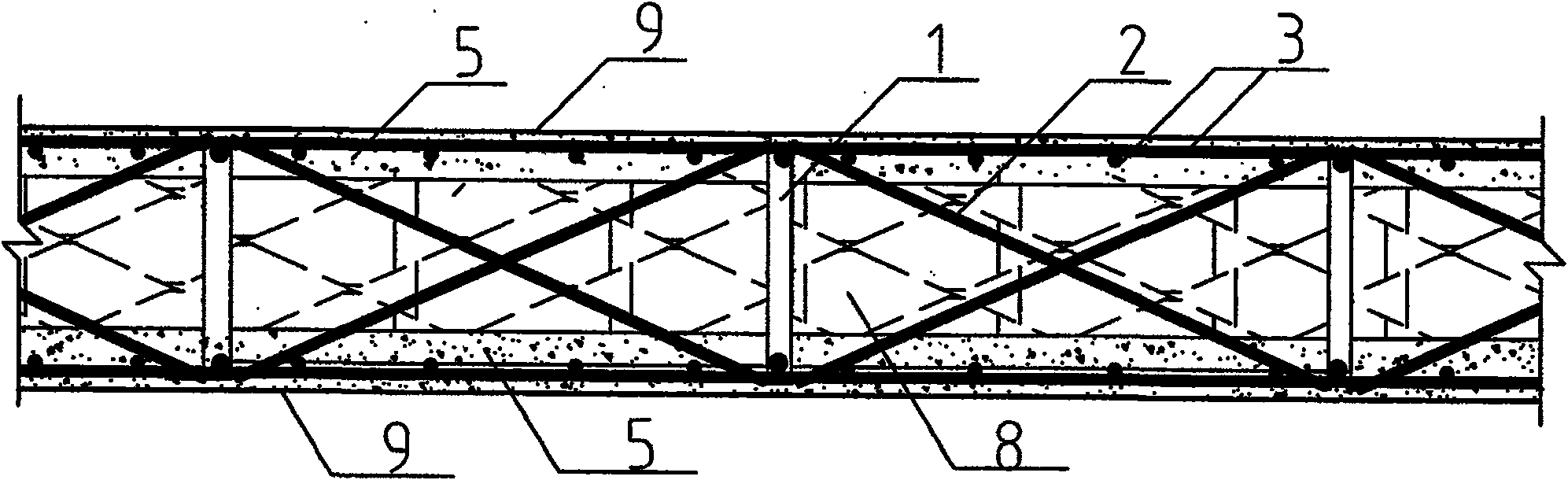

Embodiment 2

[0030] The difference from Example 1 is that when making the steel wire grid skeleton, the outer layer mesh should have a proportional extension than the inner layer mesh, so that the outer layer mesh and the inner layer mesh can form a 90° angle with the connecting steel column. ° vertical angle, and then change the column length, scissors brace length and diameter level from one end to the other end of the length direction of the slab, and then form a steel wire mesh frame with a slope. The outer surface of the manufactured roof panel also forms a required water slope.

[0031] The method is used in the manufacture of heat-insulating roof panels for flat roofs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com