Optical module and laser cutting device

A technology of optical module and optical path, which is applied in the field of engineering optics, can solve the problems affecting the processing effect of materials and achieve high-quality focusing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiment of the present invention provides an optical module, which is used to effectively solve the problem that the light leakage in the center of the existing axicon prism affects the processing effect of the material.

[0037] The invention provides an optical module, which is used to effectively solve the problem that the light leakage at the center of the existing axicon prism affects the processing effect of materials.

[0038] The optical module provided by the present invention includes:

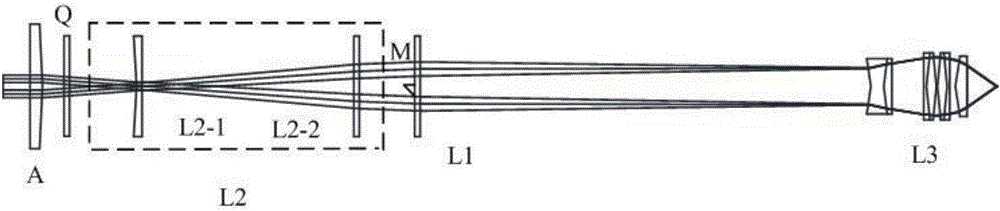

[0039] coaxially arranged axicon prism A, beam expander L2, first lens L1, condenser lens L3 and reflector M;

[0040] The axicon prism A is placed at the beginning of the optical path, and its tapered part is set away from the laser to generate a ring-shaped spot;

[0041] The first lens L1 is placed at the rear end of the axicon prism A, and is used for ring-focusing the ring-shaped spot;

[0042] The beam expander L2 is placed at the front end of the first lens L1;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com