Automatic coffee maker with detachable bean grinding device

A coffee machine and bean grinding technology, which is applied in coffee mills, beverage preparation devices, spice mills, etc., can solve the problems of coffee powder residue, inconvenient operation and use, and can not prevent the powder outlet channel from being blocked, so as to prevent the powder from being blocked, Easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

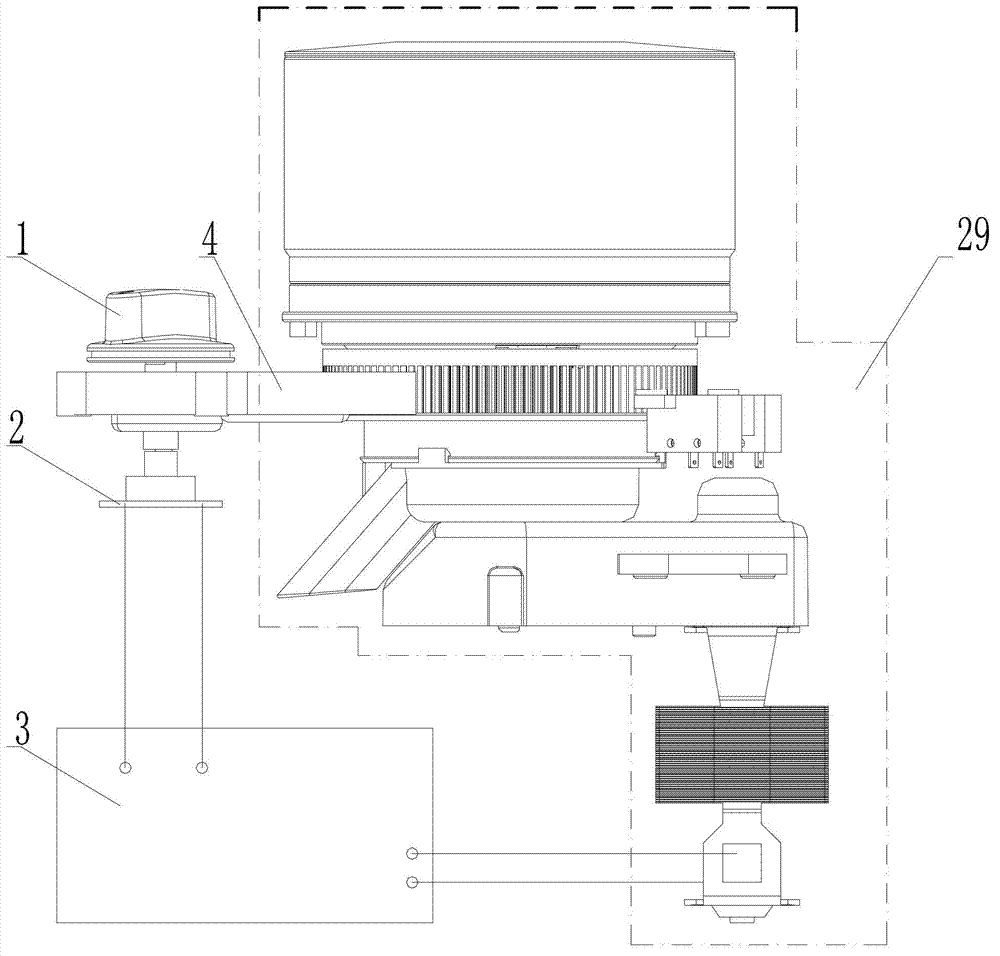

[0045] like figure 1 , 4 5. In the automatic coffee machine with detachable bean grinding device of this embodiment, the knob 1 is installed on the body 15, the connecting device adopts a gear set 4, and the knob 1 is connected with the detachable adjustment mechanism of the bean grinding device 29 through the gear set 4 and The bean grinding device is driven to disassemble and assemble the adjustment mechanism to perform the adjustment action; the knob 1 is connected to the gear switch 2 and is electrically connected to the control device 3 .

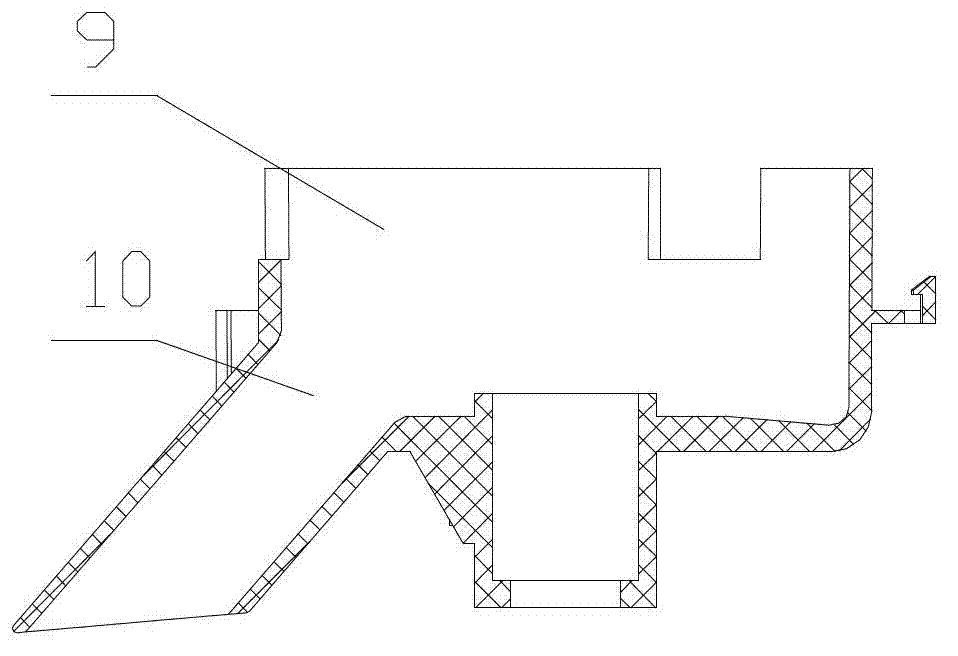

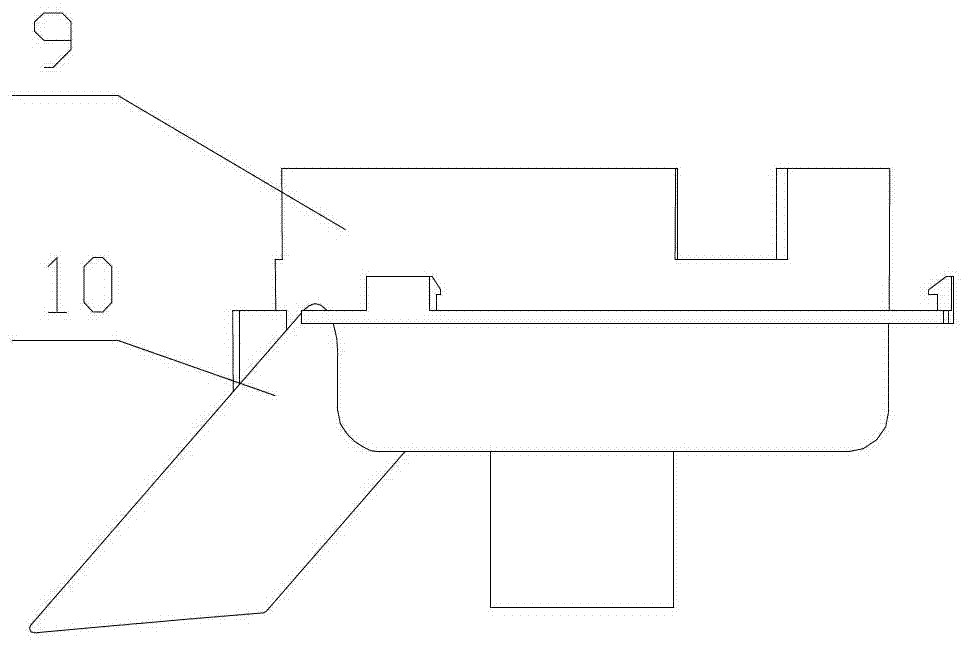

[0046] like Figure 2a , 2b , 12, the bean grinding chamber 10 adopts a cylindrical container-like structure with an open top surface, and the part where the side wall 32 and the bottom 34 of the shell 33 of the bean grinding chamber 9 are combined is provided with a powder outlet channel 10, that is, the starting point of the powder outlet channel 10 The opening of the initial part is located on the side wall 32 and the bottom 34 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com