Device and method for filling container

A container and equipment technology, applied in the weighing equipment, instruments, transportation and packaging of materials with special properties/forms, which can solve the problems of high equipment cost and achieve the effect of accurate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

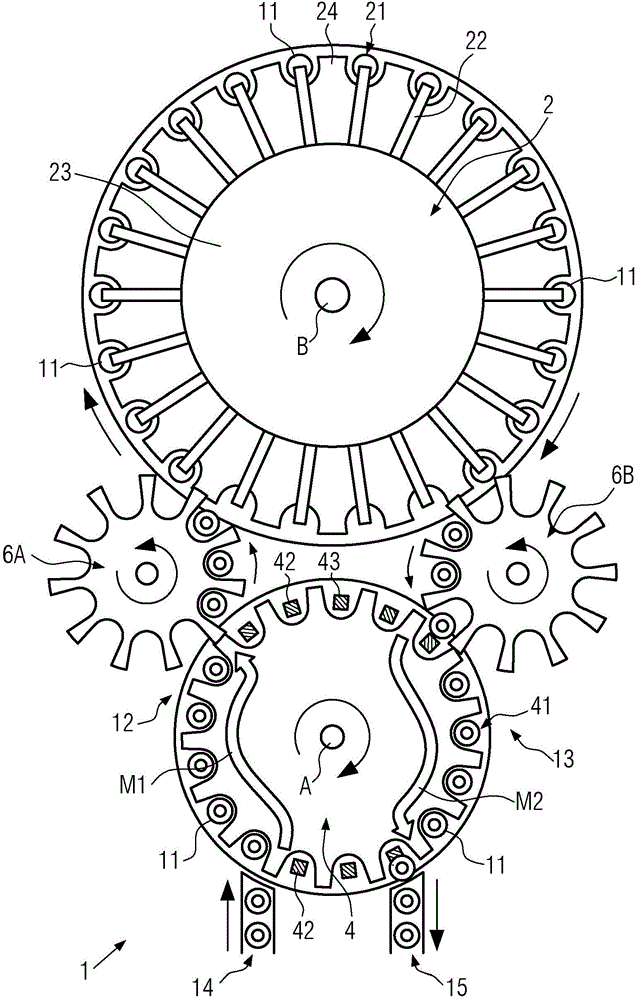

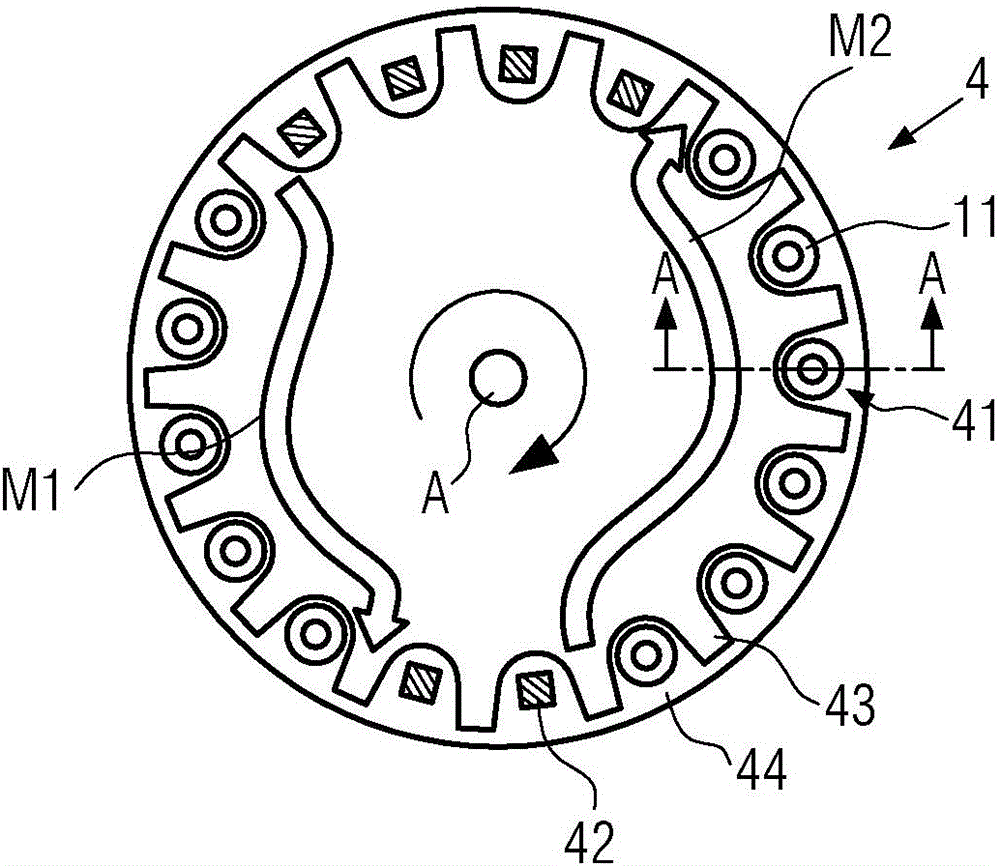

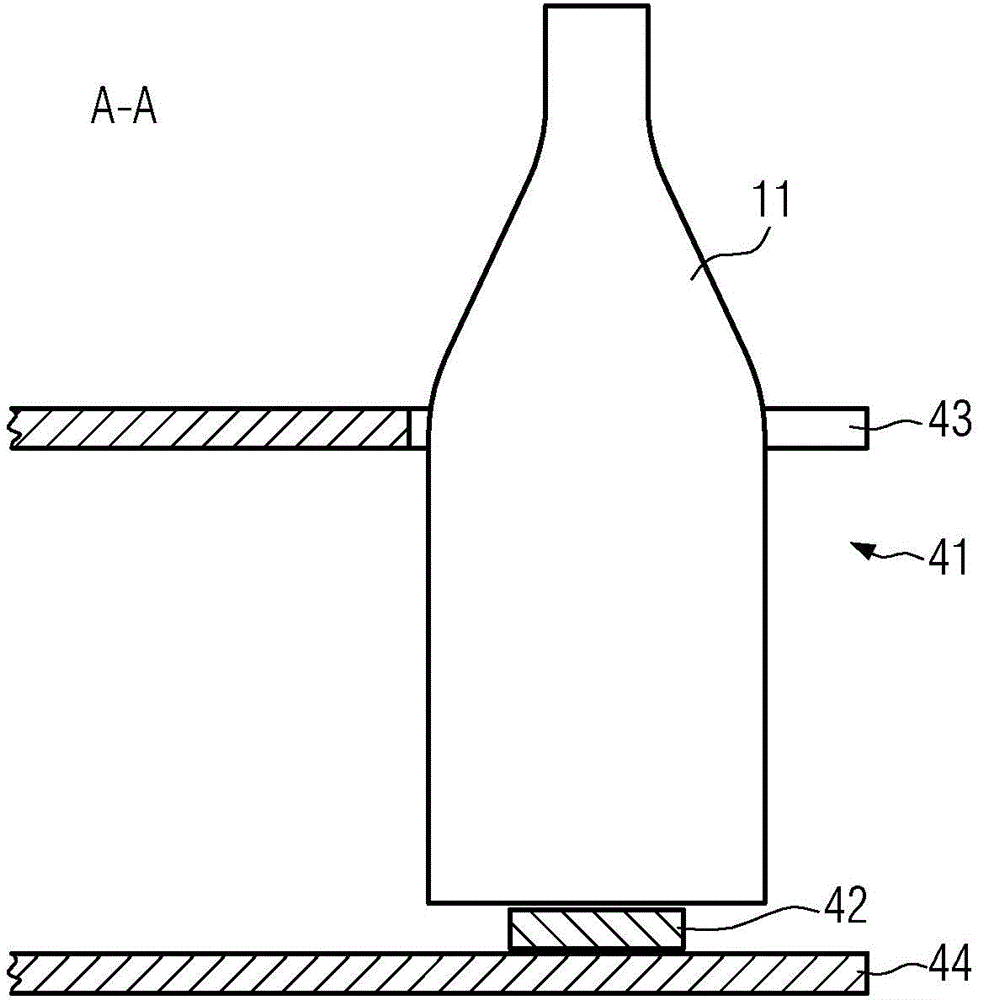

[0034] figure 1 An exemplary embodiment of the device 1 according to the invention for filling containers 11 is shown in plan view. The rotary carousel 4 can be seen with a plurality of measuring positions 41 which are regularly arranged on the periphery of the rotary carousel. In this case, the roulette 4 is designed to be rotatable about an axis A and is driven, for example, via an electric motor and a transmission (not shown), so that it rotates at a constant angular velocity. As a result, measuring point 41 likewise rotates about axis A at a constant speed. In this case, the measuring station 41 is embodied with carriers 43 which convey the containers 11 onward in the rotary carousel 4 and stabilize them during weighing. The measuring station 41 is embodied with a weighing element 42 in such a way that the containers can be weighed in the measuring station while the rotary carousel 4 is rotating and the containers 11 are being conveyed continuously.

[0035] Part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com