Patents

Literature

35results about How to "Shorten the power transmission path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

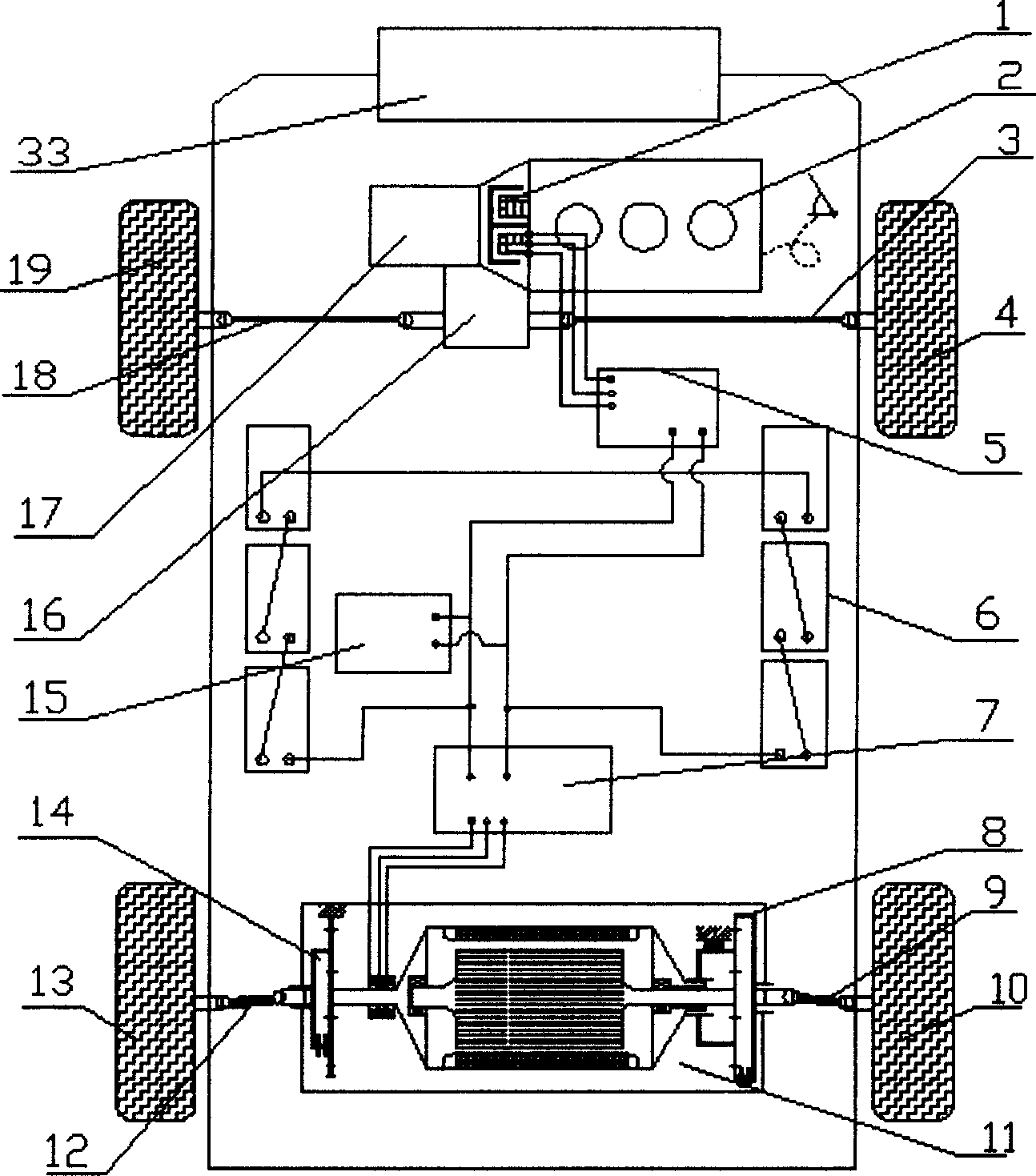

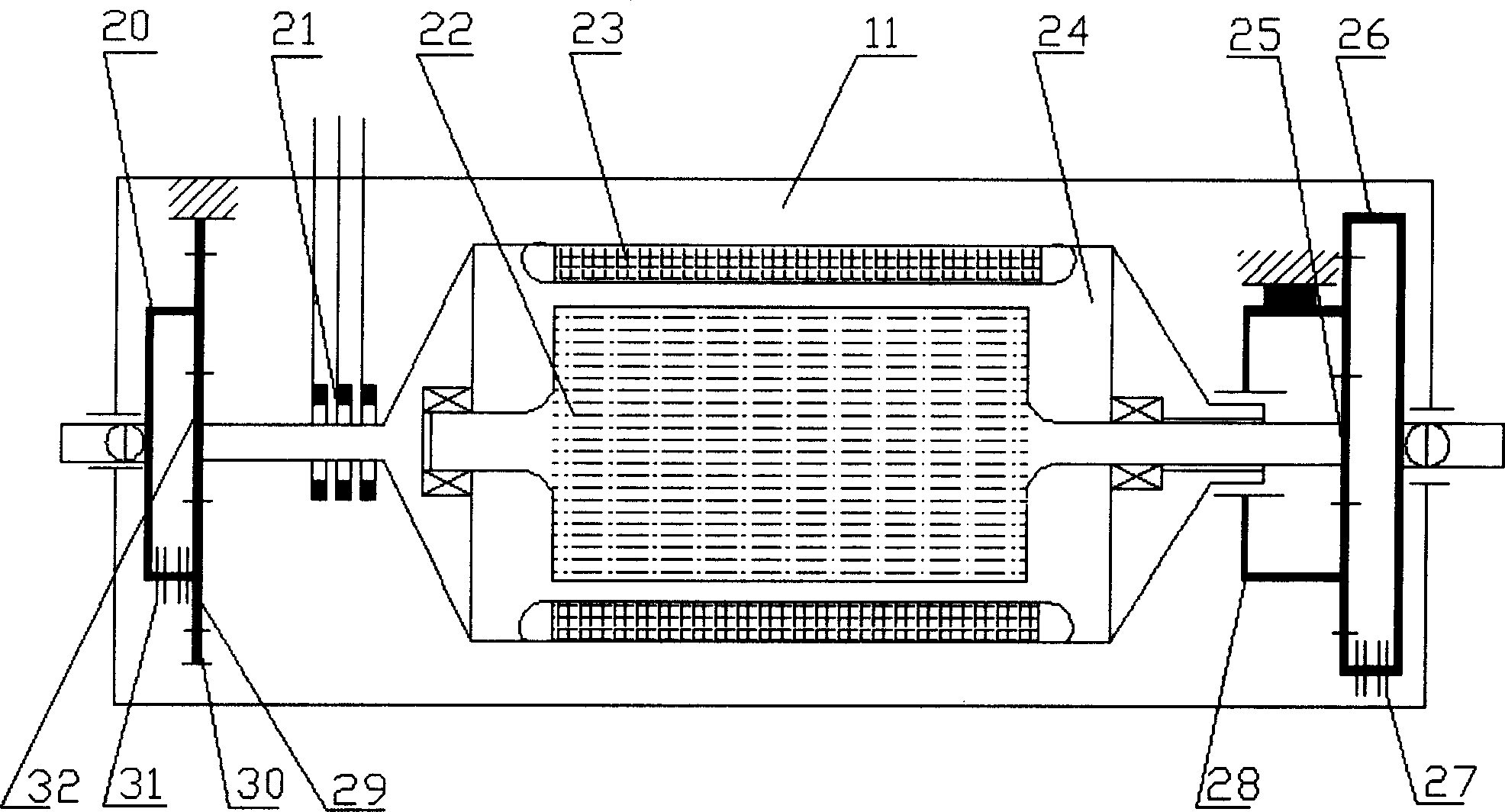

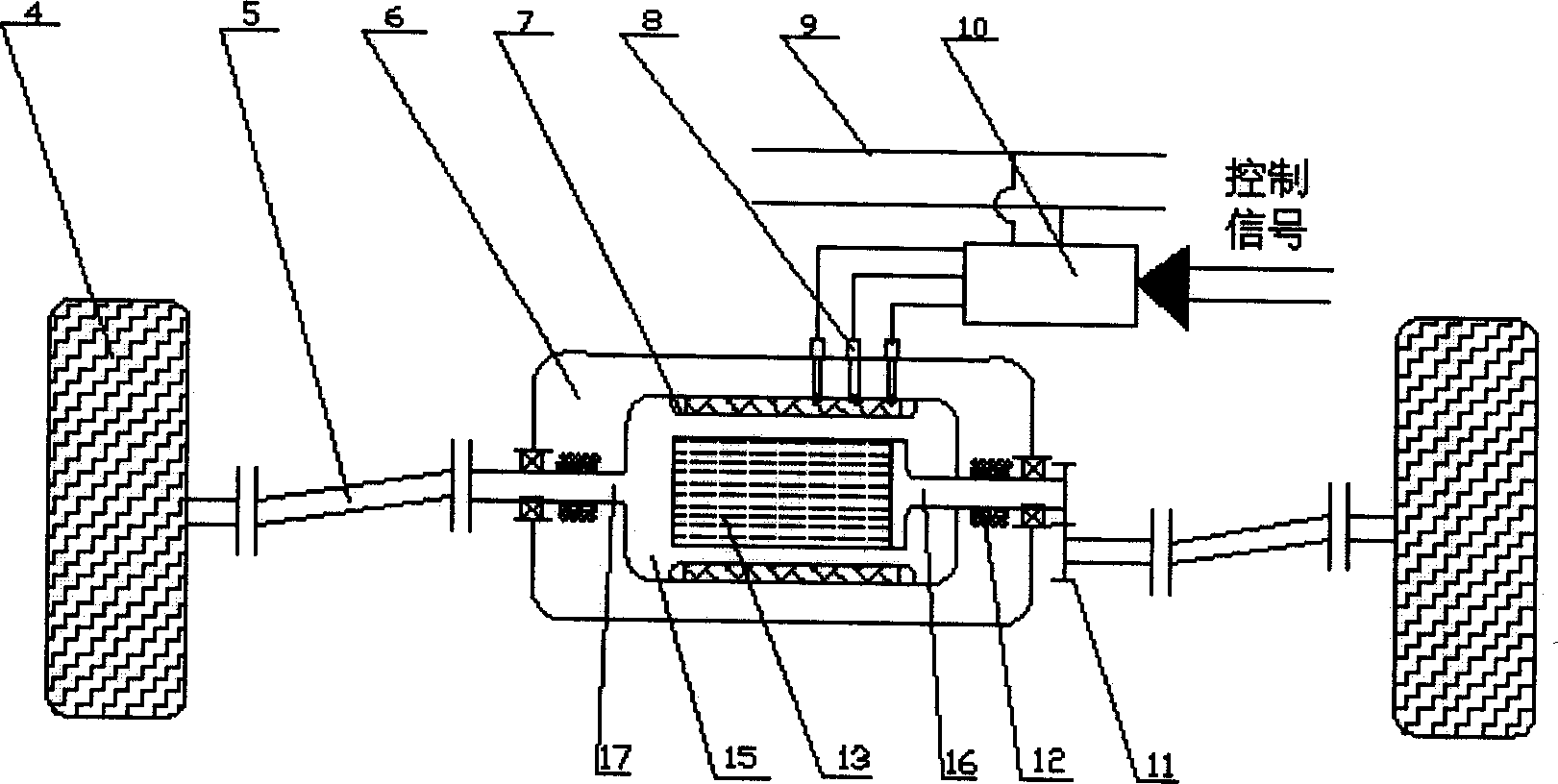

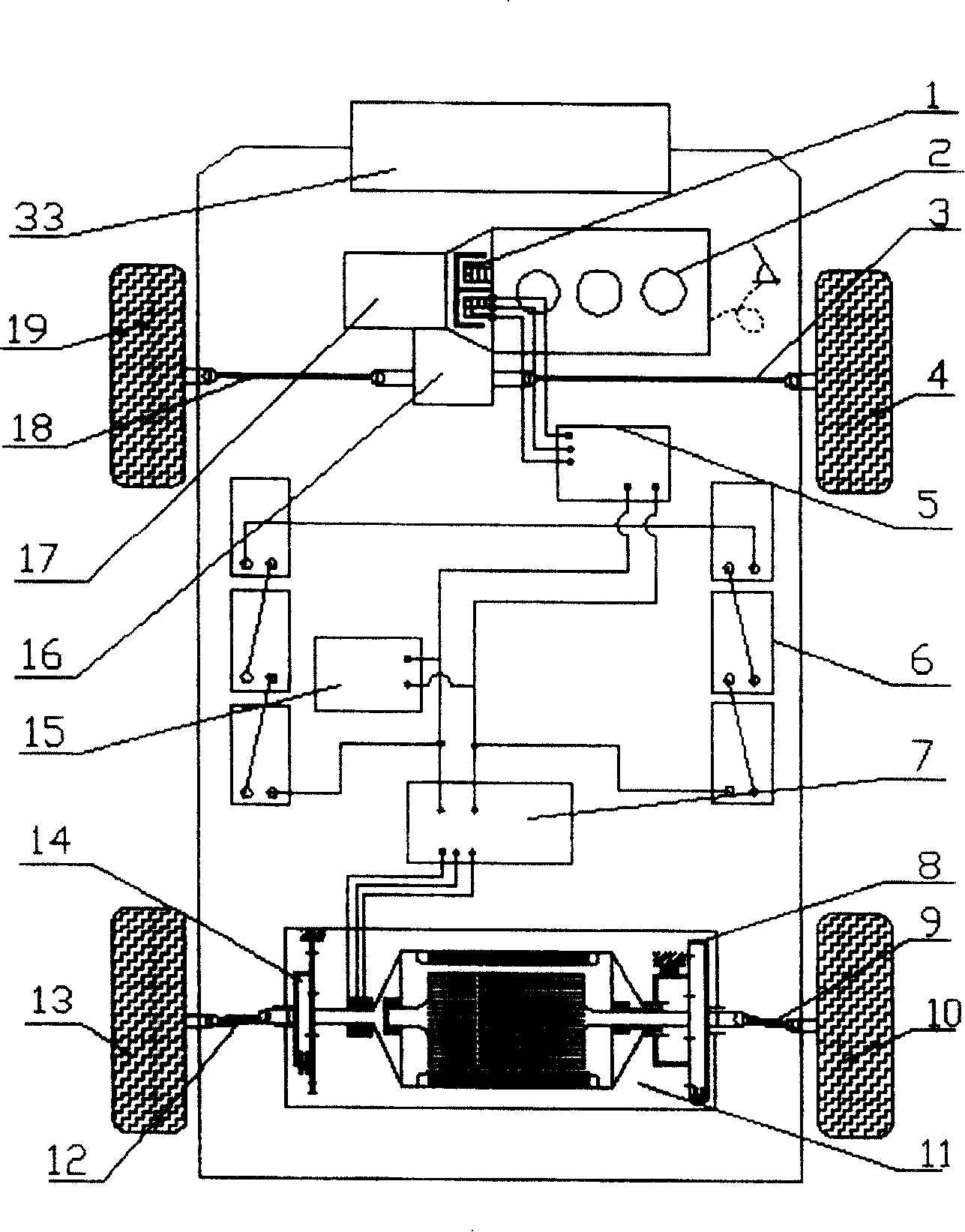

Multiple axle driving system for oil-electricity mixed power automobile

ActiveCN1810557AImprove fuel economyImprove efficiencyHybrid vehiclesSpeed controllerElectricityElectric machine

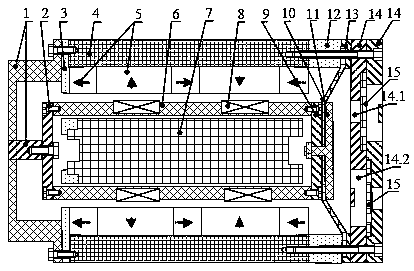

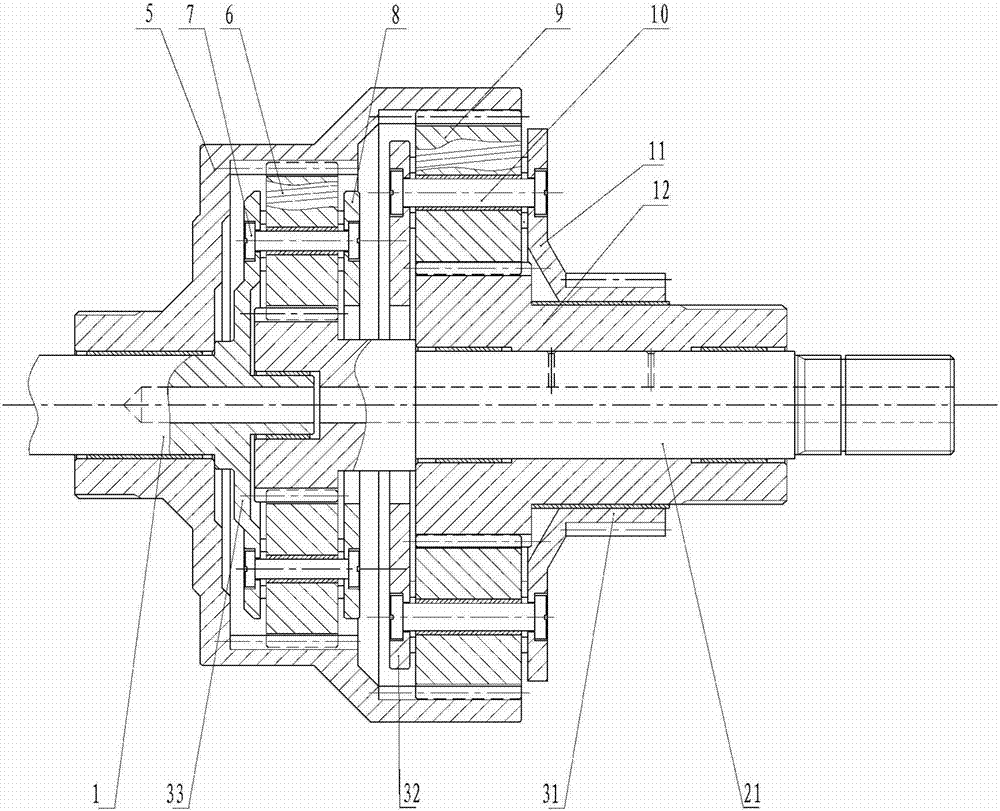

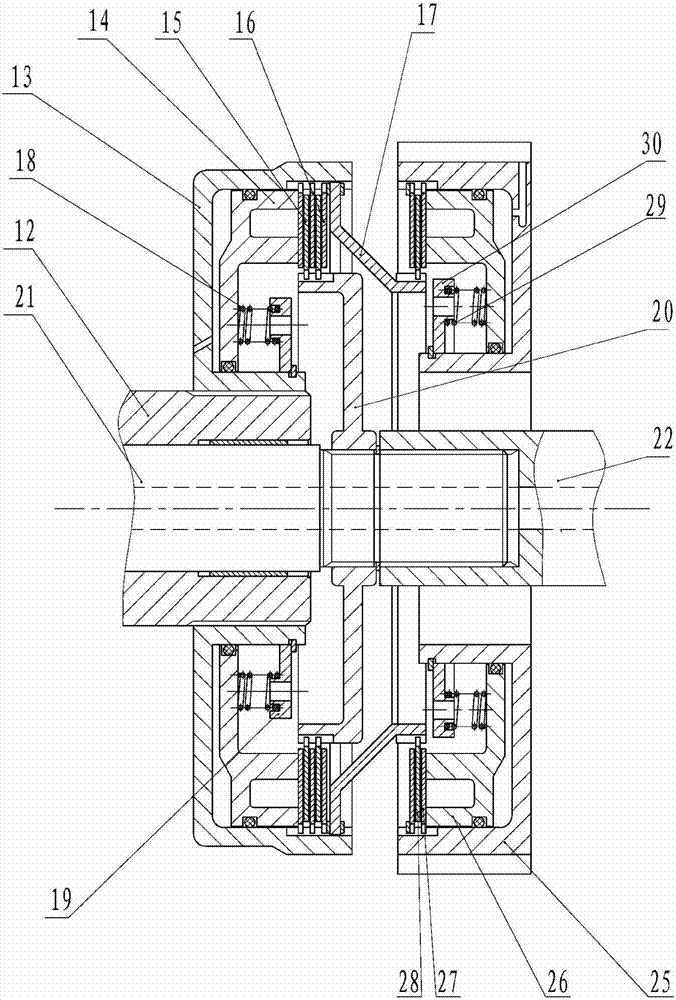

The multiple axle driving system for mixed power automobile with fuel oil and electric energy as power source includes at least one mechanical driving axle assembly, at least one electric driving axle assembly, one power source assembly, one general controller, one monitoring and communication network system, and one engine and one multifunctional double-rotor motor to drive different axles separately. The double-rotor motor consists of one outer rotor and one inner rotor, the outer rotor is connected to the hub in one side through the reducing mechanism and the versatile transmission mechanism, and the inner rotor is connected to the hub in the other side through the reducing mechanism and the versatile transmission mechanism. The multiple axle driving system integrates the technology and functions of complete mixed power, multiple axle driving, etc. and makes the automobile possess the advantages of easy realization, low cost, raised running smoothness and stability, etc.

Owner:SOUTH CHINA UNIV OF TECH +1

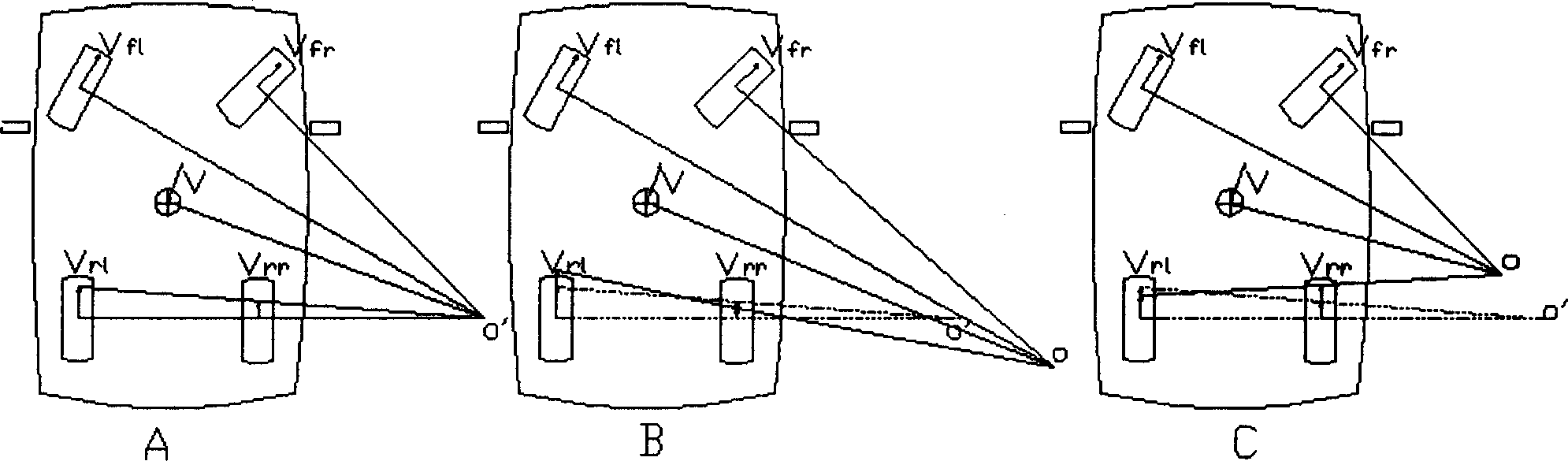

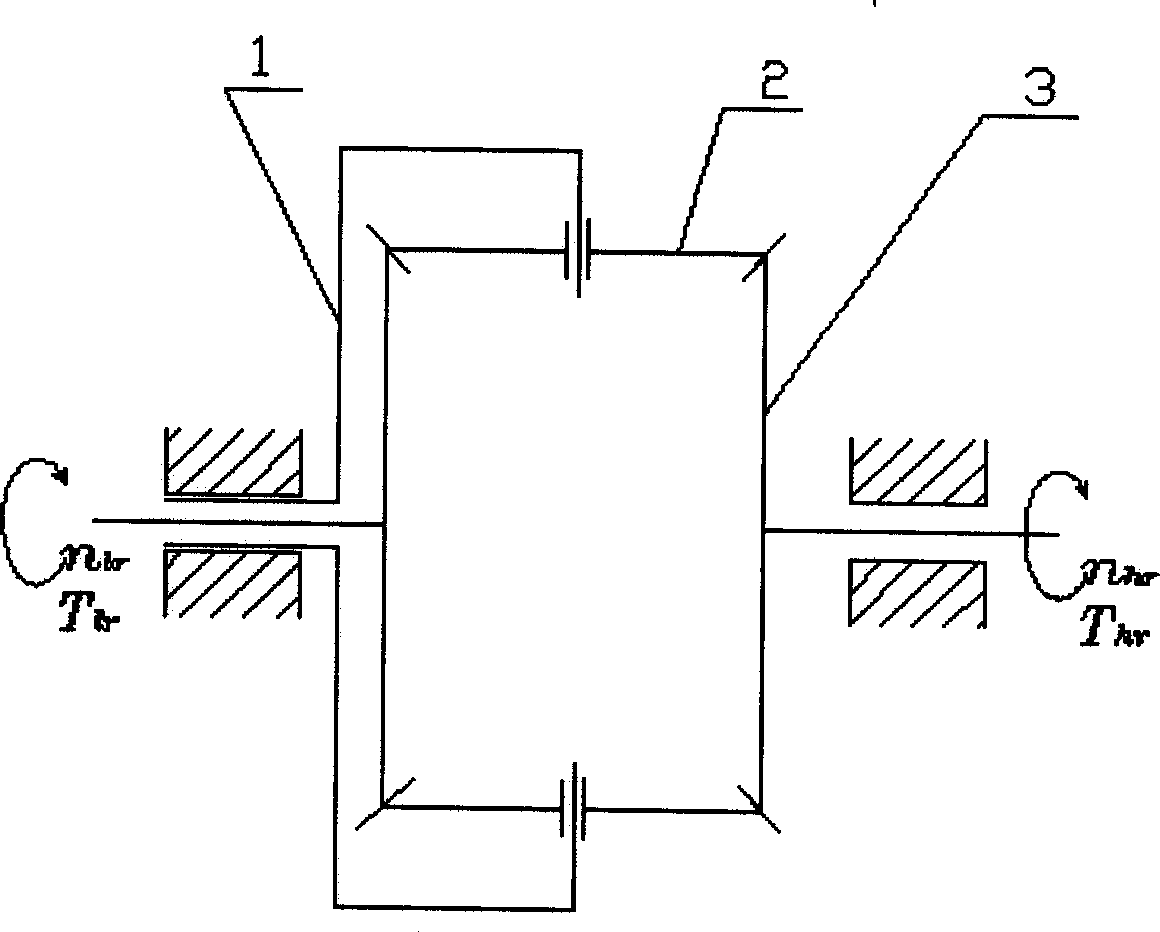

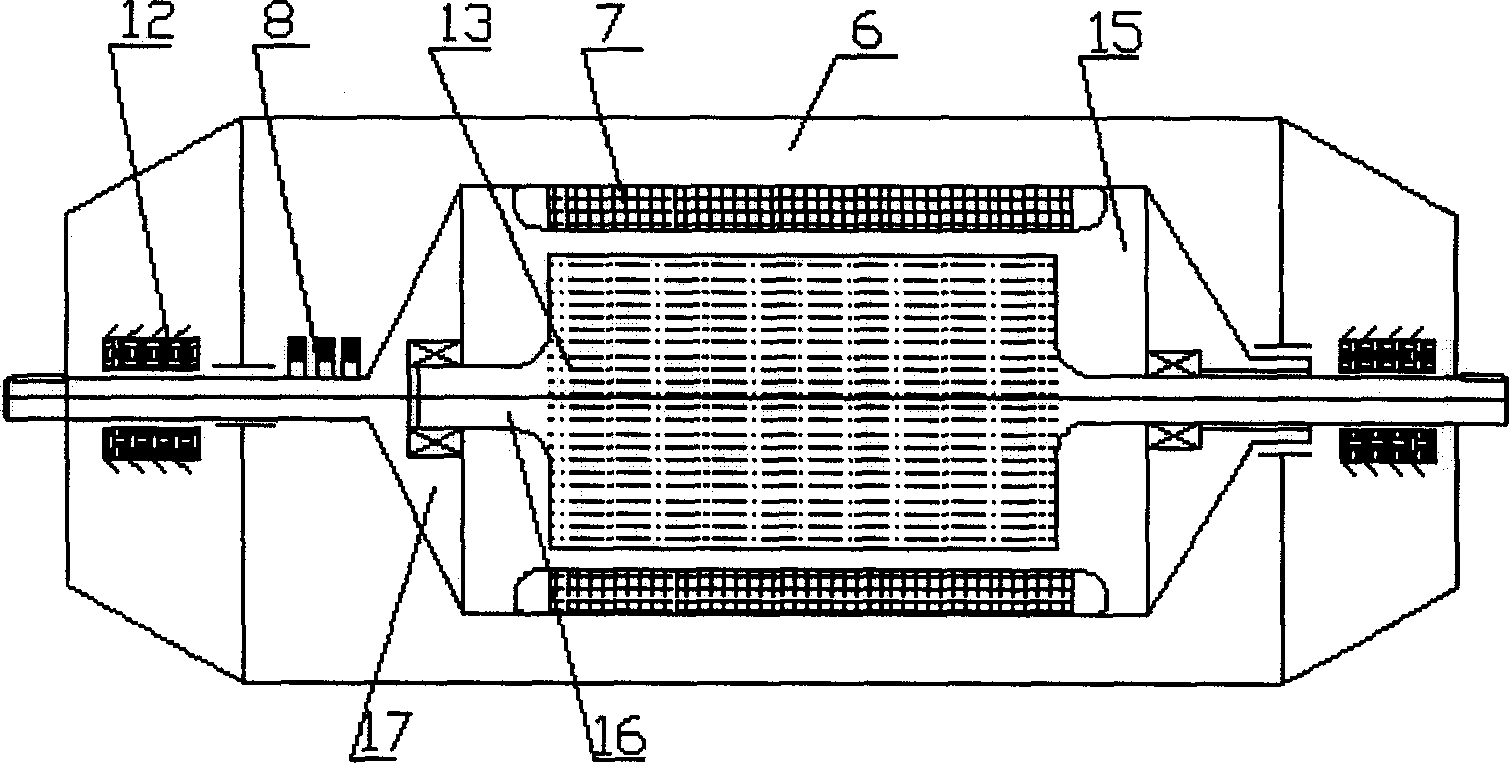

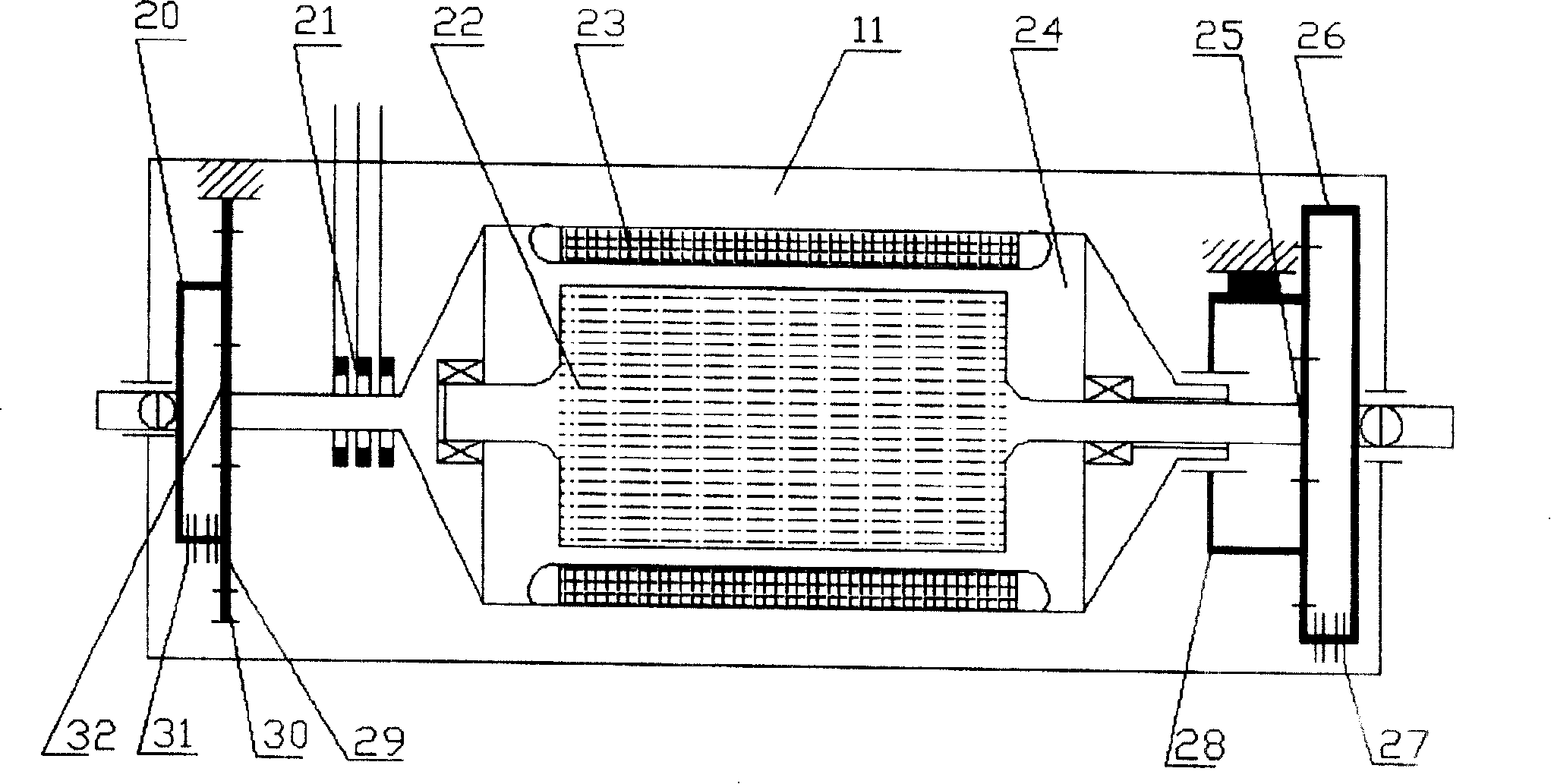

Vehicular multifunctional electromagnetic differential system

InactiveCN1799893AImprove efficiencyShorten the power transmission pathSpeed controllerElectric energy managementElectric machineElectric vehicle

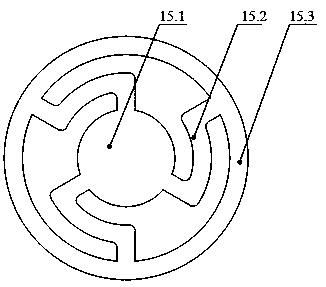

The invention relates to a multifunctional electromagnetic speed differential system which can be used a drive speed differential integrated system of electric power vehicle and mixed power vehicle, and as a speed baffle used in the driven bridge of traditional vehicle. The invention comprises a dual-rotor motor and a controller. Wherein, the dual-rotor motor is formed by a outer rotor and a inner rotor coiled by excitation winding and; one rotor via connection device is connected to the wheels on one side; another rotor via steering gear and connection device is connected to the wheel on another side; the excitation winding of outer rotor via sliding ring is connected to the controller; and the controller is connected to vehicle power resource. The invention can reduce mechanical transmission to attain high transmission efficiency, smaller size and lighter weight.

Owner:SOUTH CHINA UNIV OF TECH

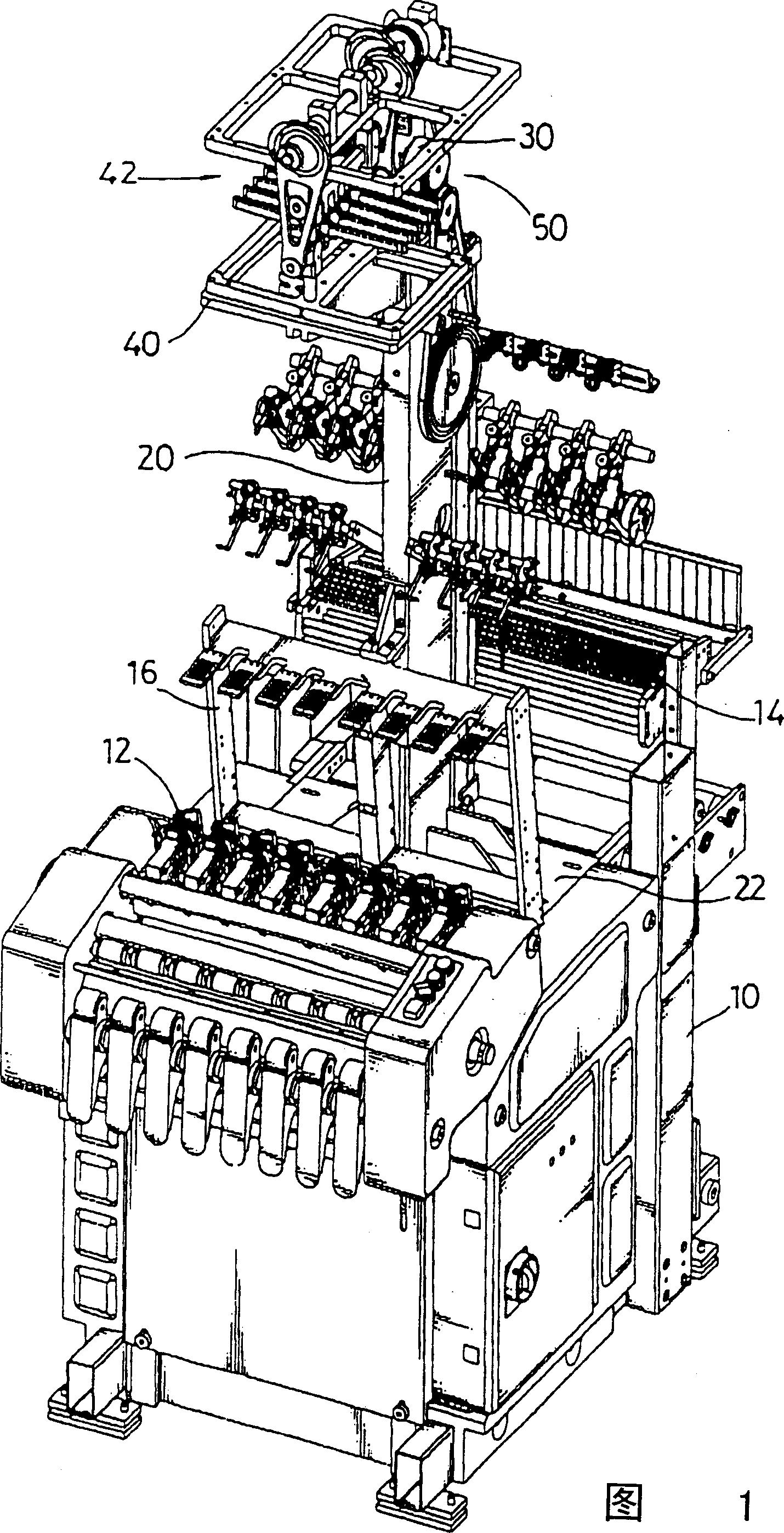

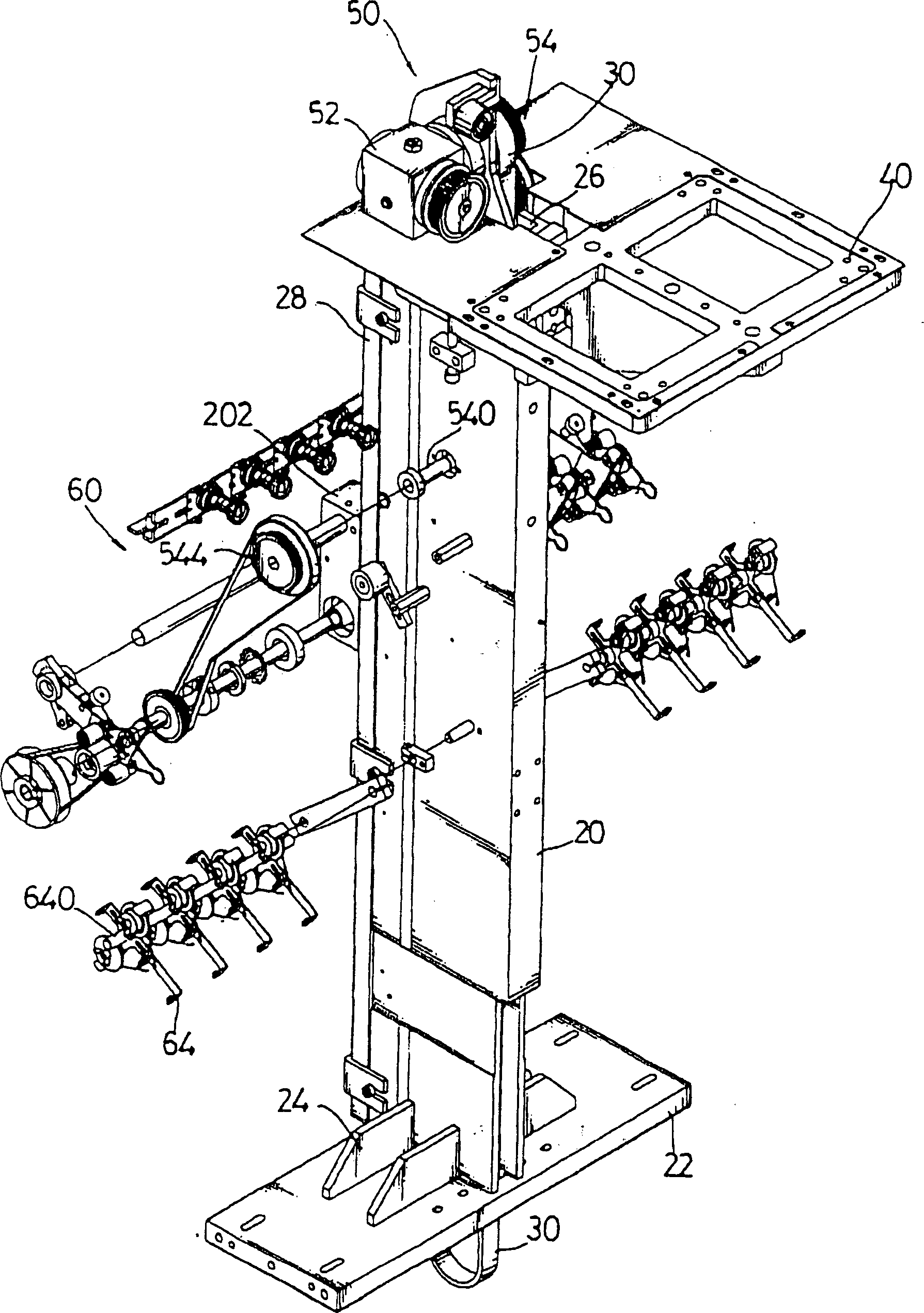

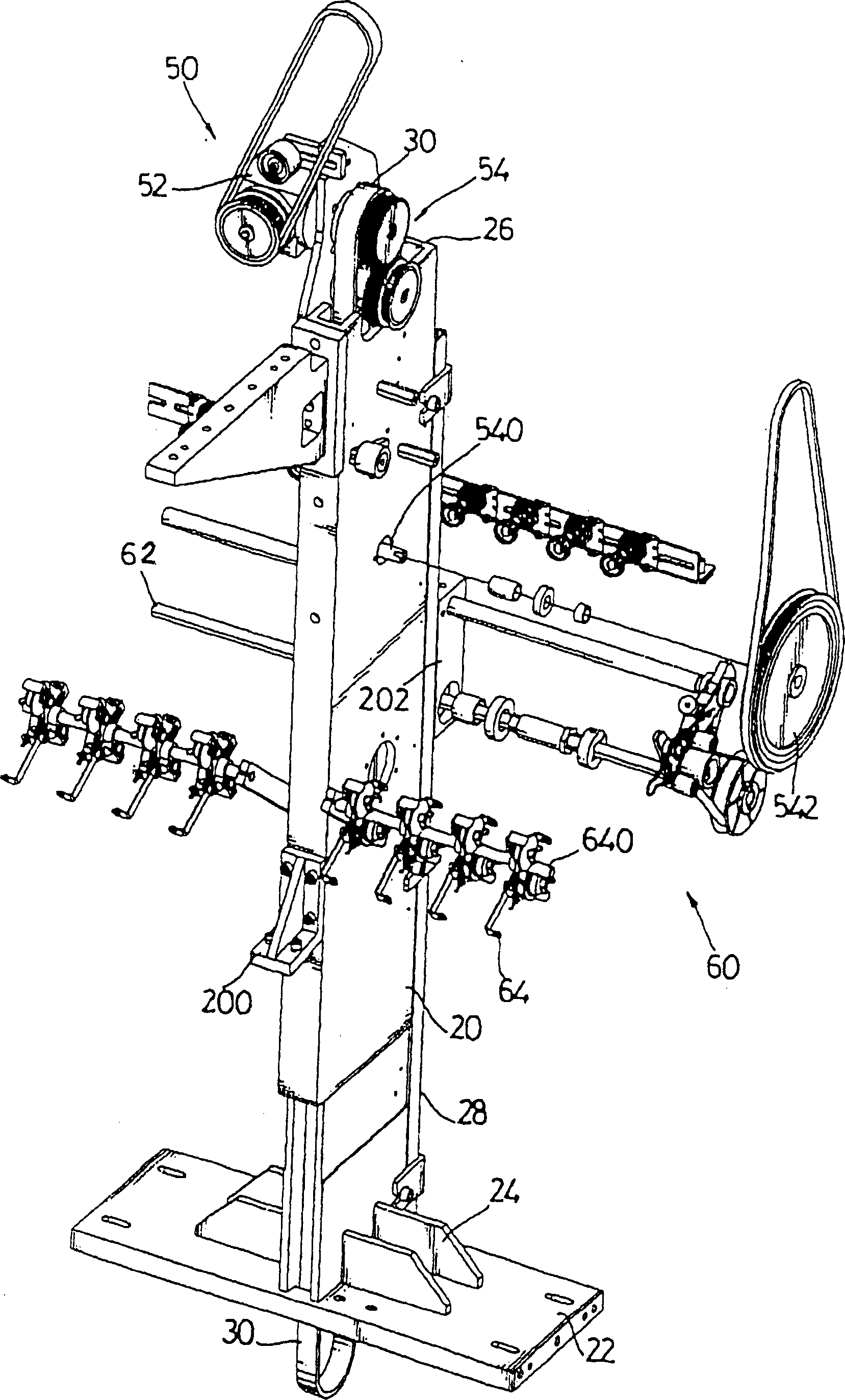

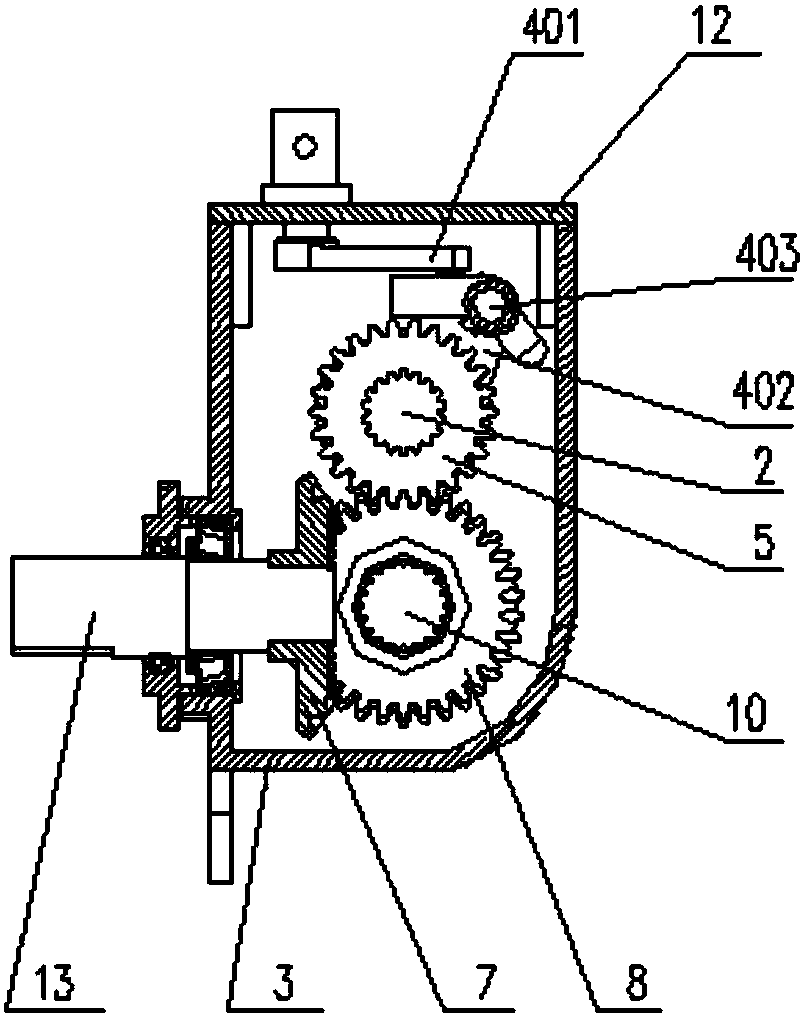

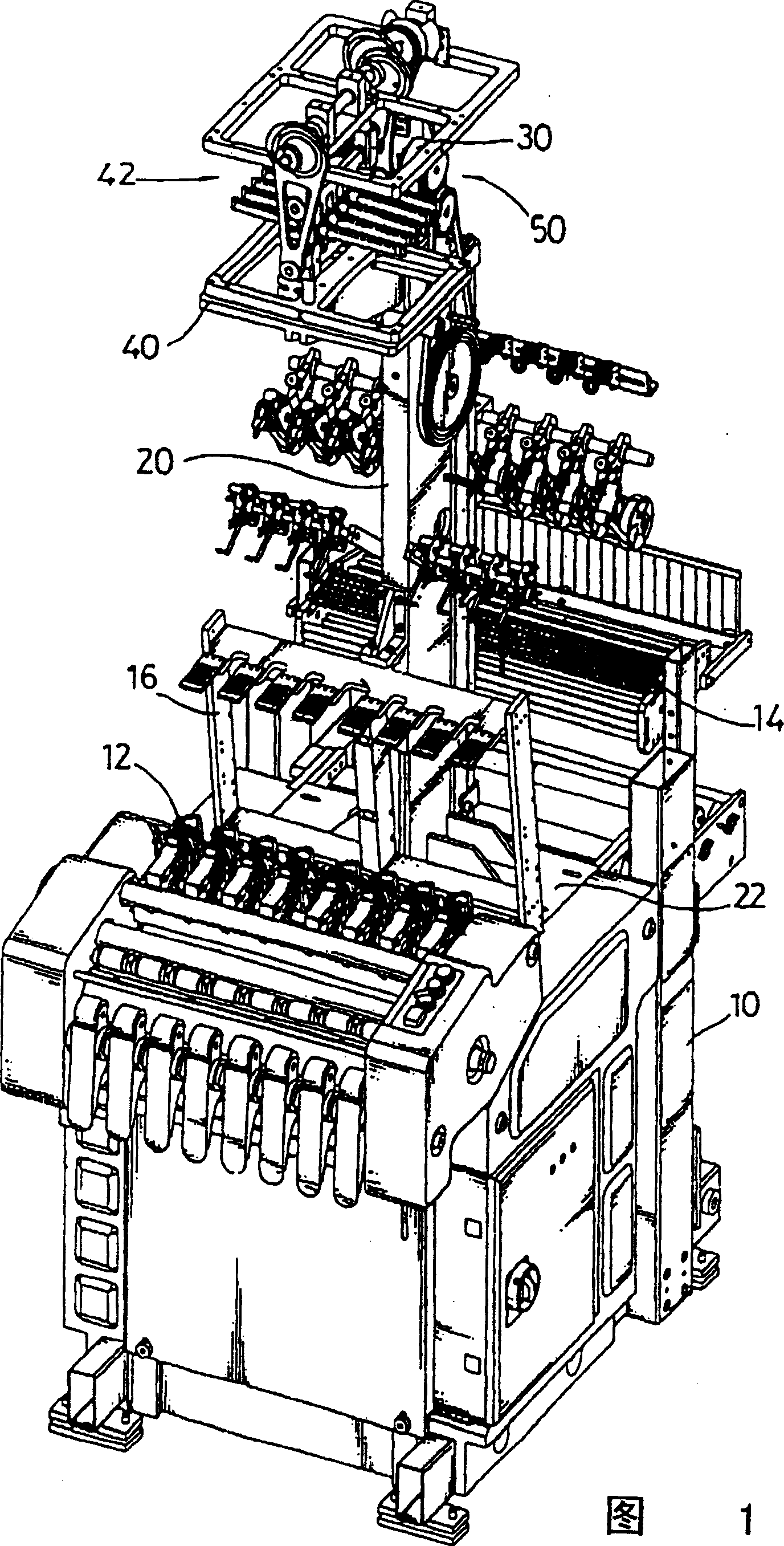

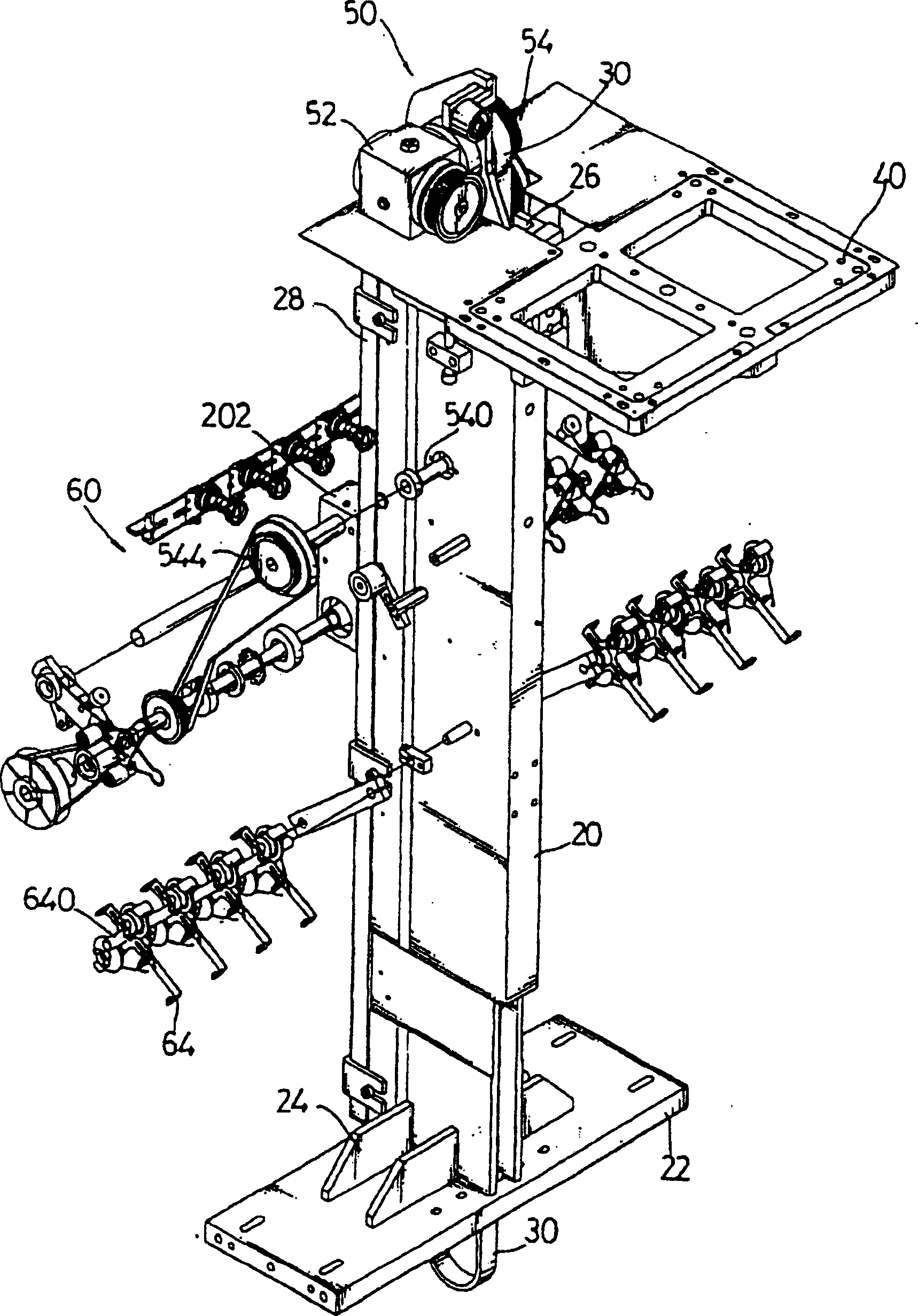

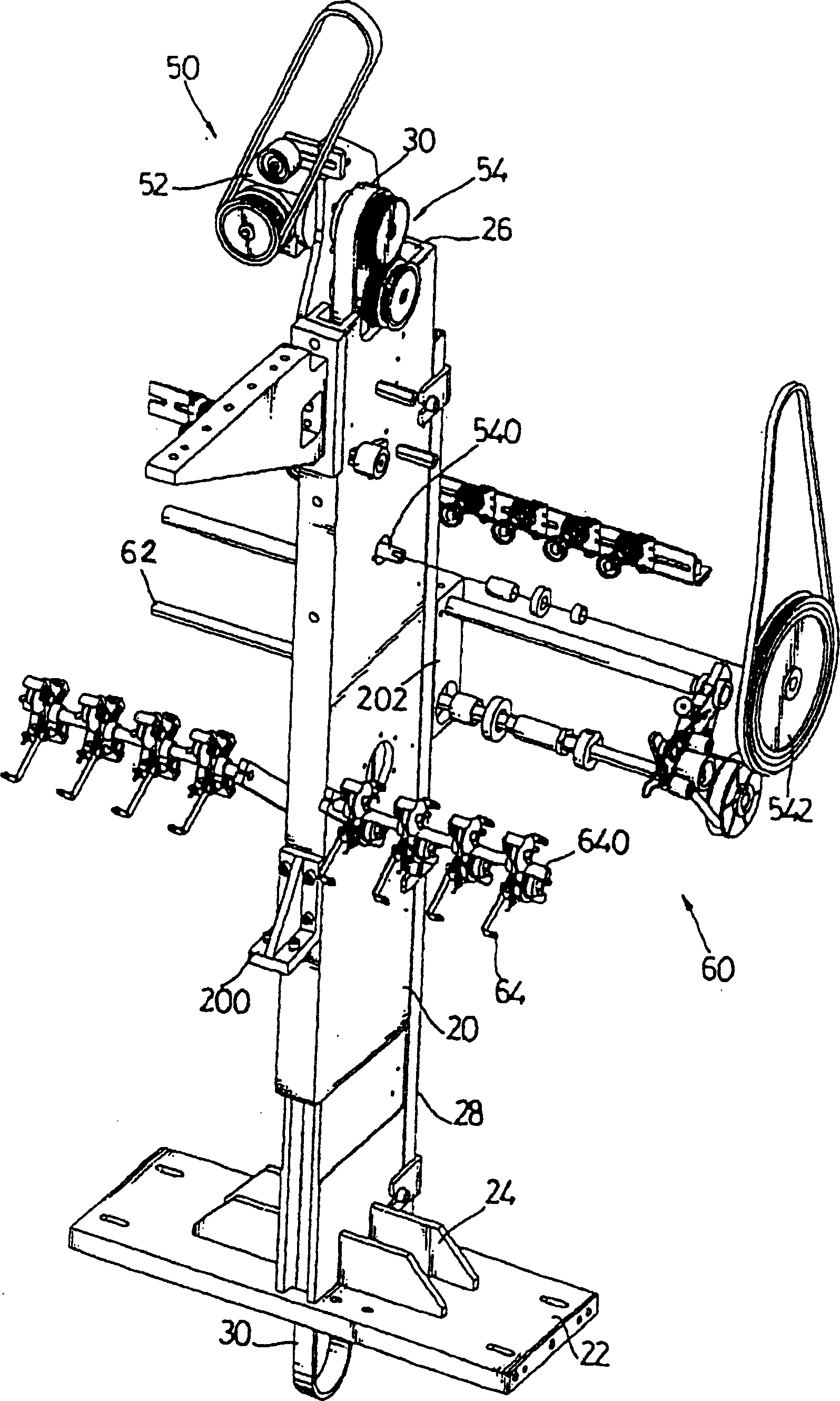

Jacquard ribbon loom with mainstay

InactiveCN1485475AReduce manufacturing costEasy maintenanceJacquardsSmallware loomsEngineeringLeather belt

A jacquard ribbon loom with a central column, comprises a hollow central column over the machine platform, the main driving belt in the central column, a spigot and a power transmission member on thetop end of the central column, weft transmission member symmetrically on the two sides of the central column. The light jacquard ribbon loom is compact and stable due to the hollow central column.

Owner:林贞惠

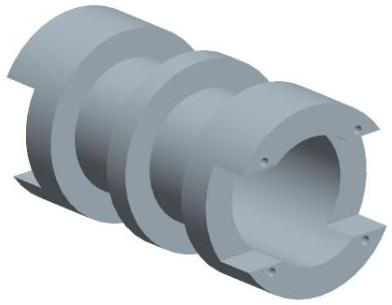

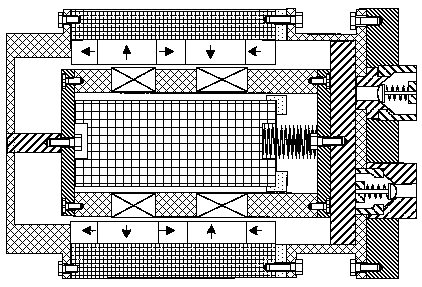

High-power-density moving-coil type electromagnetic direct-drive hydraulic pump

PendingCN111441928AGuaranteed normal outputImprove power densityPositive displacement pump componentsPump controlHydraulic cylinderReciprocating motion

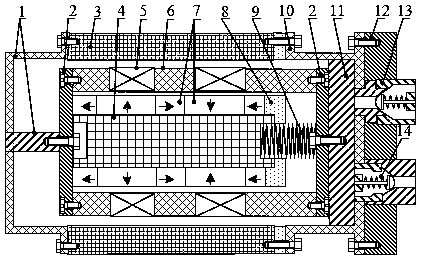

The invention relates to a high-power-density moving-coil type electromagnetic direct-drive hydraulic pump. The high-power-density moving-coil type electromagnetic direct-drive hydraulic pump comprises magnetic yokes, permanent magnet arrays, an end cover, hydraulic cylinder bodies, a valve body, a coil framework, coils, pistons, a centering spring and a one-way valve. The high-power-density moving-coil type electromagnetic direct-drive hydraulic pump is characterized in that double Halbach permanent magnet array layers formed by alternately and closely arranging axial magnetizing permanent magnets and radial magnetizing permanent magnets are adopted to be attached to the outer side of the inner magnetic yoke and the inner side of the outer magnetic yoke in a surface mode correspondingly,wherein an air gap is formed between the inner magnetic yoke and the outer magnetic yoke, and the magnetic yokes are fixedly connected with the end cover and the hydraulic cylinder bodies to serve asstators; a coil set is wound on the framework and placed in the air gap; the winding directions of the adjacent coils are opposite; the framework and the two hydraulic cylinder pistons are integrated;the pistons are directly driven to reciprocate, meanwhile, liquid pumping is completed in two hydraulic cylinders, and the pistons serve as rotors; and the centering spring, a hydraulic pump rotor and the hydraulic pump stators jointly form a resonance system, and the centering spring is in a compressed state all the time. The working efficiency and the power density of the hydraulic pump are effectively improved through the technologies of electromagnetic direct drive, the double Halbach permanent magnet array layers, a symmetrical working cavity, the centering spring and the like.

Owner:SHANDONG UNIV OF TECH

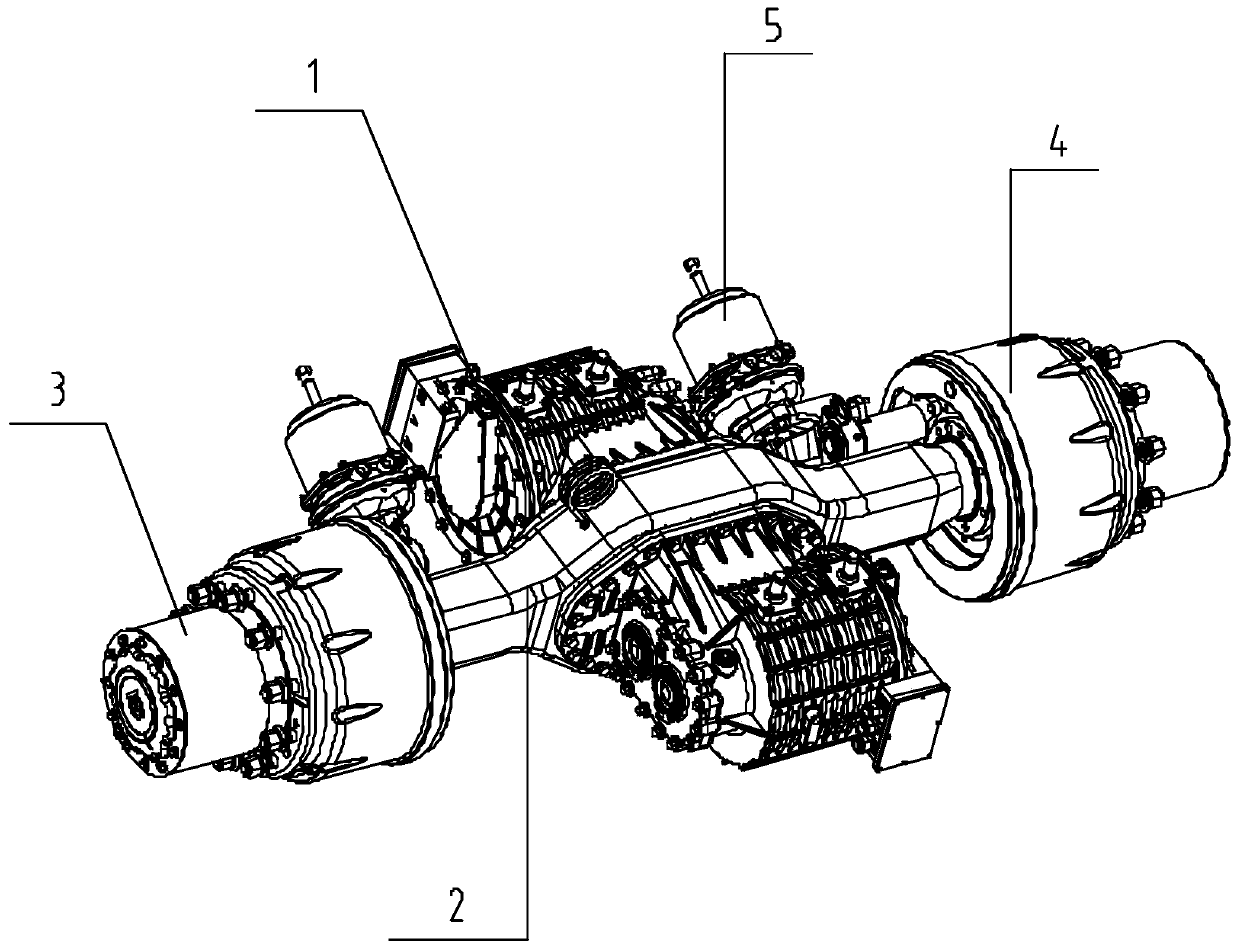

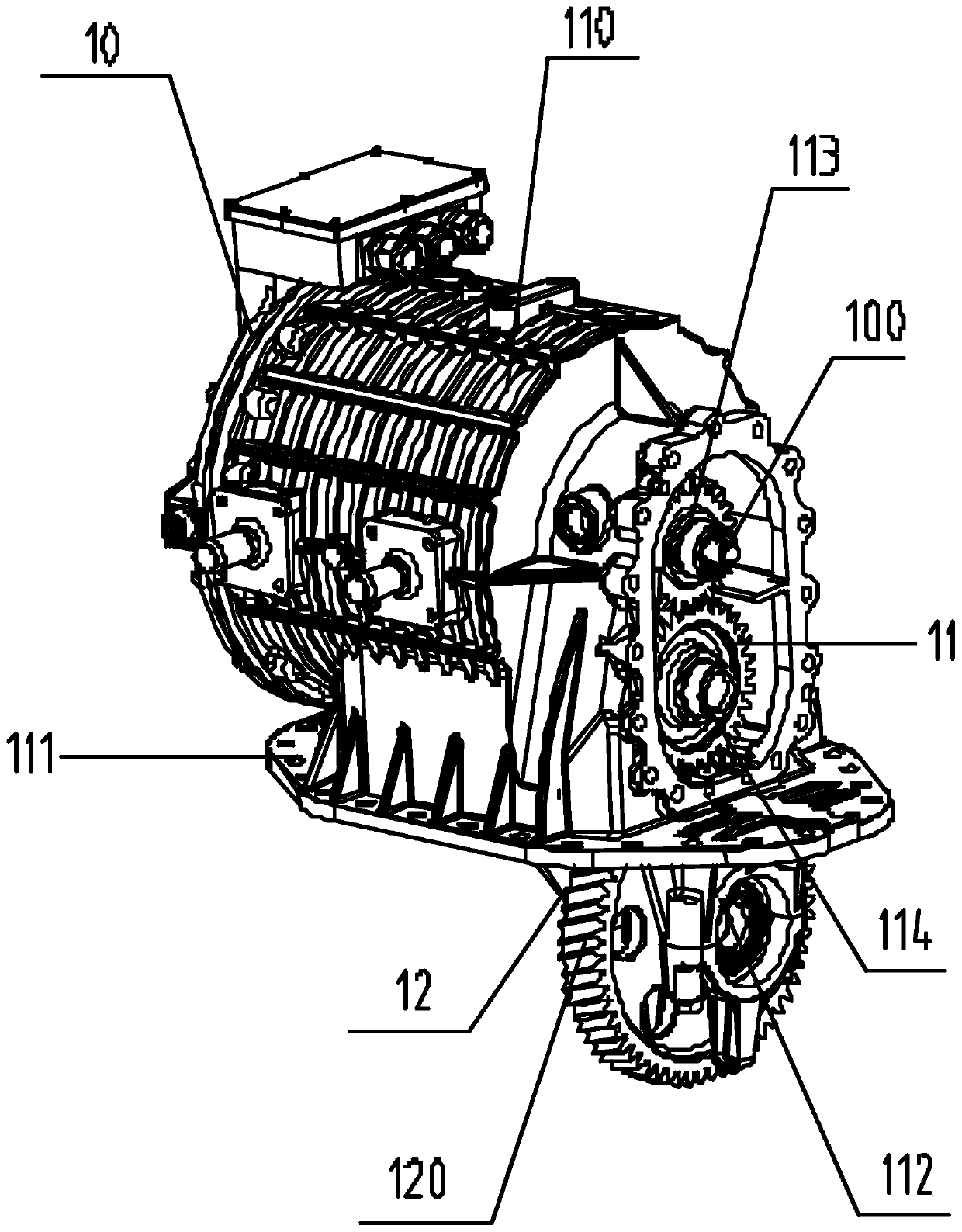

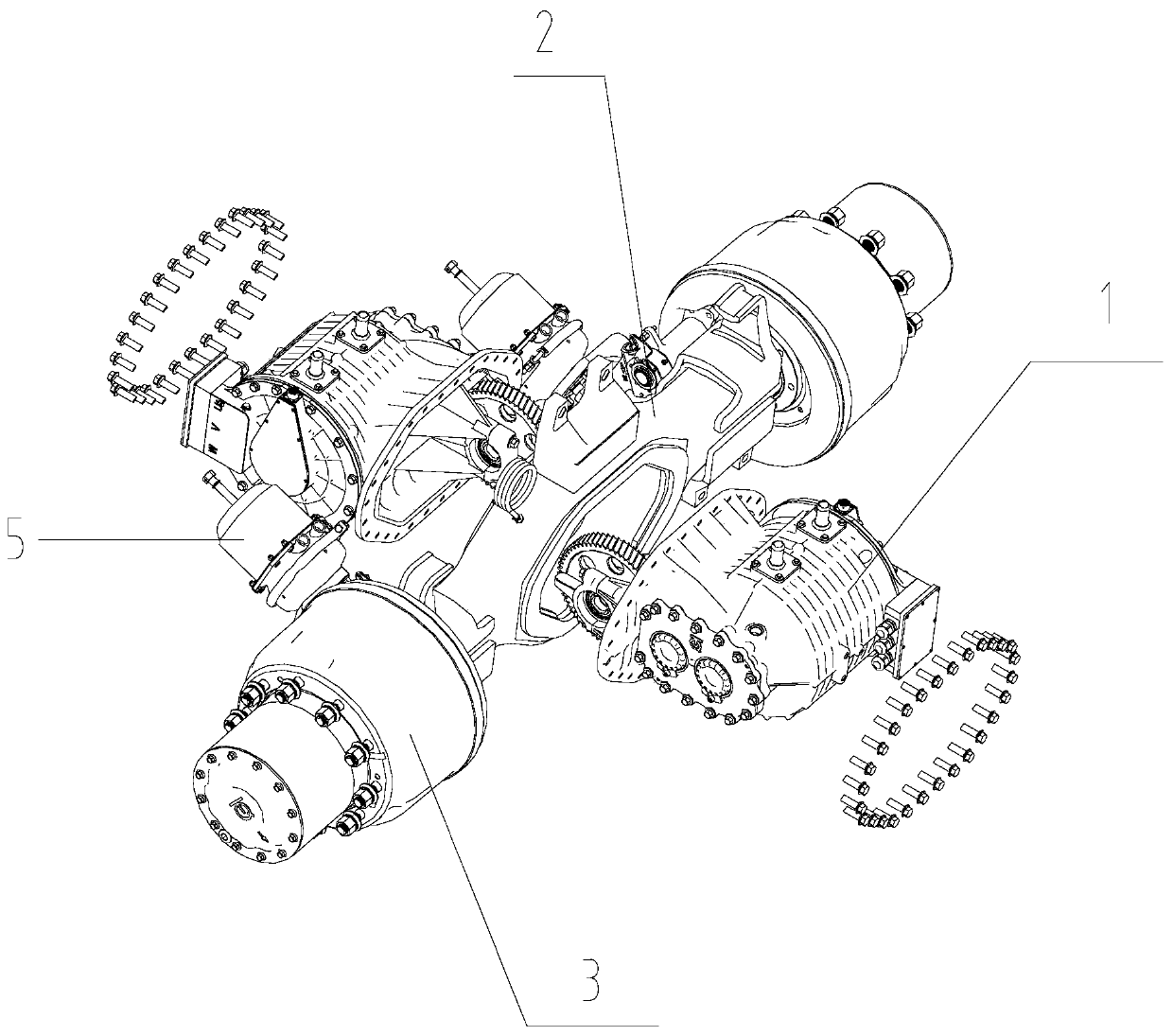

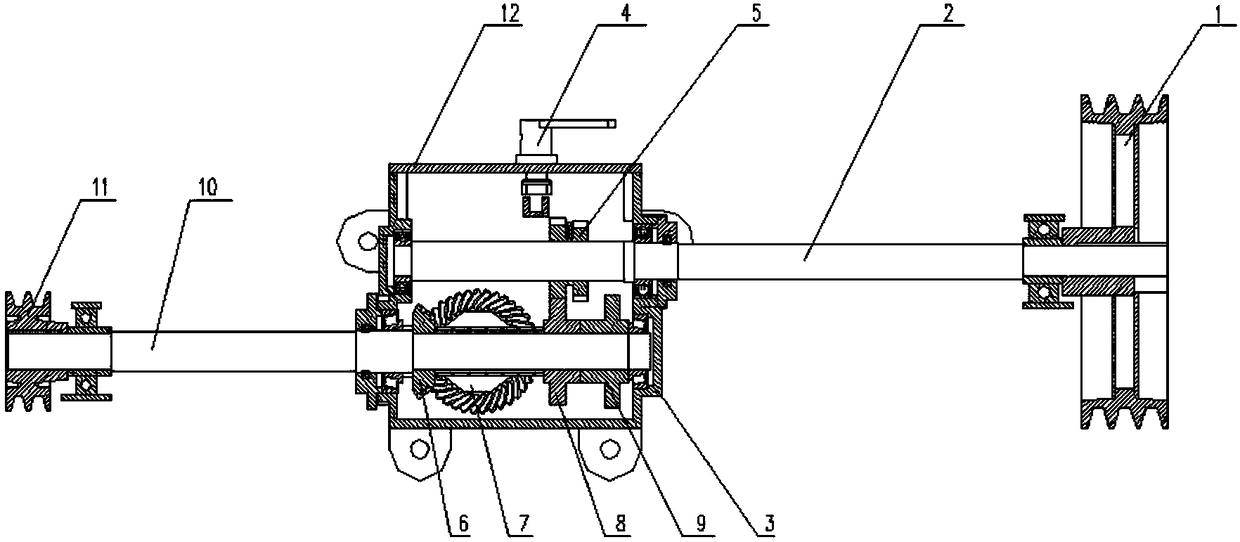

Integrated double-motor distributed drive electric drive axle

InactiveCN111169225AImprove efficiencyImprove space utilizationSpeed controllerElectric propulsion mountingReduction driveElectric machinery

The invention provides an integrated double-motor distributed drive electric drive axle. The drive axle comprises an integrated power assembly, an axle housing and a hub reduction system, the integrated power assemblies are respectively arranged at the front end and the rear end of the axle housing; the integrated power assembly comprises a driving motor, a speed reducer and a differential mechanism; the driving motor drives the speed reducer and the differential; the hub reducers are respectively arranged at the left and right ends of the axle housing; the hub reduction gear arranged at the left end of the axle housing is in transmission connection with the differential mechanism of the integrated power assembly arranged at the rear end of the axle housing through a first half shaft; thehub reduction gear arranged at the right end of the axle housing is in transmission connection with the differential mechanism of the integrated power assembly arranged at the front end of the axle housing through the second half shaft, and therefore the integrated power assembly has the advantages that the weight of the assembly is reduced, the overall efficiency of the axle is improved, and meanwhile the space utilization rate of the whole vehicle is increased.

Owner:青岛汽车零部件科技创新服务有限公司

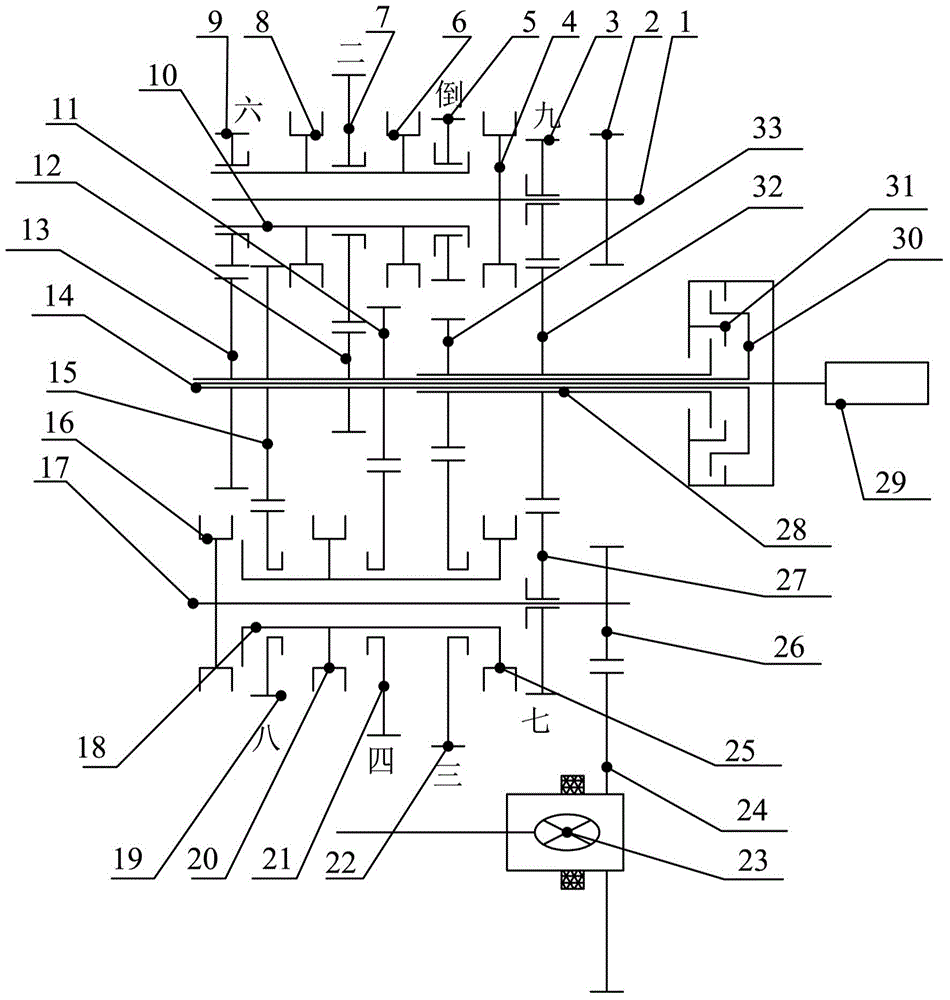

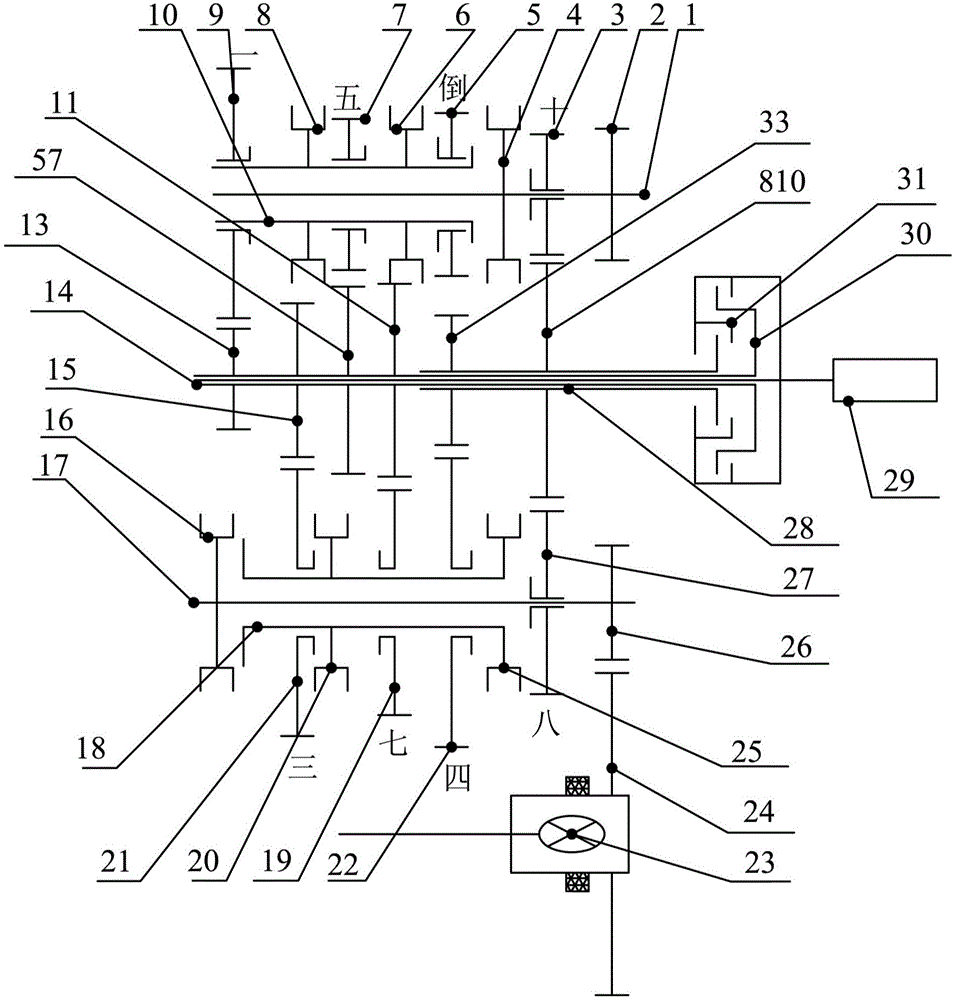

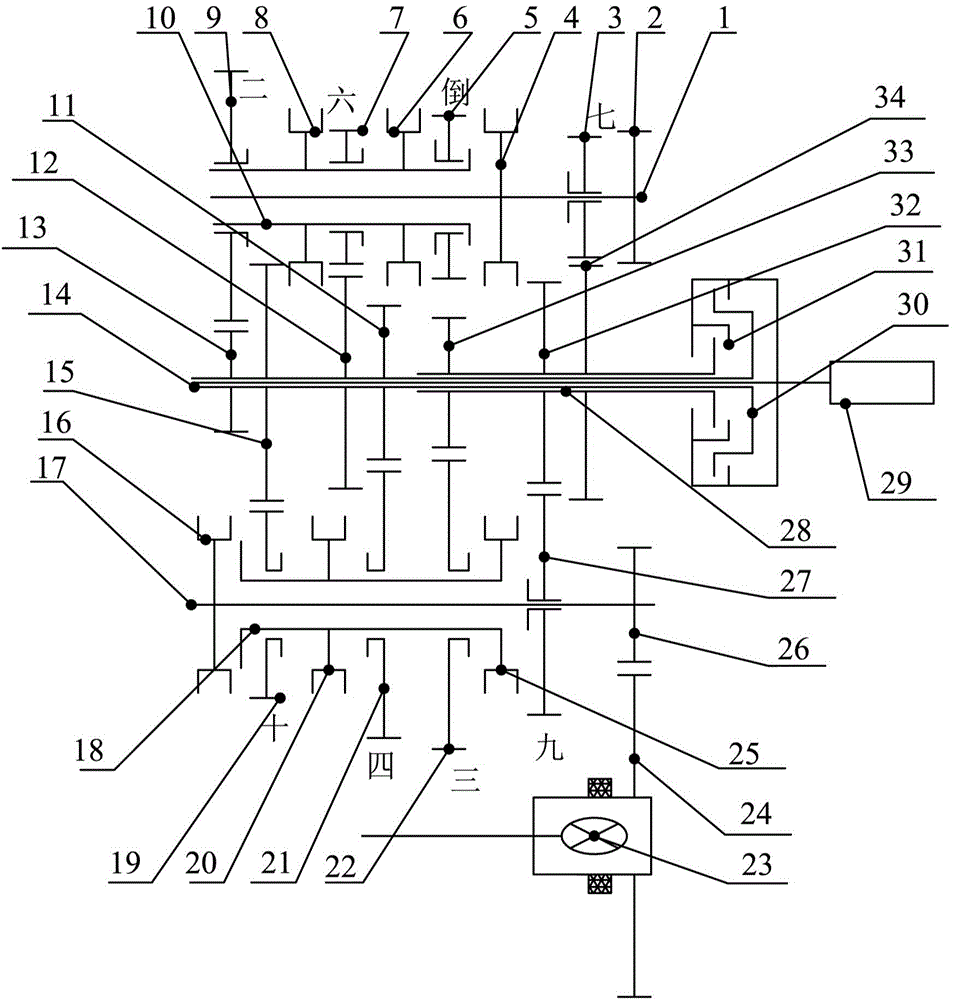

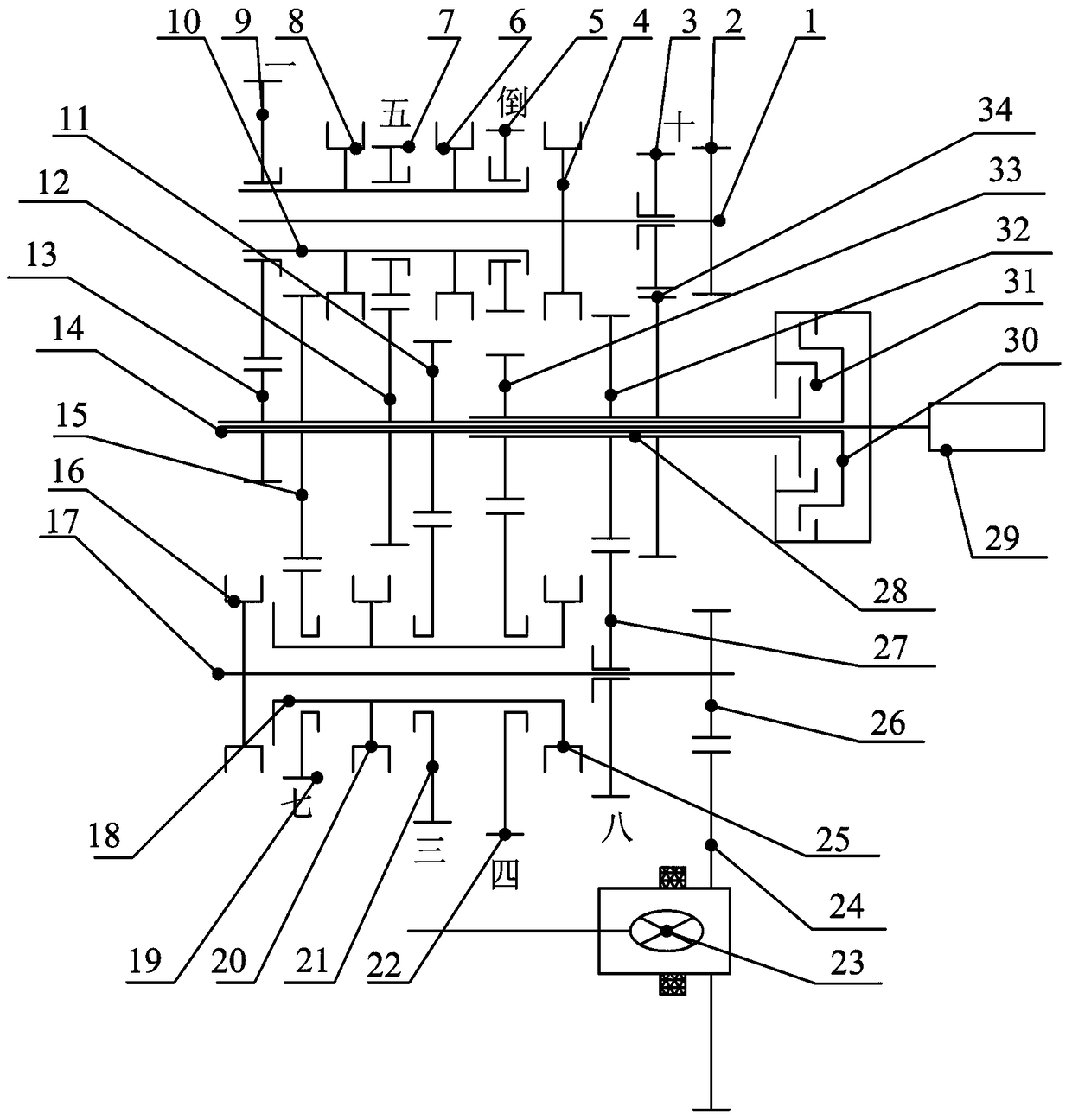

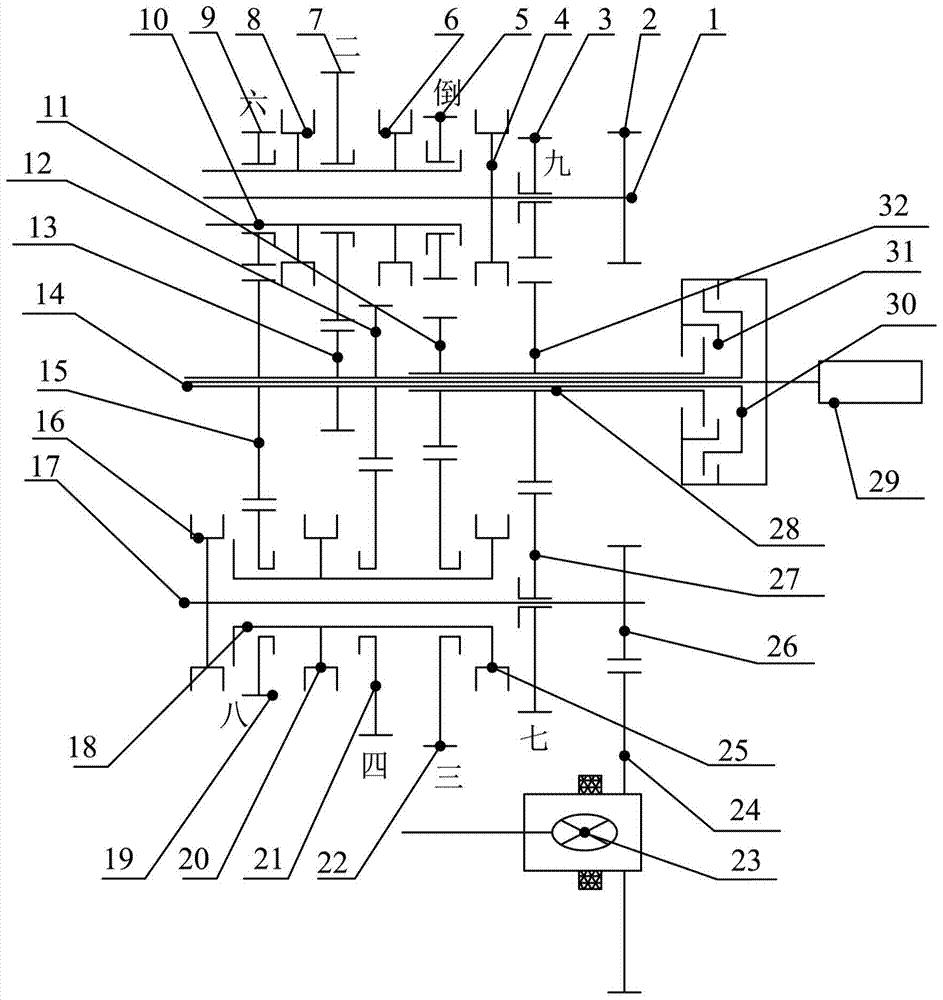

Multi-gear dual clutch transmission and vehicle

ActiveCN105443677AImprove transmission efficiencyShorten the axial lengthToothed gearingsGearing detailsGear driveEngineering

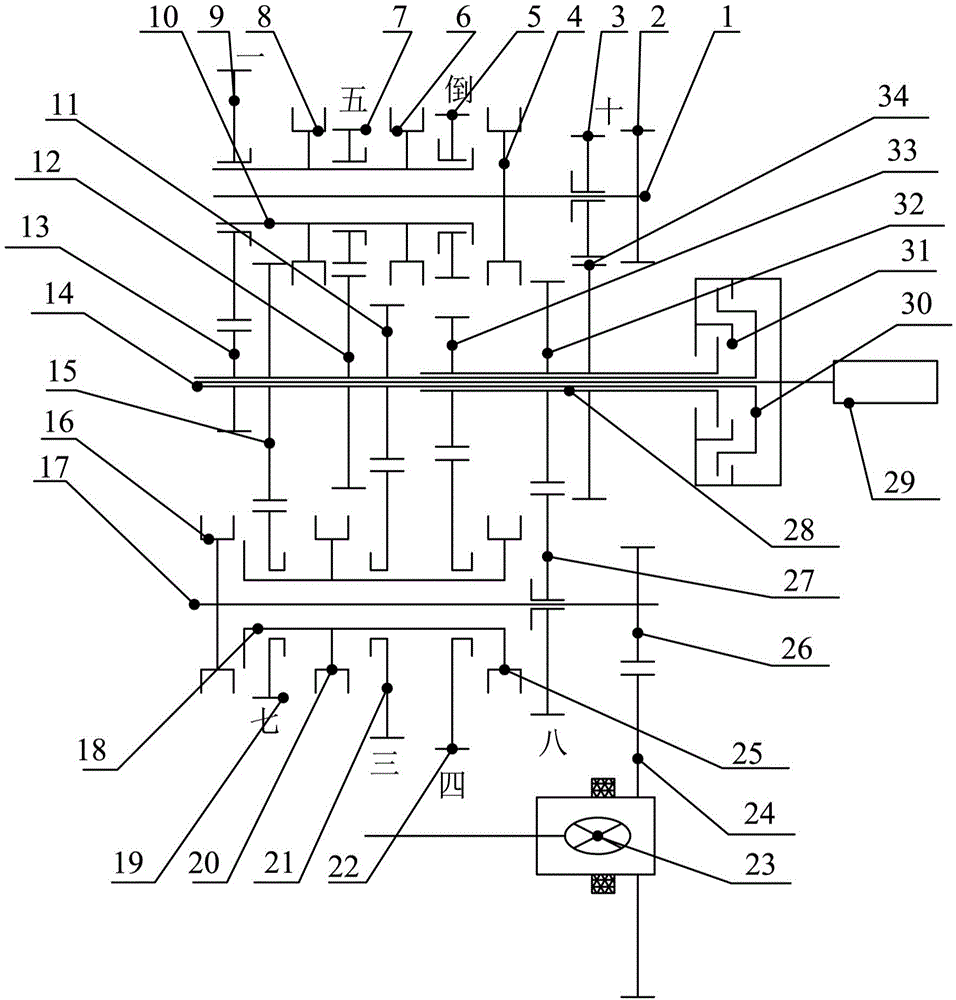

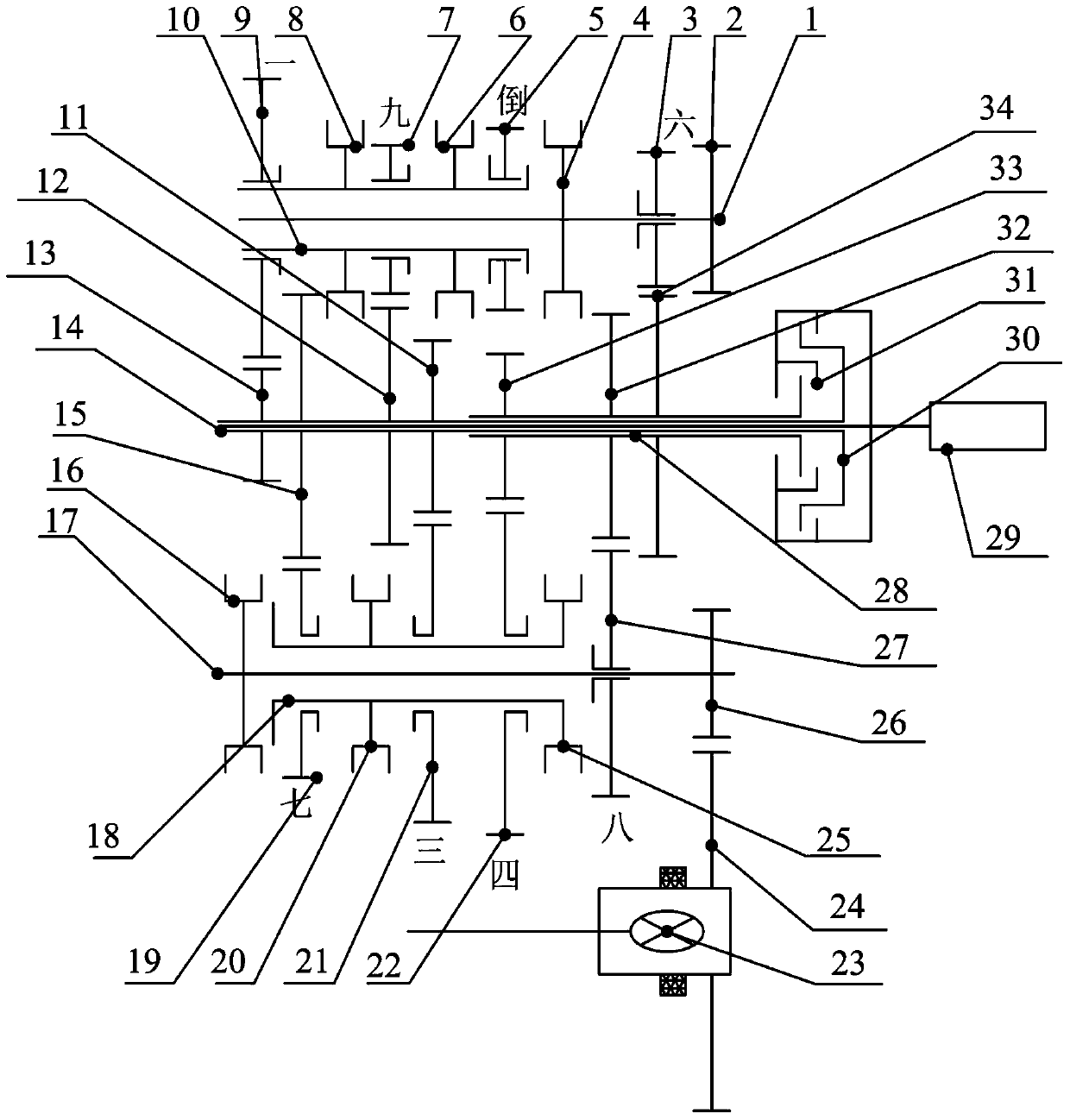

The invention provides a multi-gear dual clutch transmission and a vehicle. The multi-gear dual clutch transmission comprises an external input shaft, an internal input shaft, a first external output shaft, a first internal output shaft, a second external output shaft, a second internal output shaft and a synchronizing gear. The internal input shaft is coaxially nested in the external input shaft. A seventh-gear / ninth-gear driving gear and a third-gear driving gear are fixed to the external input shaft. A fourth-gear driving gear, a second-gear driving gear, an eighth-gear driving gear and a six-gear driving gear are fixed to the internal input shaft. The first internal output shaft is coaxially nested in the first external output shaft. The first internal output shaft is sleeved with a ninth-gear driven gear in a spaced mode. The first external output shaft is sleeved with a second-gear driven gear and a sixth-gear driven gear in a spaced mode. The second internal output shaft is coaxially nested in the second external output shaft. The second internal output shaft is sleeved with a seventh-gear driven gear in a spaced mode. The second external output shaft is sleeved with a third-gear driven gear, a fourth-gear driven gear and an eighth-gear driven gear in a spaced mode. The synchronizing gear is used for controlling the combination and separation between the driven gears of all the gears and the shafts where the driven gears are located, between the first external output shaft and the first internal output shaft as well as between the second external output shaft and the second internal output shaft. By the adoption of the multi-gear dual clutch transmission, the response time of gear shifting is shortened.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

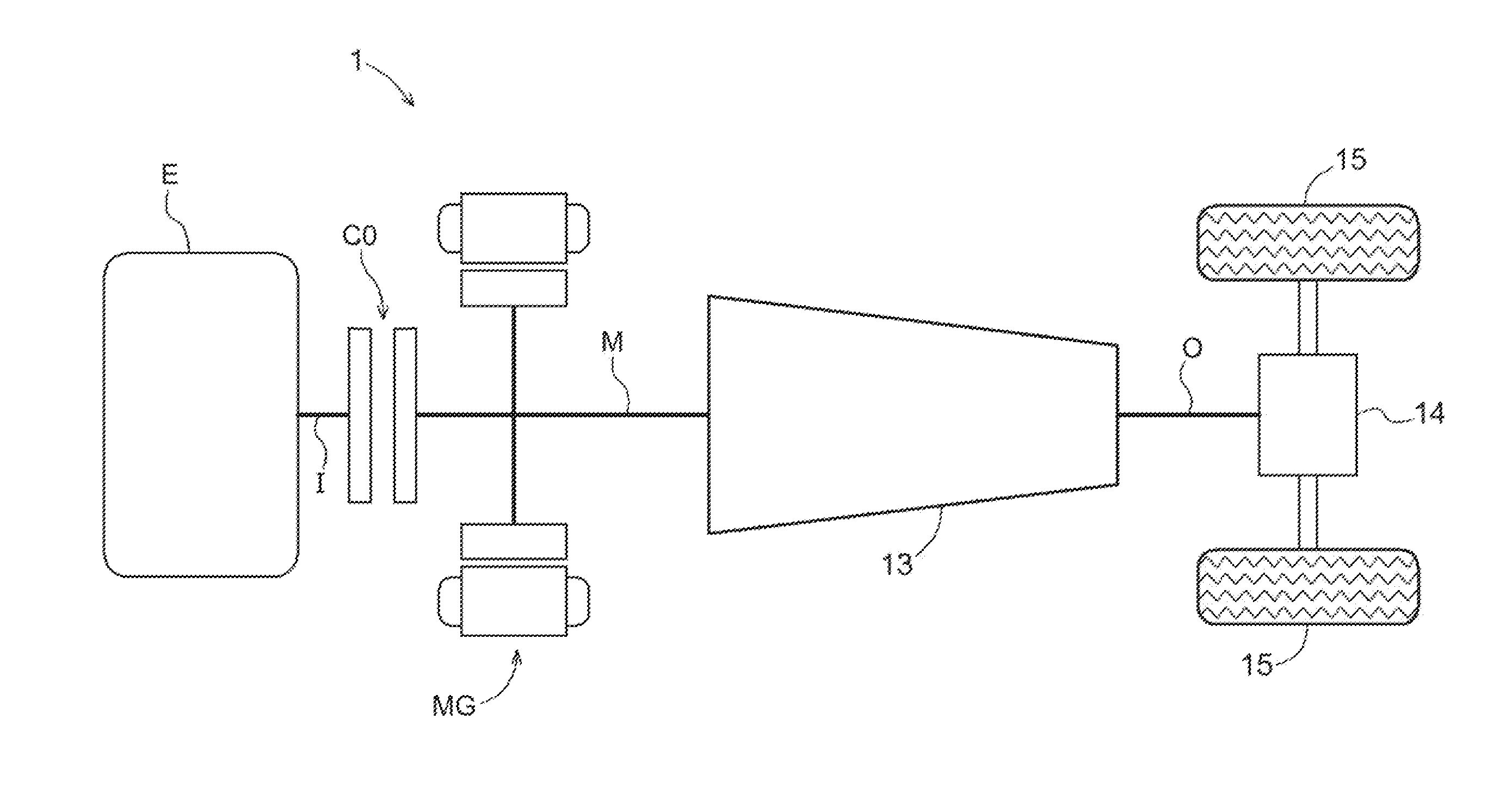

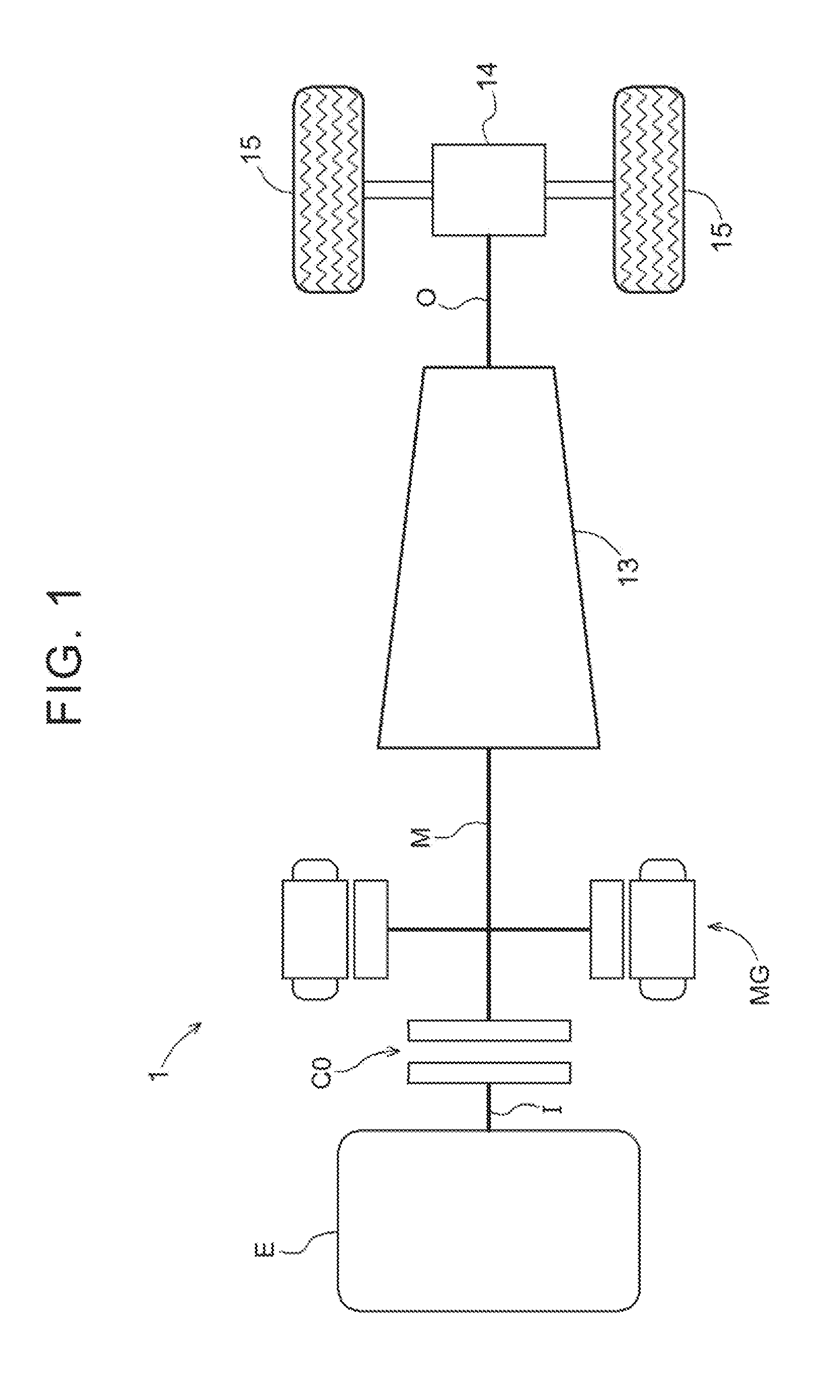

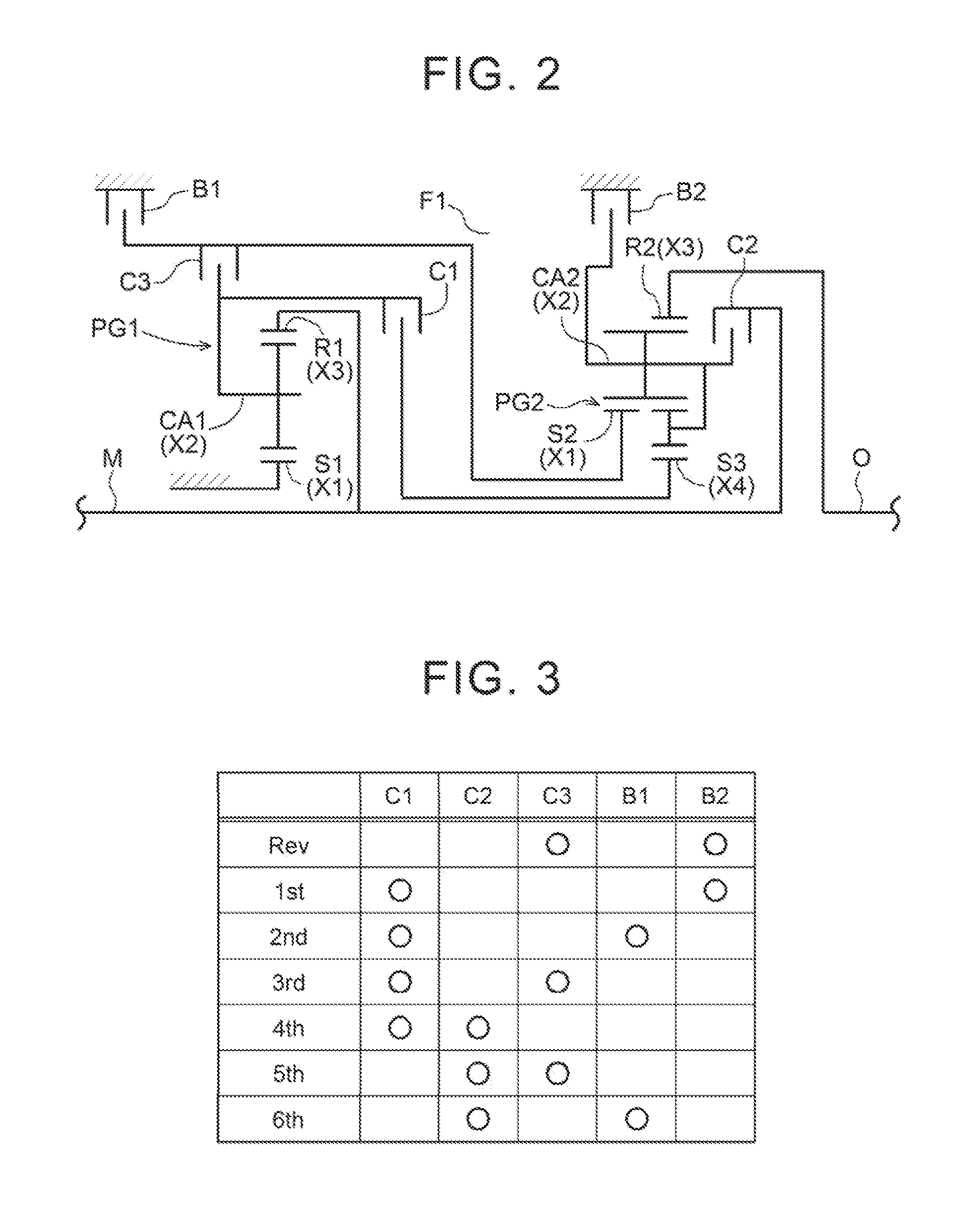

Control device

ActiveUS20140329639A1Shorten the power transmission pathIncrease engagement pressureHybrid vehiclesSpeed controllerLower limitElectric machine

A control device for a vehicle. While subject control is performed, a second engagement control unit controls the engagement pressure of the second engagement device to a mid-control set pressure that has been set to be equal to or more than a first engagement pressure and equal to or less than a second engagement pressure. The first engagement pressure is a lower limit engagement pressure capable of maintaining the second engagement device in the directly coupled engaged state, in a state in which requested torque that is torque required to be transmitted to the wheels is transmitted to the wheels. The second engagement pressure is a lower limit engagement pressure capable of maintaining the second engagement device in the directly coupled engaged state, in a state in which maximum output torque of the rotary electric machine is transmitted to the wheels.

Owner:AISIN AW CO LTD

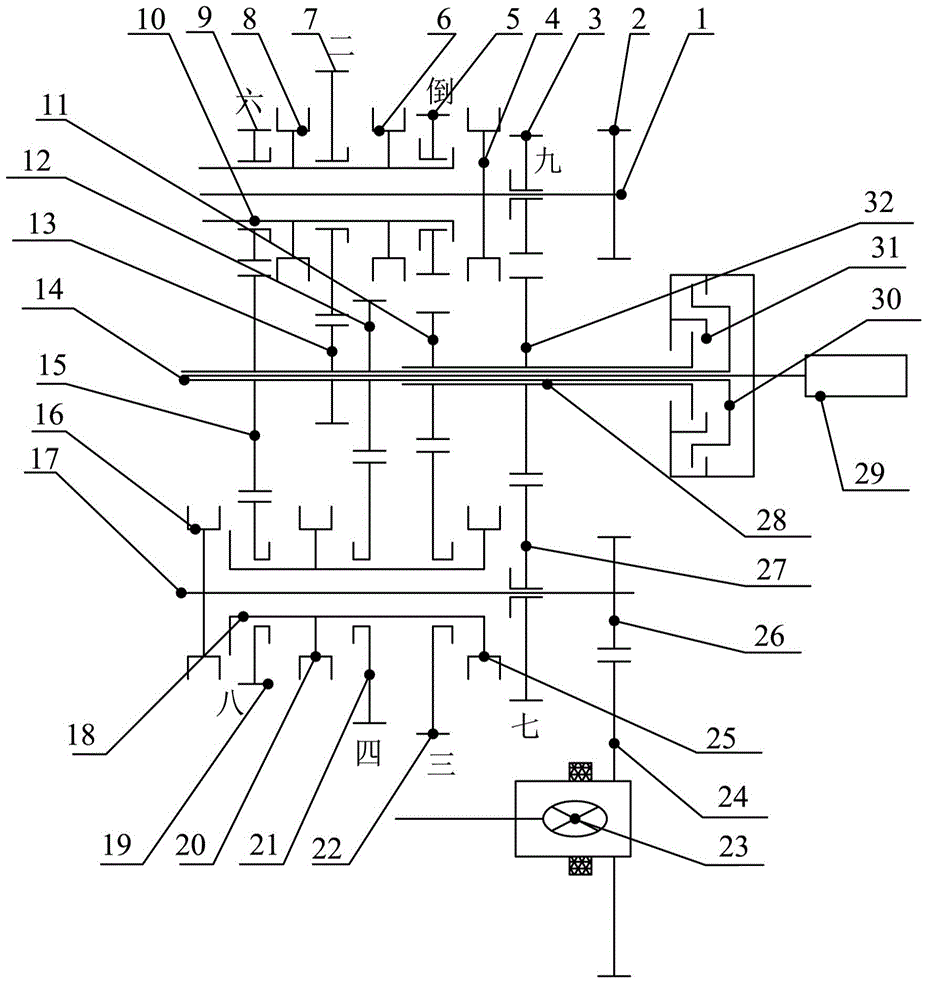

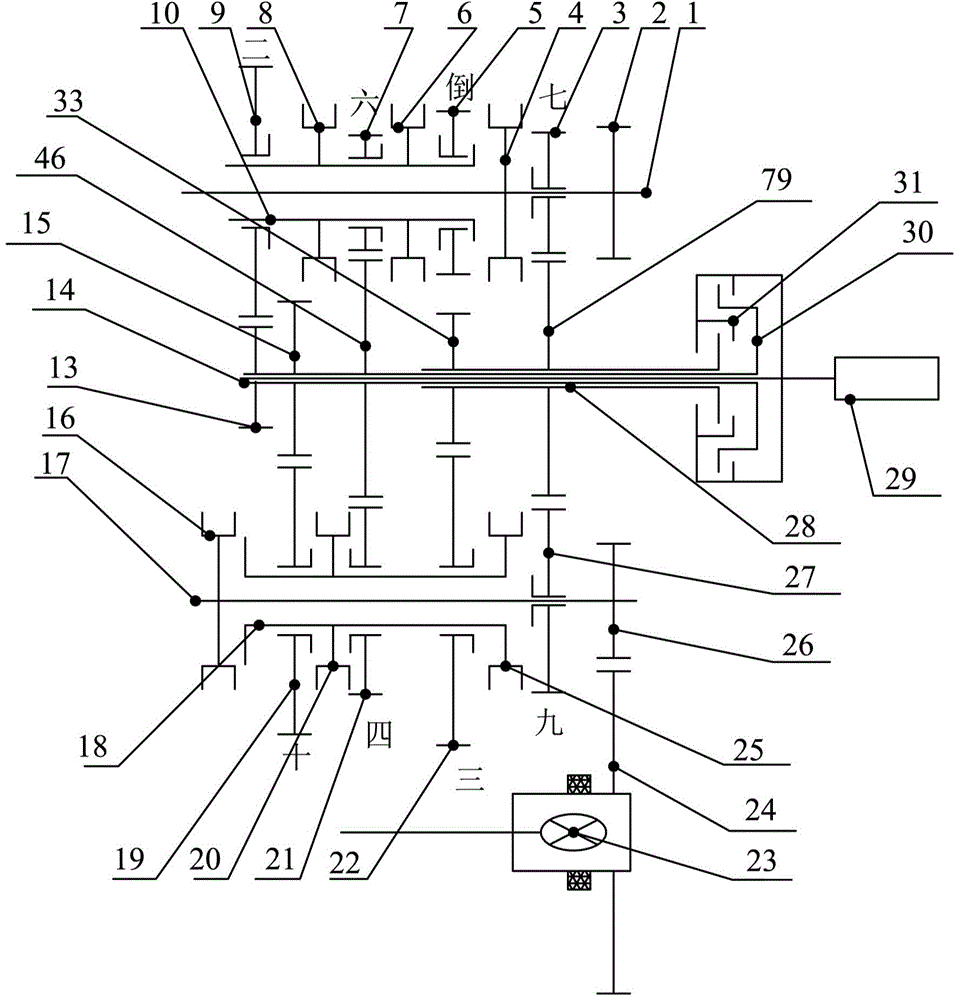

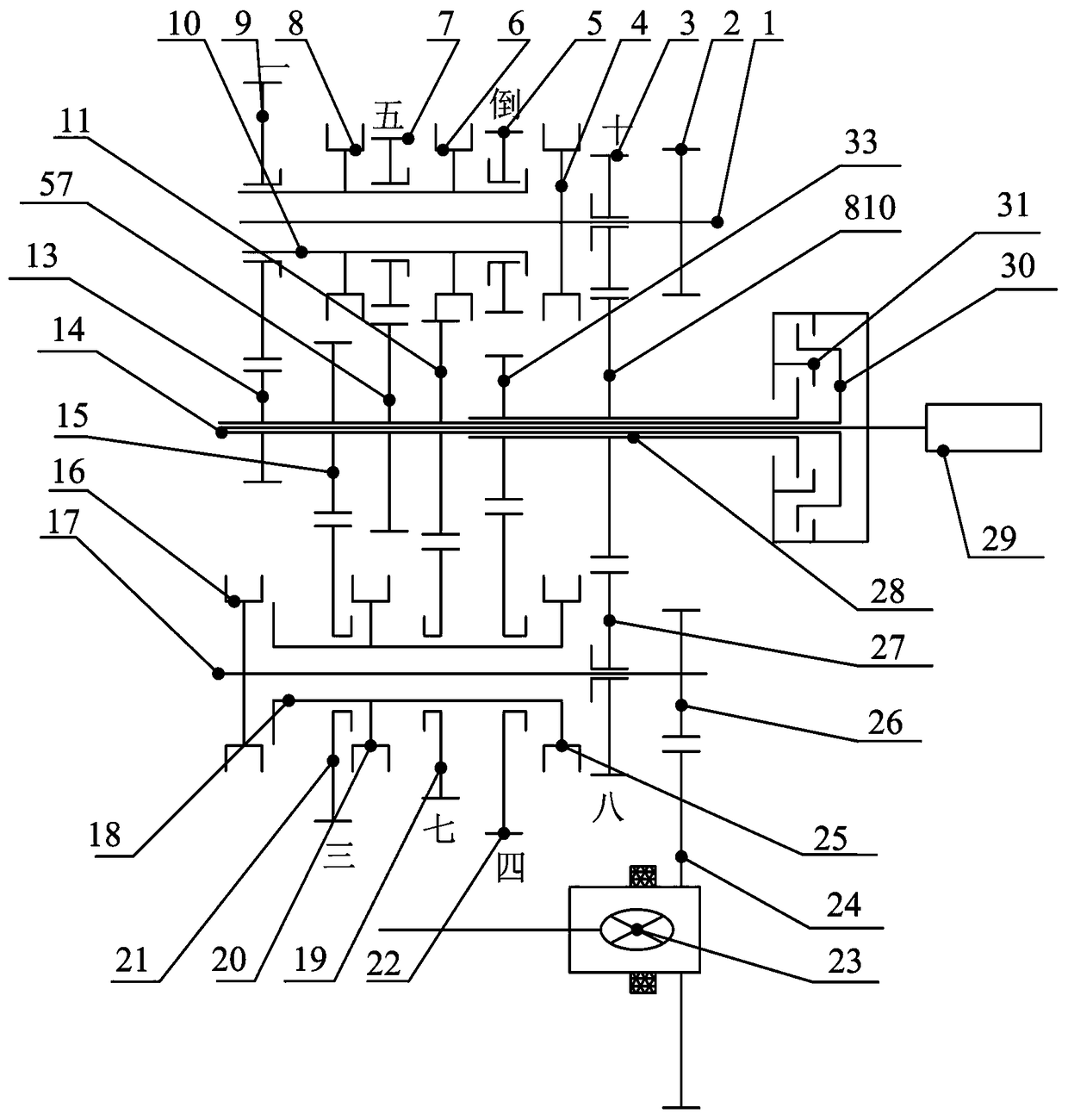

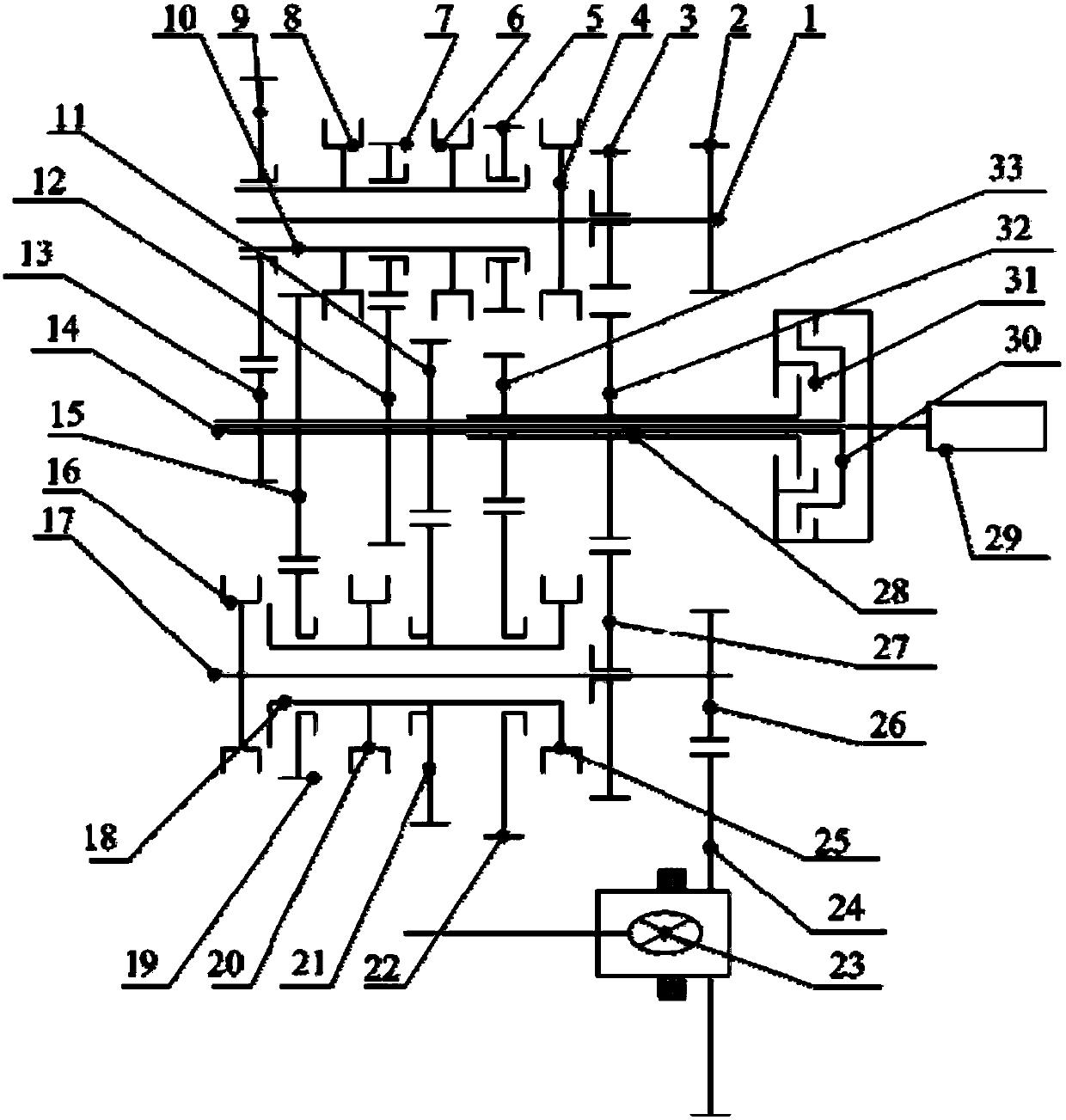

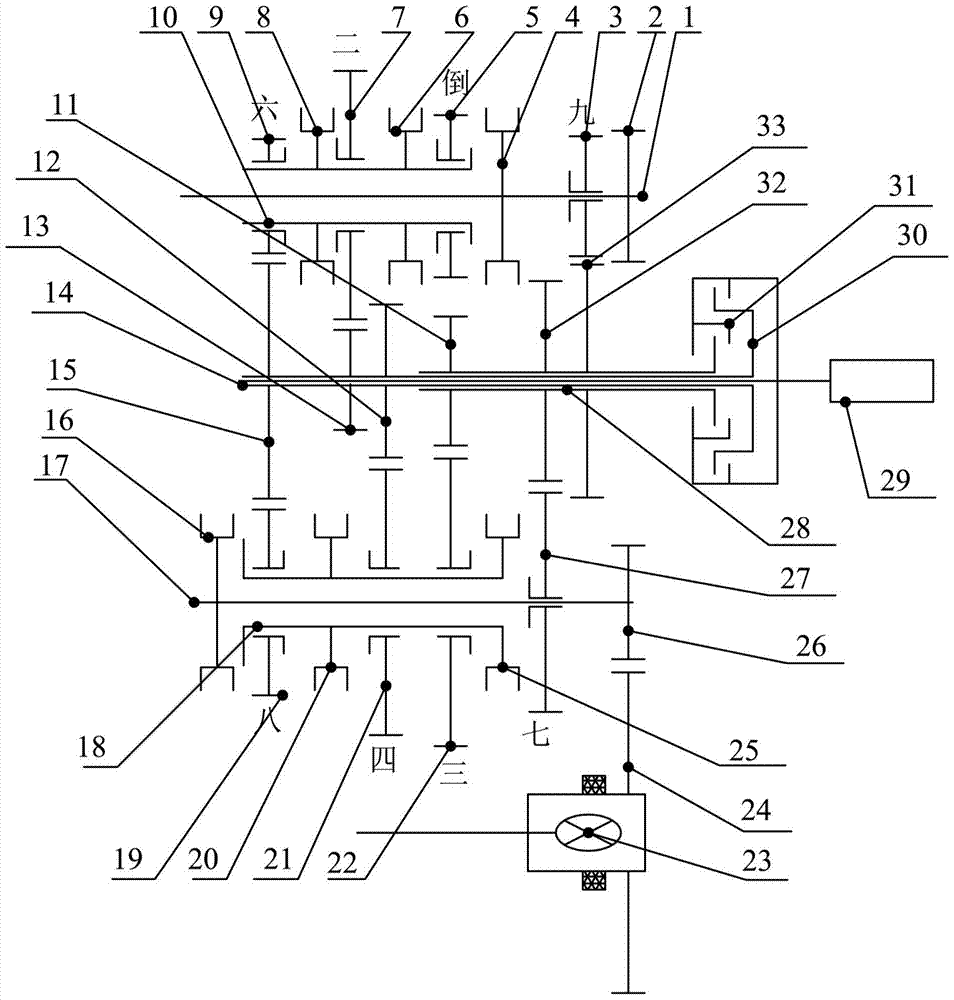

Multi-gear double-clutch transmission and vehicle

ActiveCN105370817AImprove transmission efficiencyShorten the axial lengthToothed gearingsGearing detailsGear driveControl theory

The invention provides a multi-gear double-clutch transmission and a vehicle. The multi-gear double-clutch transmission comprises an outer input shaft, an inner input shaft, a first outer output shaft, a first inner output shaft, a second outer output shaft, a second inner output shaft and a synchronization device, wherein the inner input shaft is coaxially embedded in the outer input shaft, a seven / nine-gear driving gear and a three-gear driving gear are fixedly arranged on the outer input shaft, and a four-gear driving gear, a two-gear driving gear and a six / eight-gear driving gear are fixedly arranged on the inner input shaft; the first inner output shaft is coaxially embedded in the first outer output shaft, the first inner output shaft is sleeved with a nine-gear driven gear in an idling manner, and the first outer output shaft is sleeved with a two-gear driven gear and a six-gear driven gear in an idling manner; the second inner output shaft is coaxially embedded in the second outer output shaft, the second inner output shaft is sleeved with a seven-gear driven gear in an idling manner, and the second outer output shaft is sleeved with a three-gear driven gear, a four-gear driven gear and an eight-gear driven gear in an idling manner; and the synchronization device is used for controlling all the driven gears to be combined with and separated from the shafts of the driven gears, the first outer output shaft to be combined with and separated from the first inner output shaft and the second outer output shaft to be combined with and separated from the second inner output shaft. By the adoption of the multi-gear double-clutch transmission, the gear shifting response time is shortened.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

High-integration-degree moving coil type electromagnetic direct-driven metering pump

PendingCN111502964AHighly integratedHigh measurement accuracyPositive displacement pump componentsFlexible member pumpsStator coilEngineering

The invention relates to a high-integration-degree moving coil type electromagnetic direct-driven metering pump, which comprises a displacement sensor, a connecting plate, an end cover, an outer magnet yoke, an inner magnet yoke, a coil, a skeleton, a permanent magnet array, a connecting disk, a cylinder body, a membrane, a membrane compression disk, a membrane compression plate, leaf spring valveseats and leaf springs. The high-integration-degree moving coil type electromagnetic direct-driven metering pump is characterized in that an air gap is formed between the outer magnet yoke and the inner magnet yoke; a Halbach permanent magnet array layer is adopted to enhance an air gap magnetic field; the magnet yokes, the end cover, the cylinder body, the membrane compression plate and the leafspring valve seats are fixedly connected to serve as a stator; a coil group is wound to the skeleton to be arranged in the air gap; the skeleton directly drives the membrane to carry out reciprocating motion through the connecting disk and the membrane compression disk to serve as an active cell; the membrane is still under a stretching state, so that when the metering pump does not work, the membrane is positioned on a liquid absorption starting point position, a controller feeds back a signal through the displacement sensor to control the position of the membrane of the metering pump in real time; and after the two same leaf spring valve seats are provided with the leaf springs, opposite assembling is carried out so as to form a liquid feeding / discharging check valve. According to thehigh-integration-degree moving coil type electromagnetic direct-driven metering pump disclosed by the invention, the integration degree and the metering accuracy of the metering pump can be effectively improved.

Owner:SHANDONG UNIV OF TECH

Multi-gear dual clutch transmission and vehicle

ActiveCN105443674AImprove transmission efficiencyImprove comfortToothed gearingsGearing detailsGear driveClutch

The invention provides a multi-gear dual clutch transmission and a vehicle. The multi-gear dual clutch transmission comprises an external input shaft, an internal input shaft, a first external output shaft, a first internal output shaft, a second external output shaft, a second internal output shaft and a synchronizing device. A tenth-gear driving gear, an eighth-gear driving gear and a fourth-gear driving gear are fixed to the external input shaft. A third-gear driving gear, a fifth-gear driving gear, a seventh-gear driving gear and a first-gear driving gear are fixed to the internal input shaft. The first internal output shaft is sleeved with a tenth-gear driven gear in a spaced mode. The first external output shaft is sleeved with a fifth-gear driven gear and a first-gear driven gear in a spaced mode. The second internal output shaft is sleeved with an eighth-gear driven gear in a spaced mode. The second external output shaft is sleeved with a fourth-gear driven gear, a third-gear driven gear and a seventh-gear driven gear in a spaced mode. The synchronizing device is used for controlling the combination and separation between all the driven gears and the shafts where the driven gears are located, between the first external output shaft and the first internal output shaft as well as between the second external output shaft and the second internal output shaft. By the adoption of the multi-gear dual clutch transmission, the response time of gear shifting is shortened.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

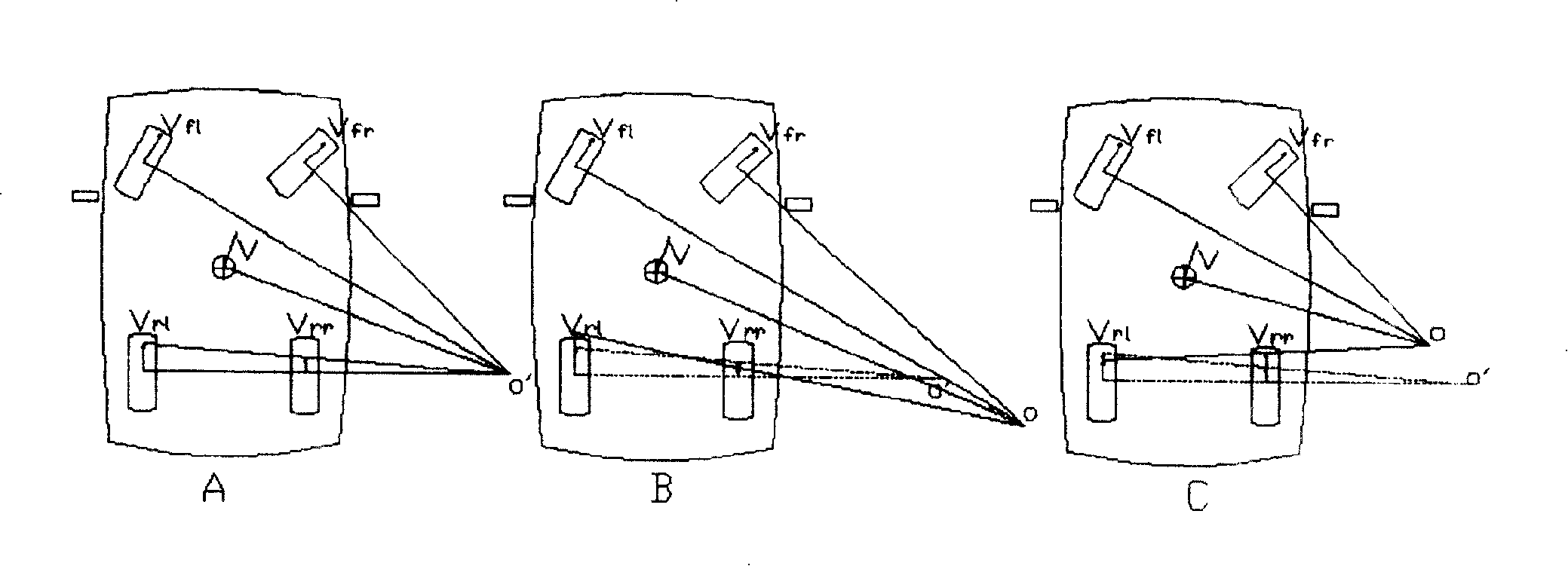

Multiple axle driving system for oil-electricity mixed power automobile and method for improving turning radius of automobile by using the system

ActiveCN100391768CImprove fuel economyImprove efficiencyHybrid vehiclesSpeed controllerElectricityElectric machine

The multiple axle driving system for mixed power automobile with fuel oil and electric energy as power source includes at least one mechanical driving axle assembly, at least one electric driving axle assembly, one power source assembly, one general controller, one monitoring and communication network system, and one engine and one multifunctional double-rotor motor to drive different axles separately. The double-rotor motor consists of one outer rotor and one inner rotor, the outer rotor is connected to the hub in one side through the reducing mechanism and the versatile transmission mechanism, and the inner rotor is connected to the hub in the other side through the reducing mechanism and the versatile transmission mechanism. The multiple axle driving system integrates the technology and functions of complete mixed power, multiple axle driving, etc. and makes the automobile possess the advantages of easy realization, low cost, raised running smoothness and stability, etc.

Owner:SOUTH CHINA UNIV OF TECH +1

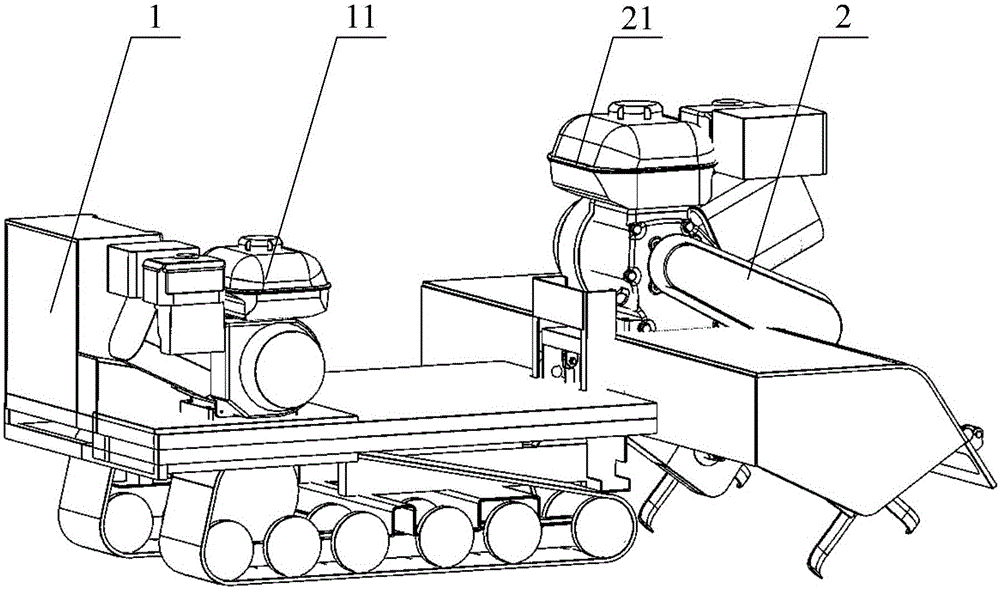

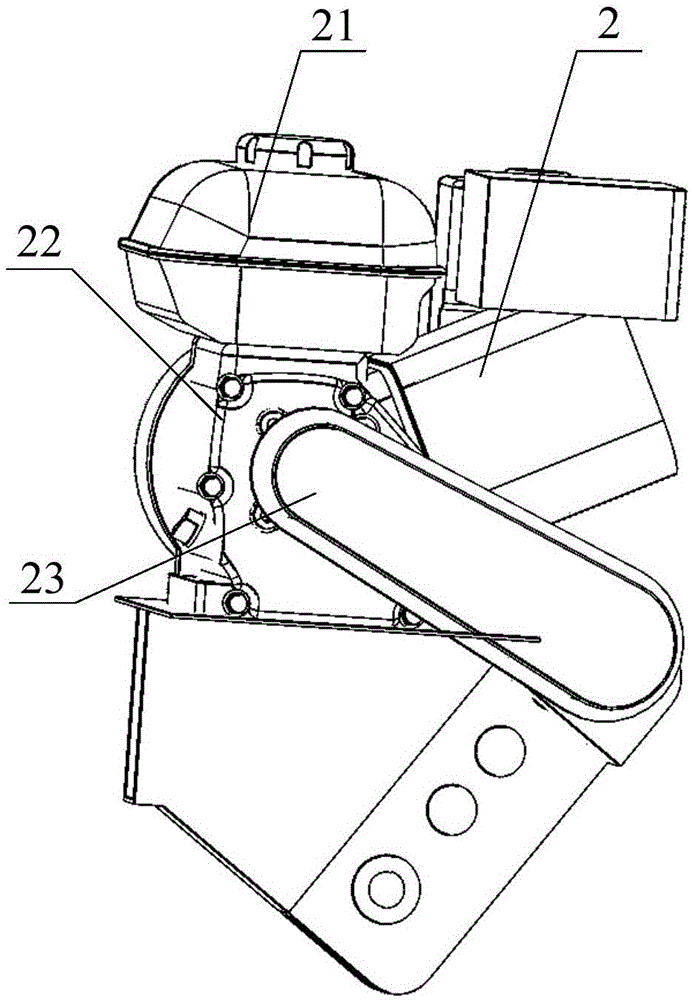

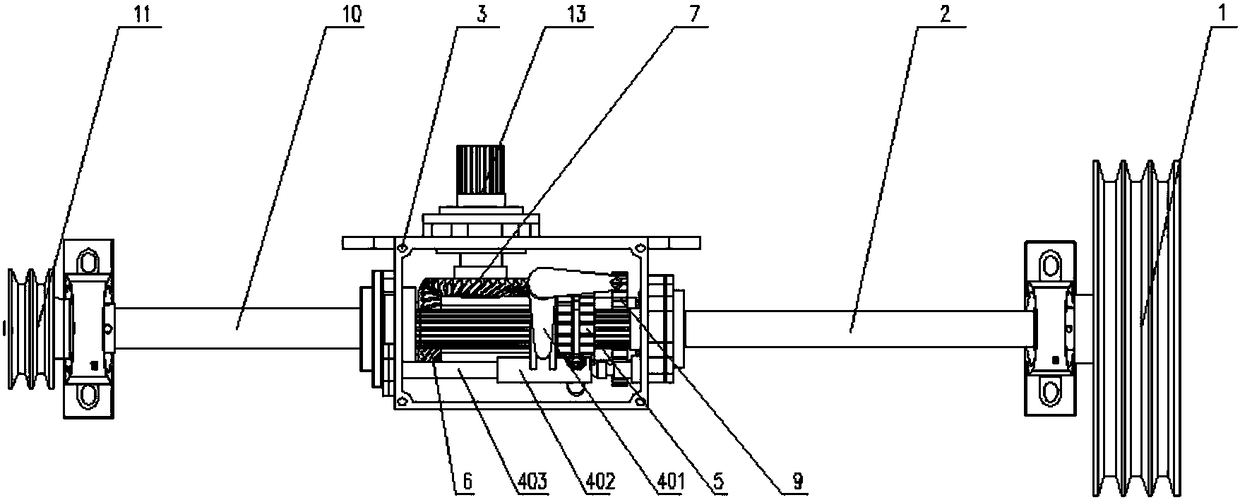

Rotary cultivator

Owner:CHONGQING QIJI TECH CO LTD

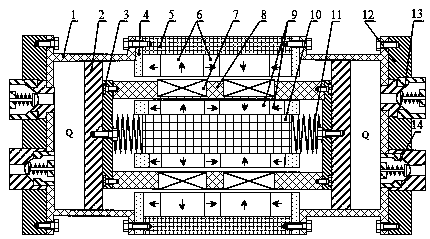

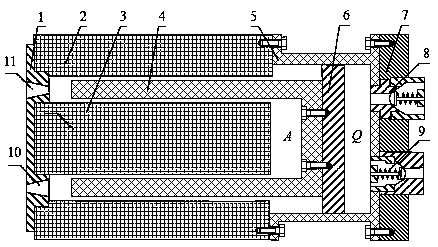

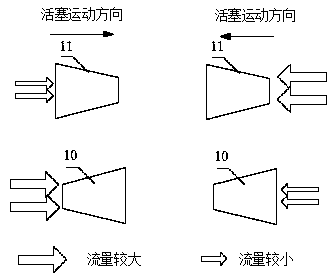

Electromagnetic direct-drive linear hydraulic pump based on dissymmetric-flow-pass heat dissipation

PendingCN111441927AWithout compromising compactnessShorten the power transmission pathPositive displacement pump componentsPump controlHydraulic cylinderReciprocating motion

The invention relates to an electromagnetic direct-drive linear hydraulic pump based on dissymmetric-flow-pass heat dissipation. The pump comprises a linear actuator rotor, linear actuator stators, anend cover, a hydraulic cylinder block, a piston, an air inlet flow pass, an exhaust flow pass, a valve body and a one-way valve. The pump is characterized in that the linear actuator rotor is integrated with the piston of the hydraulic piston to serve as a rotor, and an inner chamber of the hydraulic pump is divided into a pump liquid chamber Q and a pump air chamber A; the linear actuator outerstator and the linear actuator inner stator are axially fixed through the end cover, an air gap is formed between the linear actuator outer stator and the linear actuator inner stator, and the linearactuator outer stator is fixedly connected with the hydraulic cylinder block, fixedly connected with the valve body, to serve as a stator; the pump air chamber A communicates with the environment through the air gap, the air inlet flow pass and the exhaust flow pass respectively, and the axial section of each flow pass is trapezoid; and the linear actuator rotor directly drives the piston to moveback and forth, and is used in cooperation with the air inlet flow pass and the exhaust flow pass to carry out pump suction of air in the pump air chamber to carry out air cooling heat dissipation onthe interior of the linear actuator. With the electromagnetic direct-drive linear hydraulic pump based on dissymmetric-flow-pass heat dissipation, the problems that an electromagnetic direct-drive linear hydraulic pump emits much heat, and particularly, the heat inside is difficult to emit are solved.

Owner:SHANDONG UNIV OF TECH

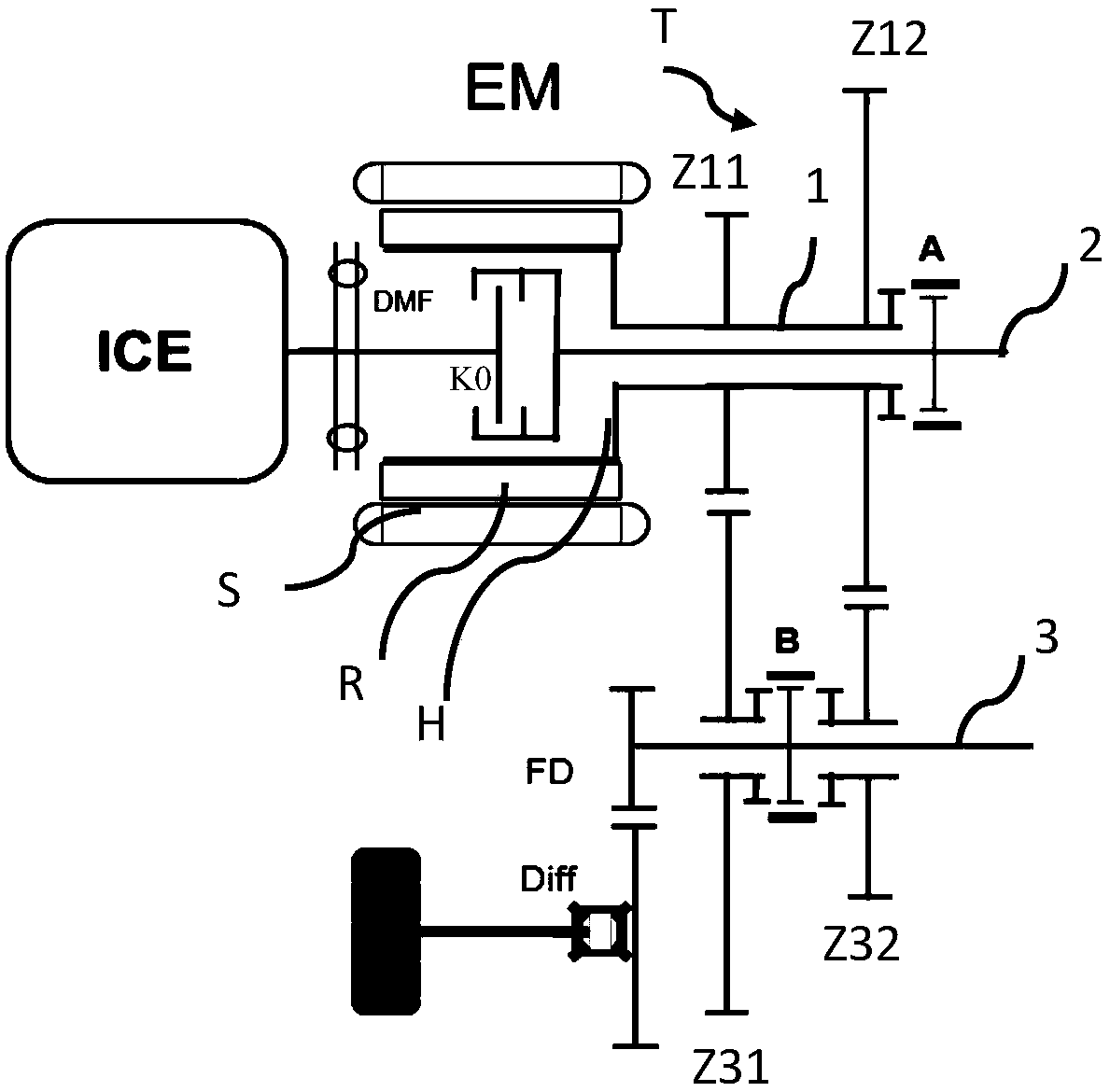

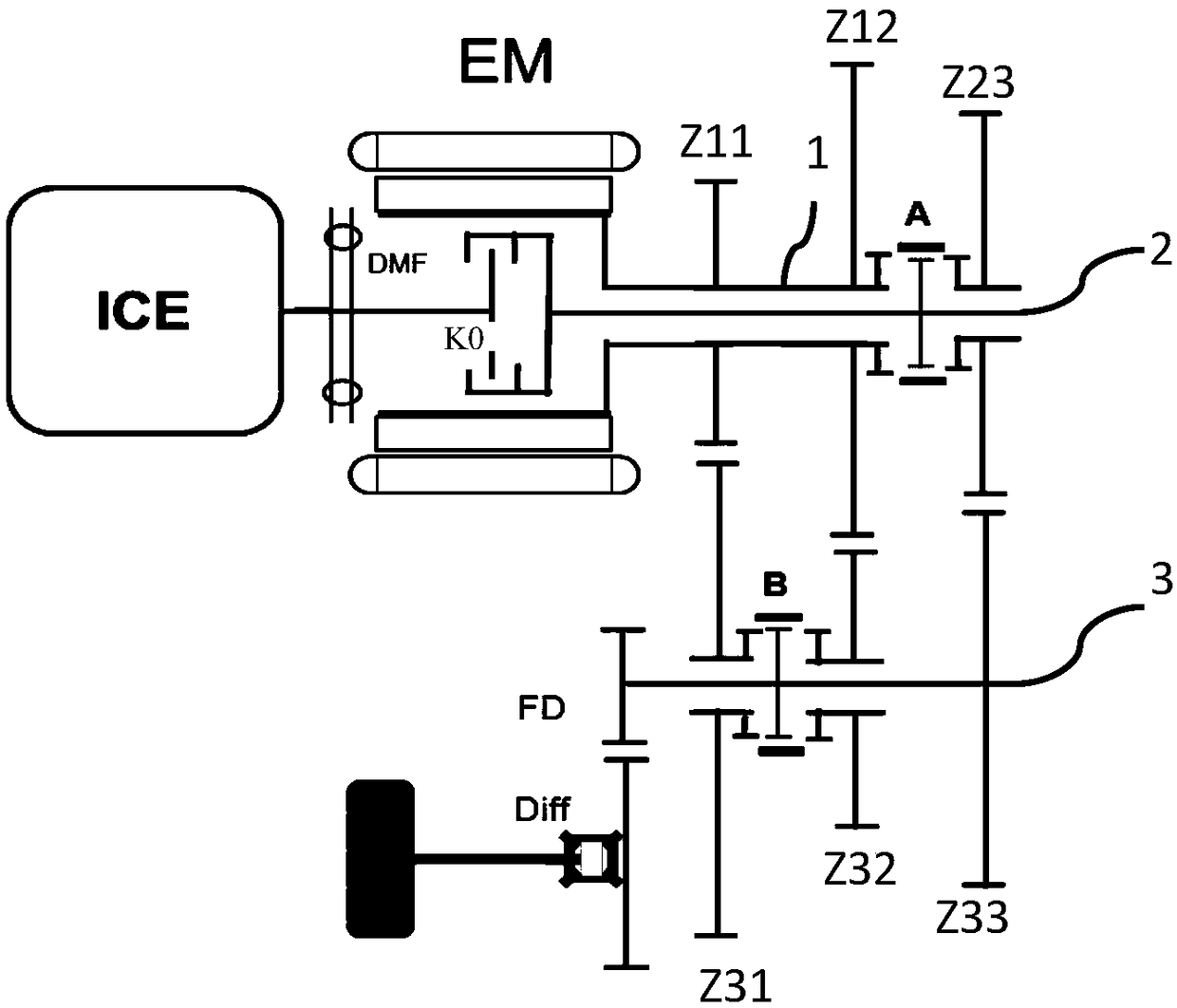

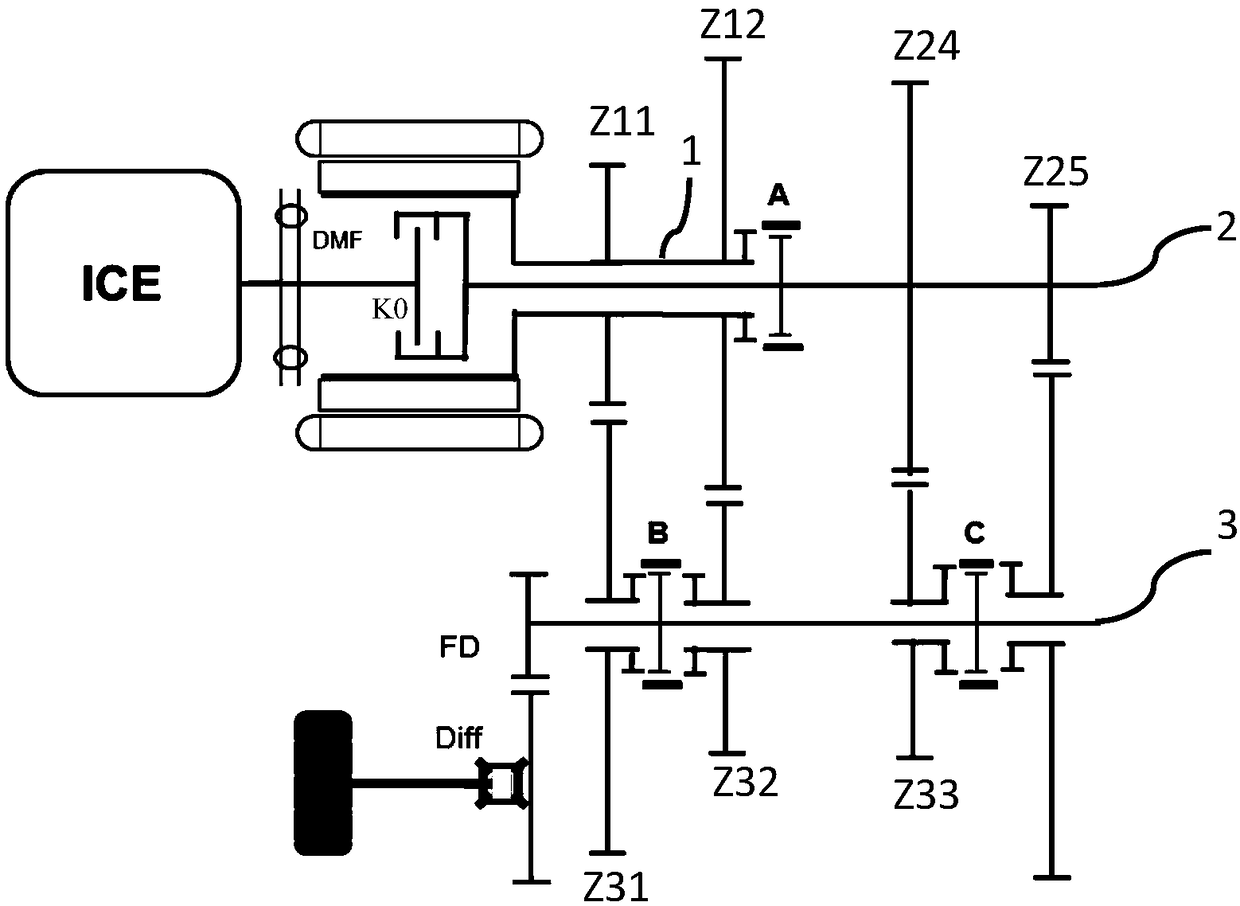

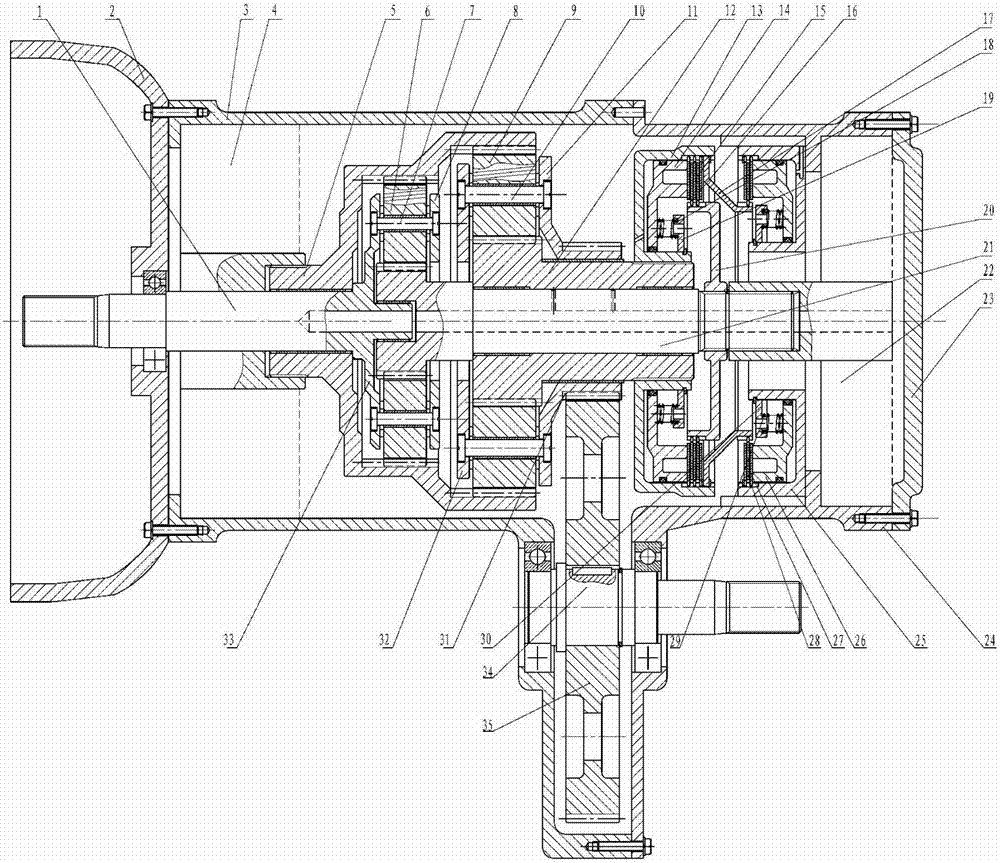

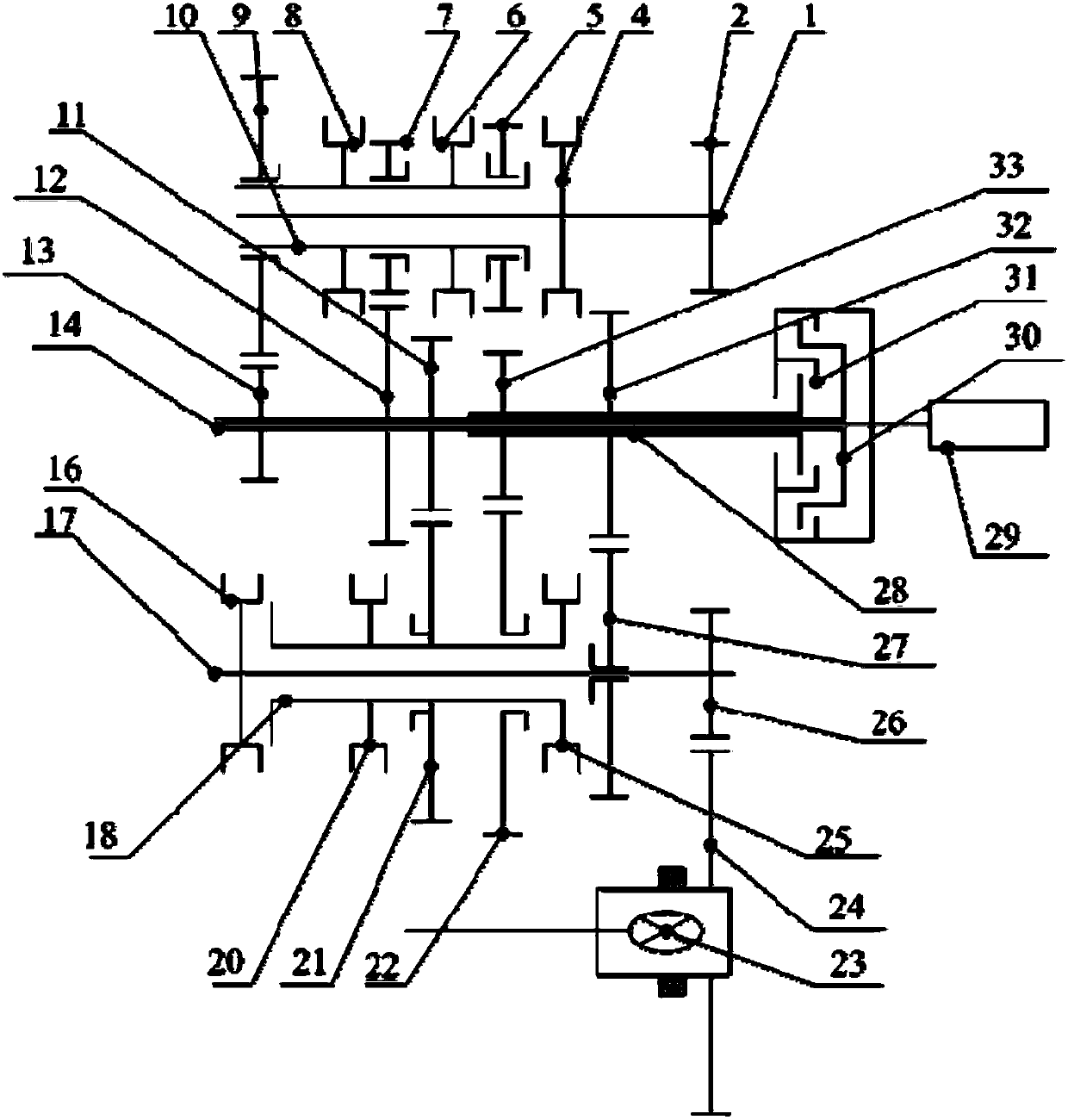

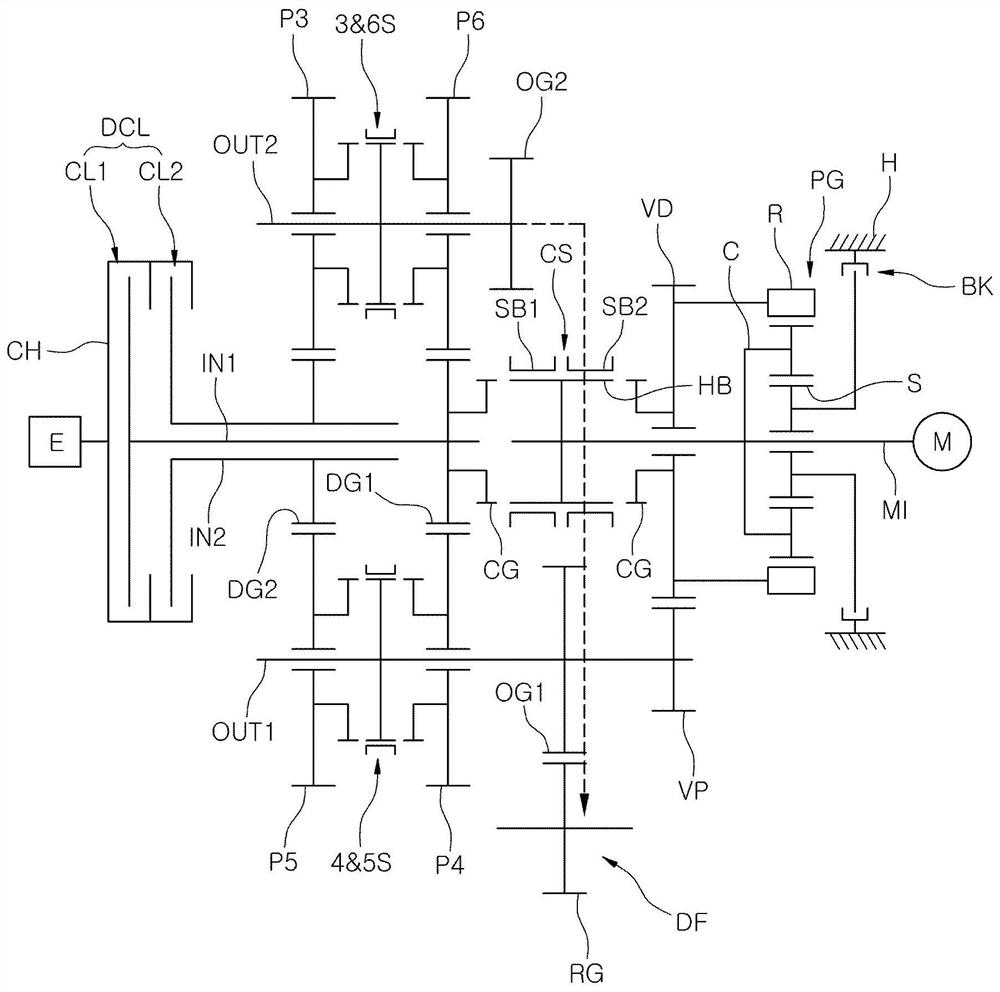

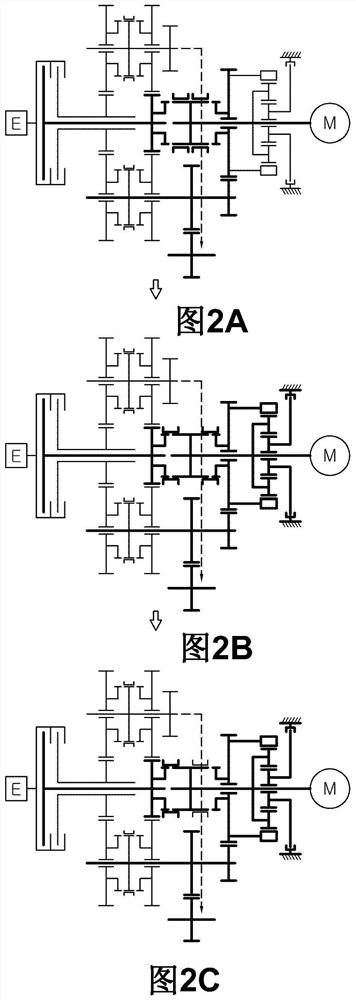

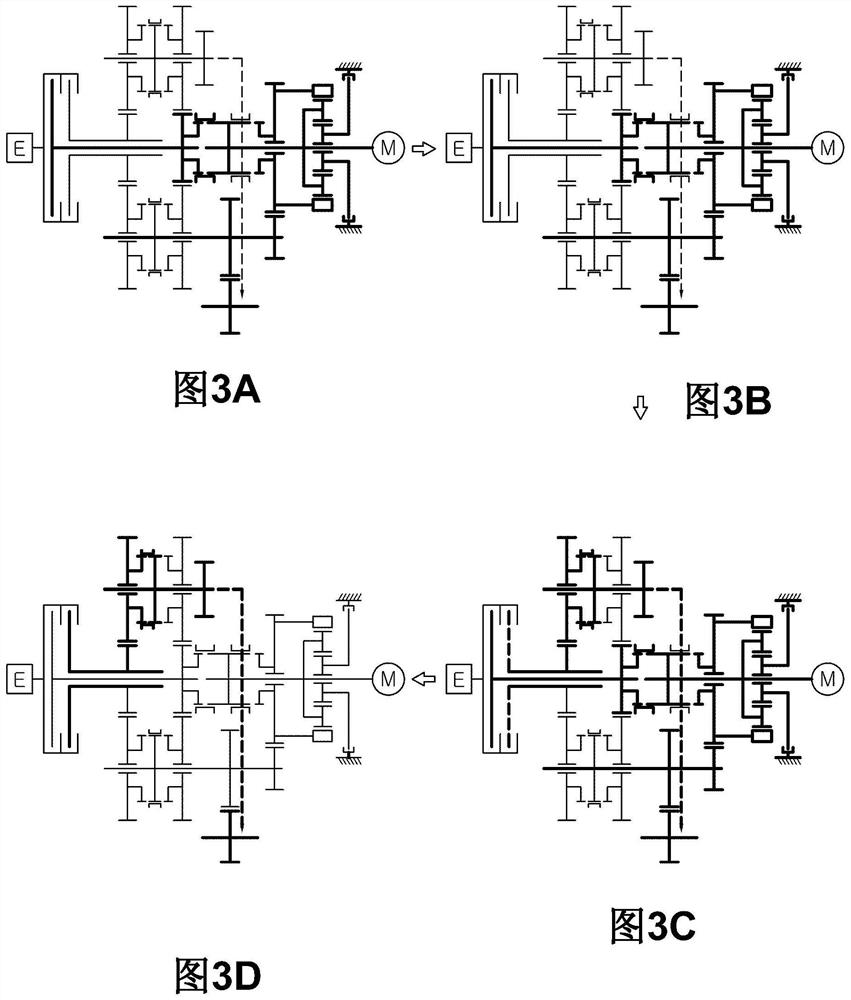

Hybrid speed changer, hybrid driving system and hybrid car

InactiveCN108612812AFew componentsShorten the power transmission pathToothed gearingsGas pressure propulsion mountingEngineeringHybrid vehicle

The invention relates to a hybrid speed changer, a hybrid driving system and a hybrid car. The hybrid speed changer comprises a first input shaft, a second input shaft and an output shaft. The first input shaft and the second input shaft are coaxially arranged. The hybrid speed changer further comprises a first gear, a second gear, a first synchronizer, a third gear, a fourth gear and a second synchronizer, wherein the first gear and the second gear are arranged on the first input shaft and are arranged adjacently in the axial direction and rotate synchronously; the second gear is arranged atone axial end of the first input shaft; the first synchronizer is arranged on the second input shaft and located at one axial side of the second gear and can be engaged with the second gear; the thirdgear, the fourth gear and the second synchronizer are arranged on the output shaft; the third gear and the fourth gear are arranged on the output shaft in an idle sleeving mode; the second synchronizer is located between the third gear and the fourth gear and can be engaged with the third gear or the fourth gear; the third gear and the fourth gear are engaged with the first gear and the second gear correspondingly.

Owner:SCHAEFFLER TECH AG & CO KG

A hybrid dual-planetary dual-mode hybrid vehicle gearbox

InactiveCN105691195BIt has the effect of decelerating and increasing torqueImprove climbing abilityGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingLow speedReduction drive

The invention provides a series-parallel double-planet-row two-mode hybrid electric automobile gearbox and relates to the technical field of automobiles. The gearbox comprises a front planet row, a rear planet row, a clutch, a brake, a motor system, a main reducer and a box body. Switching of different working modes is realized by controlling engagement and disengagement of the clutch and the brake. The grade ability of the automobiles can be improved during low-speed running. The transmission efficiency of the automobiles can be improved during high-speed running. The cost is lowered.

Owner:JILIN UNIV

High-accuracy moving-coil type electromagnetic direct-drive plunger pump

PendingCN111441929AShorten the power transmission pathQuick responsePositive displacement pump componentsPump controlPhysicsPlunger pump

The invention relates to a high-accuracy moving-coil type electromagnetic direct-drive plunger pump. The plunger pump comprises a displacement sensor, a connecting plate, an end cover, an outer yoke,an inner yoke, a coil, a skeleton, a permanent magnet array, a hydraulic cylinder block, a piston, a reset spring, a valve block, a liquid outlet valve and a liquid inlet valve. The plunger pump is characterized in that a Halbach permanent magnet array layer which is formed by arranging axial magnetizing permanent magnets and radial magnetizing permanent magnets alternatively in a close attachmentmanner is arranged on the inner side of the outer yoke or the outer side of the inner yoke in a surface mount manner, an air gap is formed between the outer yoke and the inner yoke, and the yokes arefixedly connected with the end cover and the hydraulic cylinder block to serve as a plunger pump stator; a coil assembly is winded around the skeleton and is placed into the air gap, and the skeletonis integrated with the piston to serve as a plunger pump rotor; and the axial length of the coil assembly is smaller than the axial lengths of the corresponding axial magnetizing permanent magnets, acontroller has real-time control over the position of the plunger pump rotor through feedback signals of the displacement sensor, and because of the reset spring, when the plunger pump does not work,the plunger pump is at the position of a start point of liquid suction. According to the high-accuracy moving-coil type electromagnetic direct-drive plunger pump, the working efficiency and the control accuracy of the hydraulic pump are effectively improved.

Owner:SHANDONG UNIV OF TECH

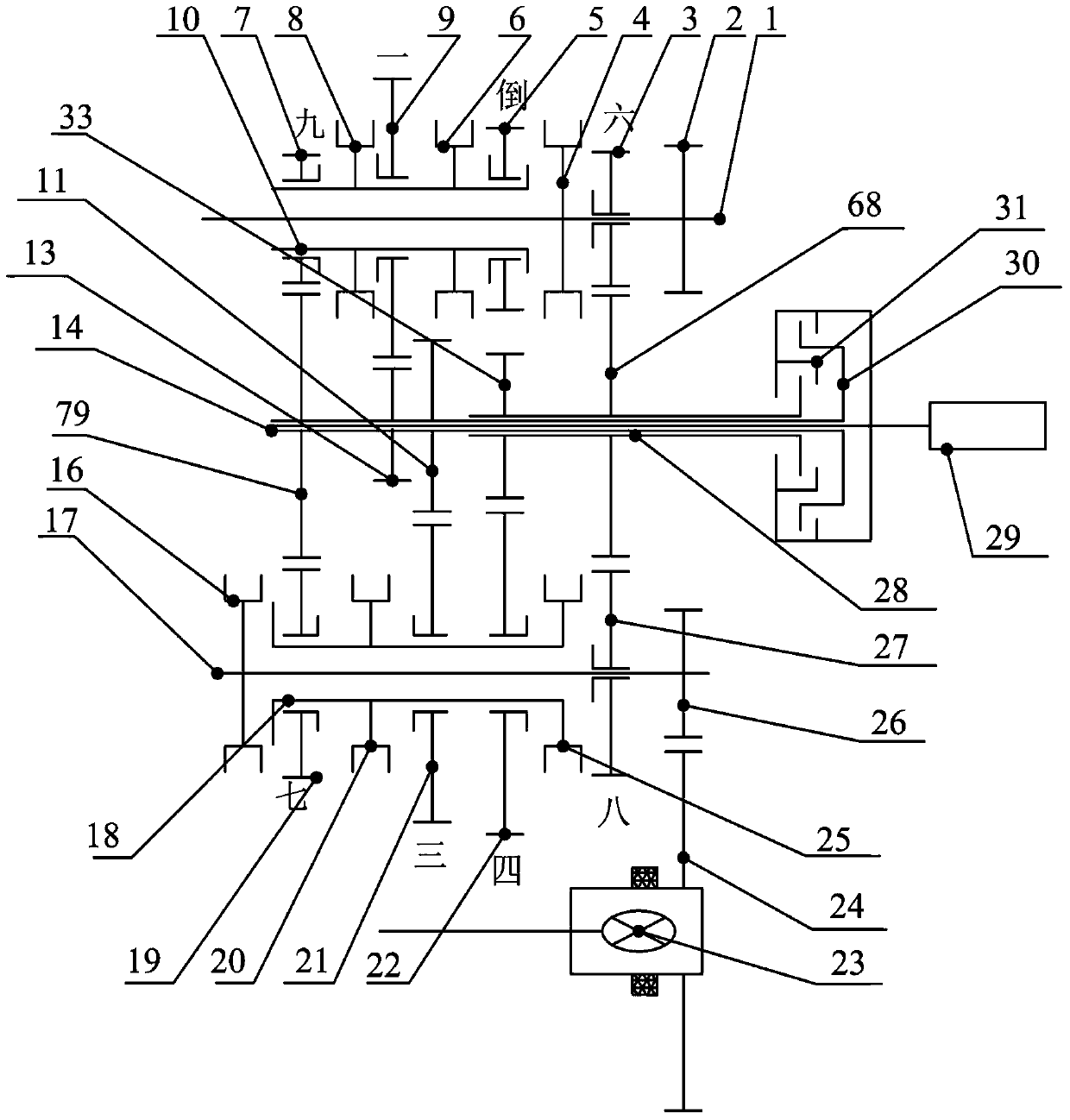

Multi-gear double-clutch transmission and vehicle

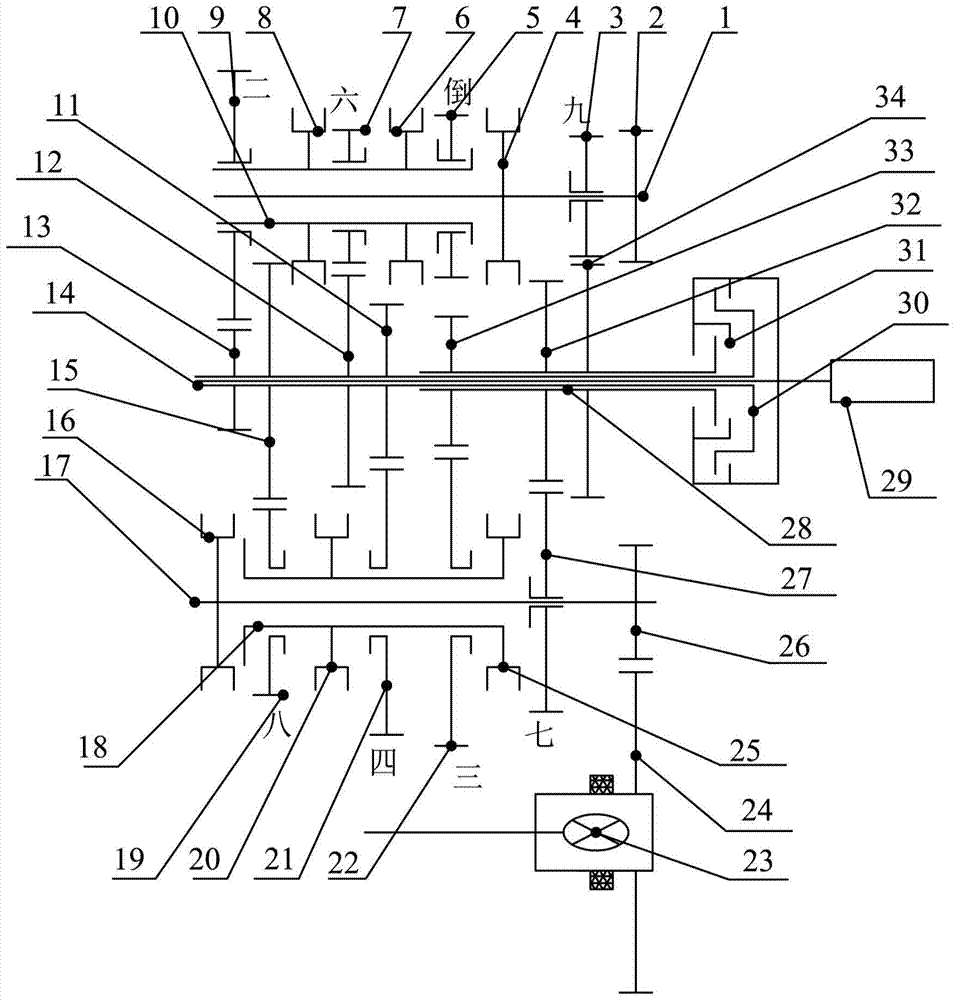

ActiveCN105370814AImprove transmission efficiencyImprove comfortToothed gearingsGearing detailsGear driveEngineering

The invention provides a multi-gear double-clutch transmission and a vehicle. The multi-gear double-clutch transmission comprises an outer input shaft, an inner input shaft, a first outer output shaft, a first inner output shaft, a second outer output shaft, a second inner output shaft and a synchronization device, wherein a seventh-gear driving gear, a ninth-gear driving gear and a third-gear driving gear are fixed to the outer input shaft and a fourth-gear driving gear, a sixth-gear driving gear, a tenth-gear driving gear and a second-gear driving gear are fixed to the inner input shaft; the first inner output shaft is sleeved with a seventh-gear driven gear in an idling manner and the first outer output shaft is sleeved with a sixth-gear driven gear and a second-gear driven gear in an idling manner; the second inner output shaft is sleeved with a ninth-gear driven gear in an idling manner and the second outer output shaft is sleeved with a third-gear driven gear, a fourth-gear driven gear and a tenth-gear driven gear in an idling manner; and the synchronization device is used for controlling all the driven gears to be combined with and separated from the shafts of the driven gears, the first outer output shaft to be combined with and separated from the first inner output shaft and the second outer output shaft to be combined with and separated from the second inner output shaft. By the adoption of the multi-gear double-clutch transmission, the gear shifting response time is shortened.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Two speed adjustable speed transmission device for tangential and longitudinal flow threshing separating transmission system

InactiveCN108443429AImprove adaptabilityImprove versatilityControlled membersToothed gearingsTransverse axisEngineering

The invention provides a two speed adjustable speed transmission device for a tangential and longitudinal flow threshing separating transmission system. A shifting fork mechanism is located on the topof a two speed gear transmission box body, an input cross shaft is right above an output cross shaft, and power is transfer between the two shafts through two pairs of shifting straight gears; the axes of an output longitudinal shaft and an output cross shaft are vertical, and power is reversed and transferred between the two shafts through a pair of reversing bevel gear; the power is transferredfrom the input cross shaft to the two speed gear transmission box body; the shifting fork mechanism adjusts the two pairs of shifting straight gears to achieve power transfer and two speed transmission; the power transferred to the output cross shaft is then transferred to the output longitudinal shaft through the pair of reversing bevel gears, and the other part of power on the output cross shaft is transferred to a belt wheel II and the power is finally transferred to a tangential flow roller and a longitudinal axial flow roller separately. According to the device, the twos speed transmission function of a threshing roller is achieved, the harvesting performance is improved, and meanwhile, the power transfer path between the tangential flow roller and the longitudinal axial flow rolleris also shortened, and the transfer efficiency is improved.

Owner:JIANGSU UNIV

Jacquard ribbon loom with mainstay

InactiveCN1273663CReduce lossShorten the power transmission pathJacquardsSmallware loomsEngineeringLeather belt

A jacquard ribbon loom with a central column, comprises a hollow central column over the machine platform, the main driving belt in the central column, a spigot and a power transmission member on the top end of the central column, weft transmission member symmetrically on the two sides of the central column. The light jacquard ribbon loom is compact and stable due to the hollow central column.

Owner:林贞惠

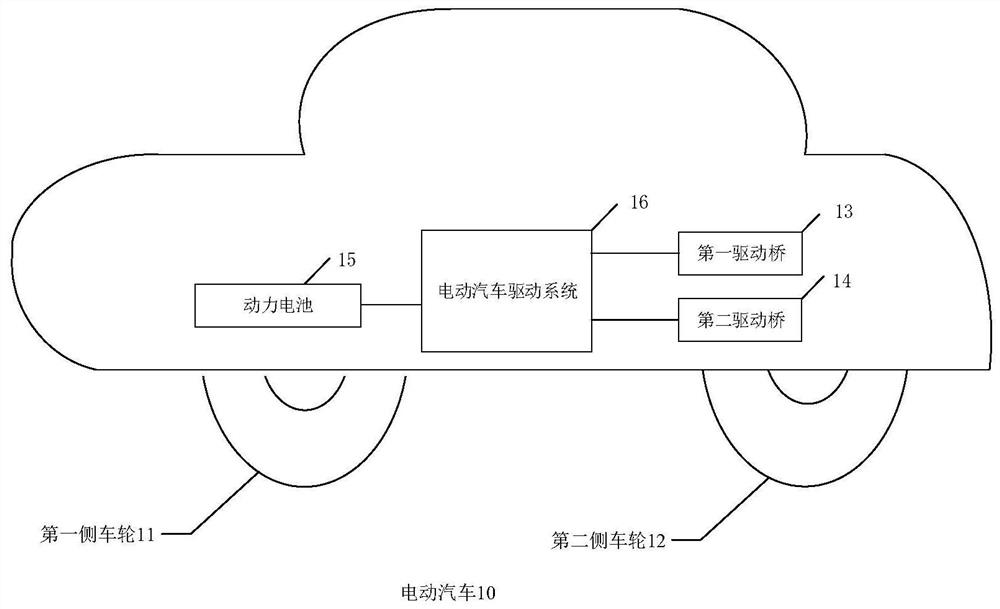

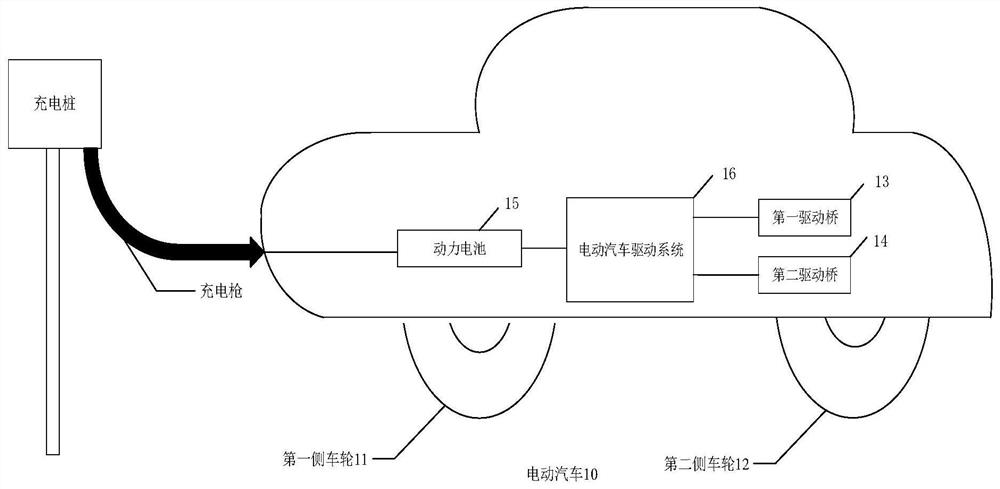

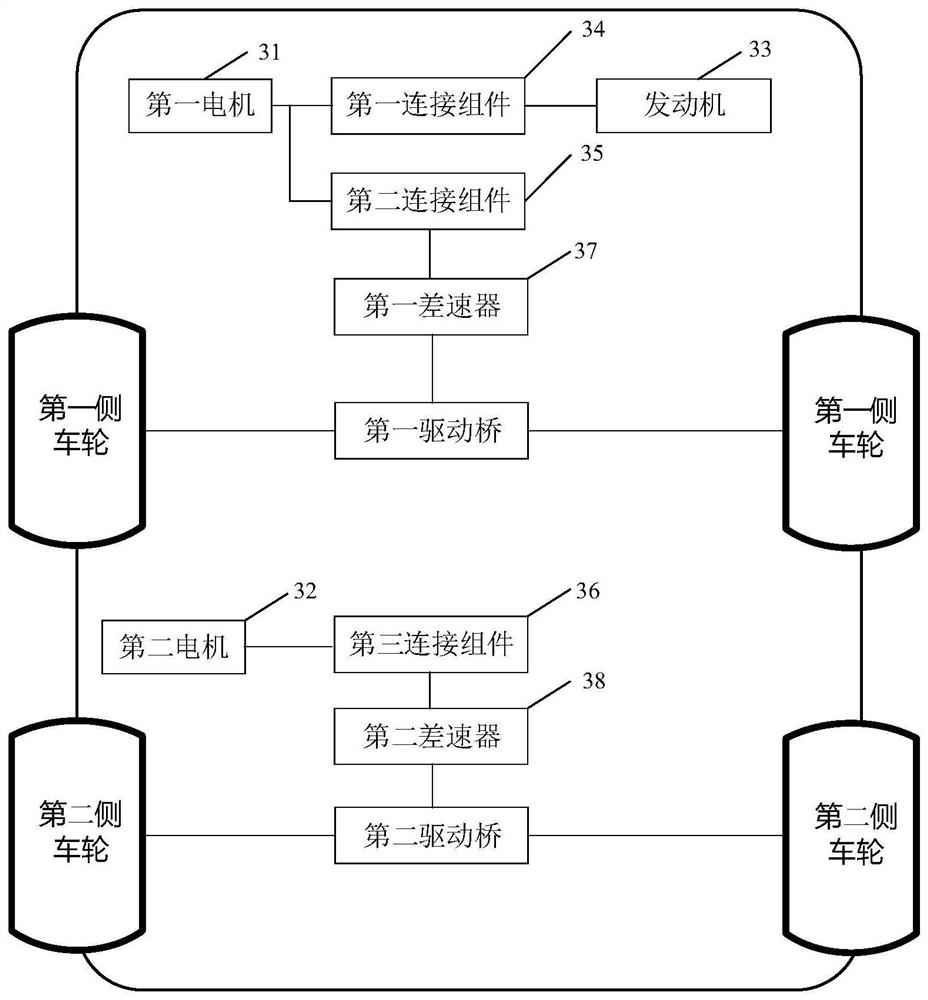

Electric automobile driving system and electric automobile

InactiveCN114083977AShorten the power transmission pathLow costHybrid vehiclesGas pressure propulsion mountingElectric machineryControl theory

According to an electric automobile driving system and an electric automobile, the driving flexibility of the electric automobile can be improved while the mileage of the electric automobile is increased. The electric automobile driving system comprises a first motor, a second motor, an engine, a first connecting assembly, a second connecting assembly, a third connecting assembly, a first differential mechanism and a second differential mechanism. The engine is connected with the first motor through the first connecting assembly and connected with the first differential mechanism through the second connecting assembly and / or the first connecting assembly. The first motor is connected with the first differential mechanism through the second connecting assembly; the second motor is connected with the second differential mechanism through the third connecting assembly; the first differential mechanism is used for being connected with a first drive axle, and the first drive axle drives first side wheels; the second differential mechanism is used for being connected with a second drive axle, and the second drive axle drives second side wheels.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

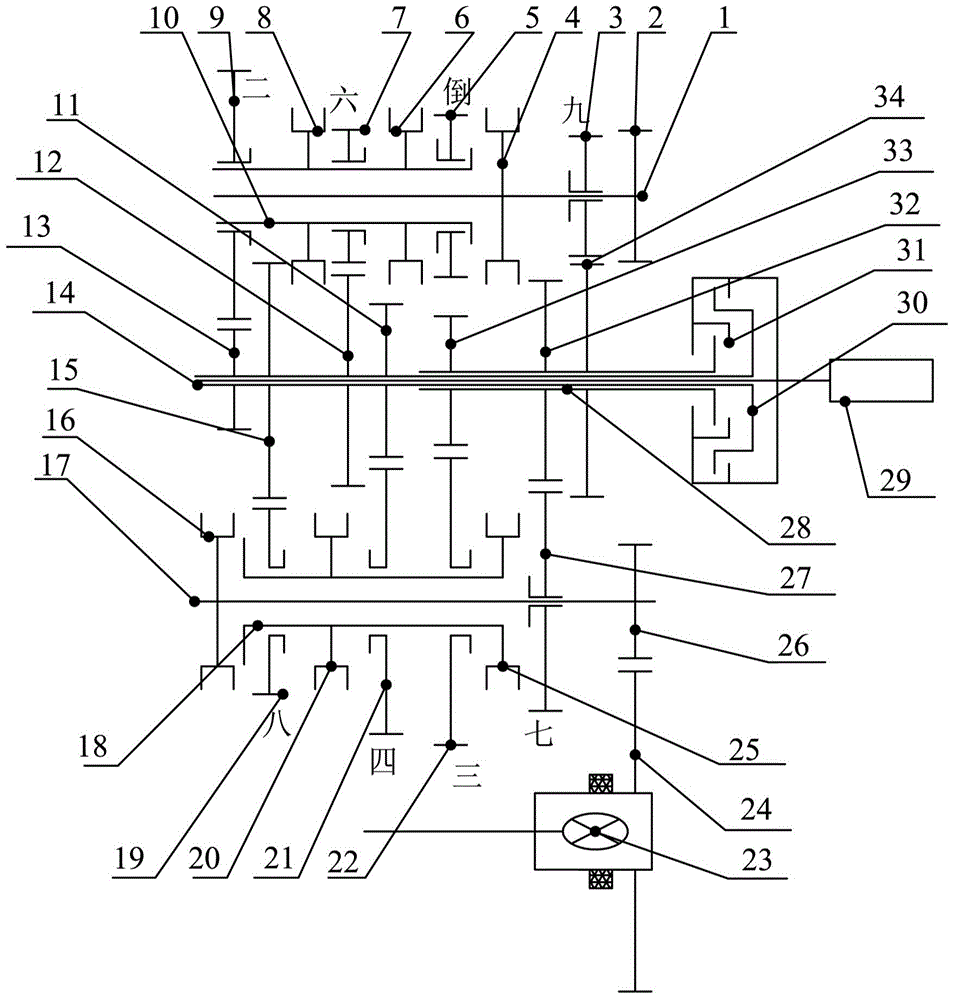

Multi-speed dual clutch transmission and vehicle

ActiveCN105443674BImprove transmission efficiencyImprove comfortToothed gearingsGearing detailsGear driveEngineering

The invention provides a multi-gear dual clutch transmission and a vehicle. The multi-gear dual clutch transmission comprises an external input shaft, an internal input shaft, a first external output shaft, a first internal output shaft, a second external output shaft, a second internal output shaft and a synchronizing device. A tenth-gear driving gear, an eighth-gear driving gear and a fourth-gear driving gear are fixed to the external input shaft. A third-gear driving gear, a fifth-gear driving gear, a seventh-gear driving gear and a first-gear driving gear are fixed to the internal input shaft. The first internal output shaft is sleeved with a tenth-gear driven gear in a spaced mode. The first external output shaft is sleeved with a fifth-gear driven gear and a first-gear driven gear in a spaced mode. The second internal output shaft is sleeved with an eighth-gear driven gear in a spaced mode. The second external output shaft is sleeved with a fourth-gear driven gear, a third-gear driven gear and a seventh-gear driven gear in a spaced mode. The synchronizing device is used for controlling the combination and separation between all the driven gears and the shafts where the driven gears are located, between the first external output shaft and the first internal output shaft as well as between the second external output shaft and the second internal output shaft. By the adoption of the multi-gear dual clutch transmission, the response time of gear shifting is shortened.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Multi-speed dual-clutch transmission and vehicle

ActiveCN105443676BImprove transmission efficiencyImprove comfortToothed gearingsGearing detailsGear driveEngineering

The invention provides a multi-gear dual clutch transmission and a vehicle. The multi-gear dual clutch transmission comprises an external input shaft, an internal input shaft, a first external output shaft, a first internal output shaft, a second external output shaft, a second internal output shaft and a synchronizing gear. A sixth-gear driving gear, an eighth-gear driving gear and a fourth-gear driving gear are fixed to the external input shaft. A third-gear driving gear, a ninth-gear driving gear, a seventh-gear driving gear and a first-gear driving gear are fixed to the internal input shaft. The first internal output shaft is sleeved with a sixth-gear driven gear in a spaced mode. The first external output shaft is sleeved with a ninth-gear driven gear and a first-gear driven gear in a spaced mode. The second internal output shaft is sleeved with an eighth-gear driven gear in a spaced mode. The second external output shaft is sleeved with a fourth-gear driven gear, a third-gear driven gear and a seventh-gear driven gear in a spaced mode. The synchronizing gear is used for controlling the combination and separation between all the driven gears and the shafts where the driven gears are located, between the first external output shaft and the first internal output shaft as well as between the second external output shaft and the second internal output shaft. By the adoption of the multi-gear dual clutch transmission, the response time of gear shifting is shortened.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Multi-speed dual-clutch transmission and vehicle

ActiveCN105370816BImprove transmission efficiencyImprove comfortToothed gearingsGearing detailsControl theoryClutch

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

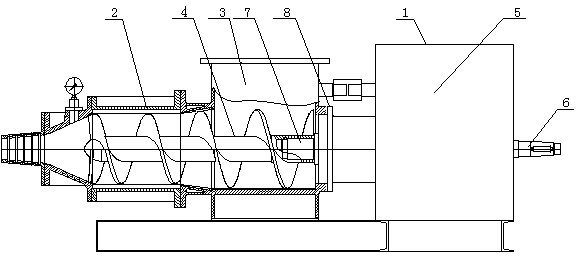

High-efficient transmission energy-saving brick making machine

The invention discloses a high-efficient transmission energy-saving brick making machine, which comprises a speed reducer and a brick making machine, wherein the brick making machine comprises a brick making machine body and a spiral reamer; the speed reducer is connected with the brick making machine body; and the output end of the speed reducer is connected with the spiral reamer of the brick making machine. In the machine, the output shaft of the speed reducer is directly connected with the spiral reamer of the brick making machine, so that the machine effectively improves transmission efficiency, is more reliably operated, saves energy and reduces consumption; and the machine has a simple structure and low manufacturing cost and is convenient to mount and dismount.

Owner:SICHUAN SANQIAO SPEED REDUCER

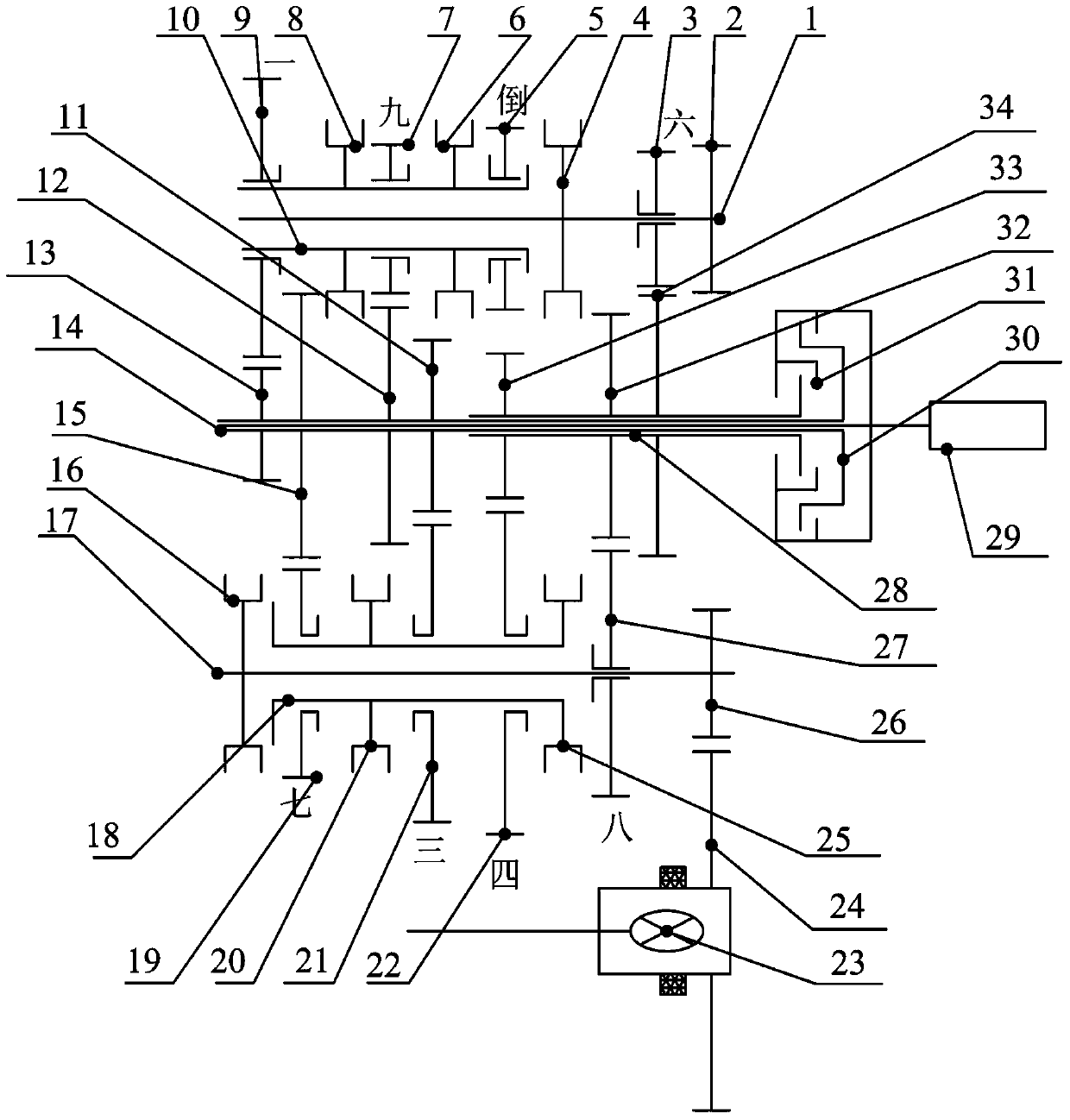

Multi-gear double-clutch transmission and vehicle

ActiveCN105370816AImprove transmission efficiencyImprove comfortToothed gearingsGearing detailsGear driveControl theory

The invention provides a multi-gear double-clutch transmission and a vehicle. The multi-gear double-clutch transmission comprises an outer input shaft, an inner input shaft, a first outer output shaft, a first inner output shaft, a second outer output shaft, a second inner output shaft and a synchronization device, wherein the inner input shaft is coaxially embedded in the outer input shaft, a seventh-gear driving gear, a ninth-gear driving gear and a third-gear driving gear are fixed to the outer input shaft, and a fourth-gear driving gear, a sixth-gear driving gear, an eighth-gear driving gear and a second-gear driving gear are fixed to the inner input shaft; the first inner output shaft is coaxially embedded in the first outer output shaft, the first inner output shaft is sleeved with a ninth-gear driven gear in an idling manner, and the first outer output shaft is sleeved with a second-gear driven gear and a sixth-gear driven gear in an idling manner; the second inner output shaft is coaxially embedded in the second outer output shaft, the second inner output shaft is sleeved with a seventh-gear driven gear in an idling manner and the second outer output shaft is sleeved with a third-gear driven gear, a fourth-gear driven gear and an eighth-gear driven gear in an idling manner; and the synchronization device is used for controlling all the driven gears to be combined with and separated from the shafts of the driven gears, the first outer output shaft to be combined with and separated from the first inner output shaft and the second outer output shaft to be combined with and separated from the second inner output shaft. By the adoption of the multi-gear double-clutch transmission, the gear shifting response time is shortened.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Multi-speed dual-clutch transmission and vehicle

ActiveCN105370817BImprove transmission efficiencyShorten the axial lengthToothed gearingsGearing detailsGear driveControl theory

The invention provides a multi-speed dual-clutch transmission and a vehicle. The multi-speed dual-clutch transmission includes an outer input shaft and an inner input shaft coaxially nested, and a seventh / ninth-speed driving gear and a third-speed driving gear are fixed on the outer input shaft , the fourth-speed driving gear, the second-speed driving gear and the sixth / eighth-speed driving gear are fixed on the inner input shaft; the first outer output shaft and the first inner output shaft are coaxially nested, and the first inner output shaft has nine empty sleeves. The second gear driven gear and the sixth gear driven gear are placed on the first outer output shaft; the second outer output shaft and the second inner output shaft are coaxially nested, and the second inner output shaft is emptier Seventh-speed driven gear, the third-speed driven gear, the fourth-speed driven gear and the eighth-speed driven gear are placed on the second outer output shaft; the synchronization device controls the driven gears of each gear and the shaft where it is located, and the first outer output shaft Combination and separation of the first inner output shaft and the second outer output shaft and the second inner output shaft. The multi-speed dual-clutch transmission reduces the reaction time for shifting gears.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

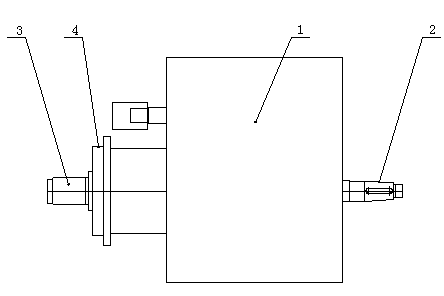

Speed reducer of efficient transmission energy-saving brick making machine

InactiveCN102242805BEliminate additional loadShorten the power transmission pathGearboxesBrickAgricultural engineering

The invention discloses a speed reducer of an efficient transmission energy-saving brick making machine. The speed reducer comprises a speed reducer box body, a speed reducer input shaft and a speed reducer output shaft; a flange is arranged at one end of the speed reducer output shaft and on the speed reducer box body; the front end of the speed reducer output shaft passes through the flange; and a sealing device and a bearing are arranged in the flange and between the speed reducer output shaft and the flange. The flange is arranged on the speed reducer box body, and the speed reducer output shaft can be directly connected with a spiral reamer of the brick marking machine, so that the transmission efficiency is improved, the operation is more reliable, energy is saved, consumption is reduced, and the service life is greatly prolonged; and the speed reducer has the advantages of simple structure, low manufacturing cost and convenience for assembly and disassembly.

Owner:SICHUAN SANQIAO SPEED REDUCER

Multi-gear dual clutch transmission and vehicle

InactiveCN110081134AImprove transmission efficiencyImprove comfortToothed gearingsTransmission elementsControl theoryClutch

The invention provides a multi-gear dual clutch transmission and a vehicle. The multi-gear dual clutch transmission comprises an outer input shaft and an inner input shaft which are coaxially nested,a first outer output shaft and a first inner output shaft which are coaxially nested, a second outer output shaft and a second inner output shaft which are coaxially nested, and a synchronizing device, wherein a plurality of driving gears are fixedly arranged on the outer input shaft and the inner input shaft; at least one driven gear meshed with the corresponding driving gear is sleeved above thefirst outer output shaft and the first inner output shaft; at least one driven gear meshed with the corresponding driving gear is sleeved above the second outer output shaft and the second inner output shaft; and the synchronizing device is used for controlling the combination and separation of all driven gears and shafts on which the driven gears are positioned, the combination and separation ofthe first outer output shaft and the first inner output shaft, and the combination and separation of the second outer output shaft and the second inner output shaft. According to the multi-gear dualclutch transmission, the transmission efficiency of the transmission is improved, and the reaction time of gear shifting is reduced.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Hybrid powertrain for vehicle

PendingCN113386550AReduce manufacturing costReduce weightHybrid vehiclesGas pressure propulsion mountingGear wheelControl theory

The invention relates to a hybrid powertrain for a vehicle, which may include a first input shaft connected to an engine, a second input shaft connected to the engine and coaxially mounted with the first input shaft, a motor input shaft coaxially mounted with the first input shaft and connected to a motor, first and second output shafts mounted in parallel to the first input shaft and the second input shaft, a variable drive gear provided at the motor input shaft to transmit power from the motor input shaft to the first output shaft, a complex synchronizer to couple and separate the first input shaft and the motor input shaft and to couple and separate the variable drive gear and the motor input shaft, and a plurality of external gear pairs configured to respectively define different gear ratios.

Owner:HYUNDAI MOTOR CO LTD +1

Multi-speed dual-clutch transmission and vehicle

ActiveCN105370815BImprove transmission efficiencyShorten the axial lengthToothed gearingsGearing detailsControl theoryClutch

The present invention provides a multi-speed dual-clutch transmission and a vehicle. The multi-speed dual-clutch transmission includes coaxially nested outer input shafts and inner input shafts. Seventh, ninth and third gears are fixed on the outer input shafts. The driving gears of fourth gear, sixth gear / eighth gear and second gear are fixed on the inner input shaft; the first outer output shaft and the first inner output shaft are coaxially nested, and the first inner output shaft is empty with the ninth gear driven gear. The second outer output shaft and the second inner output shaft are coaxially nested with driven gears for second and sixth gears; the second inner output shaft is nested with driven gears for seventh gear and second inner output shaft. The outer output shaft is equipped with driven gears for third, fourth and eighth gears; the synchronous device controls the driven gears of each gear and its shaft, the first outer output shaft and the first inner output shaft, the second outer output shaft and the second outer output shaft. The combination and separation of the two inner output shafts. The multi-speed dual-clutch transmission reduces the reaction time for shifting gears.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com