Jacquard ribbon loom with mainstay

A ribbon loom and column type technology, which is applied to jacquard looms, looms, small looms, etc., can solve the problems of convenient operation, long transmission path, and difficulty in replacement, so as to achieve easy maintenance, reduce production costs, and improve maintenance. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

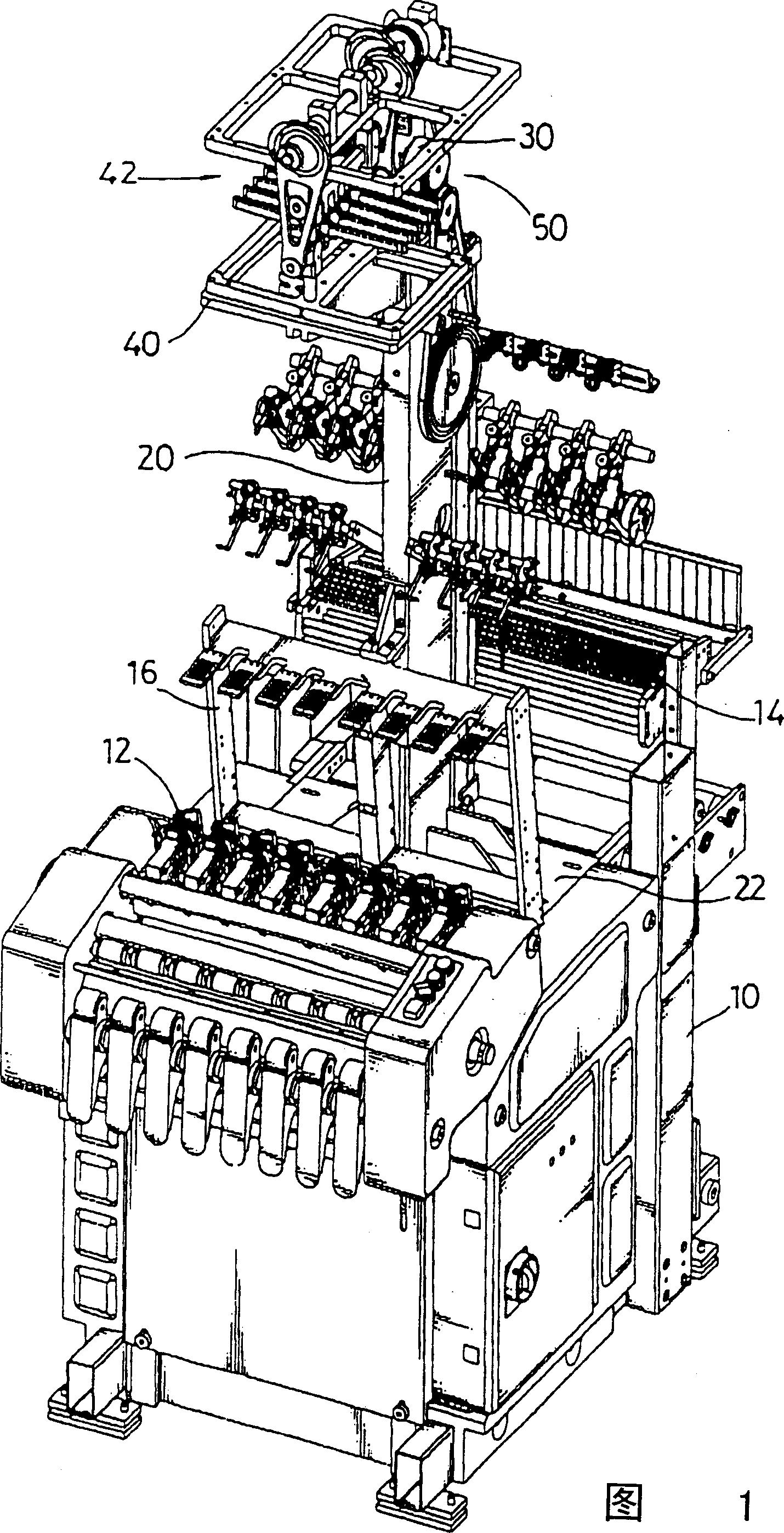

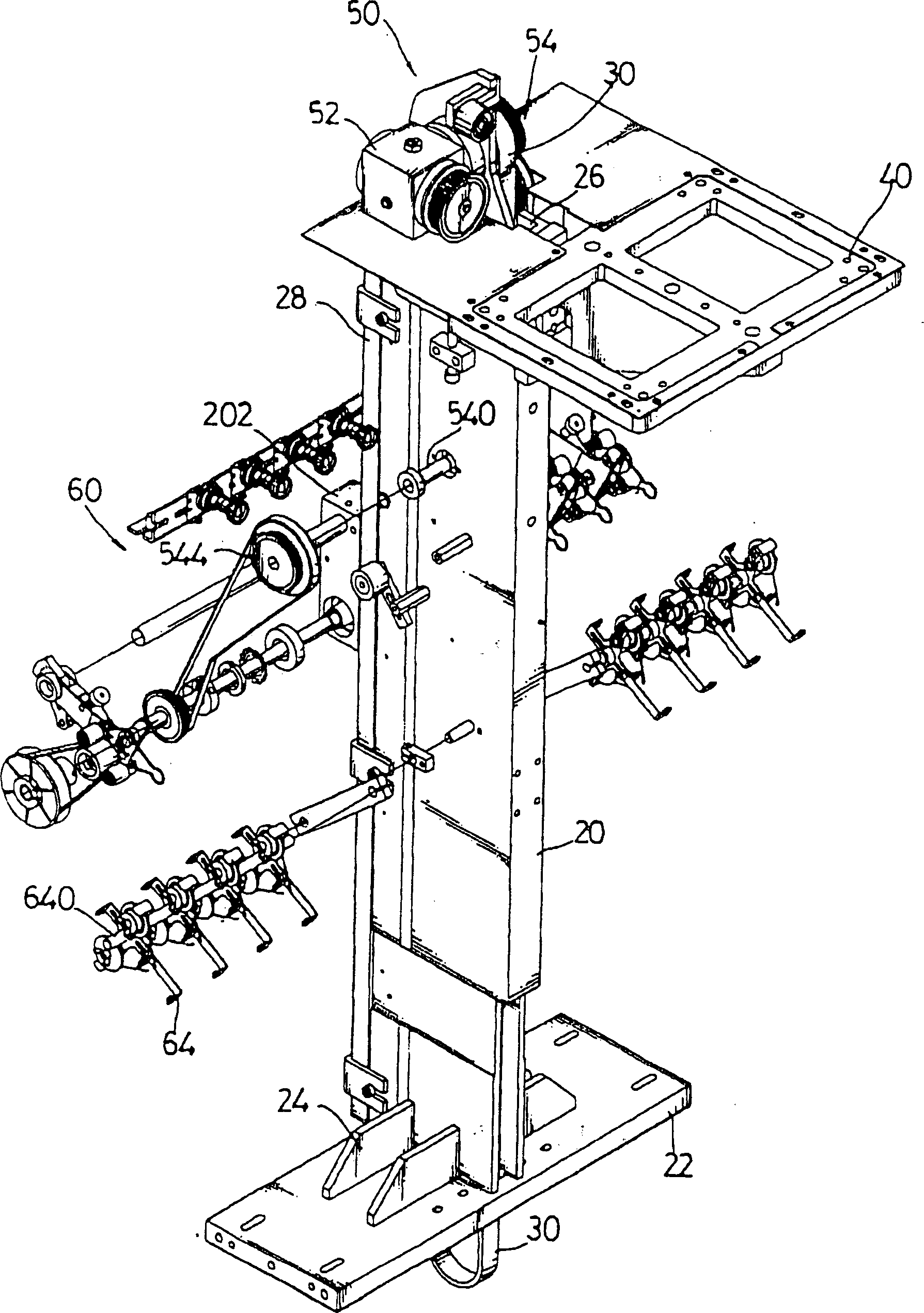

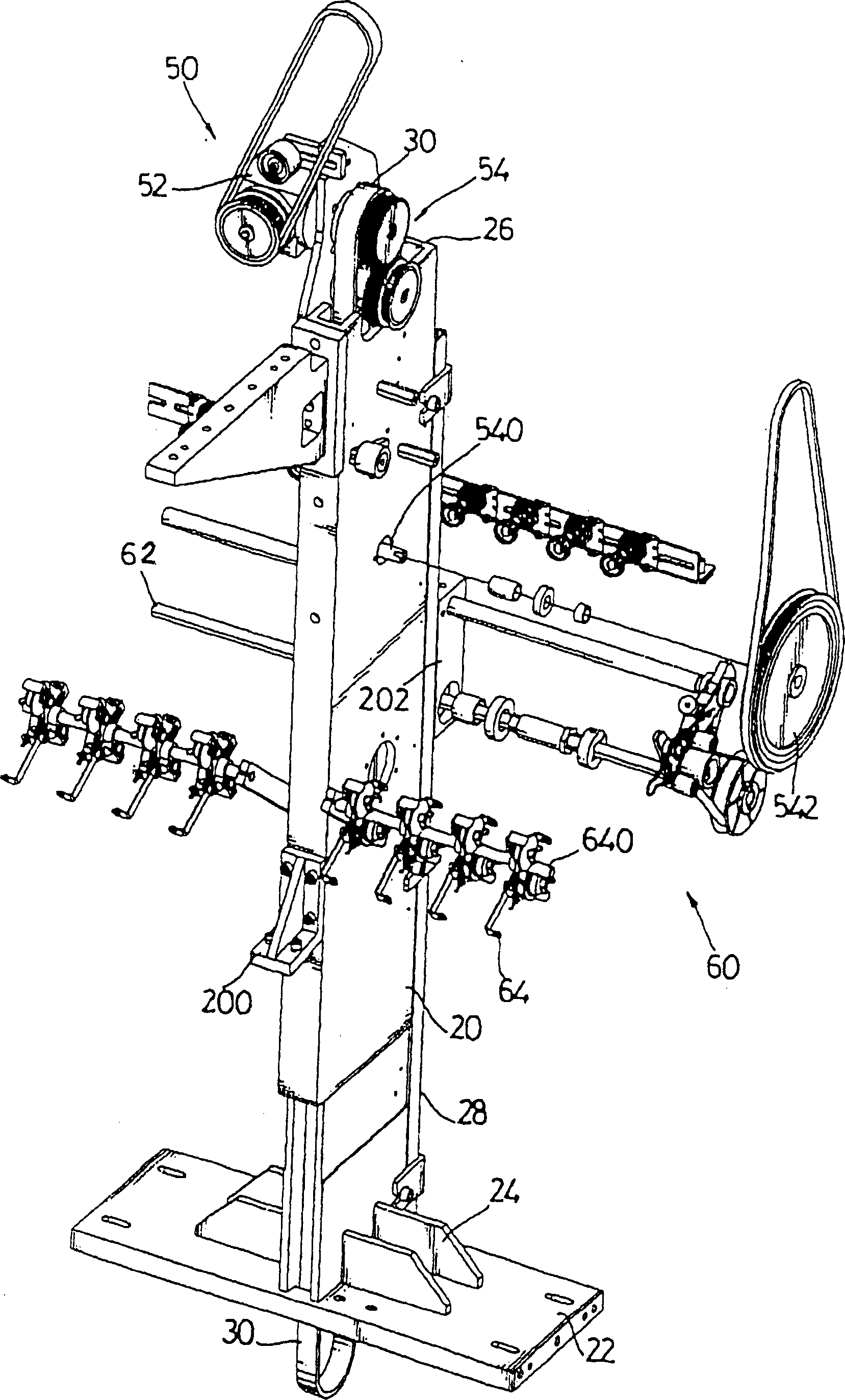

[0020] Please refer to shown in Fig. 1, it is the appearance schematic diagram of jacquard loom of the present invention, wherein can see below the present invention is a box-like machine platform 10, erects a central column 20 in the center of this machine platform 10 top; The top front edge of the machine platform 10 is a webbing mechanism 12, the rear side frame is provided with a yarn guide frame 14, and a front frame 16 is arranged between the webbing mechanism 12 and the middle column 20, which is used for assembling the heald frame (not shown in the figure). ), the structure configured on the machine platform 10 is not the structural feature of the present invention, so it will not be described in detail.

[0021] It can be seen from the figure that a middle column 20 is arranged in the center above the machine table 10, and a faucet 42 and a power transmission device 50 are installed on the top of the middle column 20. Both sides of the weft yarn transmission device 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com