Loom for producing woven goods or material with an incorporated cover thread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

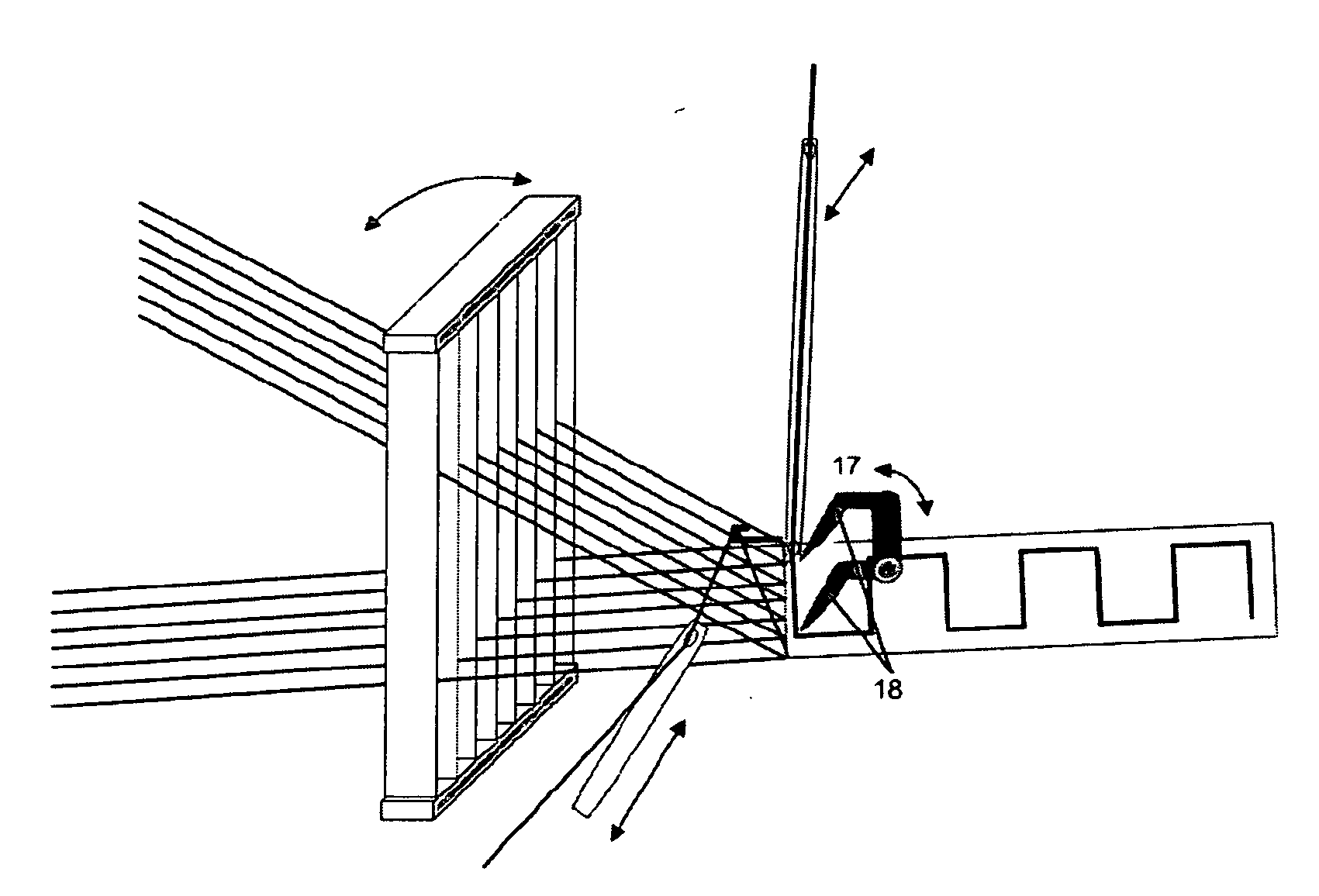

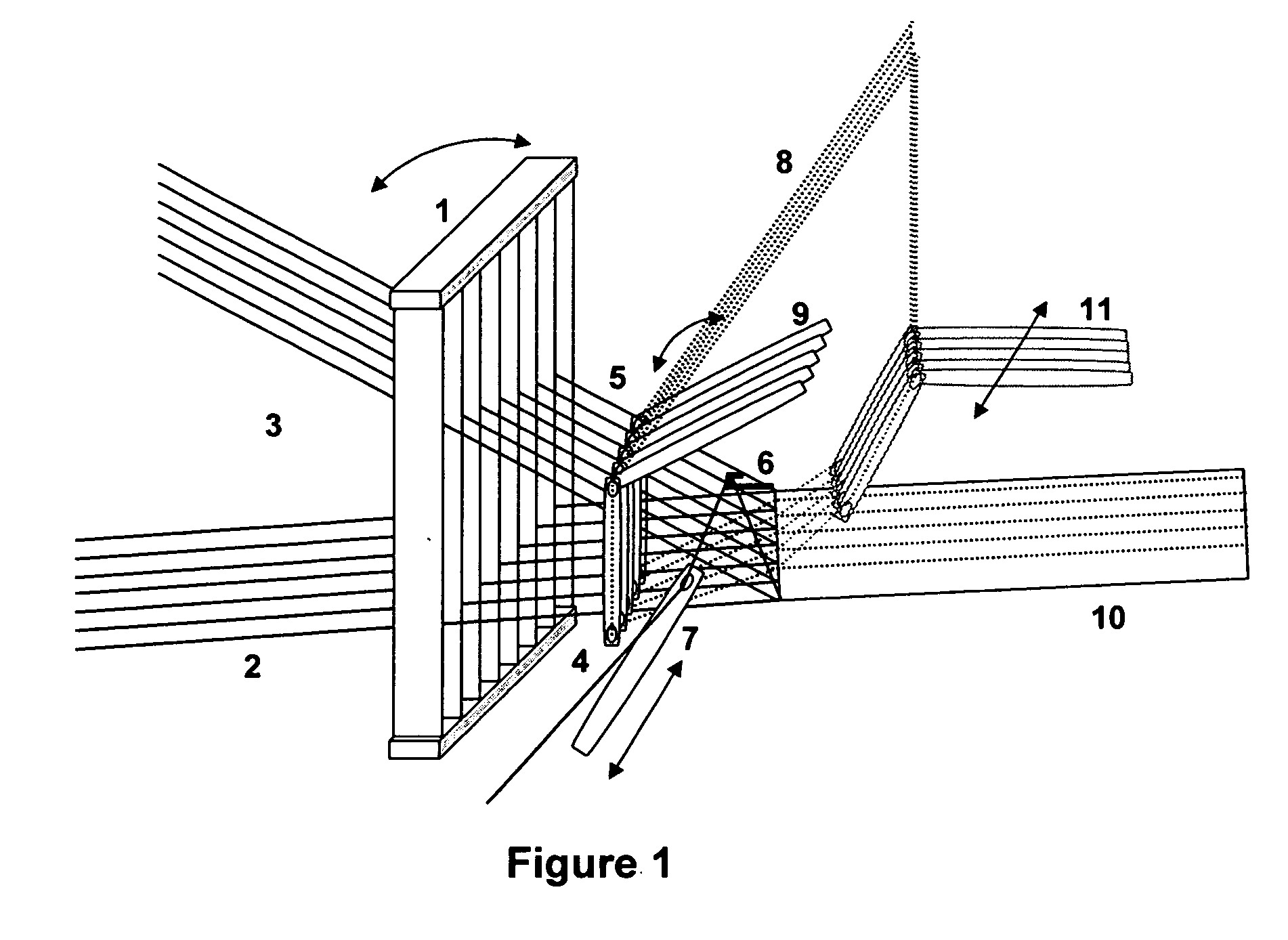

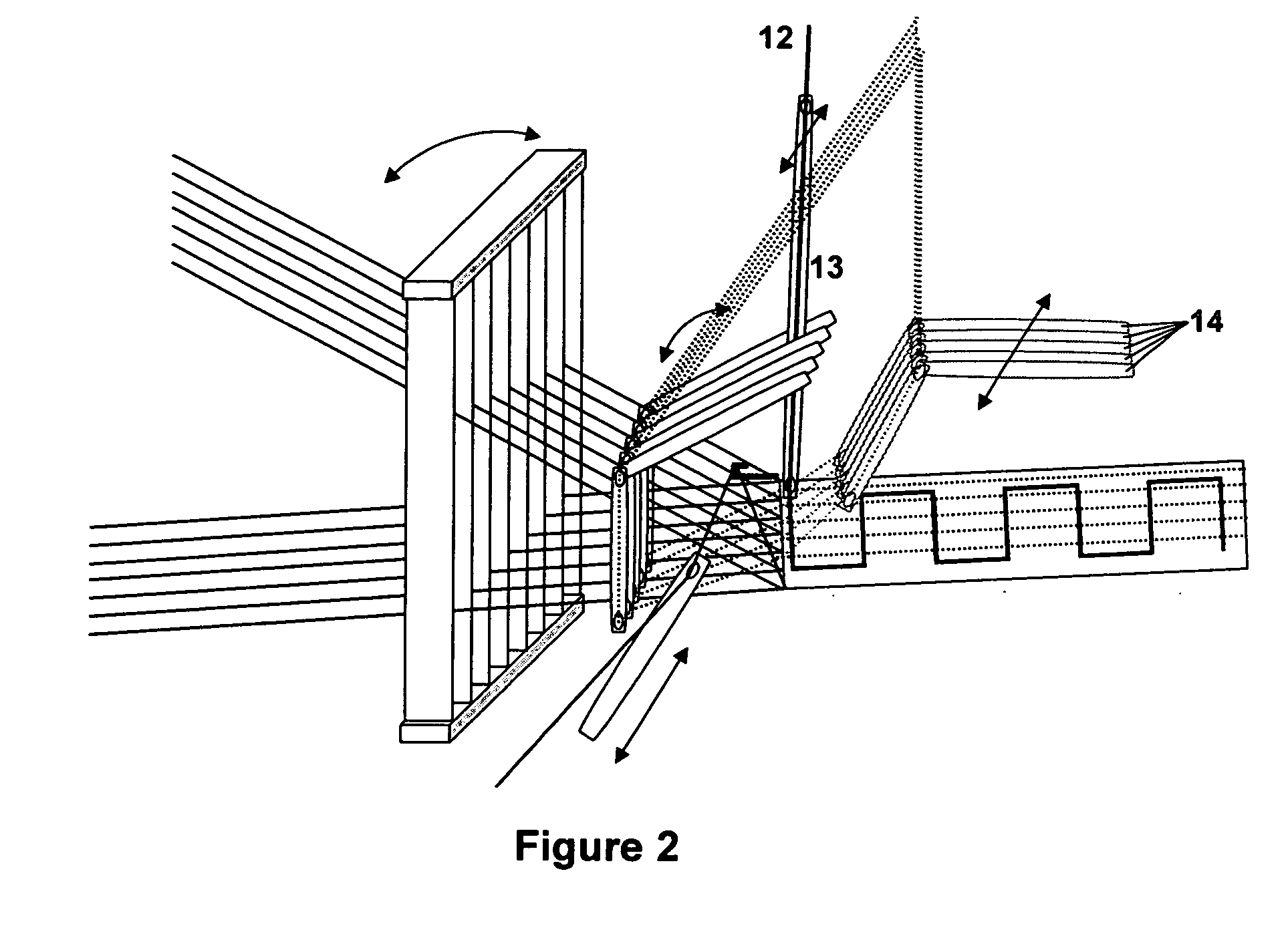

[0020]FIG. 1 shows a loom according to a first example of the present invention as a schematic view to explain the basic movement. In a gripper loom, the warp threads 2 for producing a ribbon fabric 10 form an upper shed 5 and a lower shed 4 for inserting a weft-thread by means of a weft-insertion needle 7 or a gripper. A reed 1 is arranged in a conventional manner in order to rest against the inserted weft-threads against the previously produced woven material 10.

[0021]The warp-laying device 9 is dipped in through the upper shed 5 into the lower shed 4. At the same time the reed 1 moves backward. The warp-laying device 9 can be moved in the direction of the reed 1 and also downwards into the lower shed 4. In the embodiment presented here, the warp-laying device 9 follows the movement of the reed 1. However, the warp-laying device can also be switched off or it can be dipped in at variable frequencies depending on the bonding.

[0022]The weft of the weft-insertion needle or of the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com