Method for synchronously controlling lives of spindle parts of numerical-control machine tool

A CNC machine tool and synchronous control technology, applied in metal processing and other directions, can solve the problems of lack of life status judgment of spindle parts, reduce service life, reduce the utilization rate of CNC machine tools, etc., to solve the problem of lack of accurate quantitative calculation and accurate adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

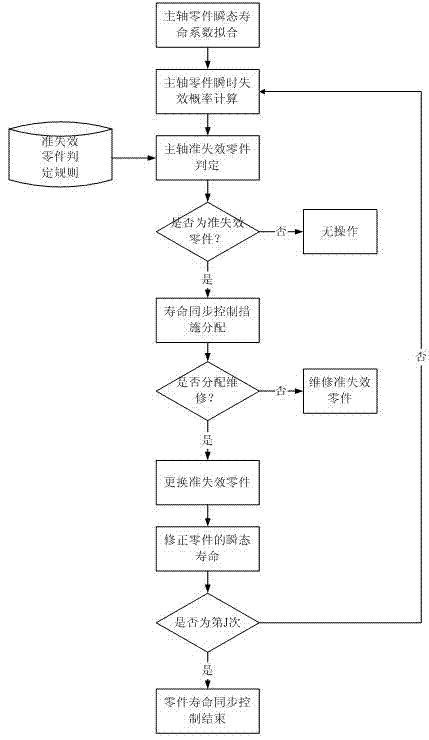

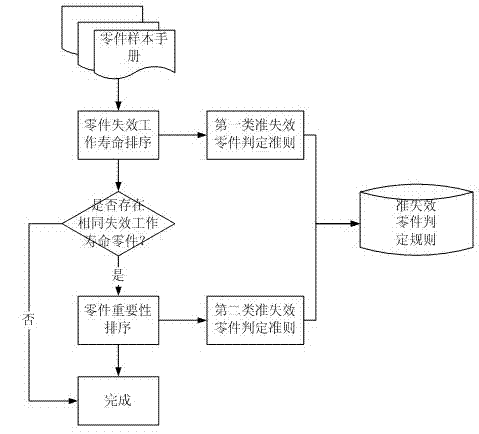

[0035] 1. The informed CNC machine tool, such as TKG46100 high-precision CNC horizontal jig boring machine, is in normal operation, record the structural dimensions of the main shaft parts of the machine tool, the information of the sample manual of parts procurement parts and the operating parameters of the main shaft of the machine tool, and fit the CNC machine tool spindle Parts transient life coefficient, establish the transient life model of CNC machine tool spindle parts, and describe the instantaneous working life of parts at any time during the continuous operation of CNC machine tool spindle parts:

[0036] 1.1) Start the informed CNC machine tool and record the spindle operating parameters of the machine tool;

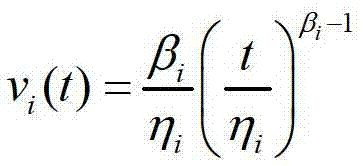

[0037] 1.2) Use the operating state system of the CNC machine tool spindle to fit the transient life coefficients η and β of the CNC machine tool spindle parts;

[0038] Table 1 Fitting value of transient life coefficient of spindle parts

[0039]

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com