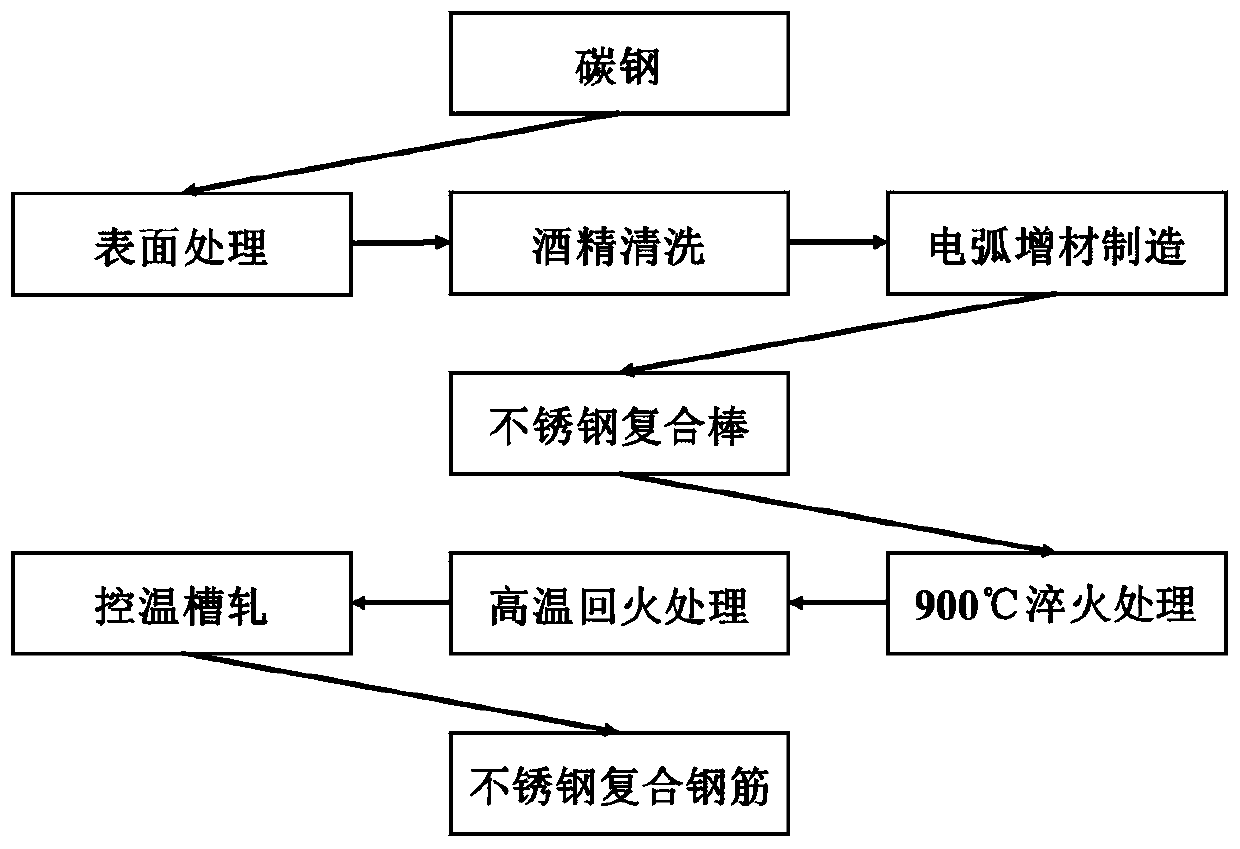

A method of additive manufacturing-temperature-controlled slot rolling for preparing stainless steel composite steel bars

A technology for additive manufacturing and composite steel bars, which is applied in the fields of temperature-controlled slot rolling of metal materials and arc additive manufacturing, which can solve the problems of poor corrosion resistance of carbon steel and low impact toughness at low temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Grind the surface of 45# steel with an angle grinder and sandpaper to remove the oxide layer until the surface is polished and bright. Among them, the size of 45# steel is 28mm*28mm*180mm.

[0035] (2) Clean the polished 45# steel surface with alcohol, remove the oil on it, and dry it with a hair dryer.

[0036](3) Use the YA-1VAR61CJ0 welding robot produced by Tangshan Matsushita Industrial Machinery Co., Ltd. to weld a layer of 3mm thick SUS304 stainless steel around the 45# steel. The specific operation is as follows: put the 45# steel flat, weld on one of the sides, perform weaving welding with an amplitude of 7mm on the two sides, and perform a straight line welding in the middle, so that one side is welded, and repeat the above for the other 3 sides step. Welding parameters: Weaving welding: amplitude 7mm, undulating point current 120A, welding speed 0.15m / min; straight line welding: undulating point current 150A, welding speed 0.3m / min.

[0037] (4) After ...

Embodiment 2

[0044] (1) Grind the surface of Q345 steel with an angle grinder and sandpaper to remove the oxide layer until the surface is polished and bright. Among them, the size of Q345 steel is 28mm*28mm*180mm.

[0045] (2) Clean the polished Q345 steel surface with alcohol, remove the oil stains on it, and dry it with a hair dryer.

[0046] (3) Use the YA-1VAR61CJ0 welding robot produced by Tangshan Matsushita Industrial Machinery Co., Ltd. to surfacing a layer of 3mm thick SUS304 stainless steel around the Q345 steel. The specific operation is as follows: put the Q345 steel flat, weld on one of the sides, perform weaving welding with an amplitude of 7mm on the two sides, and perform a straight line welding in the middle, so that one side is welded, and repeat the above steps for the remaining 3 sides . Welding parameters are the same as in Example 1.

[0047] (4) After all the four sides are welded, the Q345 steel edges are fixed and laid flat, and then the four edges are filled a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile properties | aaaaa | aaaaa |

| tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com