Sample loom used for test weaving of leno weave

A prototype loom and leno weave technology, which is applied in the field of trial weaving leno weave prototype looms, can solve the problems of no twisted heald function, long trial production period, single variety of fancy patterns, etc., so as to avoid unclear shed, The effect of reducing R&D investment and saving effective resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

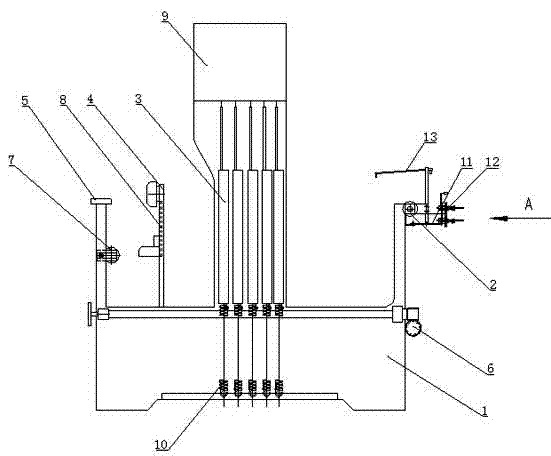

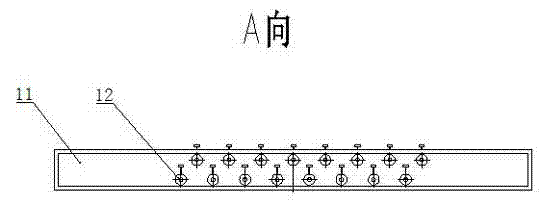

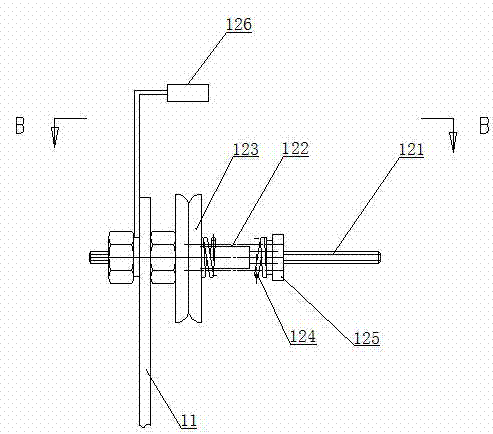

[0021] Such as figure 1 As shown, it includes frame 1, rear beam 2, heald frame 3, sley 4, breast beam 5, warp beam 6, cloth rolling roller 7, steel reed 8, electronic heald lifting mechanism 9, heald return spring 10, warp let-off bracket 11. Let-off tension disc 12 and tension compensation mechanism 13.

[0022] Back beam 2, heald frame 3, sley 4 and breast beam 5 are arranged sequentially from back to front on the above-mentioned frame 1, and warp beam 6 is set below the back beam 2, cloth roll 7 is set below the breast beam 5, and sley 4 Steel reed 8 is installed on.

[0023] There are several pieces of heald frames 3, which include conventional heald frames 3a and twisted heddle frames 3b installed with twisted heddles. Two pieces of twisted heald frames 3b form a group, and 1-2 groups are set according to requirements. The twisted heald frame 3b is arranged on The front side of each heald frame, that is, the side near the chest beam. The upper end of each heald frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com