Patents

Literature

70results about How to "Drive directly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

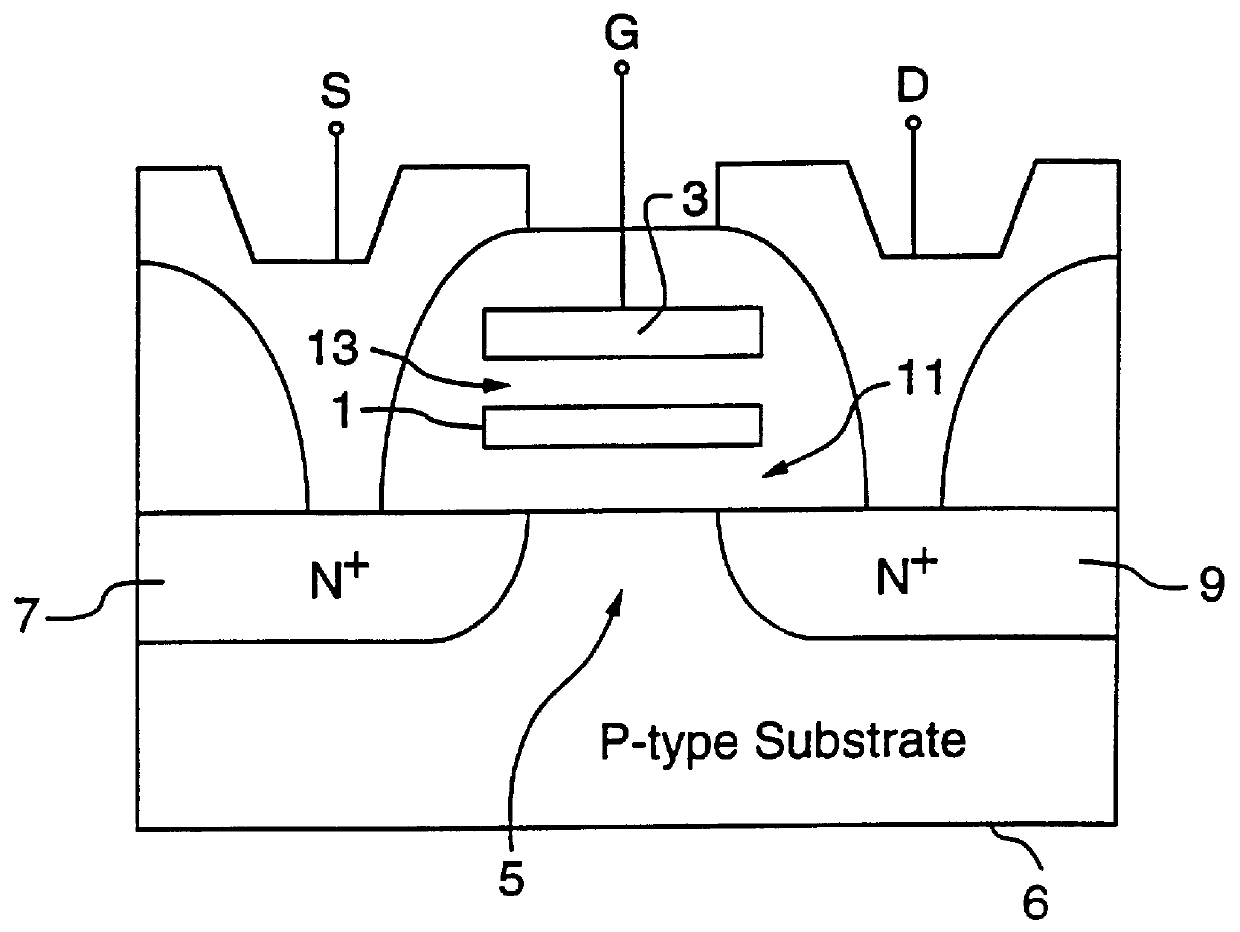

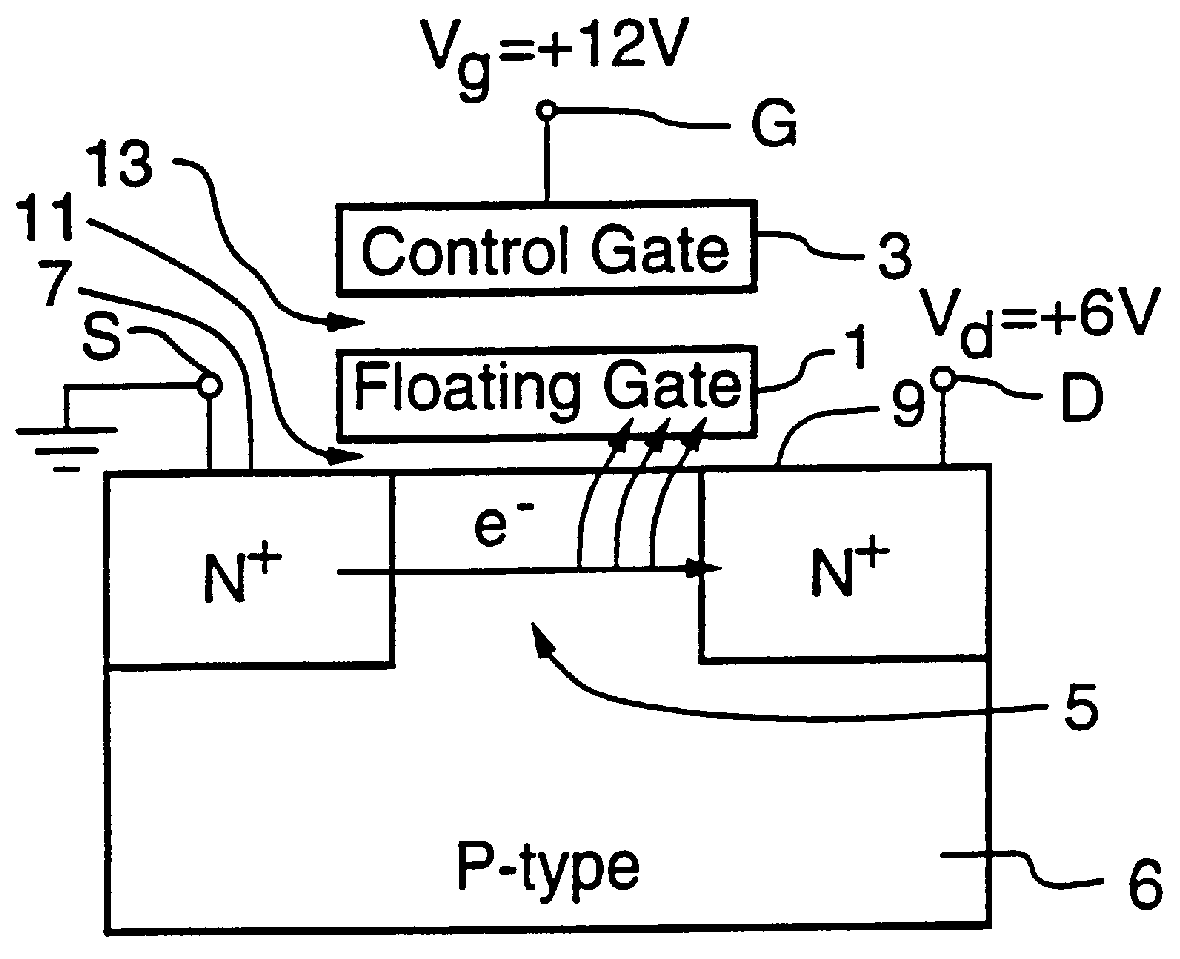

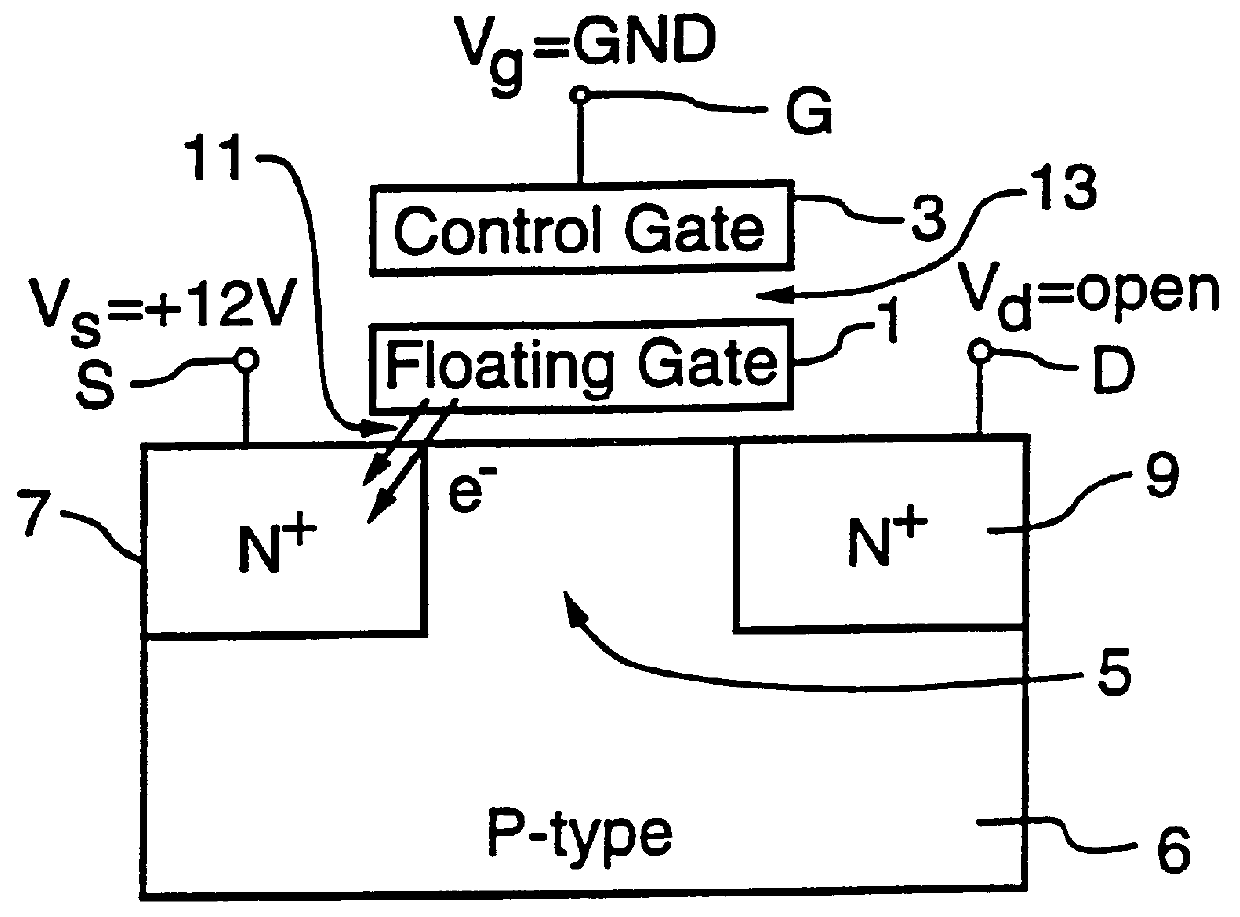

Method of fabricating a fast programmable flash E2PROM cell

InactiveUS6034896ALarge capacitySuitable for battery operated portable equipmentTransistorRead-only memoriesElectric fieldHot electron

PCT No. PCT / CA96 / 00446 Sec. 371 Date Jun. 24, 1998 Sec. 102(e) Date Jun. 24, 1998 PCT Filed Jul. 3, 1996 PCT Pub. No. WO97 / 02605 PCT Pub. Date Jan. 23, 1997A flash E2PROM cell having source and drain regions disposed in a substrate, a channel region intermediate to the source and drain regions, a tunnel dielectric layer overlying the channel region, a floating gate overlying the tunnel dielectric layer, an inter-poly dielectric layer overlying the floating gate, and a control gate overlying the inter-poly dielectric layer. The flash E2PROM cell further having a highly doped p+ pocket implant covering a portion of the cell width and adjacent to at least one of the drain and source regions. The flash E2PROM cell is comprised of two sections butted together. The portion (width-wise) that is covered by the highly doped p+ pocket implant is referred to as a program section. The remaining portion (width-wise) not covered by the highly doped p+ pocket implant resembles a conventional flash E2PROM cell and is referred to as a sense section. The highly doped p+ pocket implant and the n+ drain and / or source regions create a junction having narrow depletion width so that when the junction is reversed biased, an electric field is created for generating hot electrons for storage on the floating gate, thereby programming the flash E2PROM cell when a high positive potential is applied to the control gate.

Owner:UNIV OF TORONTO INNOVATIONS FOUND THE

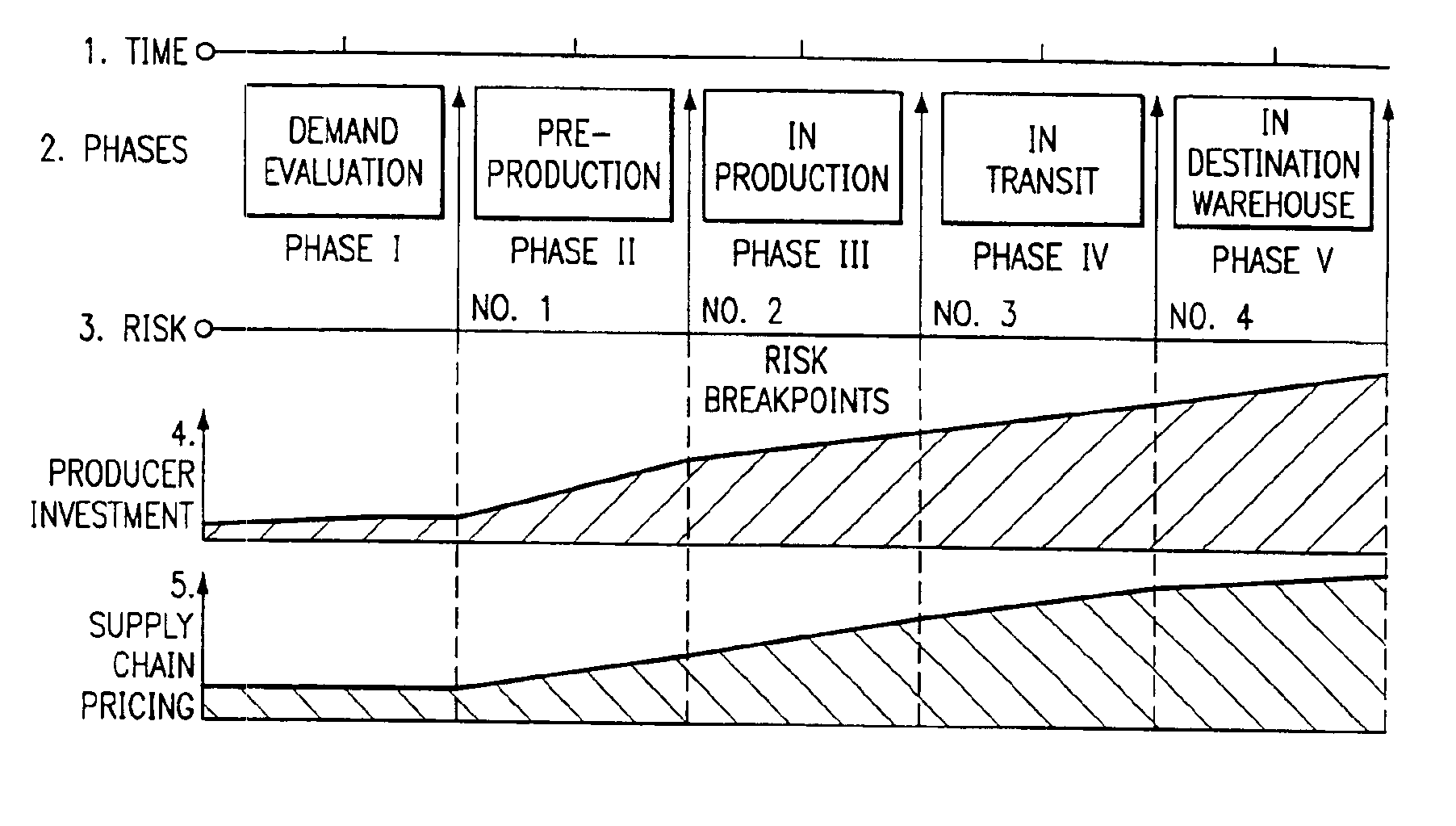

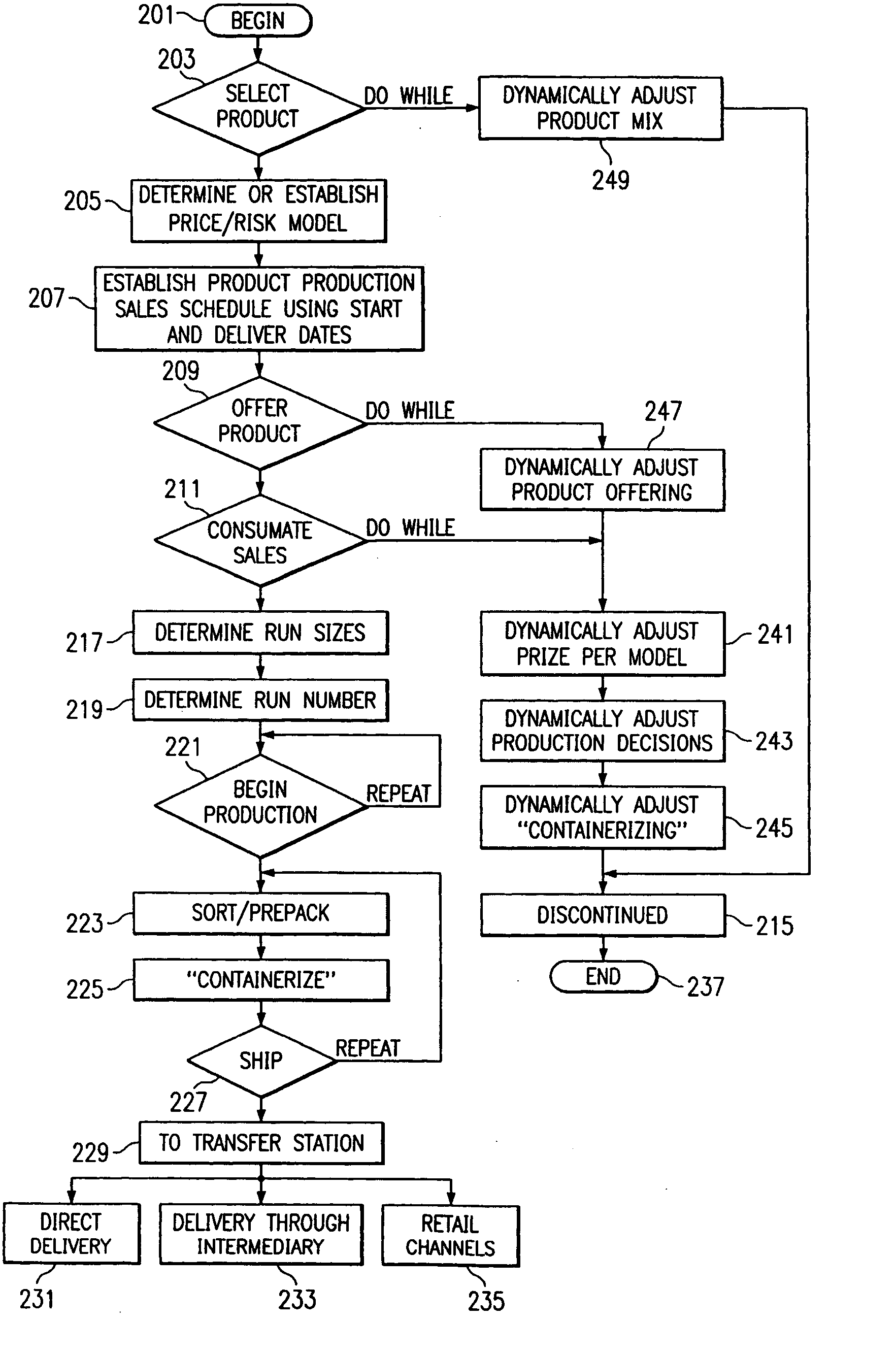

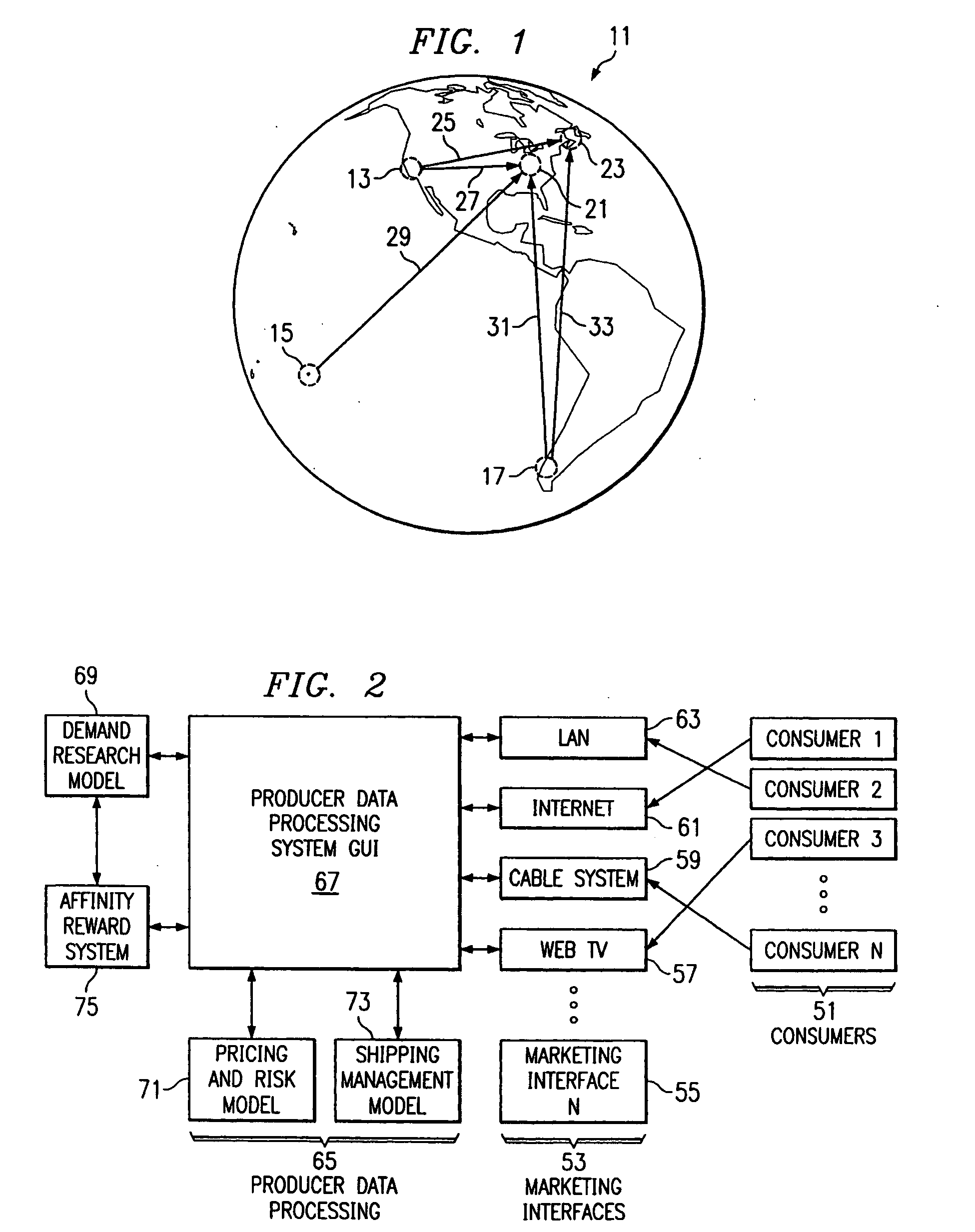

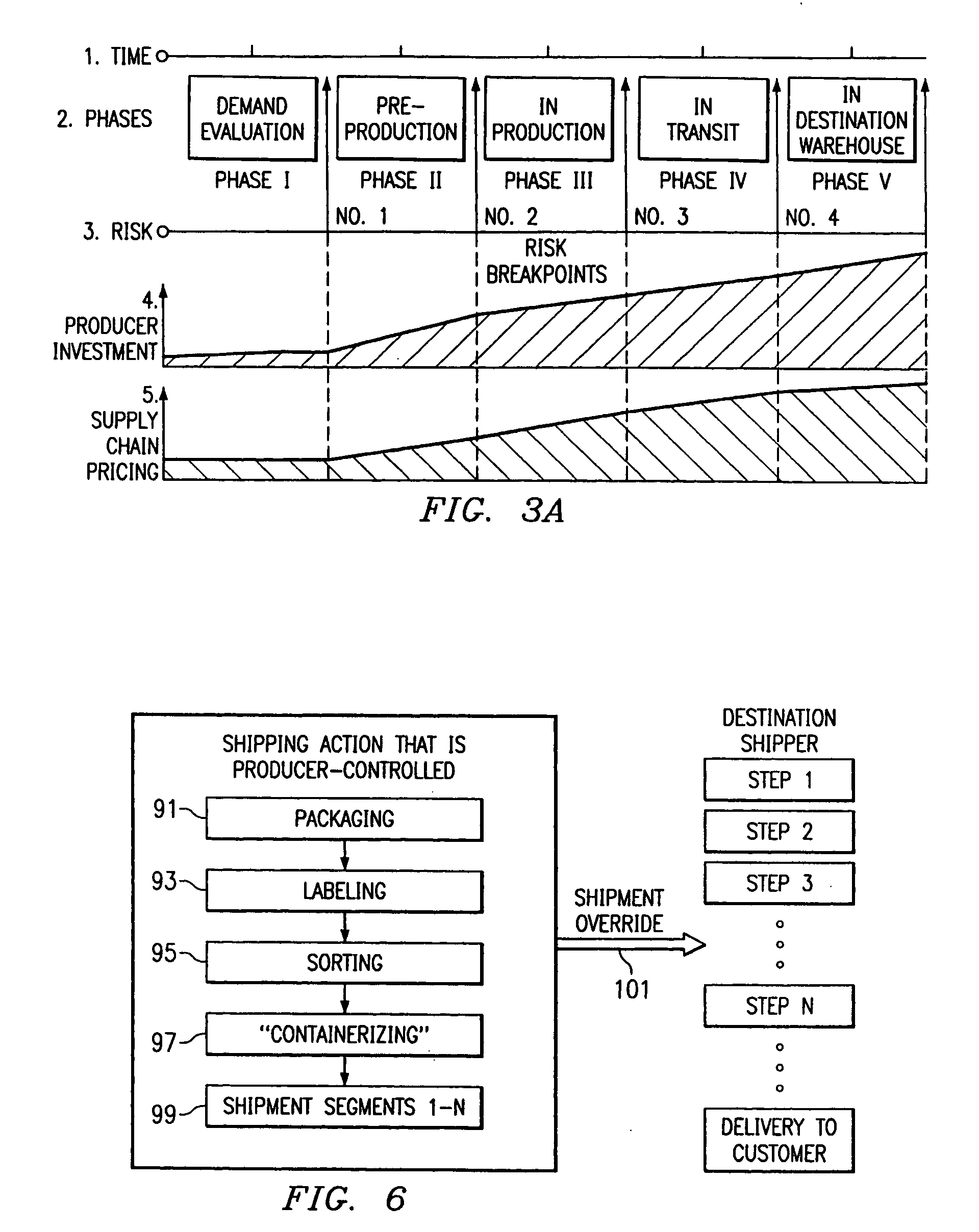

Method of producing, selling, and distributing articles of manufacture

InactiveUS6954734B1Simple preparation conditionsLess riskHand manipulated computer devicesDiscounts/incentivesElectronic communicationMilestone

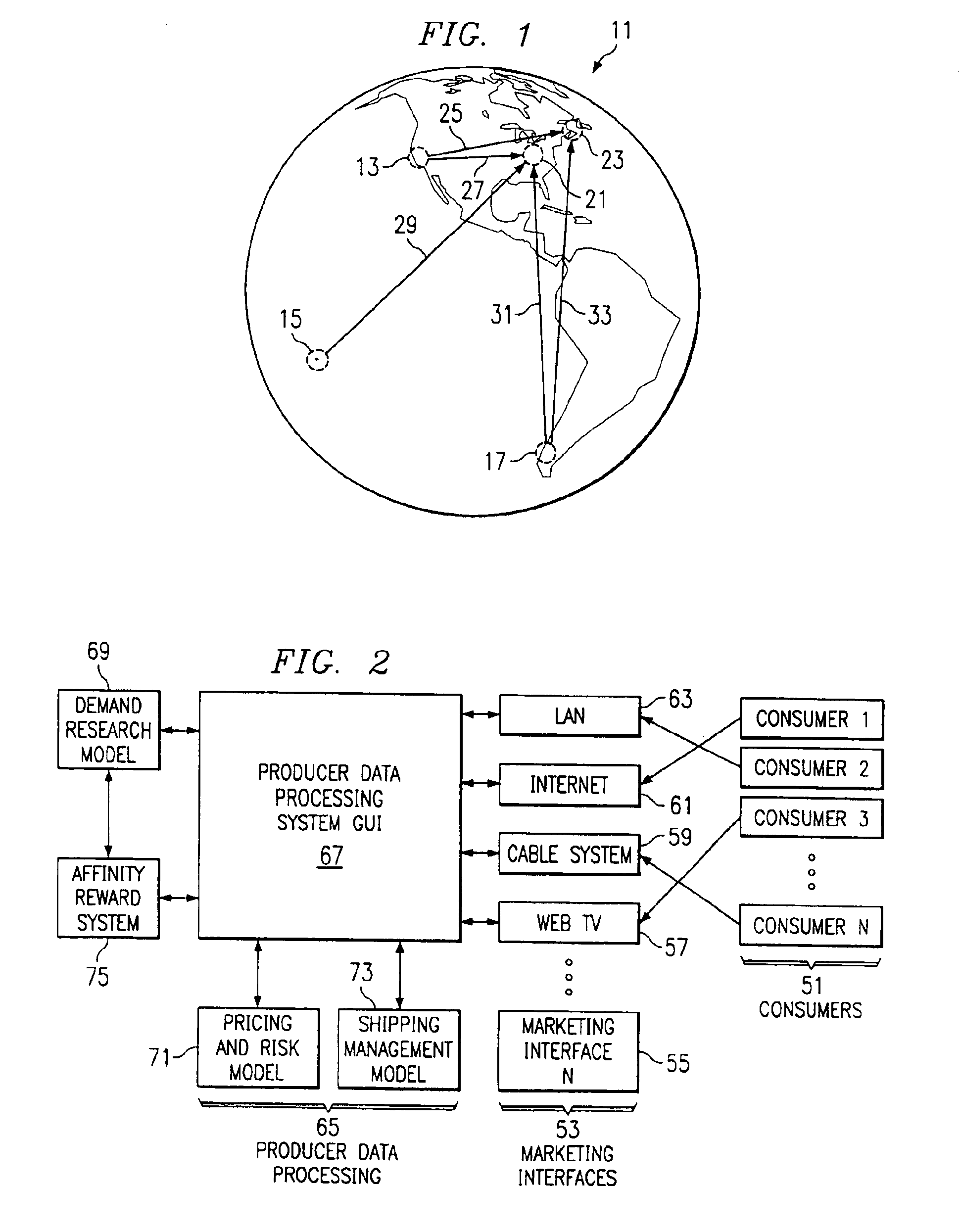

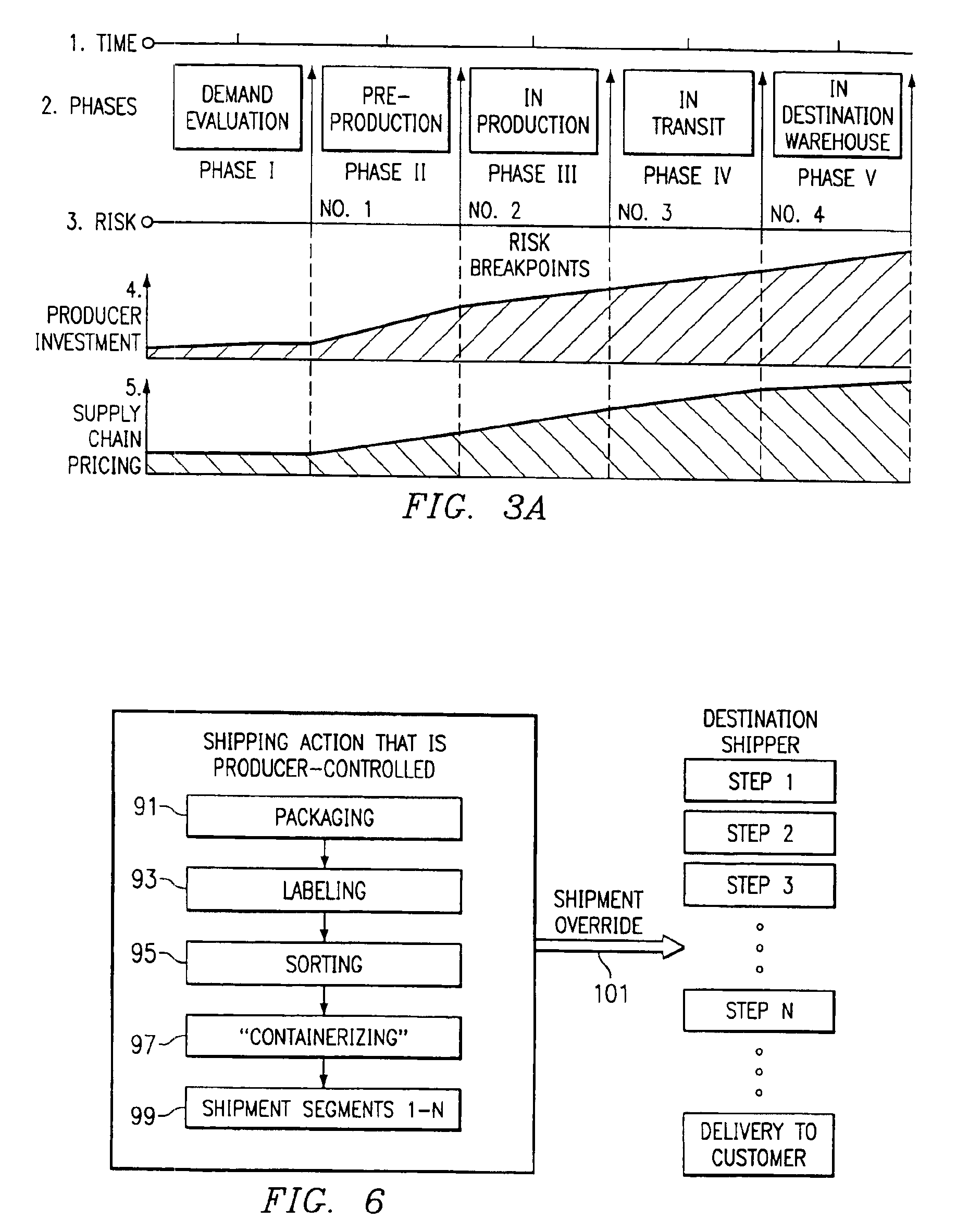

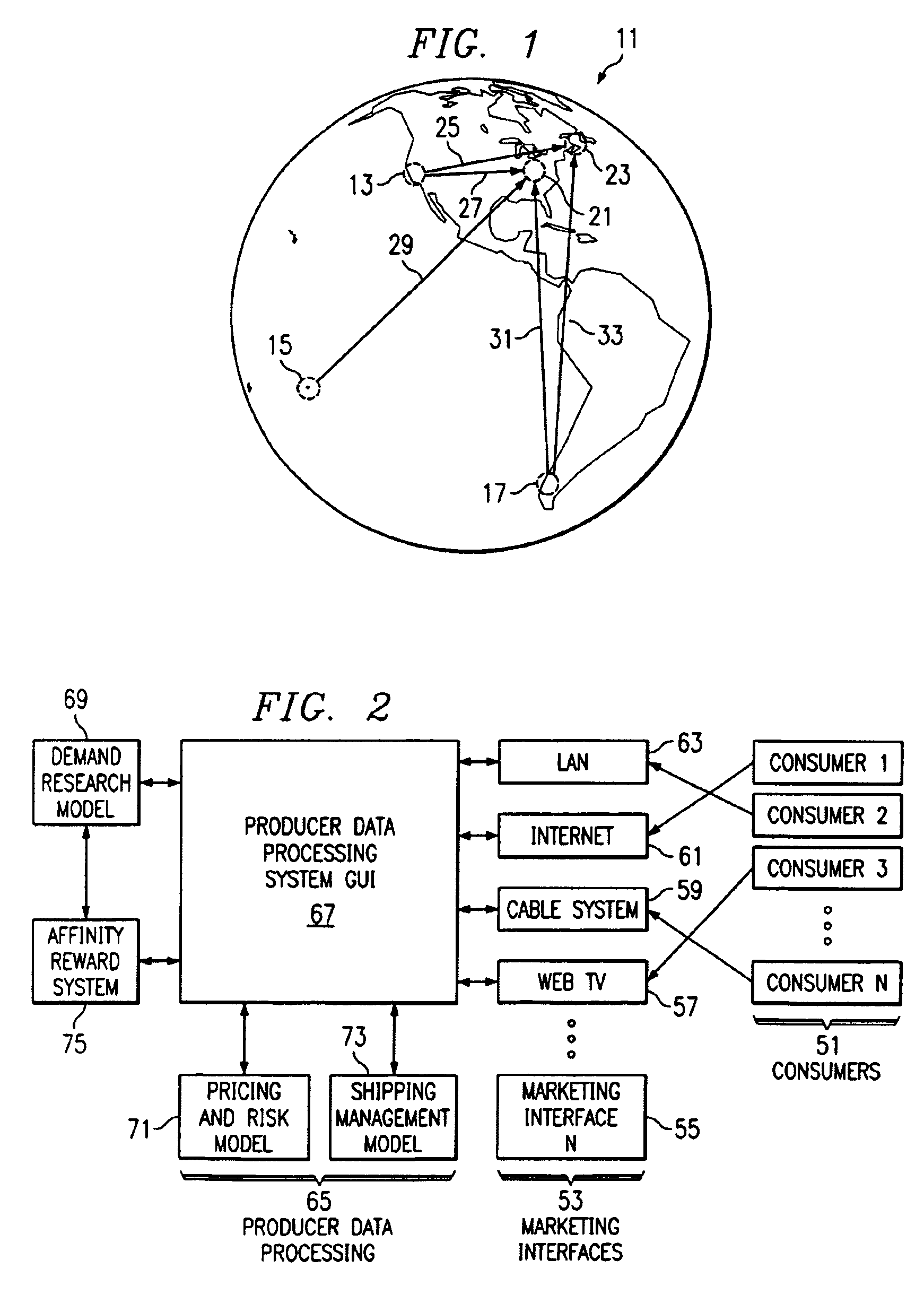

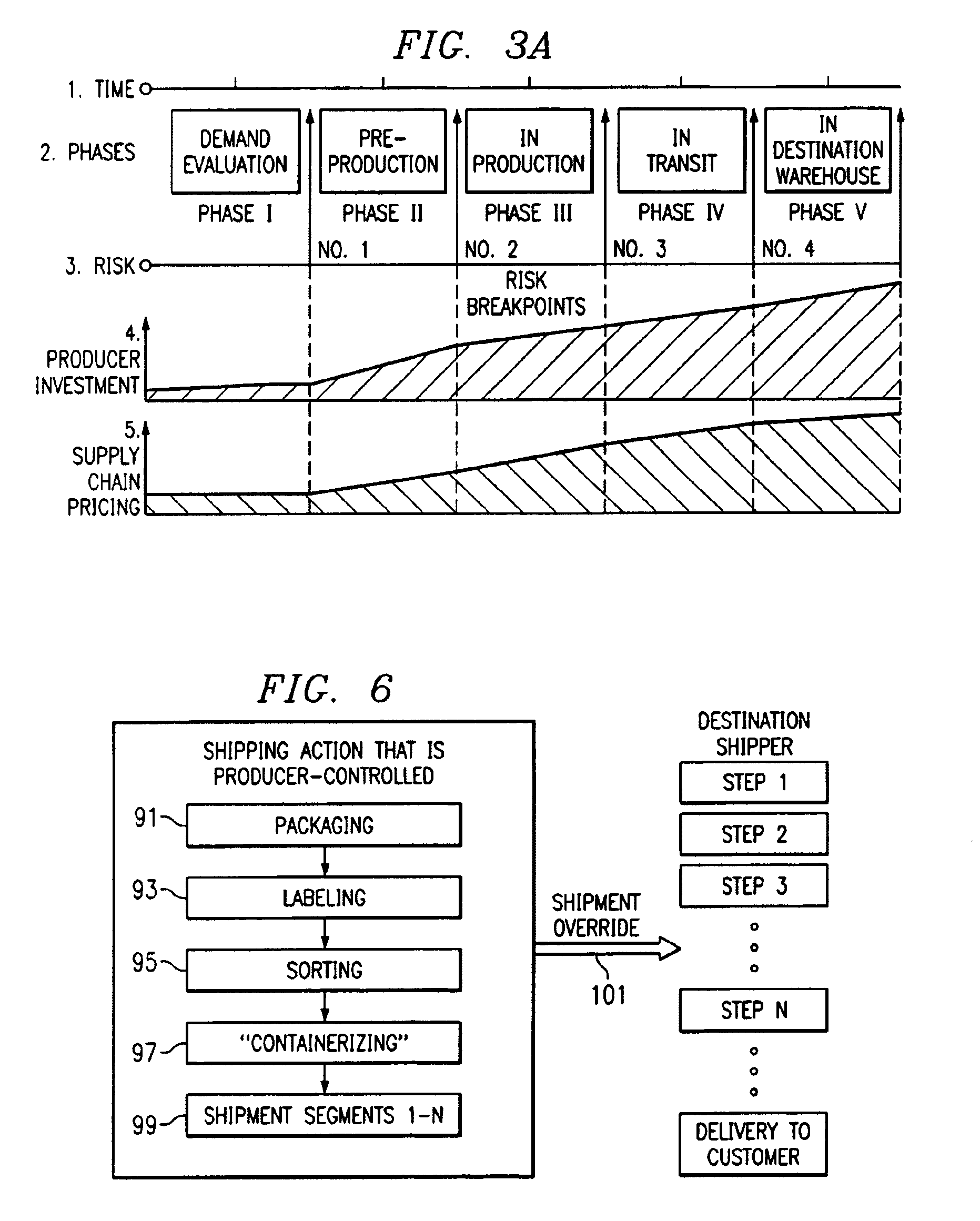

A method of selling articles of manufacture which utilizes an electronic communication system to identify a plurality of articles of manufacture, from a plurality of manufacturing entities, which are available for purchase by said plurality of potential purchasers. The steps of the method include: Identifying pricing milestones in each of (1) a manufacturing phase and (2) a distribution phase, which correspond to an increase in commercial risk. Determining a separate price for each of said pricing milestones to establish a range of prices for said selected ones of said plurality of articles of manufacture, taking into account a change in said commercial risk as said pricing milestones are experienced. Making conditional offers for sale to potential purchasers at each of the pricing milestones, with the conditional offers specifying at least a minimum number of articles which must be ordered in aggregate before the conditional offer becomes binding upon a manufacturing entity. Communicating with potential purchasers and aggregating commercial commitments from potential purchasers for each pricing milestones and thereby selling articles of manufacture. Such that each pricing milestone corresponds to a period of availability in which costs of future supply chain activities or savings related to avoidance of future supply chain activities are reflected in an offer price. The method may also include the use of a trusted intermediary, which may use a virtual exchange.

Owner:LAKESOUTH HLDG LLC

Method of producing, selling, and distributing articles of manufacture through the automated aggregation of orders and the visual representation of standardized shipping volumes

InactiveUS7136830B1Simple preparation conditionsLess riskBuying/selling/leasing transactionsSpecial data processing applicationsManufactured suppliesIndustrial engineering

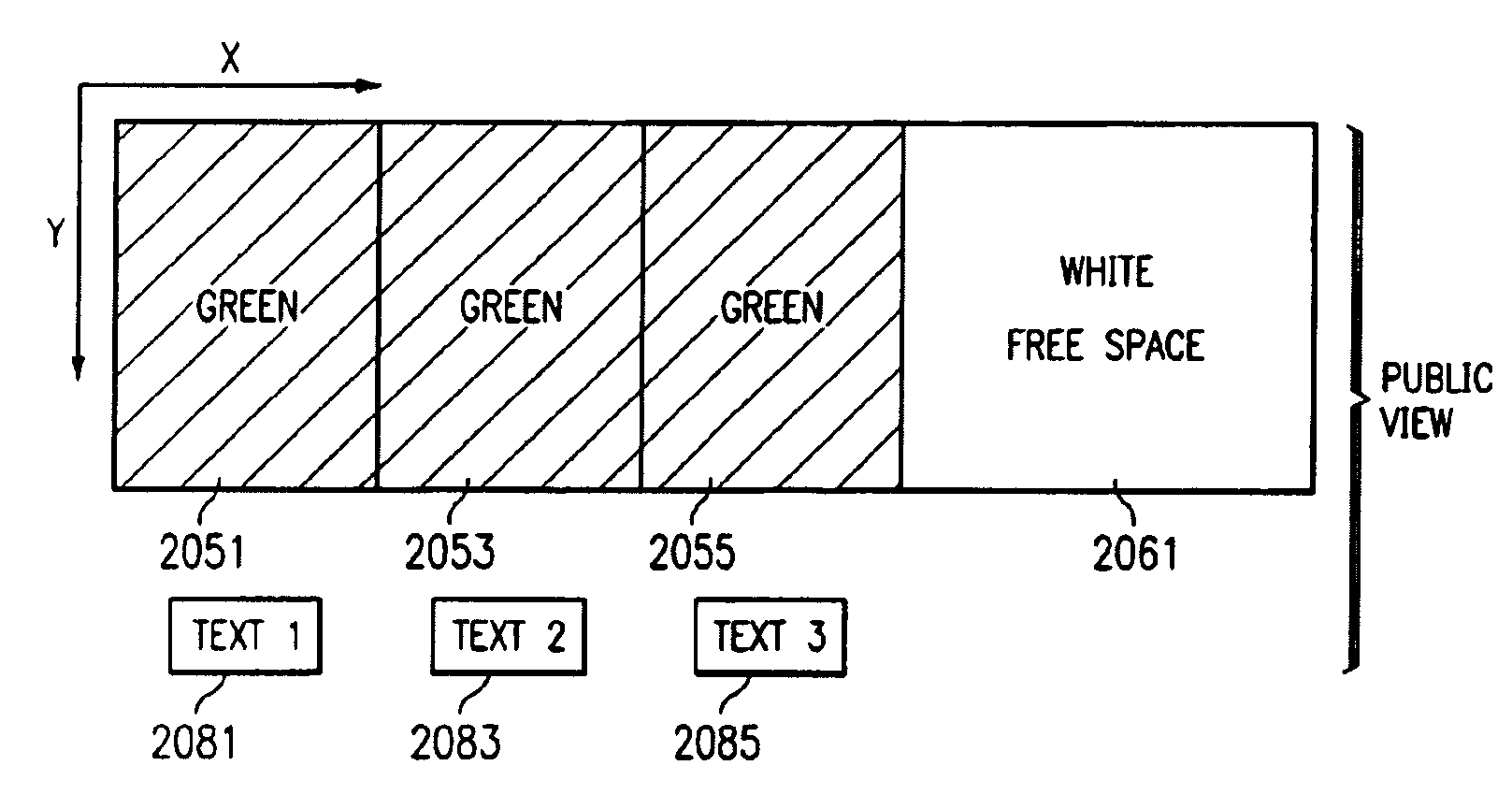

The present invention also provides a dynamic on-line order gathering system that enables sellers to offer one or a combination of goods whose availability (production and / or shipping) may be economically linked in some ways with other items and which facilitates aggregation of demand across related items so as to enable the ability to reach critical mass of demand for the related goods by a more efficient means than currently available.

Owner:LAKESOUTH HLDG LLC

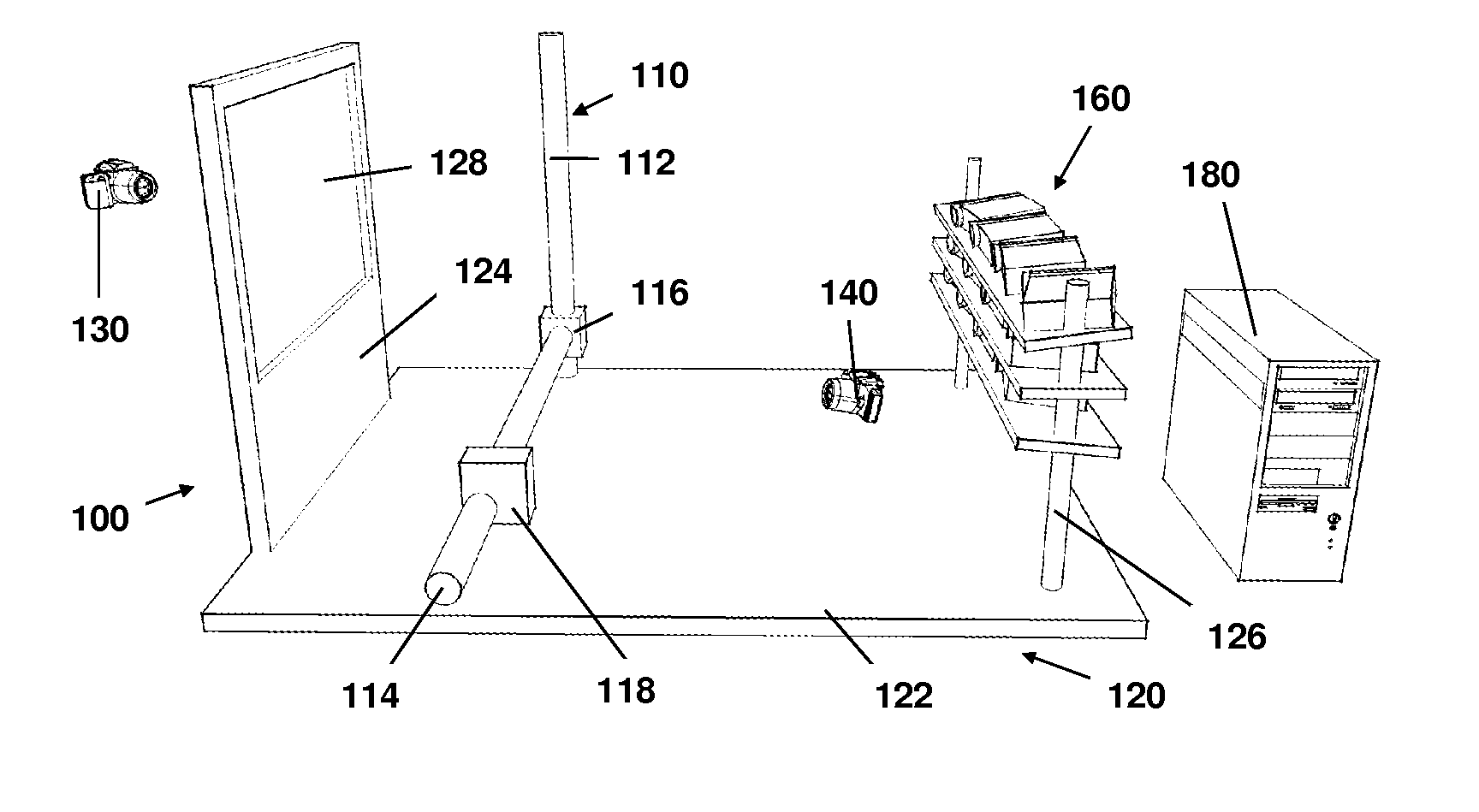

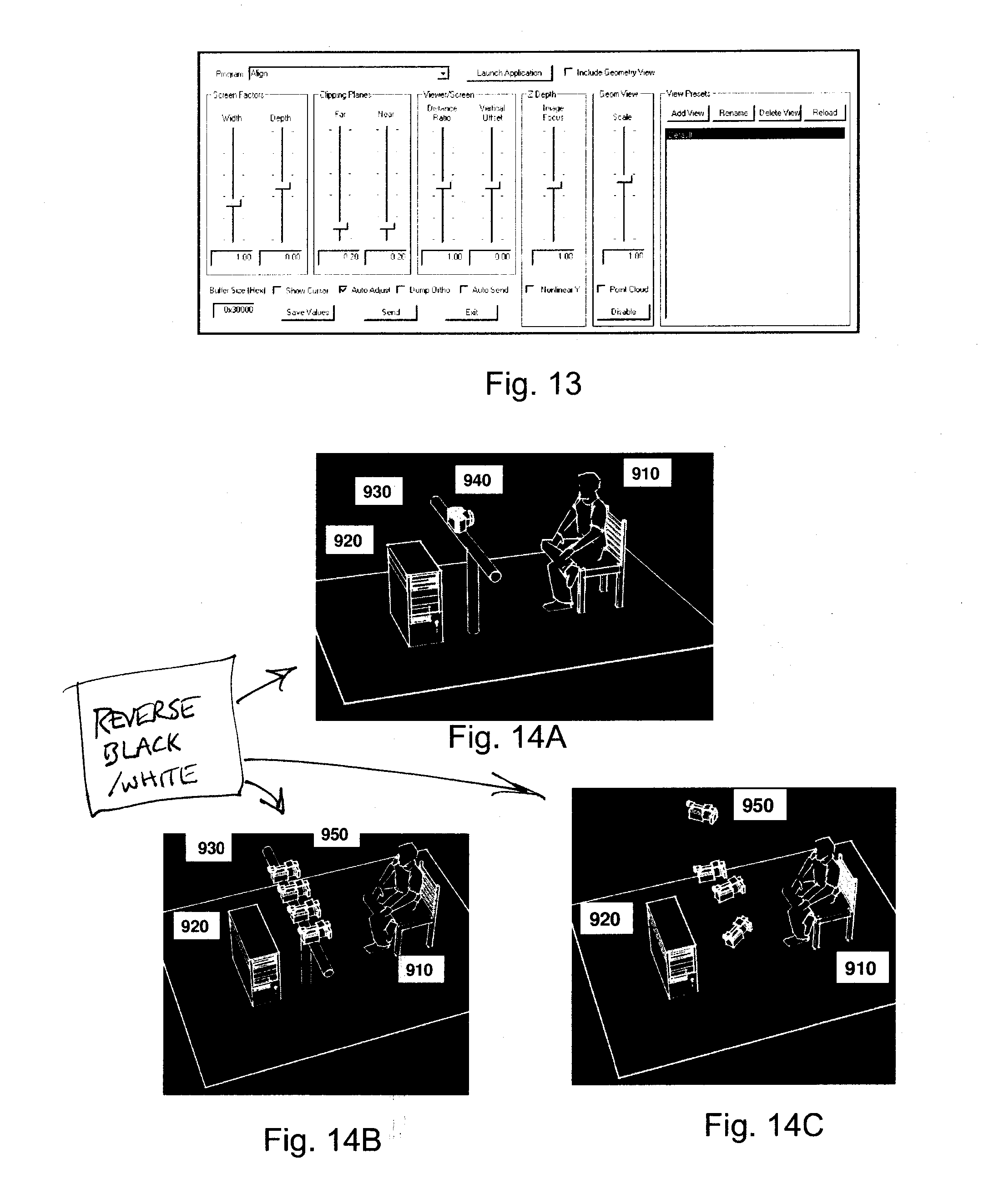

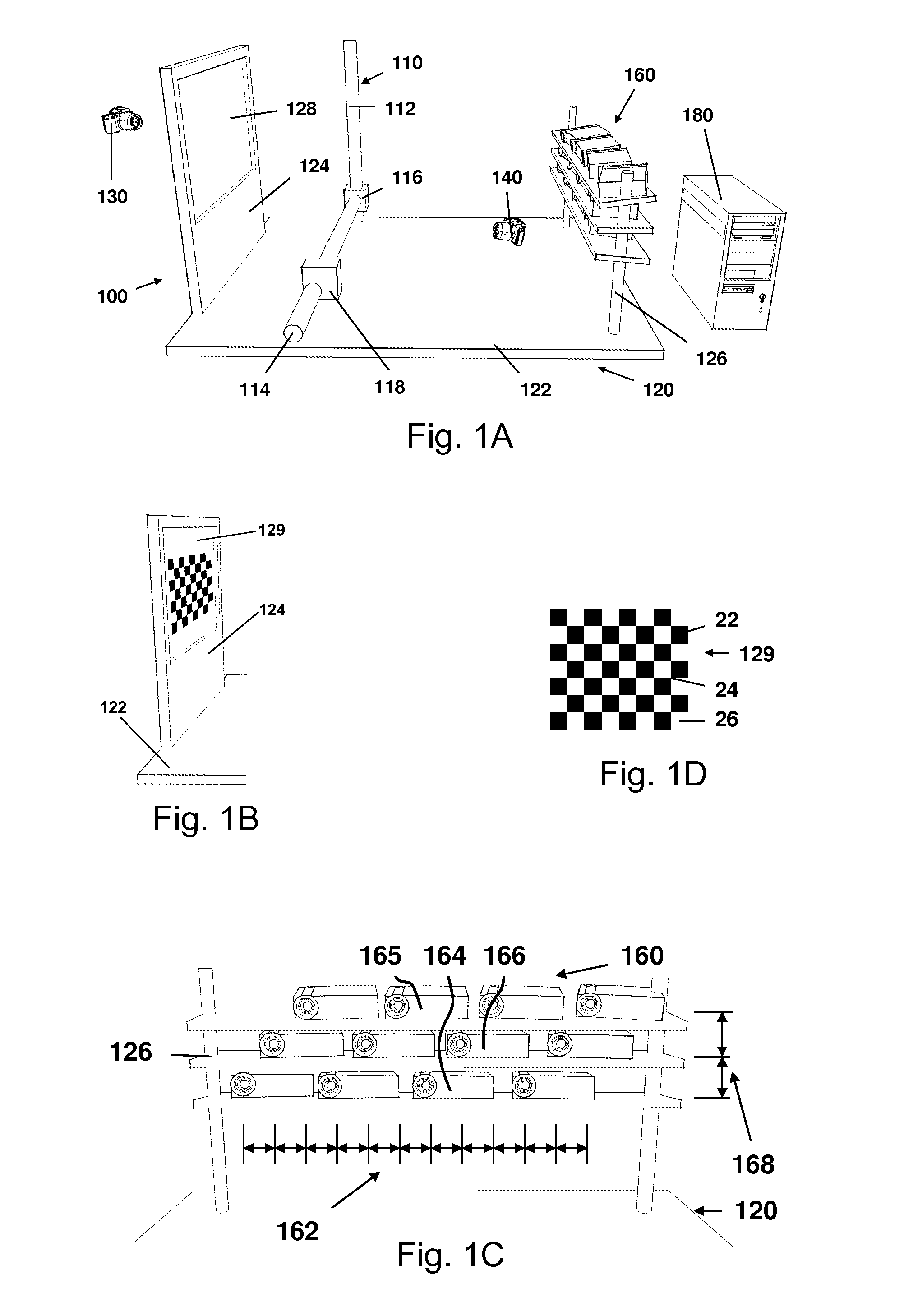

Systems and Methods for Alignment, Calibration and Rendering for an Angular Slice True-3D Display

ActiveUS20120300044A1Well mixedDrive directlyImage enhancementImage analysisParallaxProjection image

Systems and methods for calibrating a 3D display system. In one embodiment, a system includes a display screen, 2D image projectors that project 2D projection images onto the screen and a camera that captures calibration images of the screen. A computer generates the 2D projection images, which include calibration patterns, and processes the captured calibration images. The computer uses the calibration images to calculate corrections based upon the calibration images. The computer can then generate corrected 2D projection images that are projected by the 2D image projectors onto the screen to produce a substantially visually correct 3D image with continuous viewing, true horizontal parallax, and a different view for each eye within a valid viewing zone. The corrections to the images may include corrections to the geometry (including distortion, alignment, etc.) color (including intensity and related parameters).

Owner:THIRD DIMENSION IP

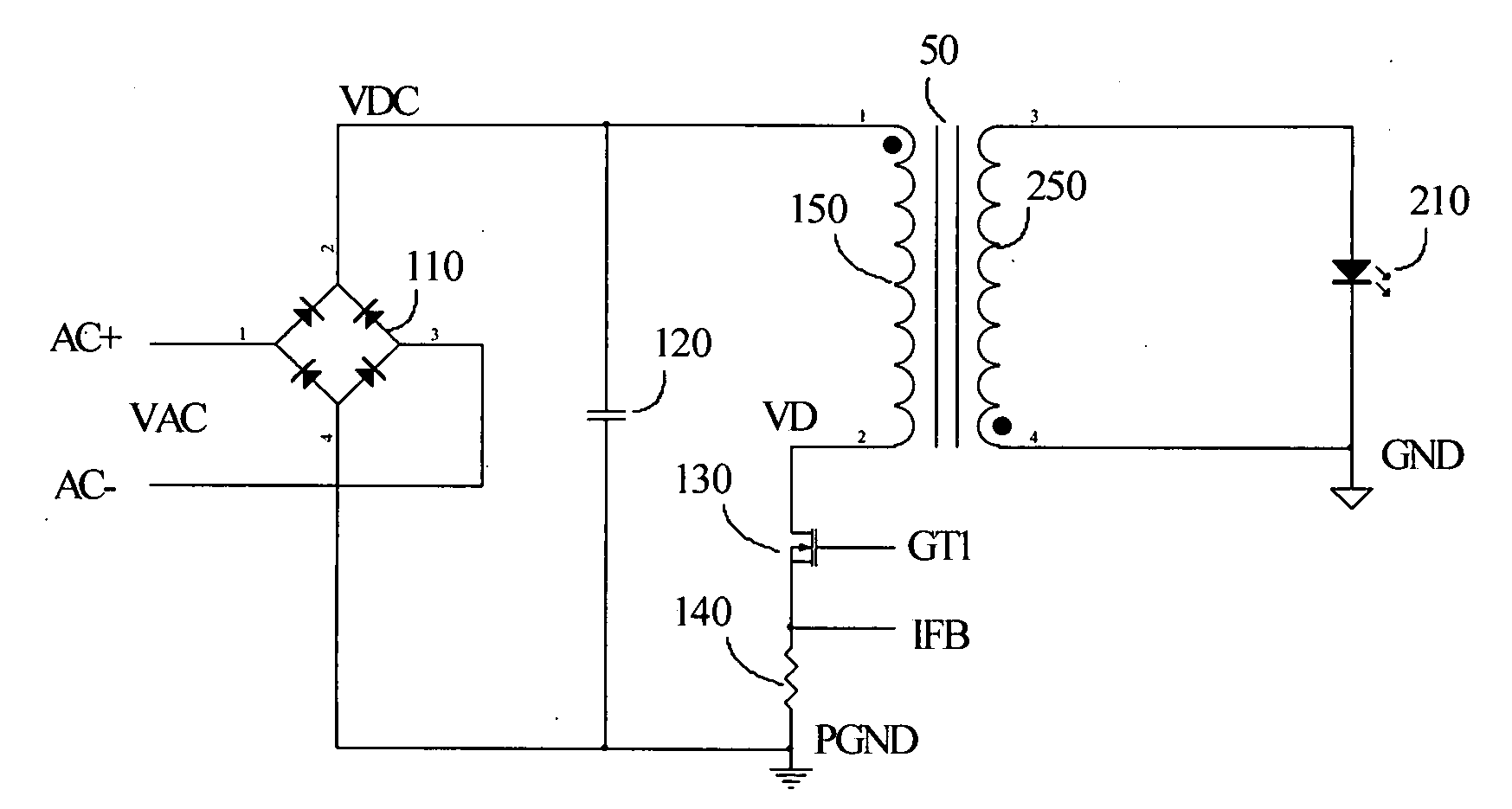

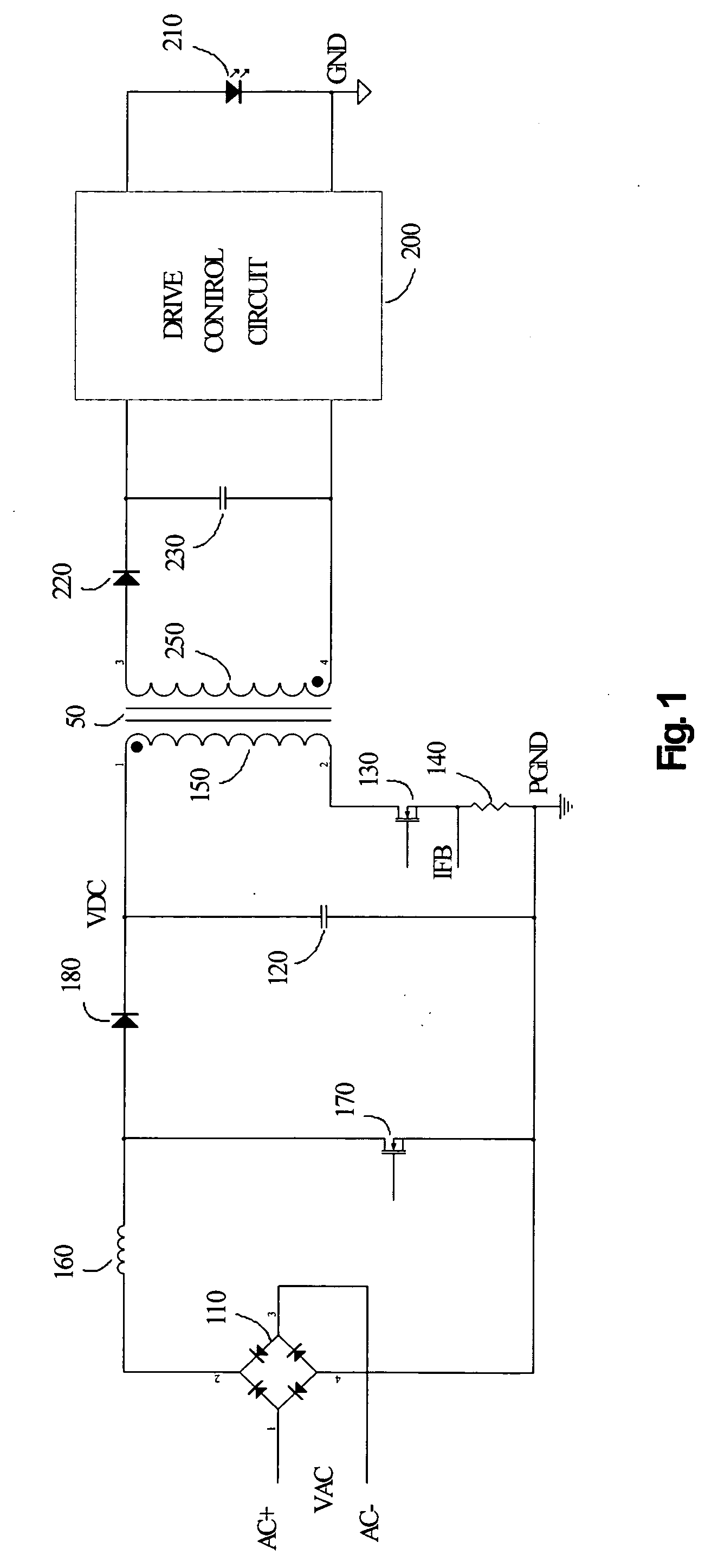

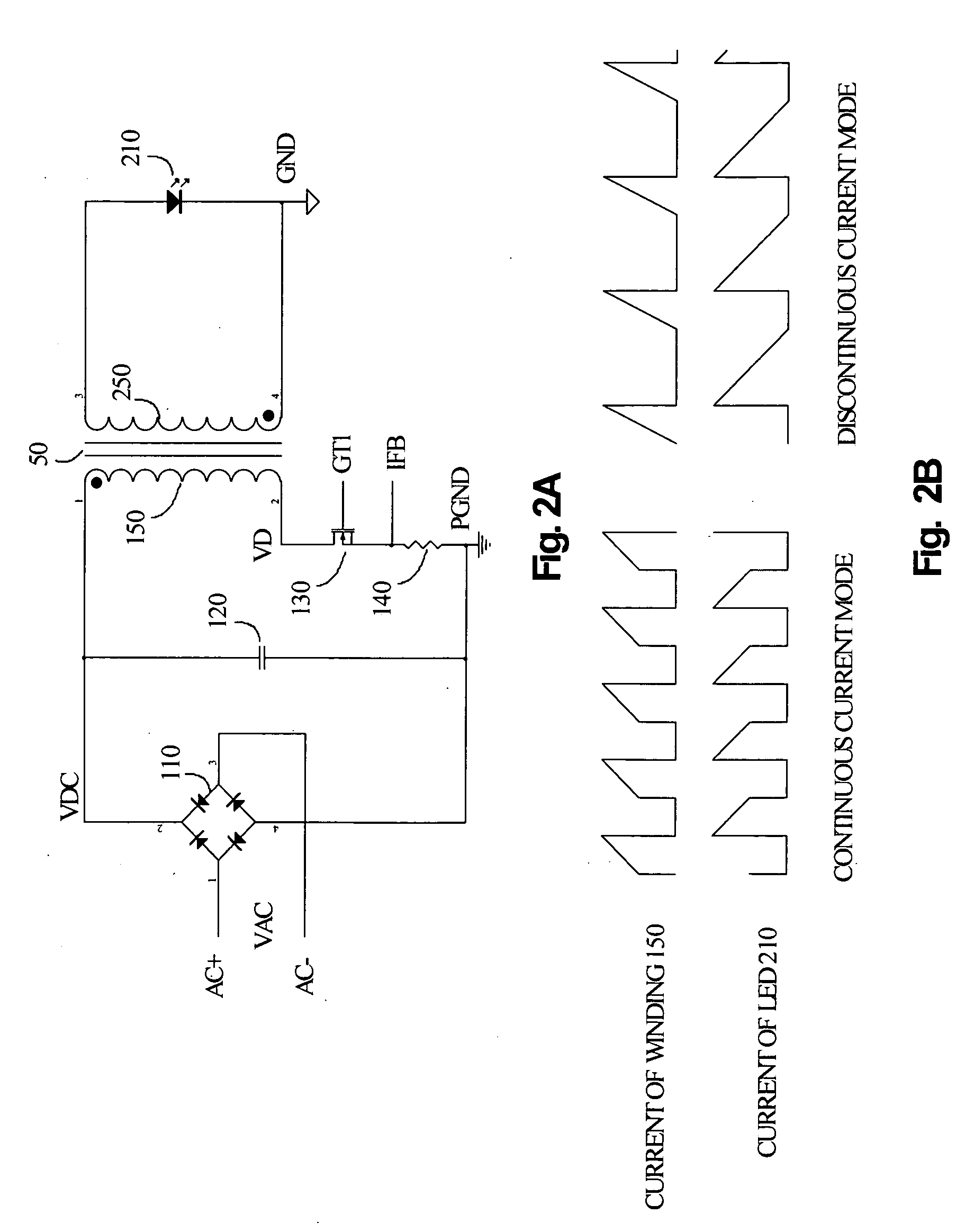

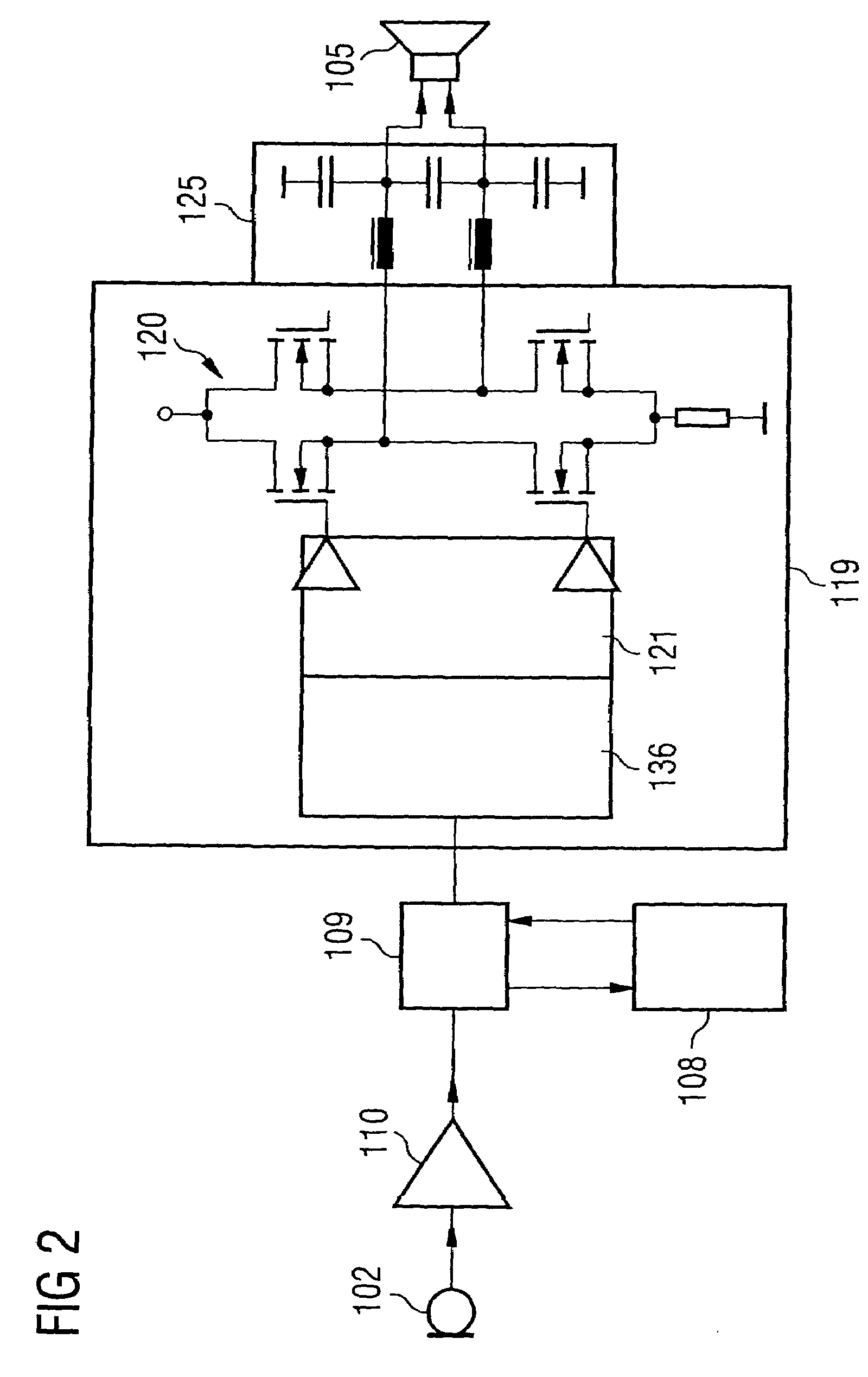

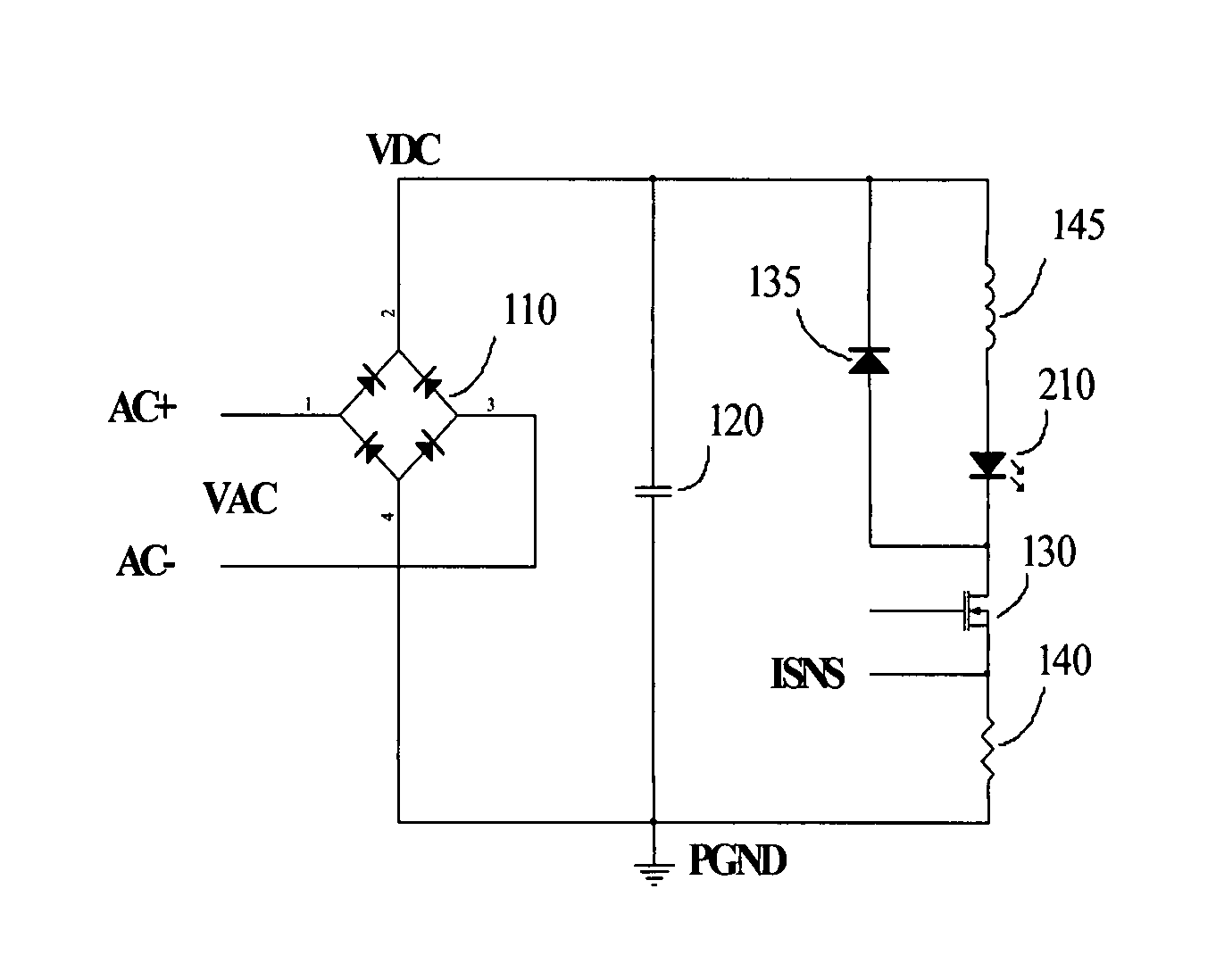

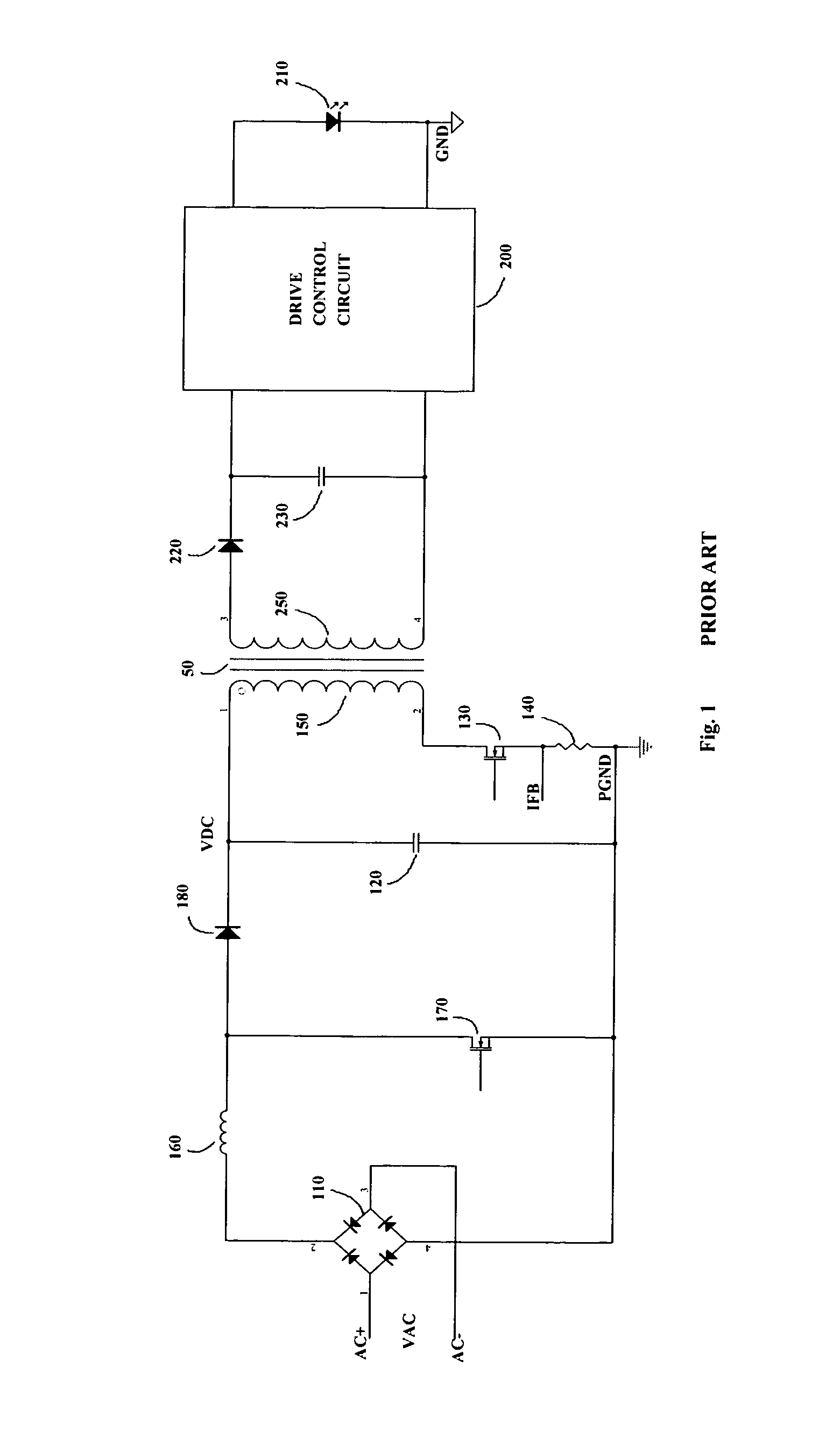

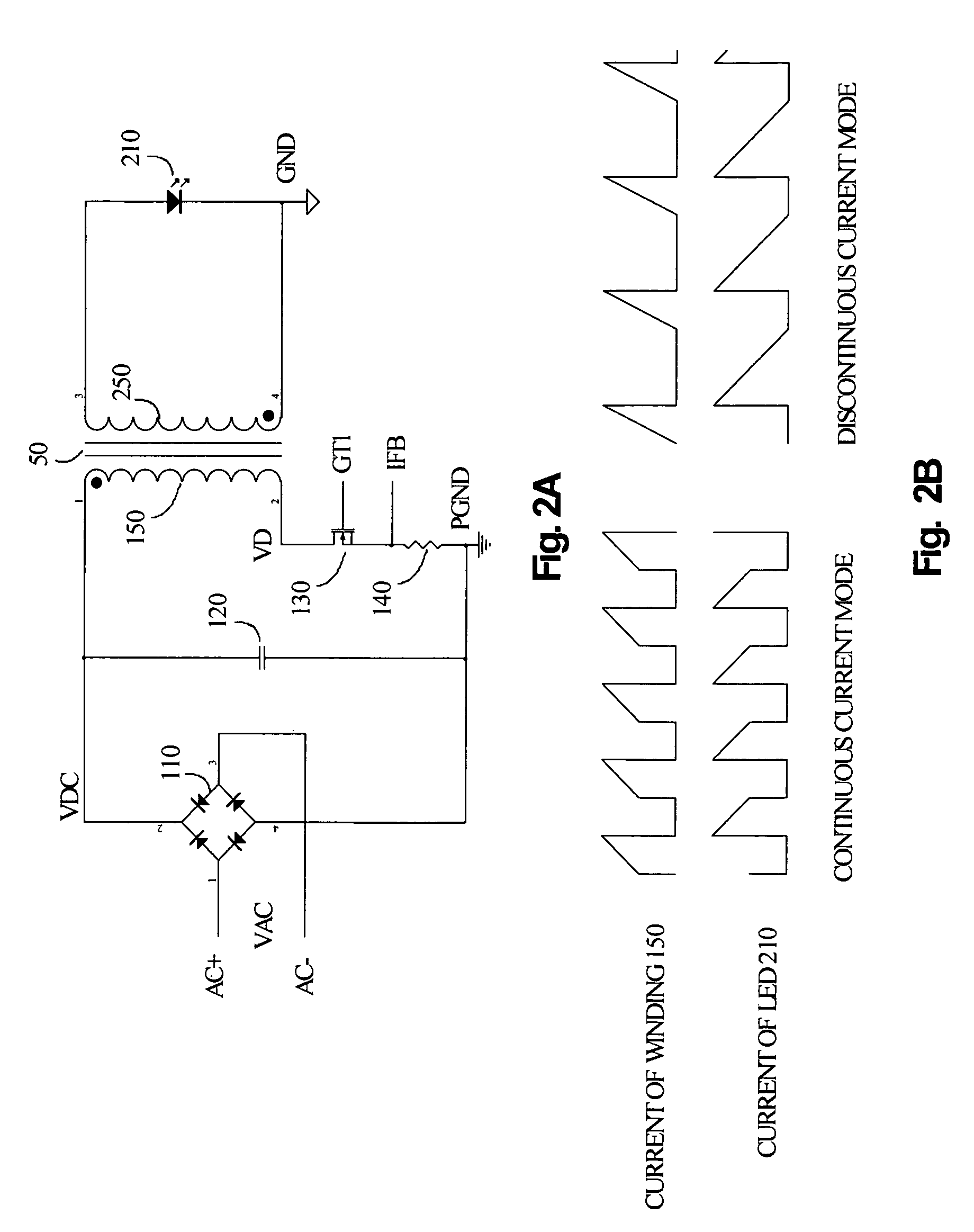

Method and appratus of driving LED and OLED devices

InactiveUS20100213857A1Suppress voltage stressImprove efficiencyElectrical apparatusStatic indicating devicesDc currentDimmer

A group of novel power conversion concept is developed with this invention for LED and OLED drive applications. The concept utilizes a single power conversion stage to fulfill multiple functions, including Power Factor Correction, DC voltage to DC current conversion, or DC voltage to DC voltage conversion etc. that are necessary for driving LED devices from an AC power input. Multiple dimming control schemes have also been developed to facilitate wide range of application requirements and enable the system to work with different input power format including AC mains power and variable AC voltage from the existing AC dimmer installations.

Owner:SUNTEC ENTERPRISES

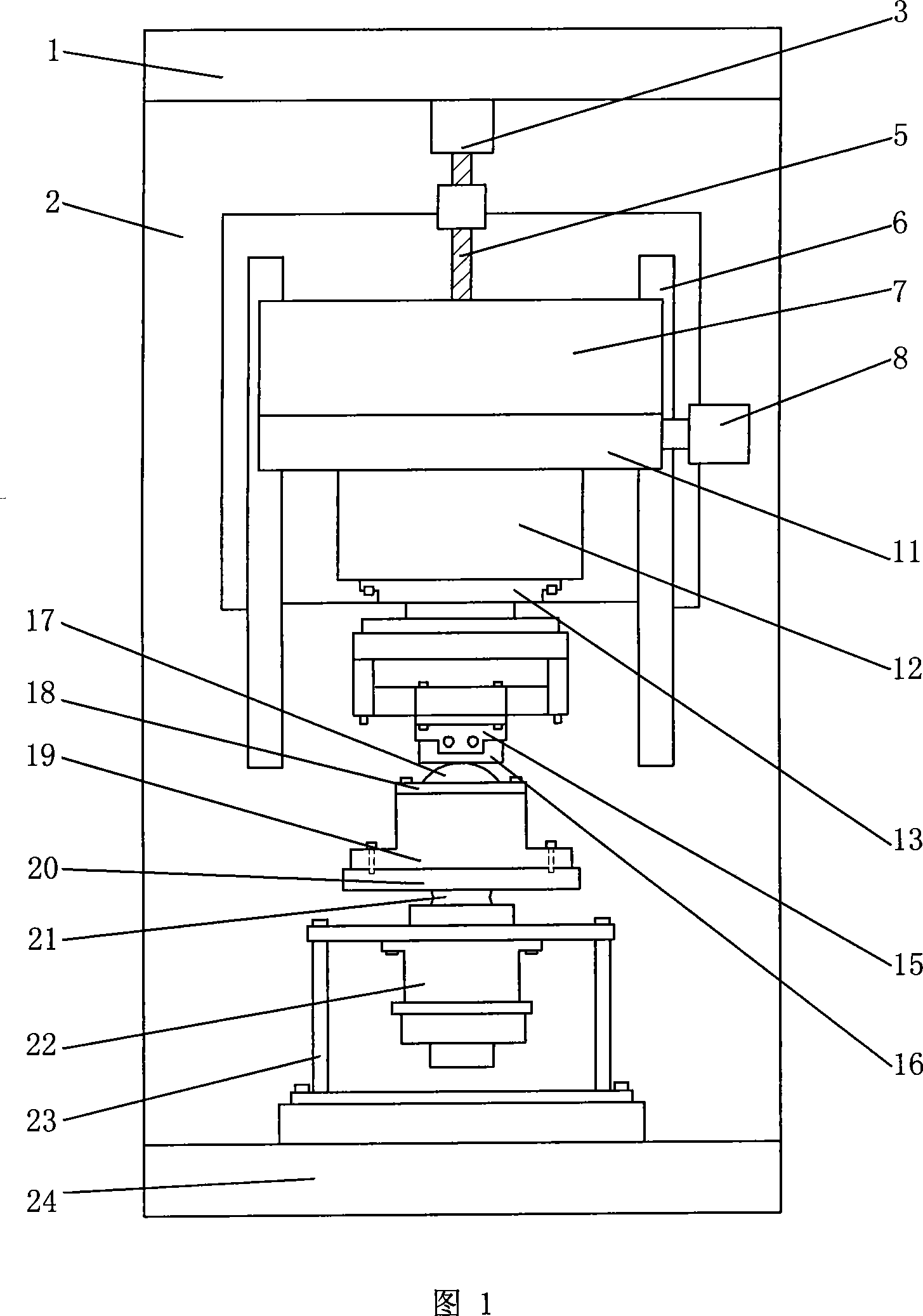

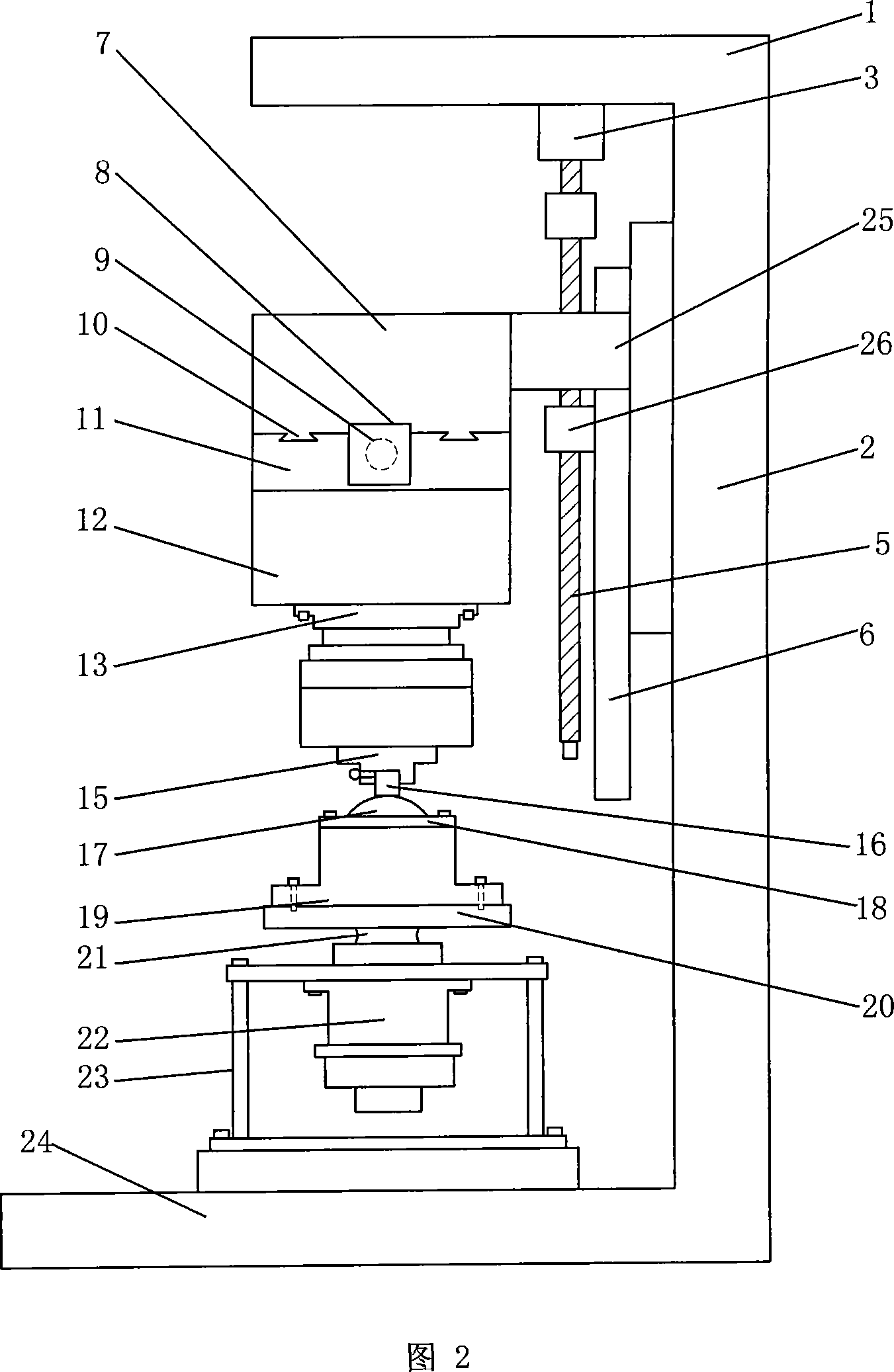

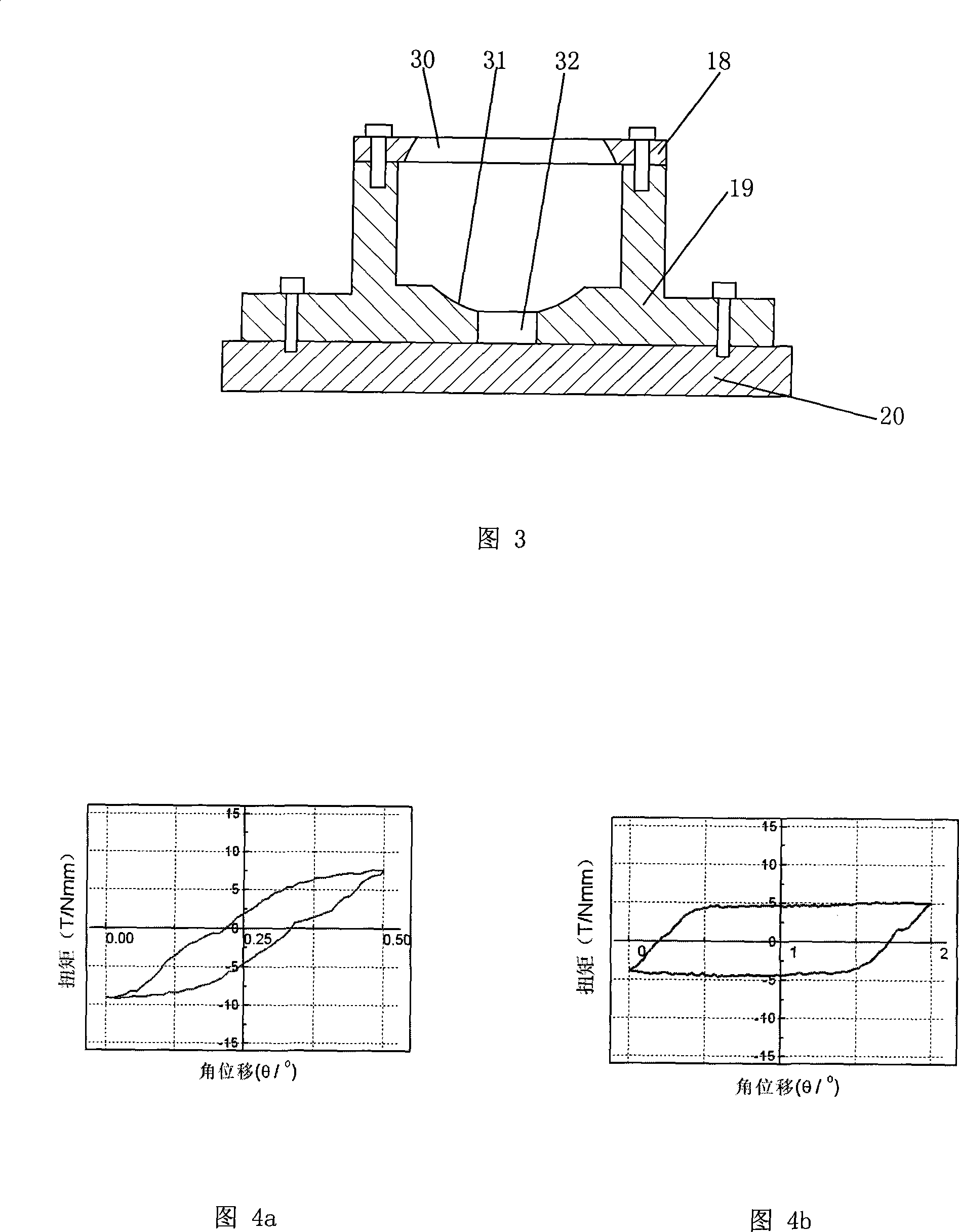

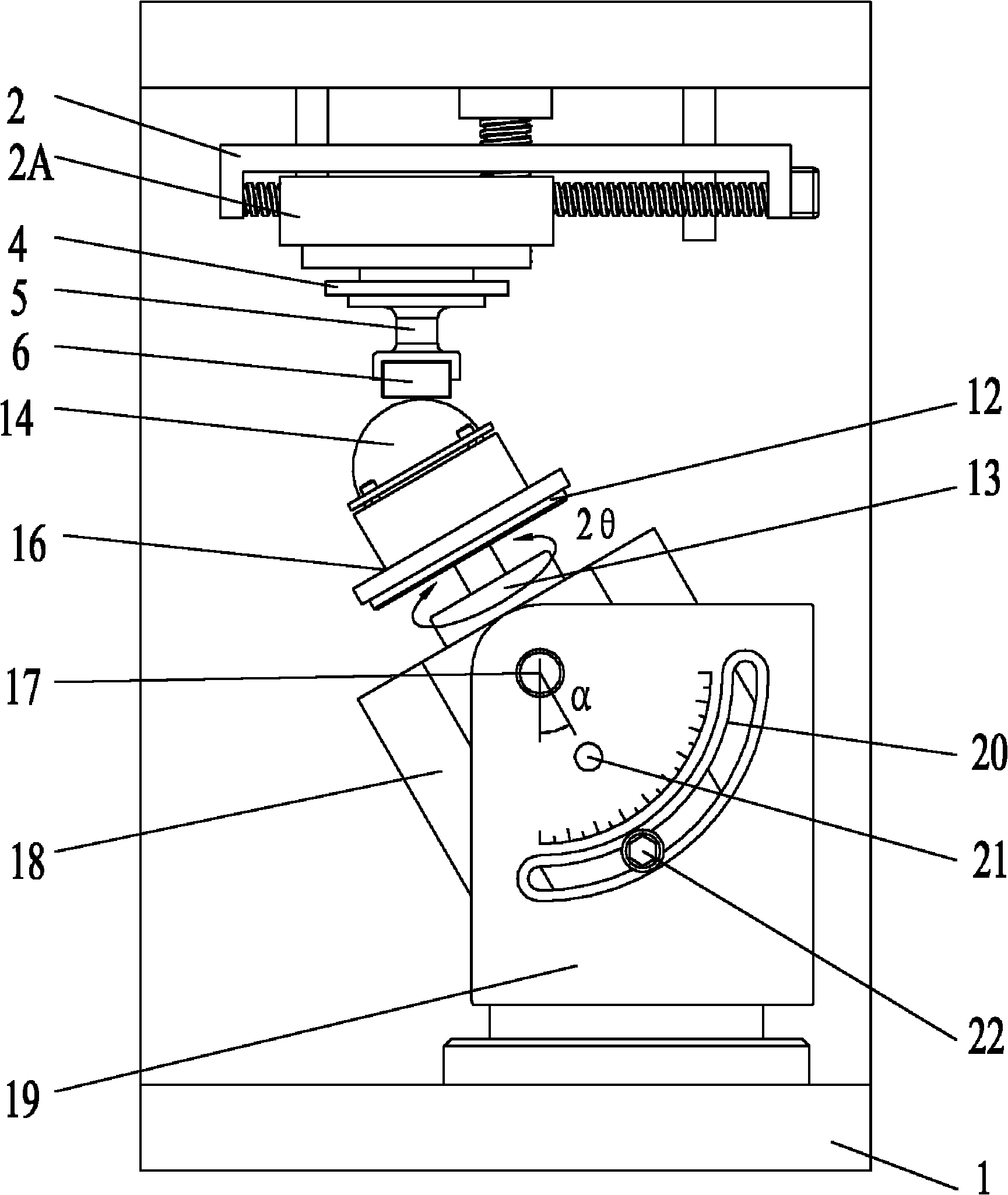

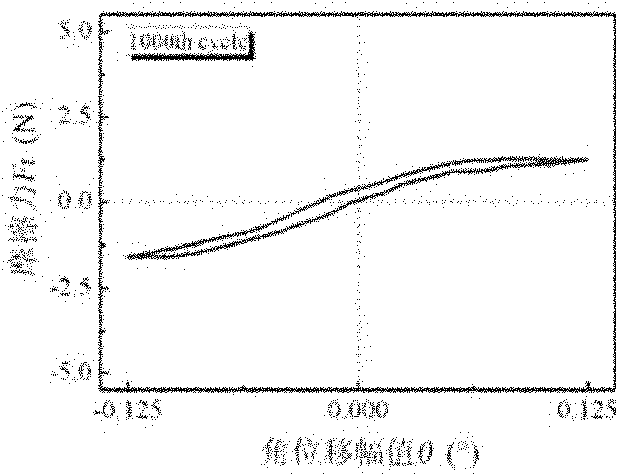

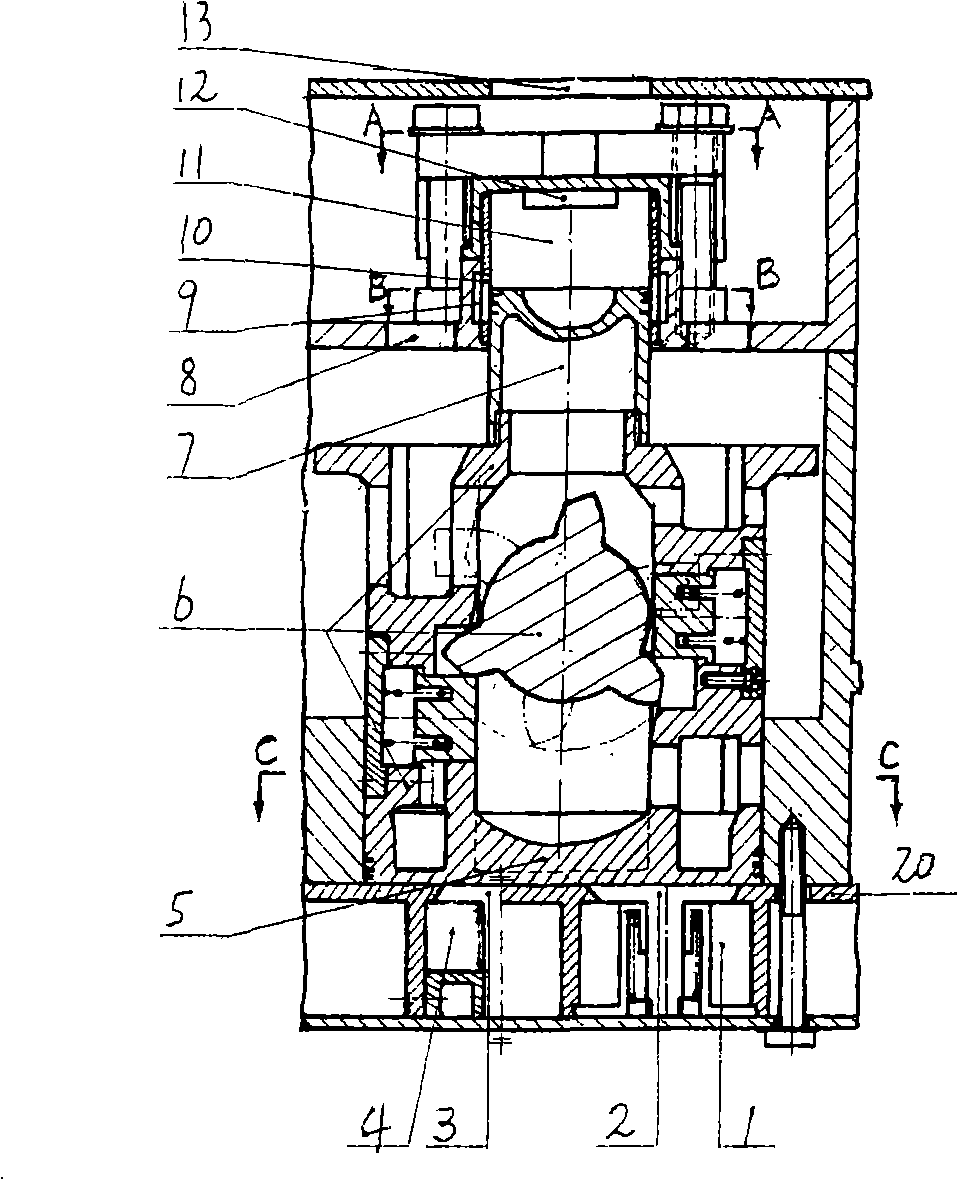

Twisting or micro-moving frictional wear test method and device thereof

InactiveCN101178345ANo wear and tearAccurately characterize kinetic propertiesStructural/machines measurementInvestigating abrasion/wear resistanceLow speedFriction torque

The invention relates to a torsional fretting friction wear test method, the method is that: an upper testing part is clamped in an upper clamp, a lower clamp is fixed with a high-precision low-speed rotation table by a thread, a vertical central line of a holding cavity of the lower clamp is aligned with a rotating shaft of the high-precision low-speed rotation table, a spherical lower testing part is clamped by the lower clamp; the upper clamp is controlled for up and down movements by a data collection control system, the upper and lower testing parts are contacted and are exerted by a set load, at the same time, the lower clamp and the lower testing part clamped by the lower clamp are controlled by the data collection control system to carry out a plurality of times of reciprocating rotations by a set rotation speed and a rotation angle; at the same time, the friction torque is measured by a six-dimension force / torque sensor which is connected with the upper clamp and is sent to the data collection control system, and a torque-angular displacement curve under the set rotation speed and the load conditions can be obtained by analysis. The method can conveniently allow the materials to generate the small angle torsional fretting friction wear, the degree of the automation is high, the precision of the control and the test is high and the reproducibility of the test data is good.

Owner:SOUTHWEST JIAOTONG UNIV

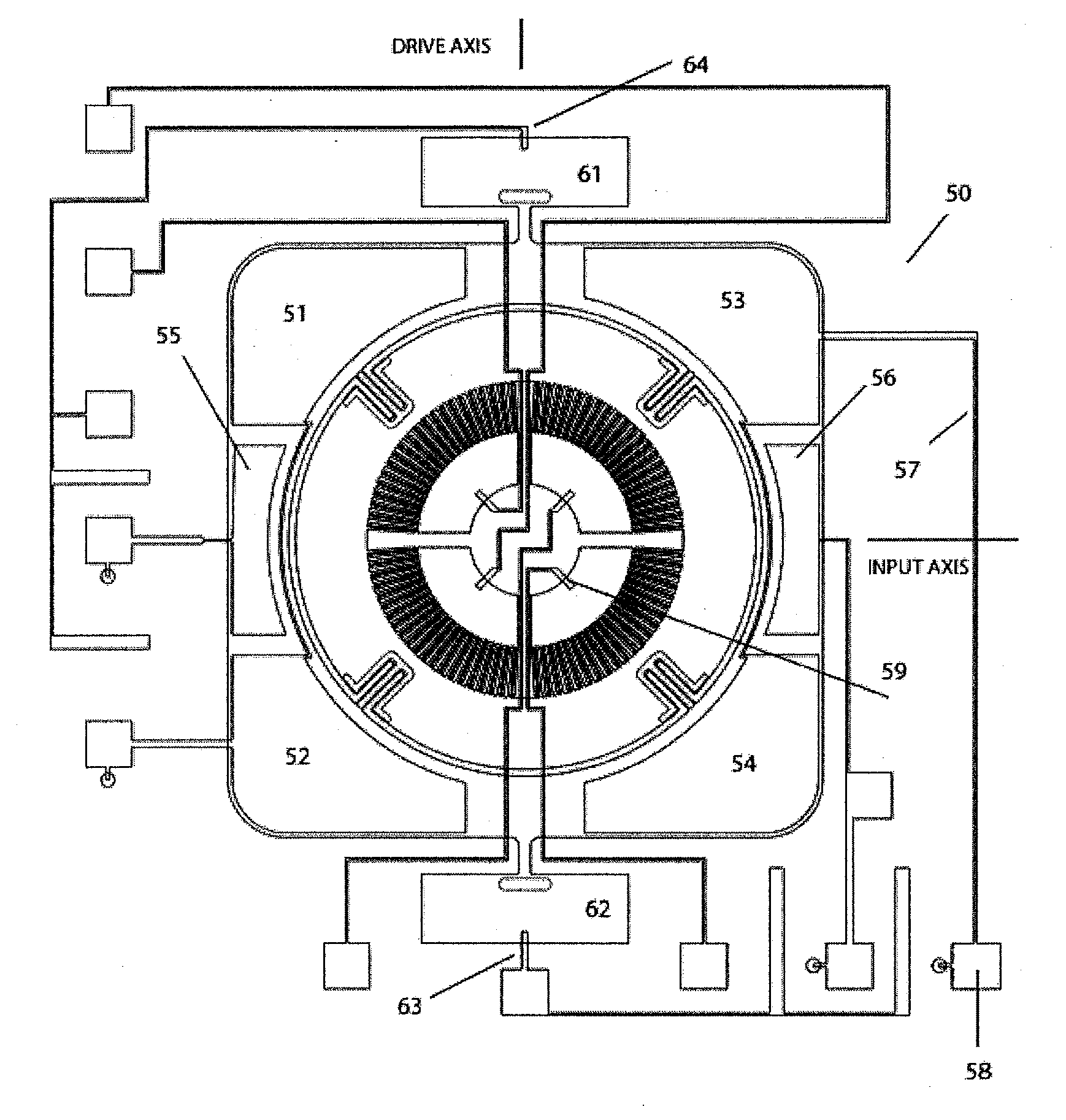

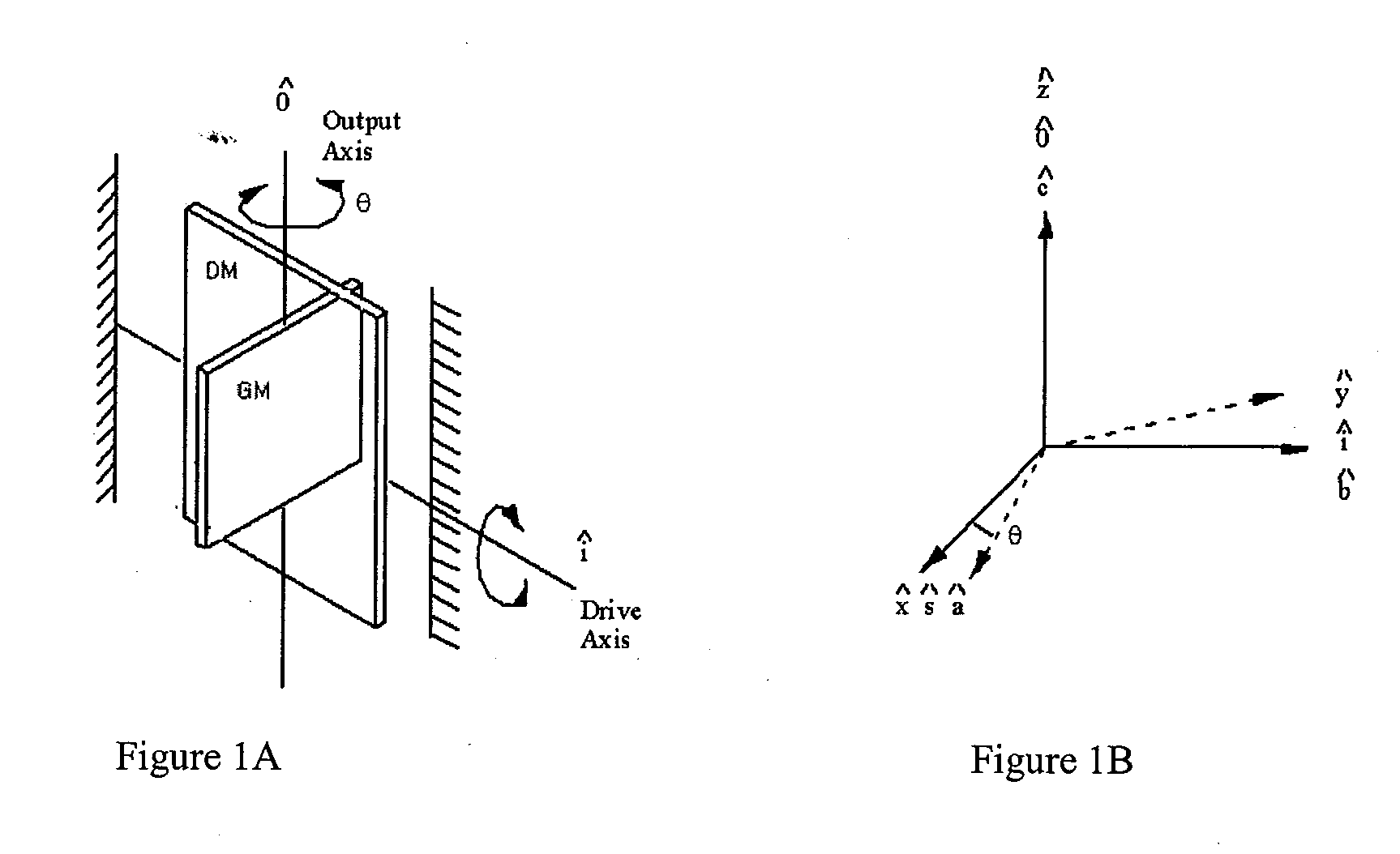

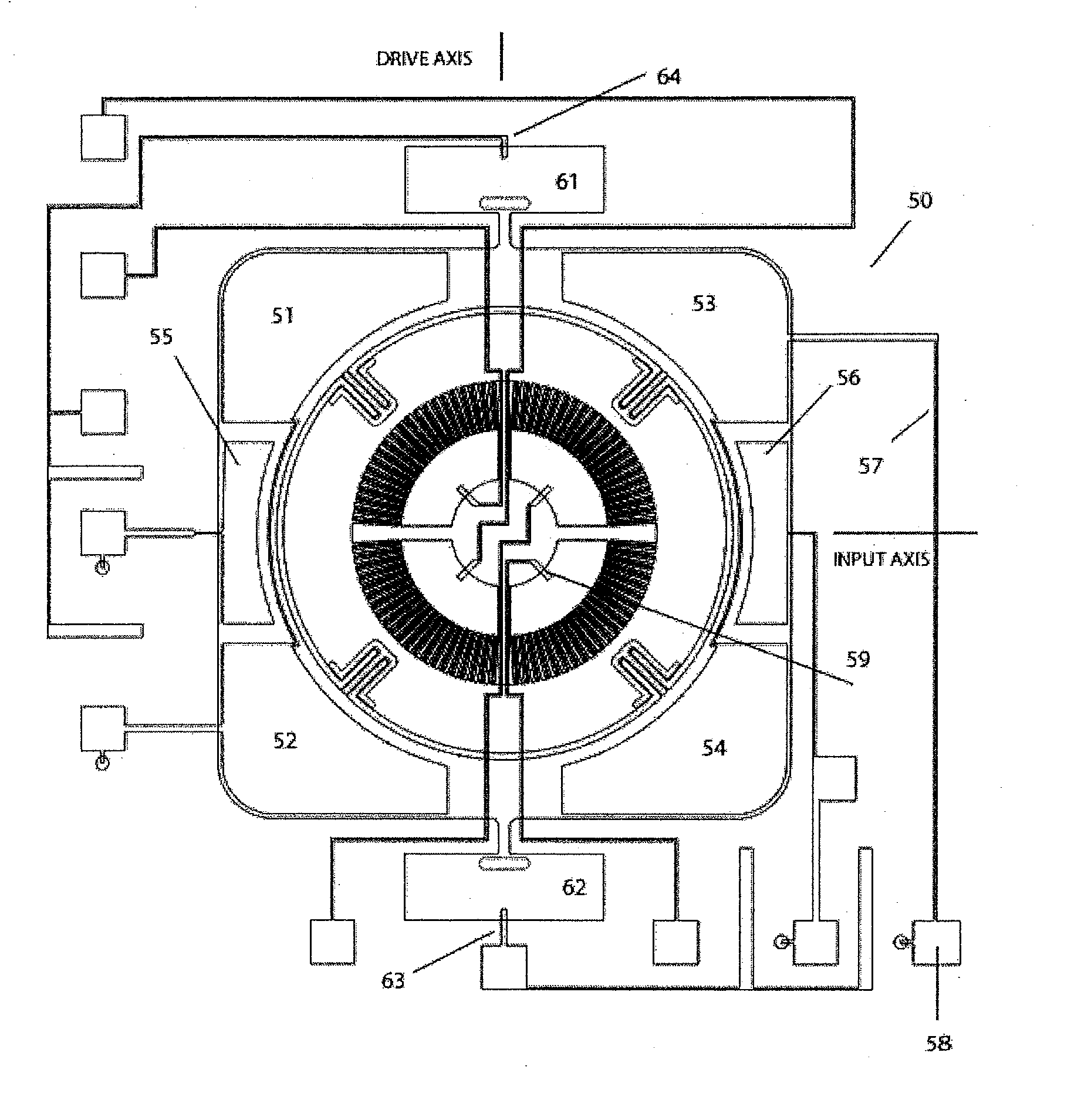

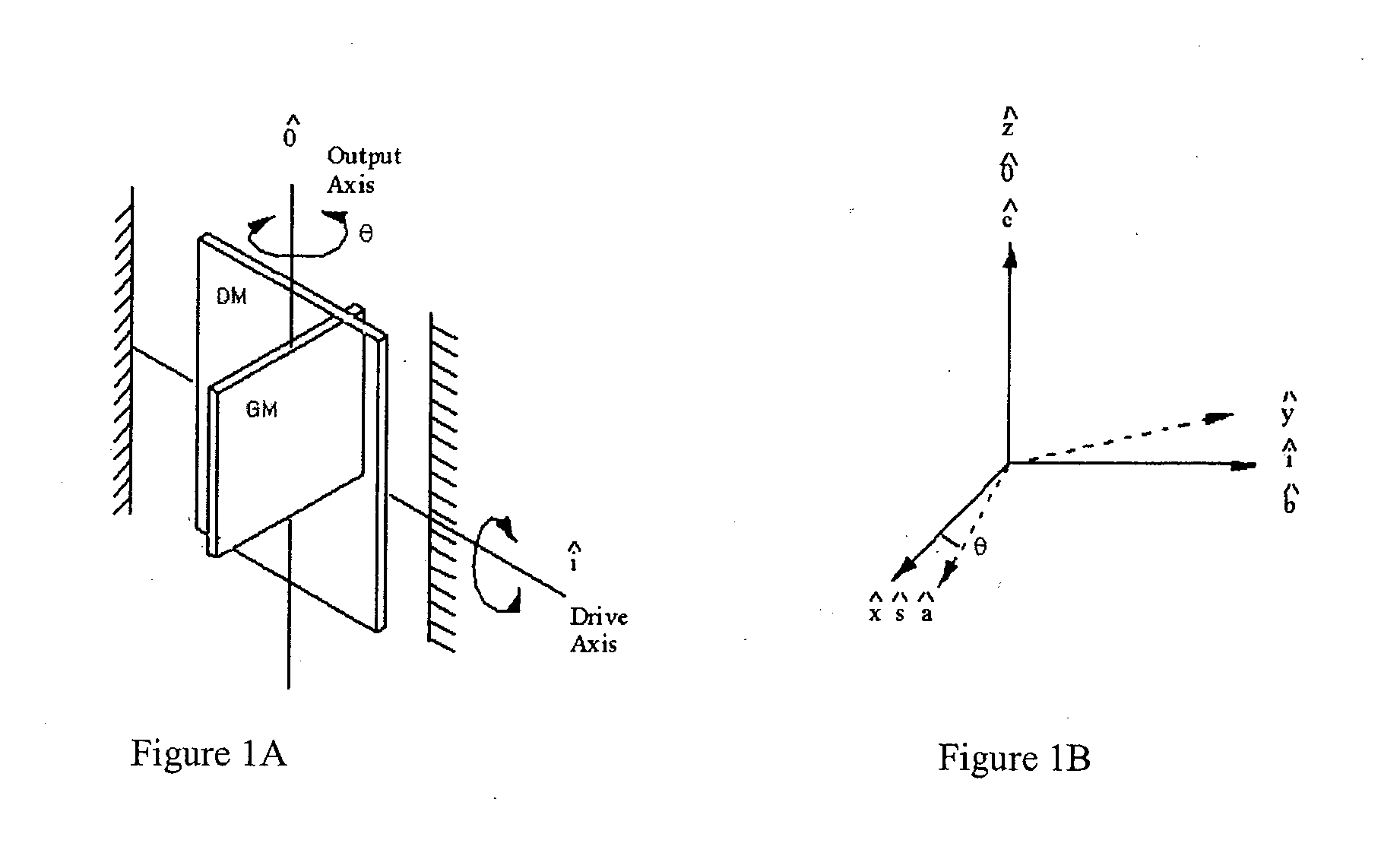

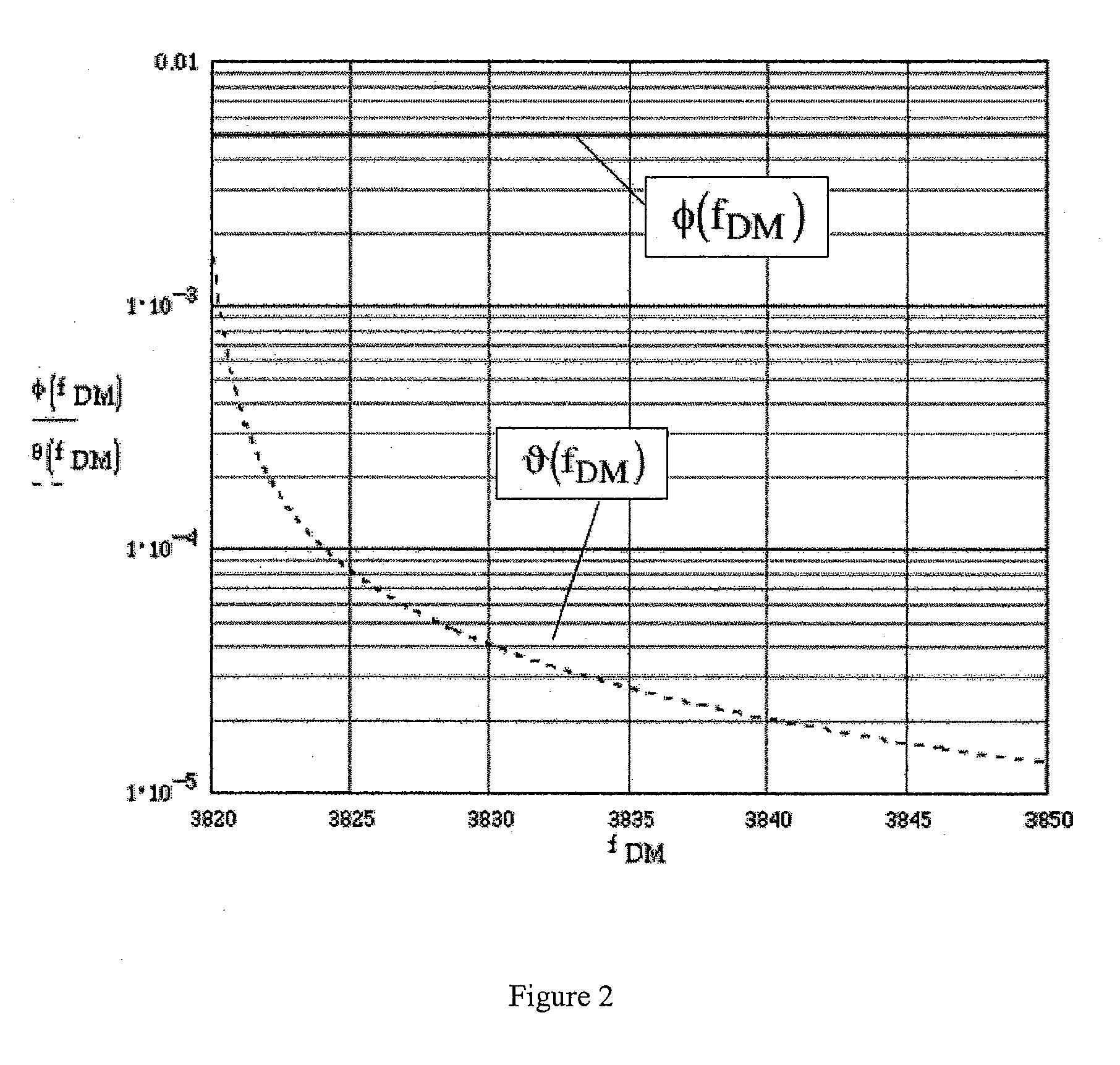

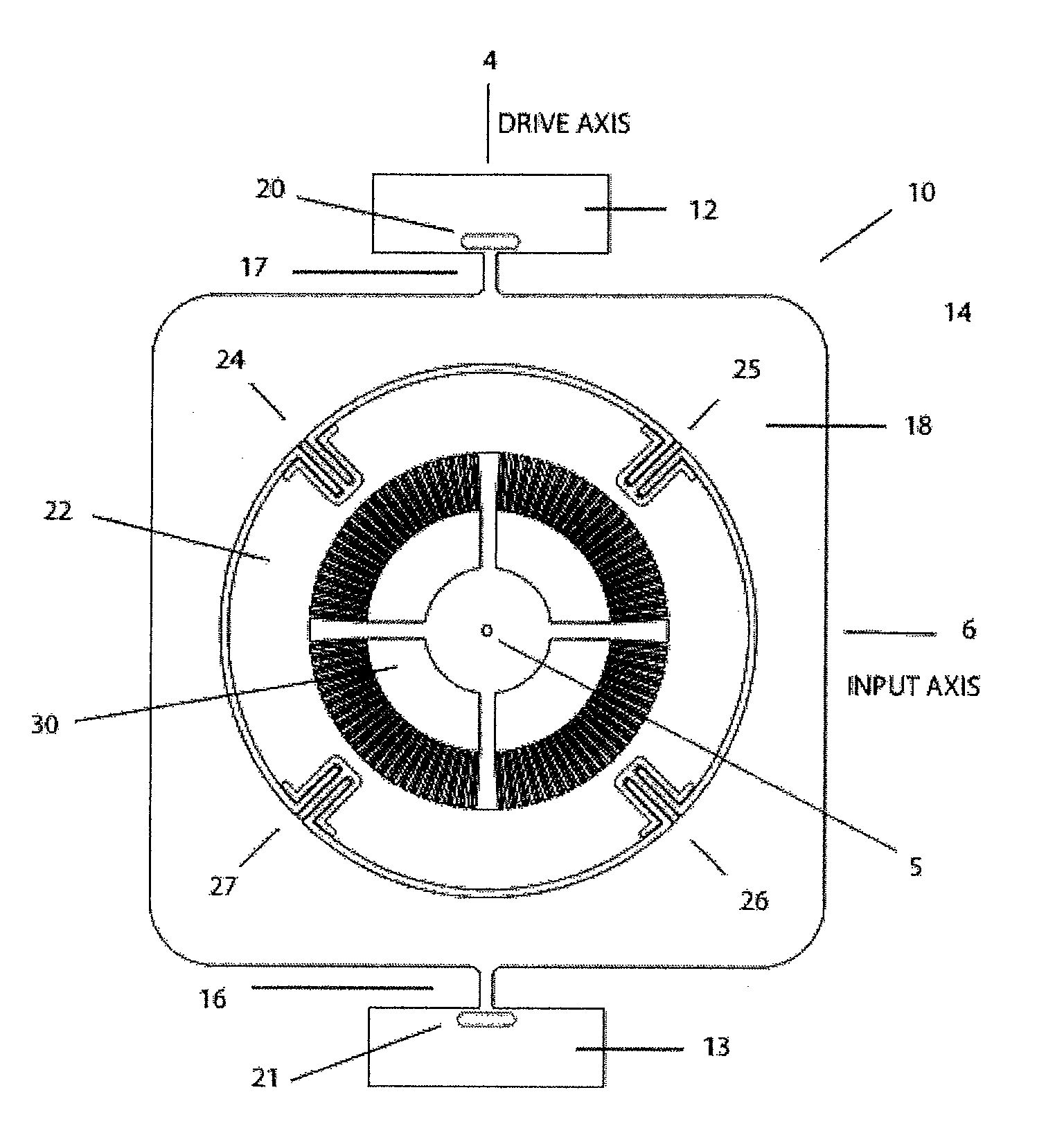

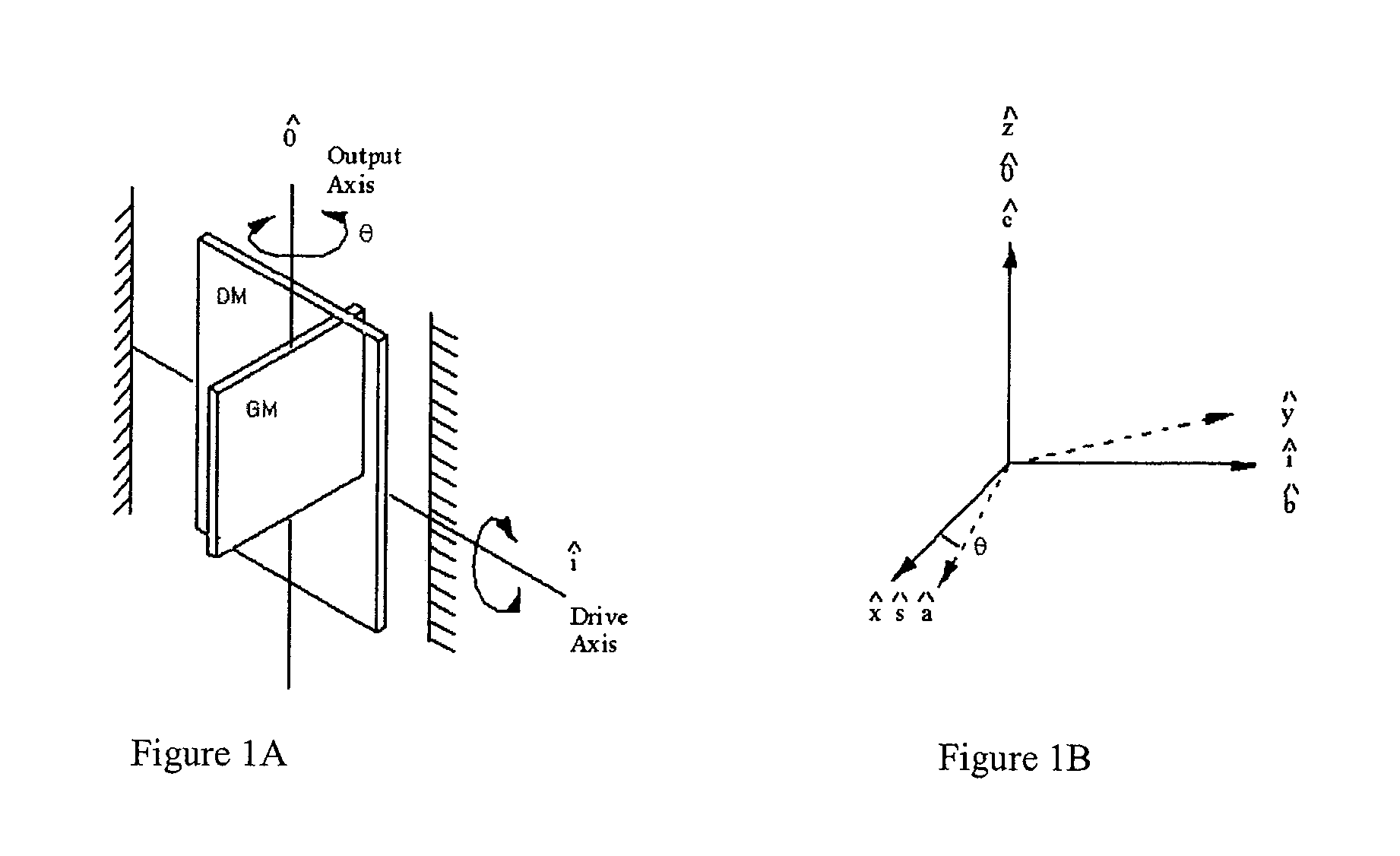

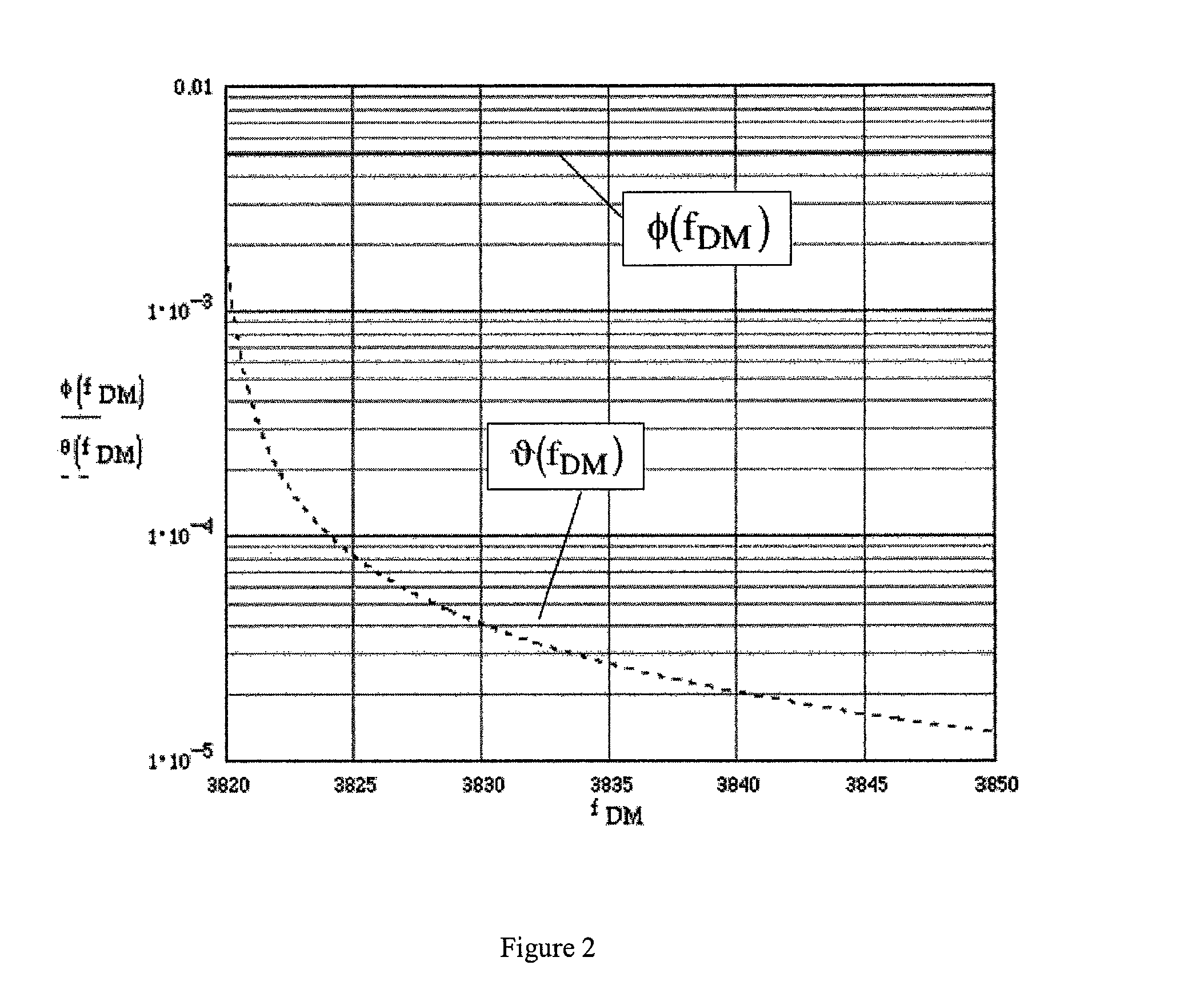

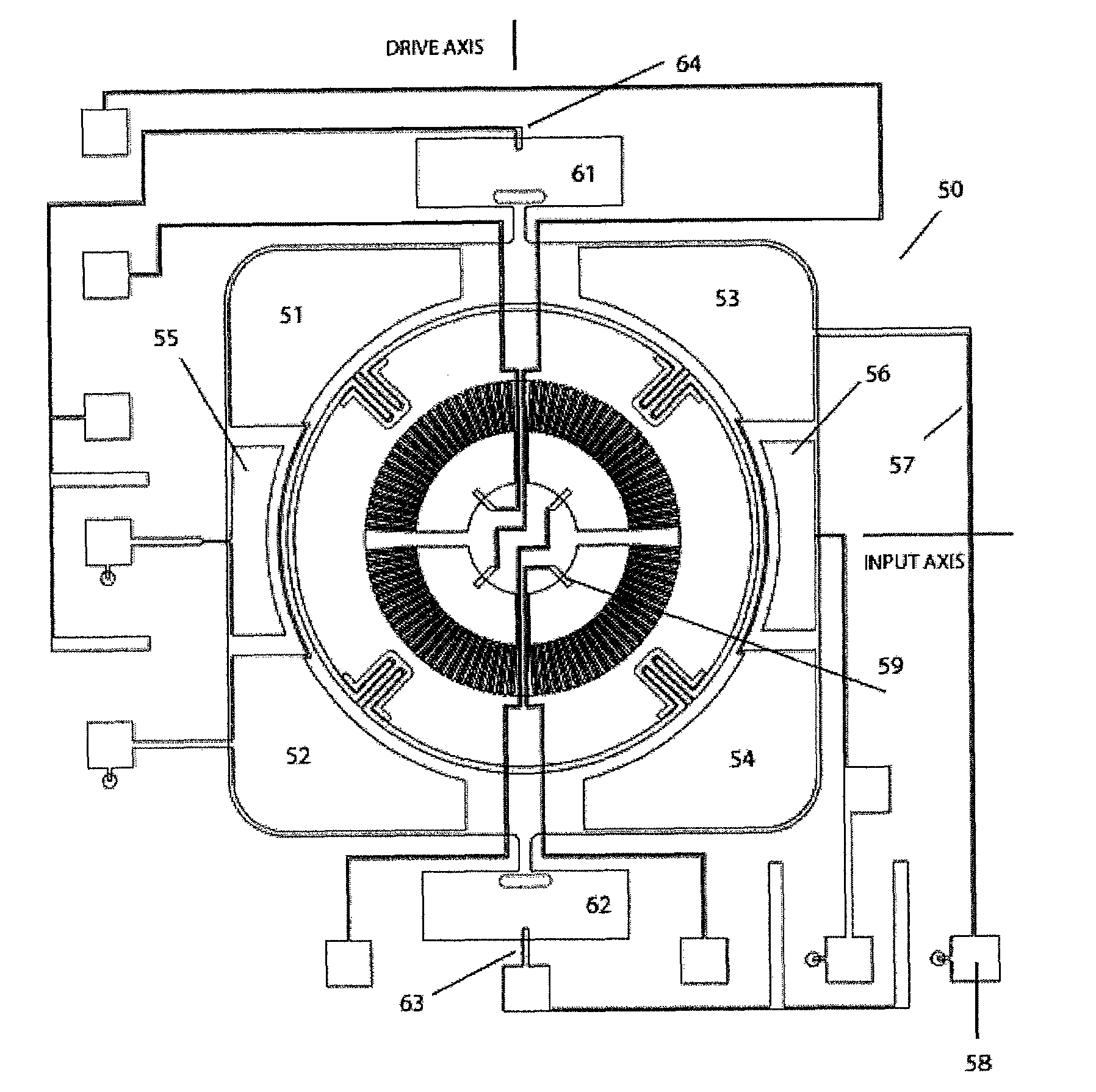

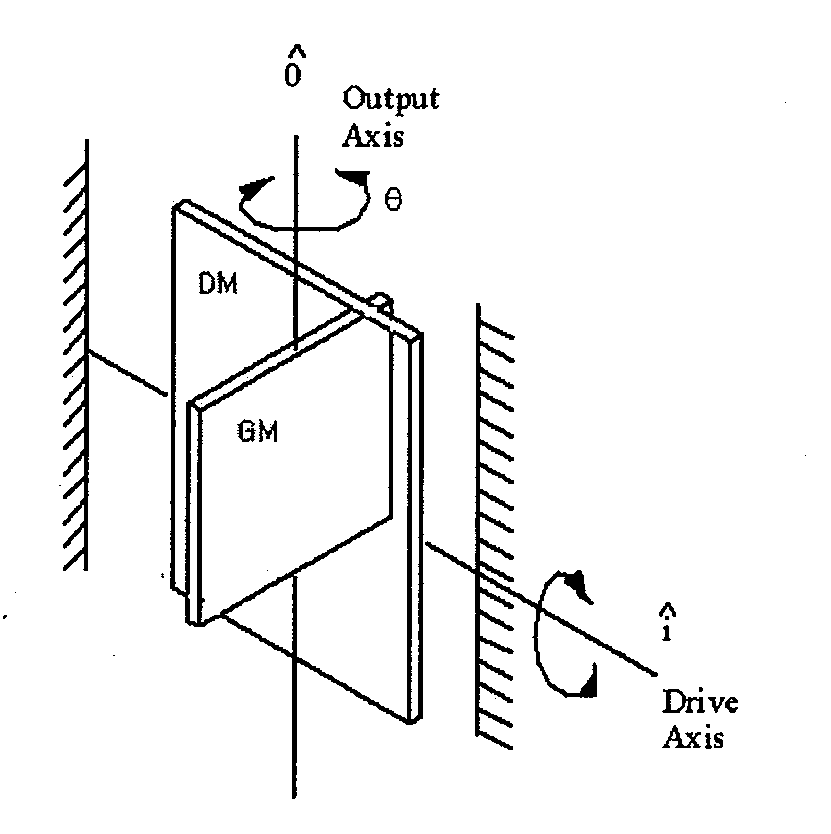

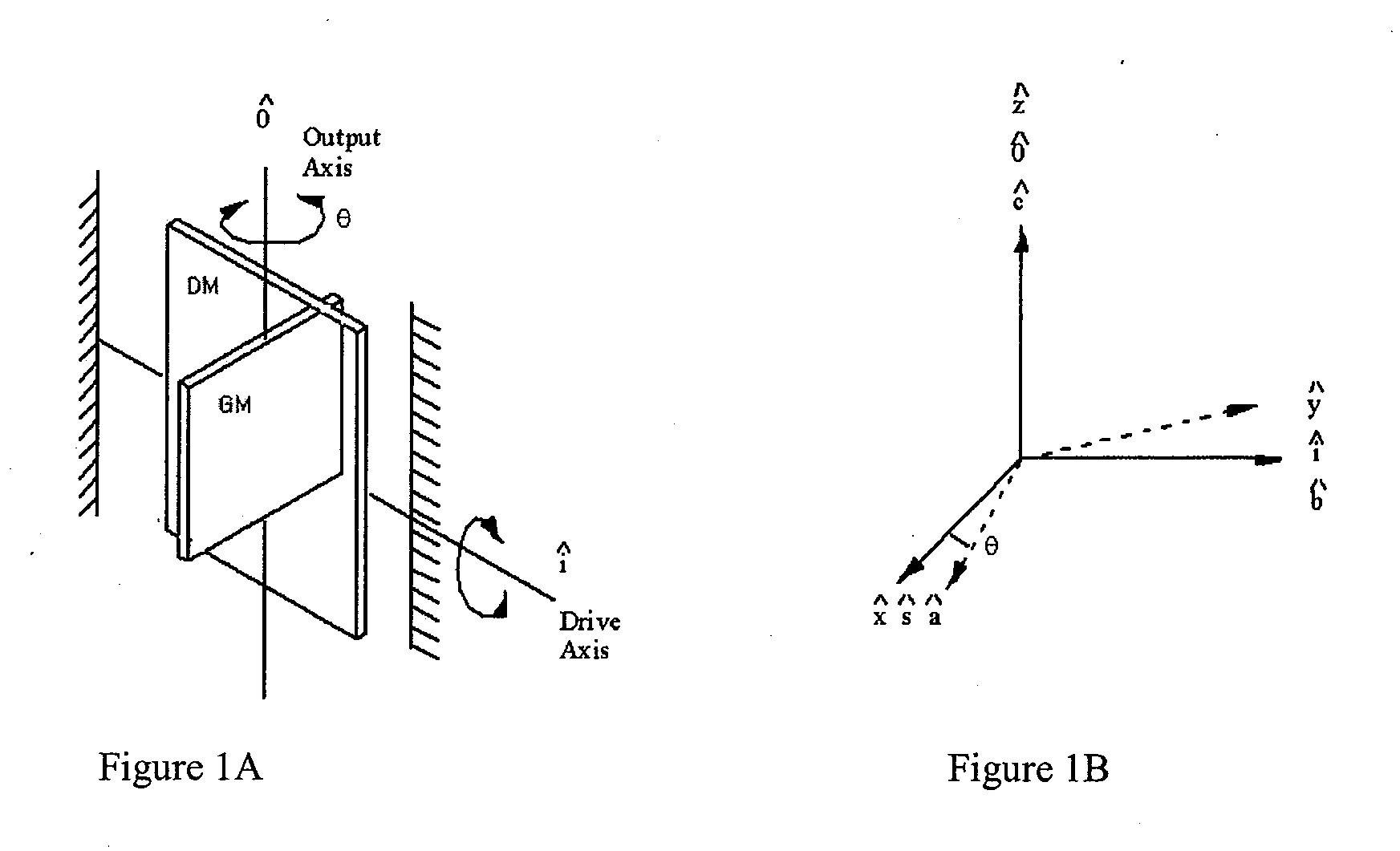

Scale Factor Measurement For Mems Gyroscopes And Accelerometers

InactiveUS20100024548A1Reduce sensitivityError minimizationAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGyroscopeAccelerometer

An inertial instrument such as an accelerometer or gyroscope having scale factor functionality, and that lies generally in a plane. The gyro detects rotation rate about a gyro input axis. The gyroscope has a substrate, a generally planar scale factor gimbal flexibly coupled to the substrate such that it is capable of oscillatory motion about the input axis, a generally planar support member coplanar with and flexibly coupled to the scale factor gimbal such that the support member is capable of oscillatory motion about a drive axis that is orthogonal to the input axis, and a generally planar gyro member coplanar with and flexibly coupled to the support member such that it is capable of rotary oscillatory motion relative to the support member about an output axis that is orthogonal to the plane of the members. There are one or more first drives for oscillating the support member about the drive axis, and one or more second drives for oscillating the scale factor gimbal about the input axis. One or more gyro output sensors that detect oscillation of the gyro member about an output axis that is orthogonal to both the input axis and the drive axis.

Owner:MILLI SENSOR & ACTUATOR SYST

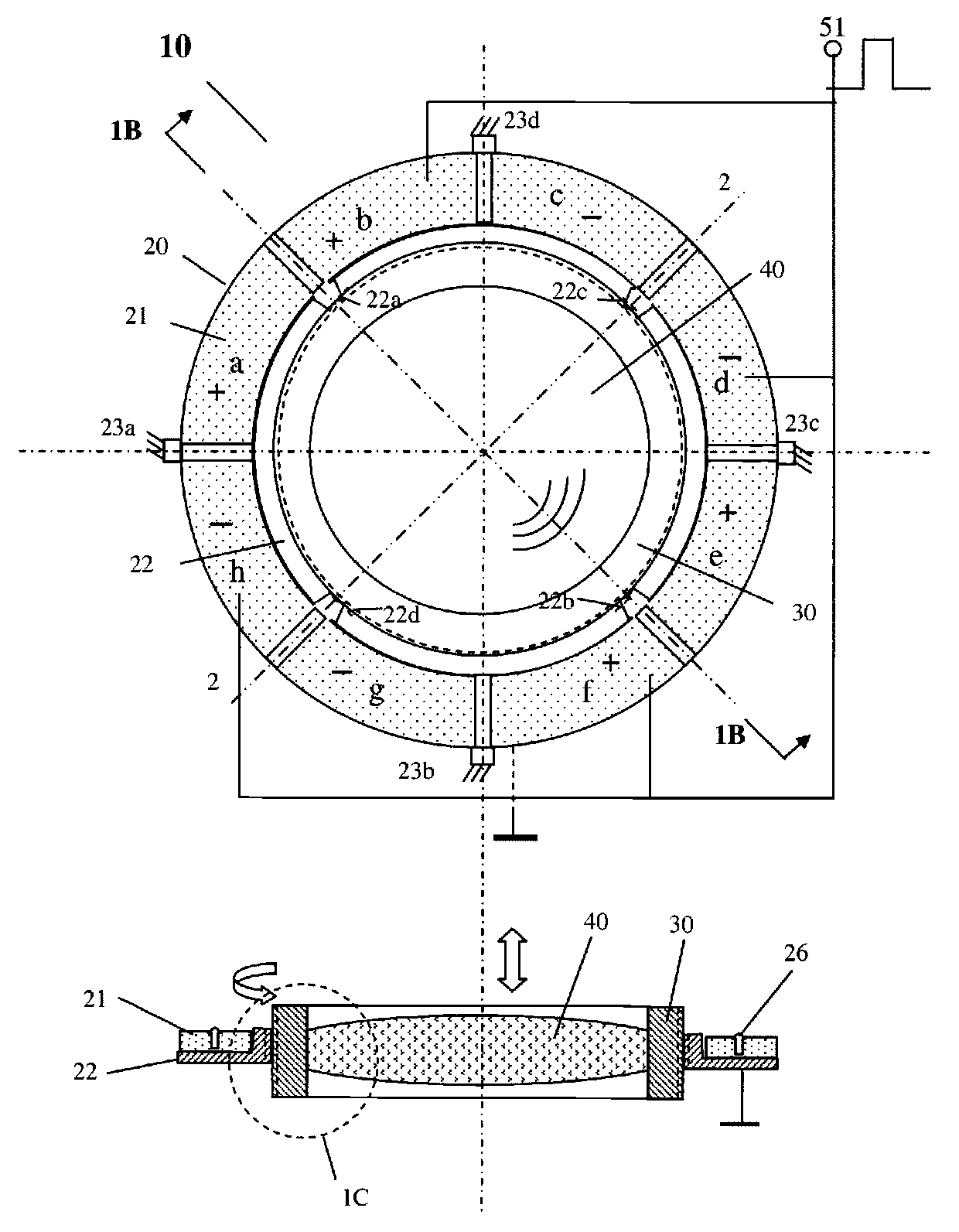

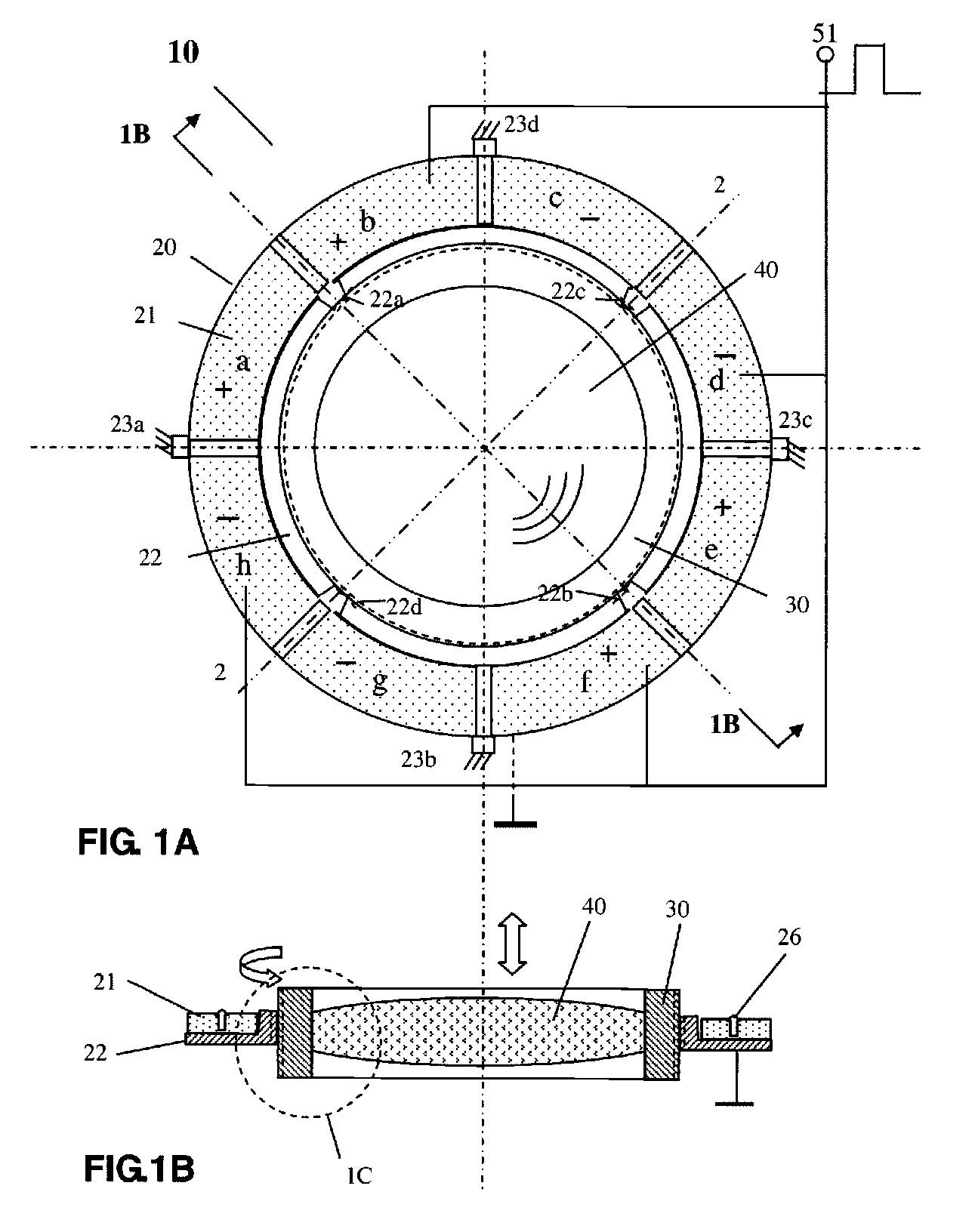

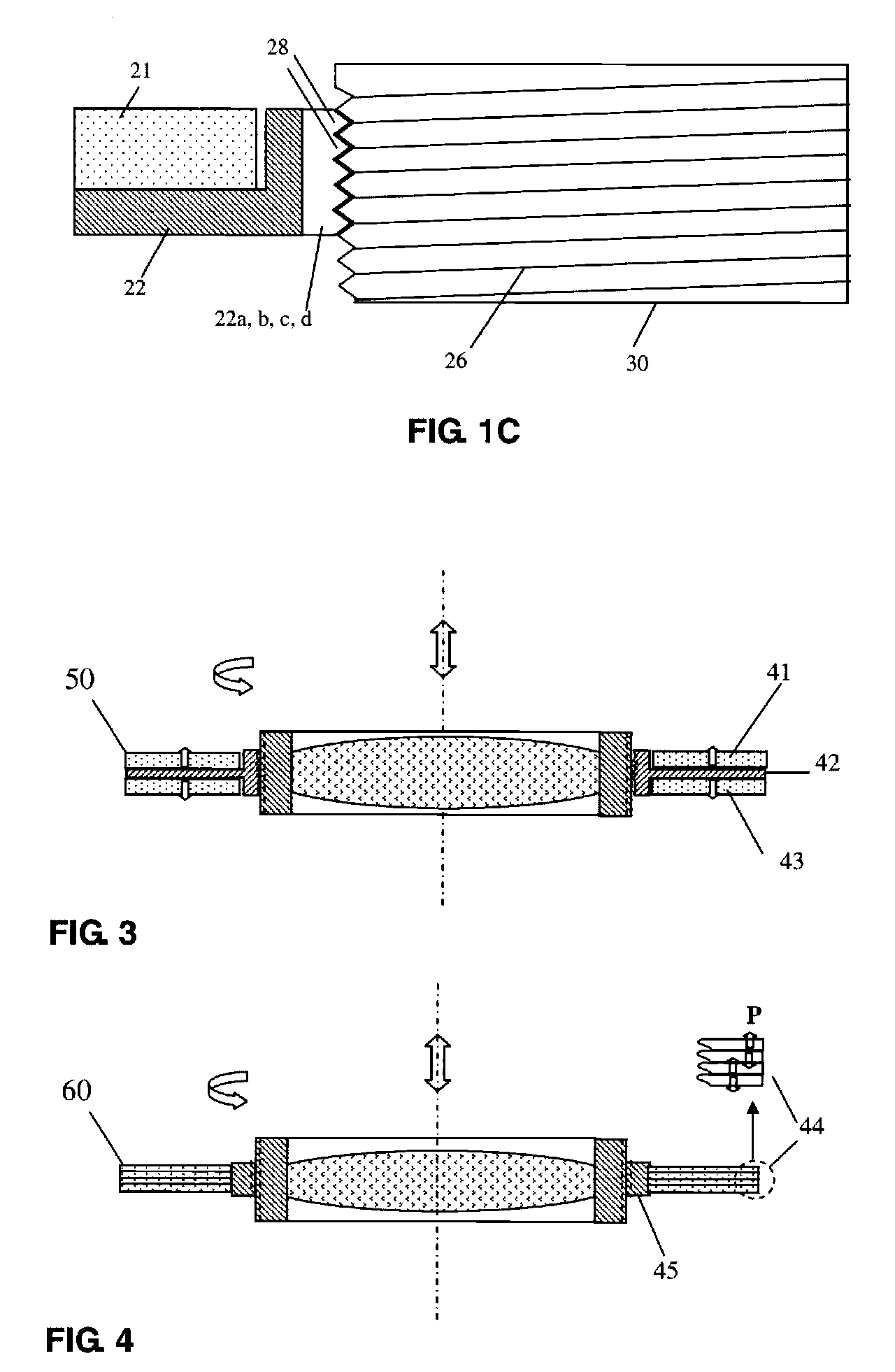

Miniature Piezoelectric Motor and Method of Driving Elements Using Same

InactiveUS20080247059A1Reduce module sizeImprove efficiencyPiezoelectric/electrostriction/magnetostriction machinesMountingsElectricityLinear motion

The present invention provides a piezoelectric ultrasonic motors and a method of driving a motor with a standing wave. The motors include a thin ring / cylinder-type stator having one or two piezoelectric (ceramic or single crystal) rings / cylinders, coated with a segmented top / outer electrode and a bottom / inner electrode and poled in a thickness / radial direction, a metal ring / cylinder which is laminated with piezoelectric ring(s) / cylinder(s) having several inner threaded protrusions. The motor also includes a power source for supplying an alternating voltage to one group of electrodes of the piezoelectric stator to excite a standing wave vibration along one diameter direction of the stator ring / cylinder. The motor further includes a short cylinder rotor, which may have a lens inside for certain optical applications, or it may include other elements. The rotor is attached to the stator at the threaded surface of the protrusions and is driven to produce a circular motion, which may also be translated into a linear motion by the threaded surface through standing wave deformation at protrusions. Reverse motion of the rotor can be realized by applying the alternating voltage to another group of electrodes of the stator.

Owner:DONG SHUXIANG

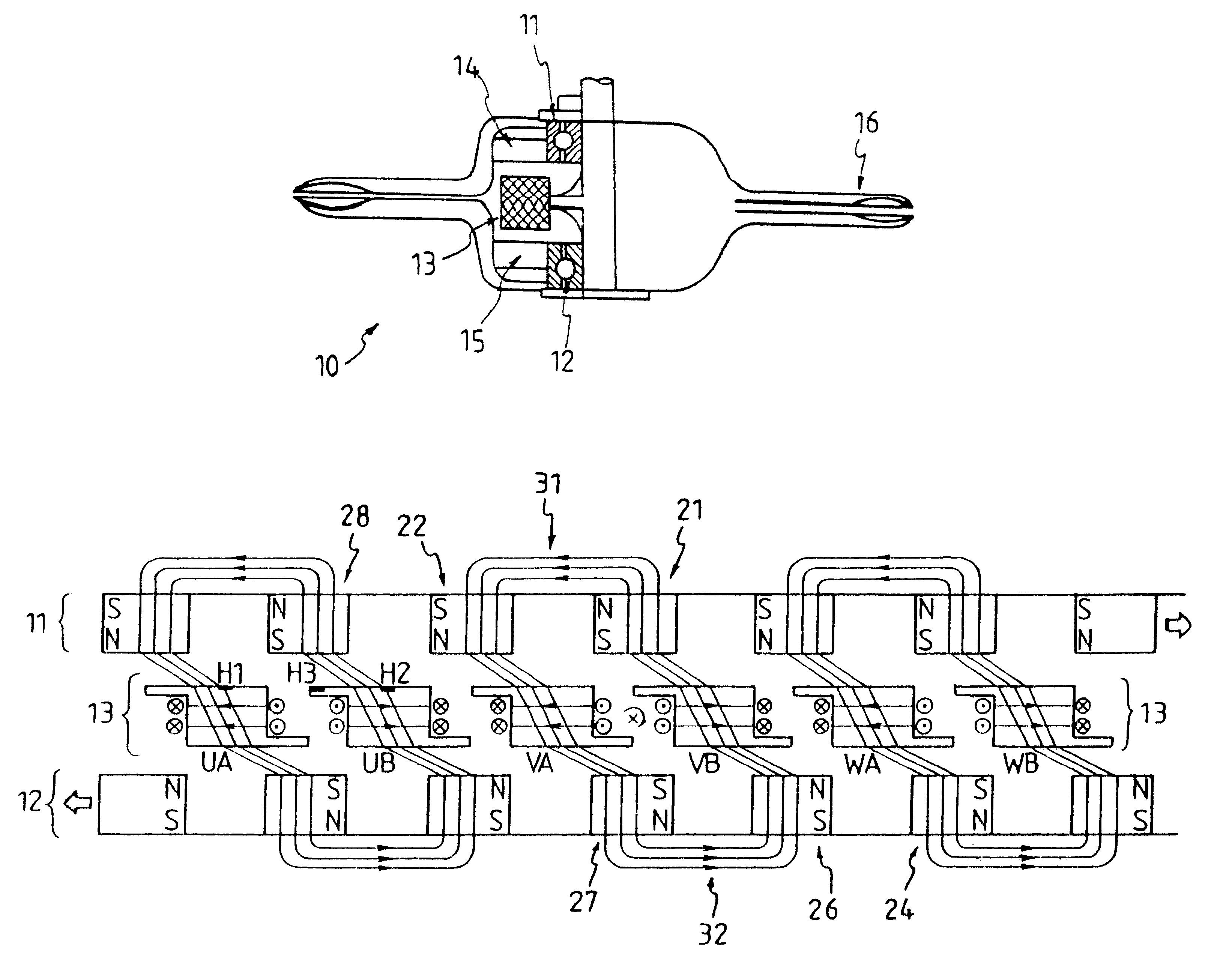

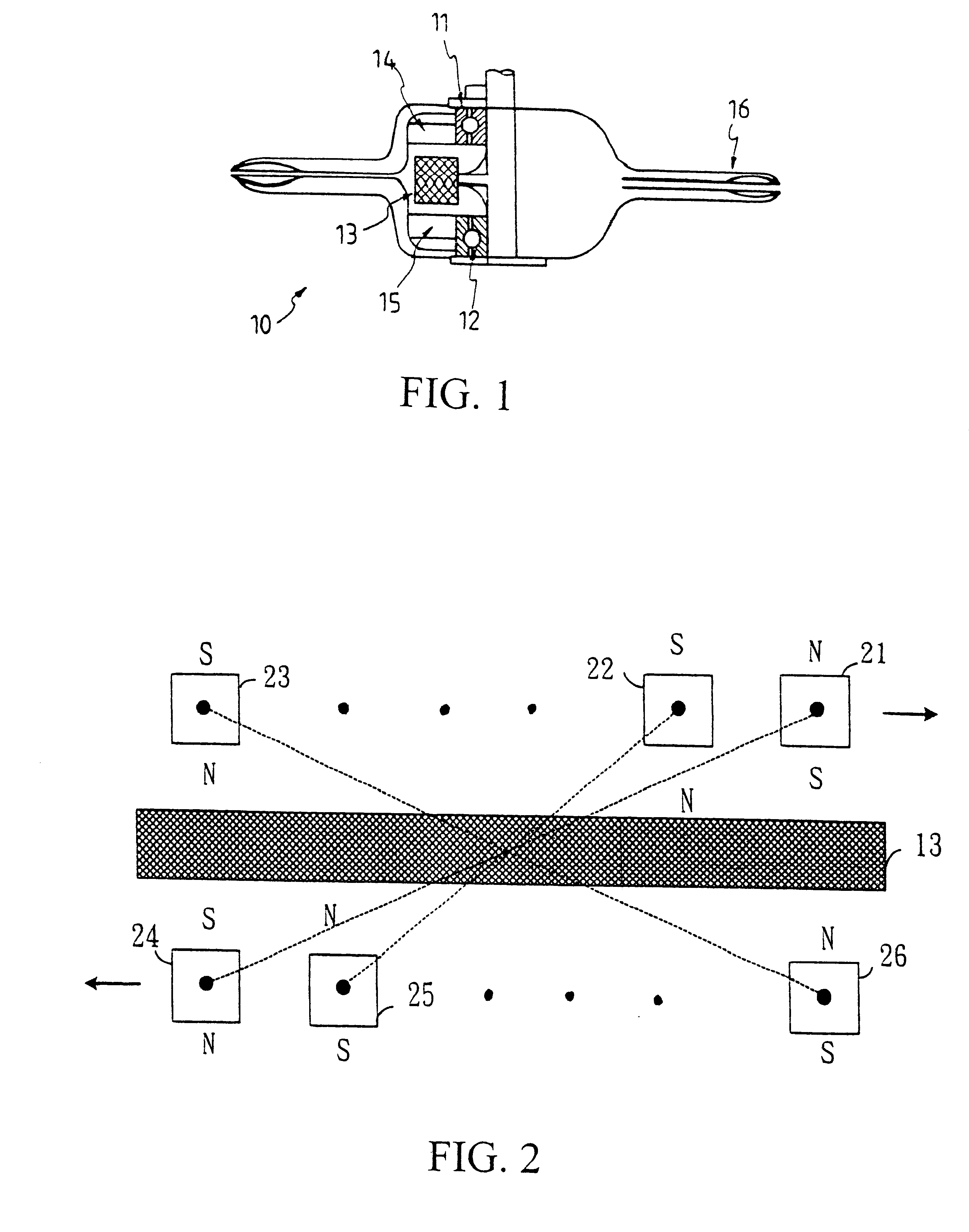

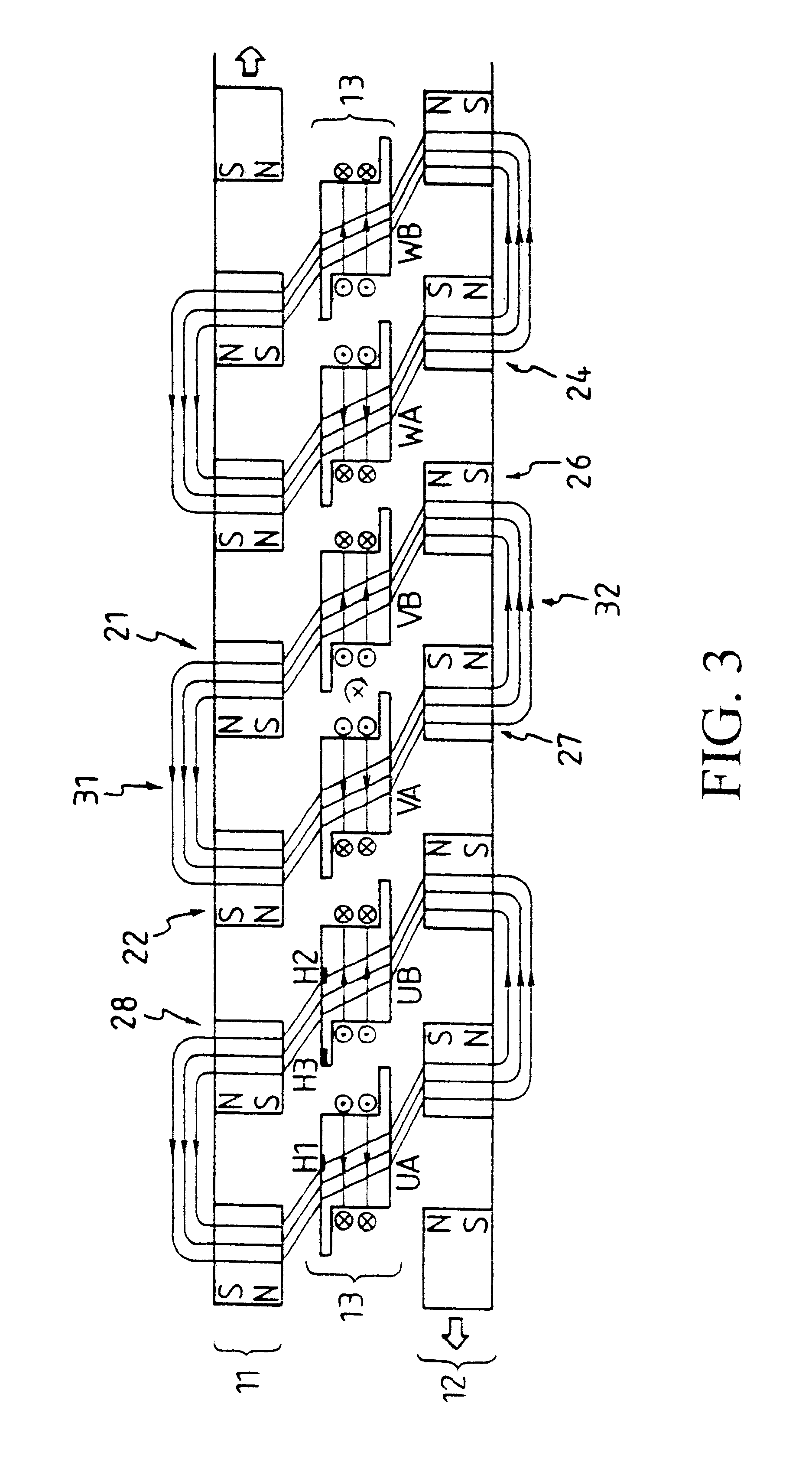

Multiple layer double rotor single stator skew symmetry permanent magnet rotating motor

InactiveUS6455969B1Simple structureHigh-efficient powerMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic polesRotation cycle

A single-stator-double-rotor rotating motor has one upper-layer rotor, one intermediate-layer armature and one lower-layer rotor. The upper-layer rotor and lower-layer rotor are embedded with the same number of magnets to form a magneto type magnetic pole, stator electrodes of the same number as the number of magnets are disposed on the intermediate-layer armature to form an electro type magnetic pole. A skew symmetry exists between an upper-layer rotor and a corresponding lower-layer rotor, and the upper-layer rotor and the lower-layer rotor are rotated in opposite directions by commutation of the current flowing through exciting coils of the stator electrodes every T / N of time, wherein T is a rotation period of the upper-layer rotor, and N is the number of the magnets.

Owner:NAT CHUNG SHAN INST SCI & TECH

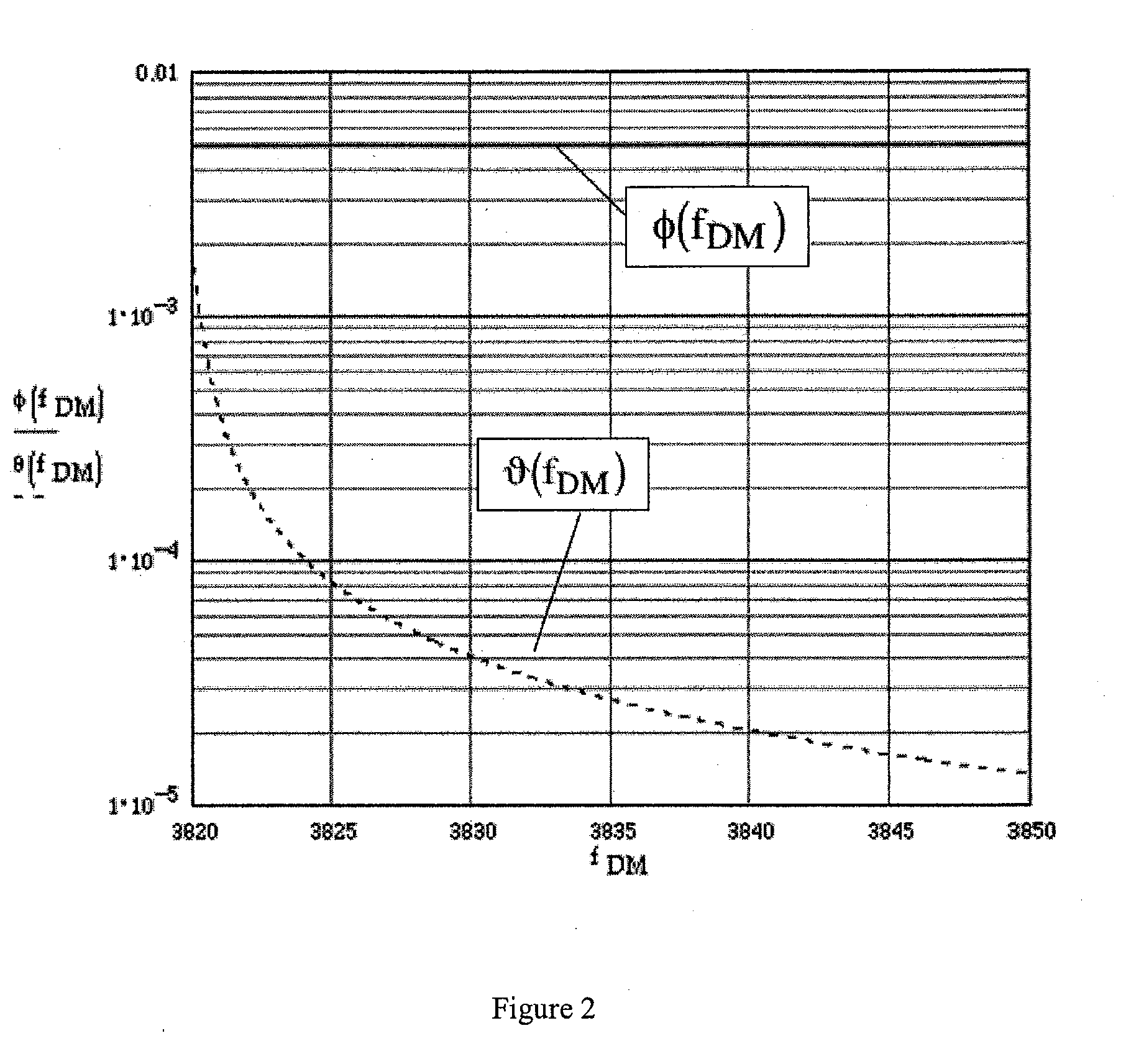

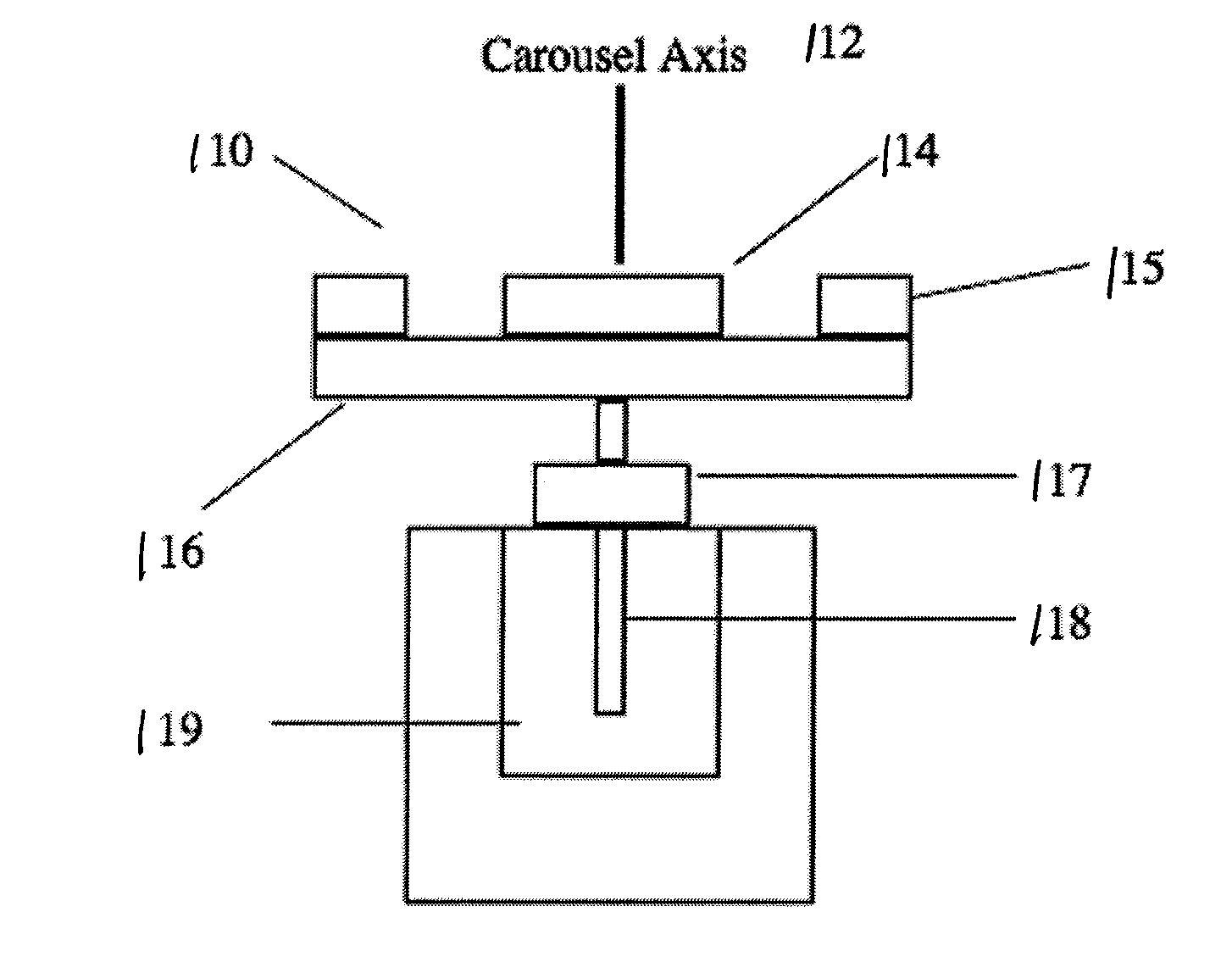

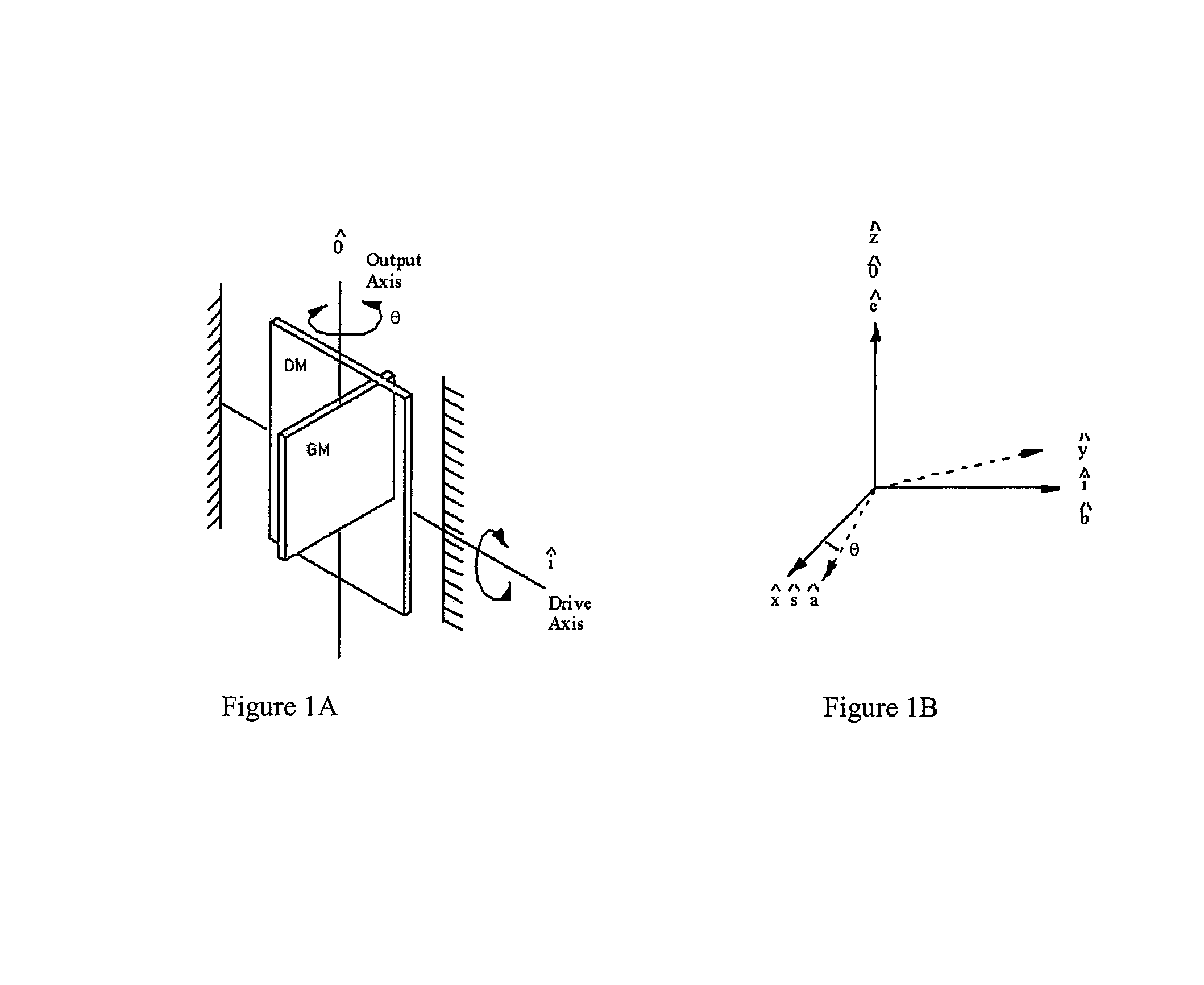

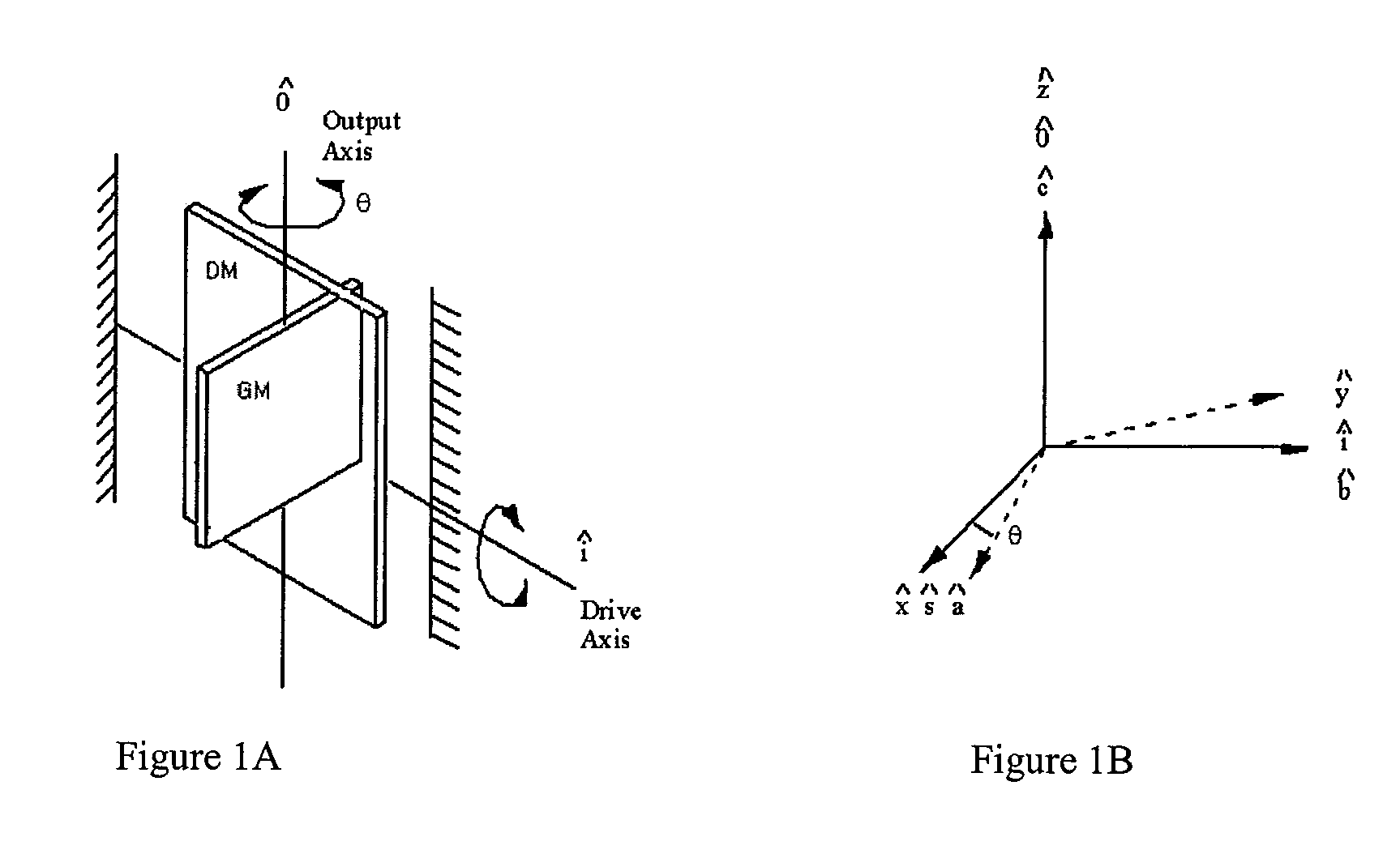

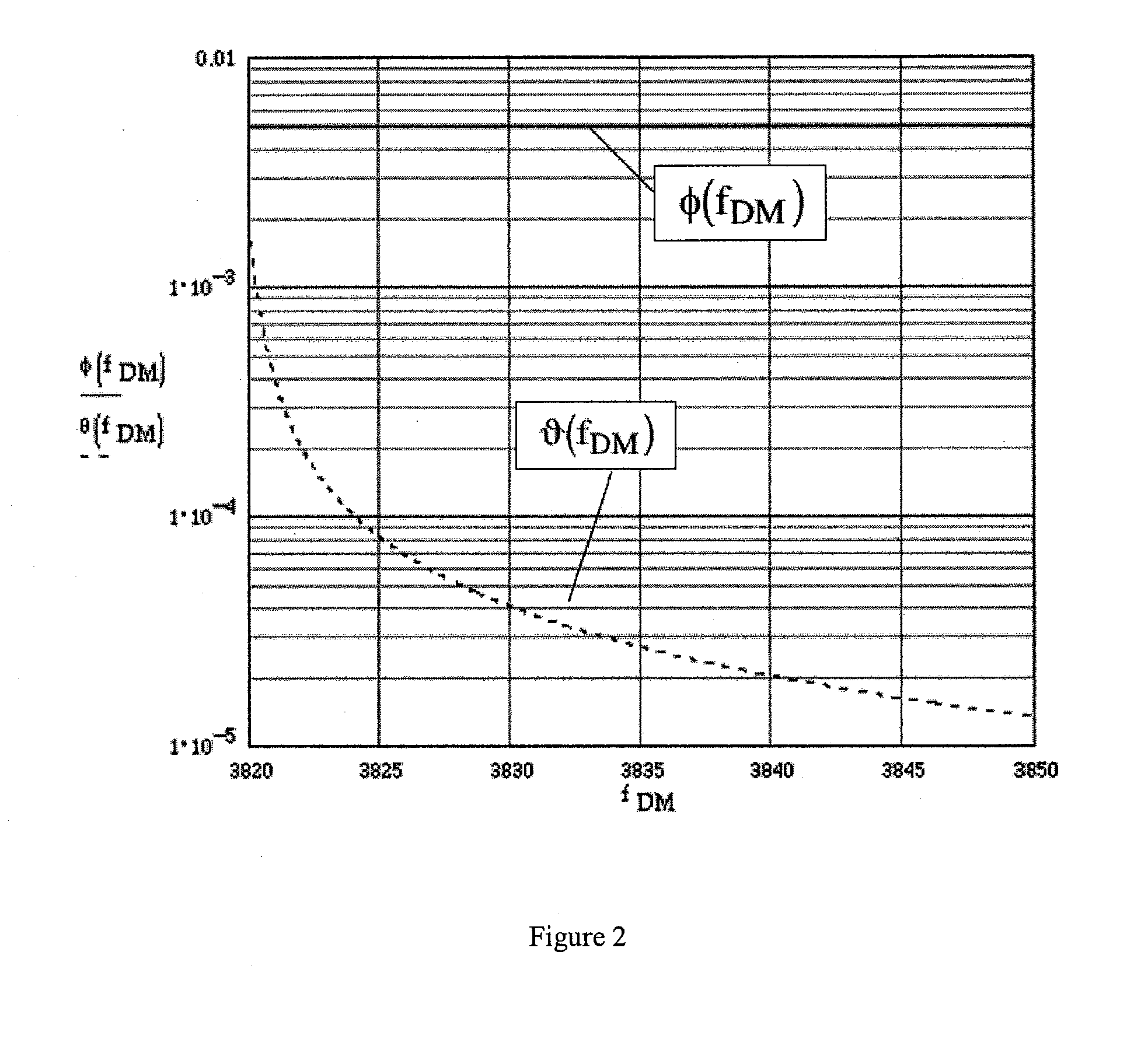

Small Angle Bias Measurement Mechanism For MEMS Instruments

InactiveUS20070245826A1Eliminate bias driftReduce sensitivityAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsInstabilityEngineering

A system and method for separating bias instability of MEMS inertial instruments such as gyroscopes or accelerometers from the instrument signal, in which the inertial measurement instrument has an input axis and an output signal, and the bias instability has a frequency. The instrument is oscillated about an oscillation axis that is orthogonal to the input axis, at a frequency that is greater than the bias instability frequency. The instrument output signal is detected, and demodulated with a phase-sensitive detection method referenced to the instrument rotation.

Owner:MILLI SENSOR & ACTUATOR SYST

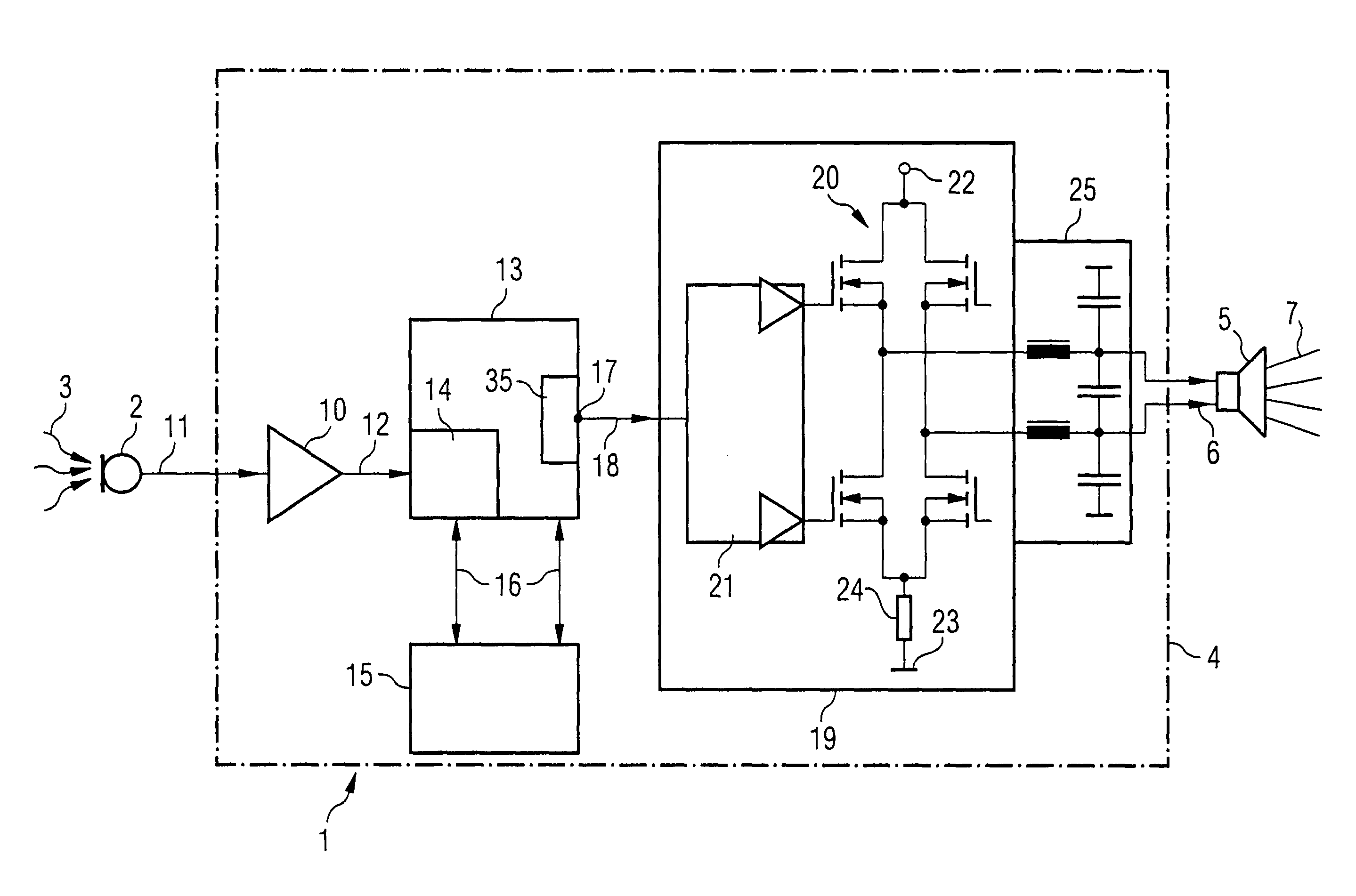

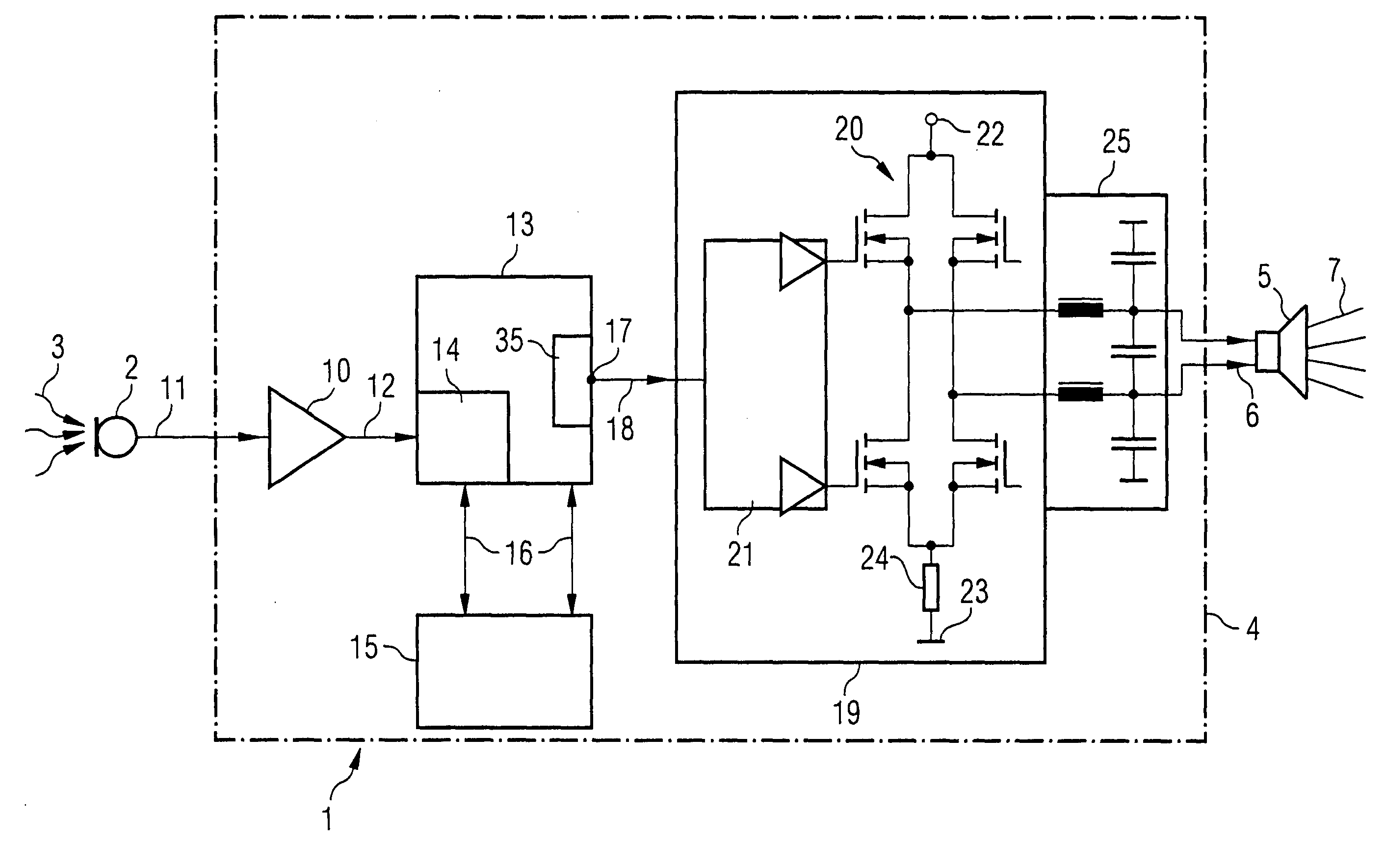

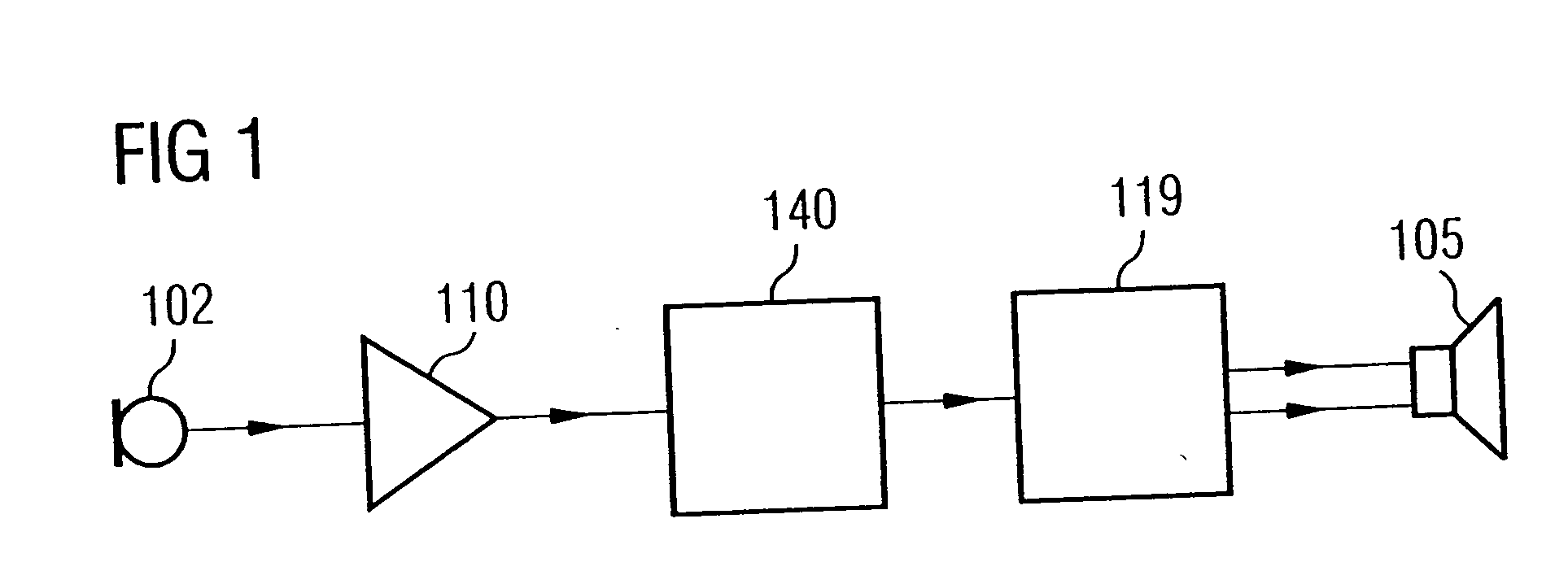

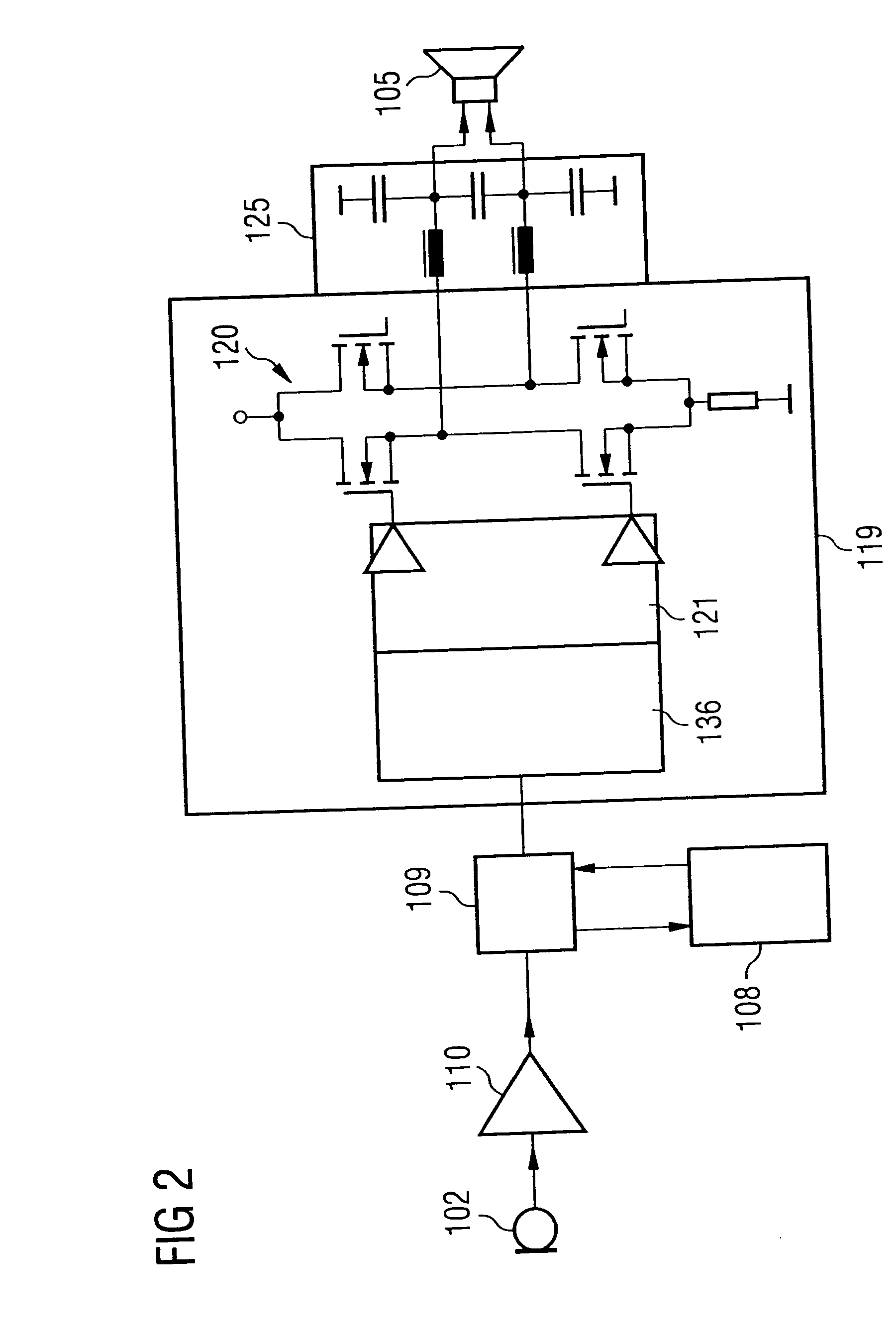

Drive circuit, device, and method for suppressing noise, and use

InactiveUS7279964B2Good flexibilityLow costNegative-feedback-circuit arrangementsAmplifier modifications to reduce noise influenceMicrocontrollerNoise suppression

Owner:CONTINENTAL AUTOMOTIVE GMBH +1

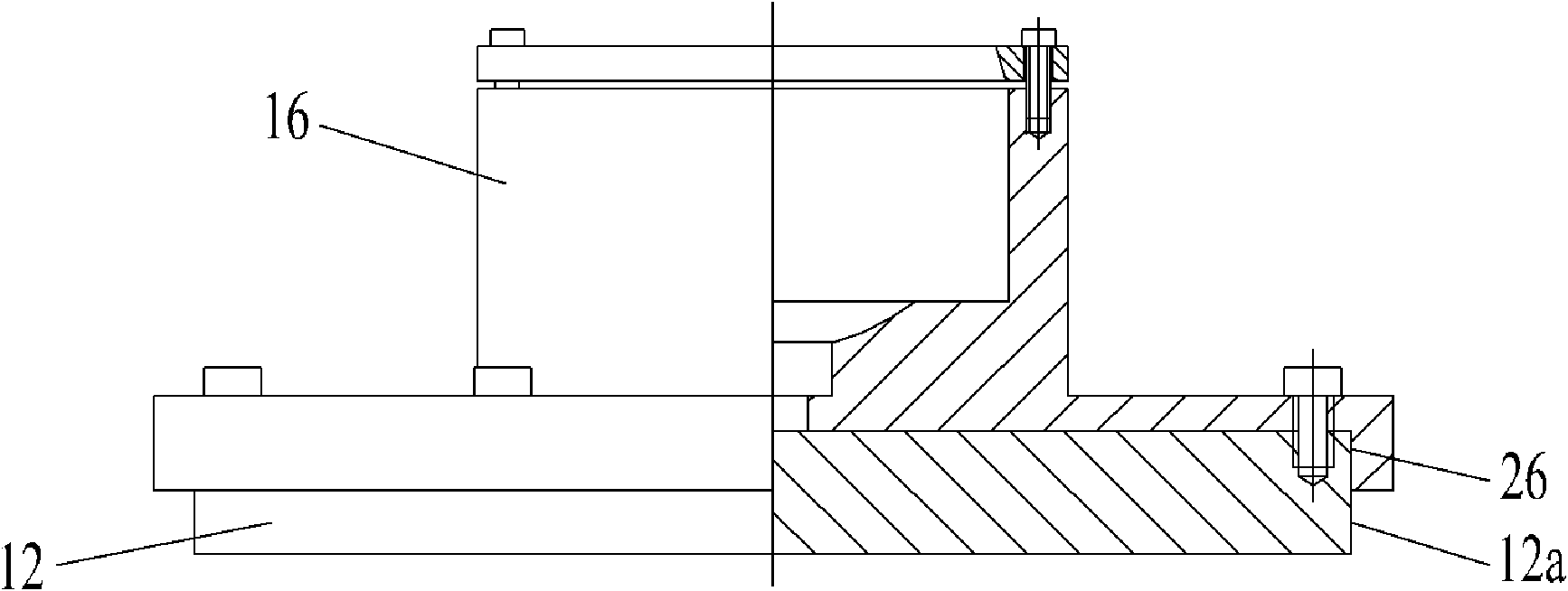

Test method and test device for torsional composite fretting friction wear

InactiveCN101963563AReal and effective analysisReal and effective testInvestigating abrasion/wear resistanceNormal loadFretting

The invention discloses a test method and a test device for torsional composite fretting friction wear. The method comprises the following steps that: a, an upper test piece is clamped on an upper fixture connected with a six-axis force / moment sensor, and a lower test piece is clamped by a lower fixture, wherein the lower fixture is fixed on an inclined rotary motor (13) shaft; b, a data acquisition control system controls the upper fixture and the upper test piece to move up and down and move left and right to make the upper fixture and the upper test piece contact and keep a set normal load Fn, and the data acquisition control system controls a rotary motor and the lower test piece to rotate in set parameters; and c, the six-axis force / moment sensor measures a tangential force, namely a frictional force Ft, the frictional force Ft is sent to the data acquisition control system, and the curve of the frictional force Ft and a rotary angle displacement amplitude theta is obtained through analysis to represent dynamic characteristics of torsional composite fretting. By the method, composite fretting damage of a component in complex stress is more really simulated; the precision of control and test is high; the repeatability of experimental data is good; and the automation degree is high.

Owner:SOUTHWEST JIAOTONG UNIV

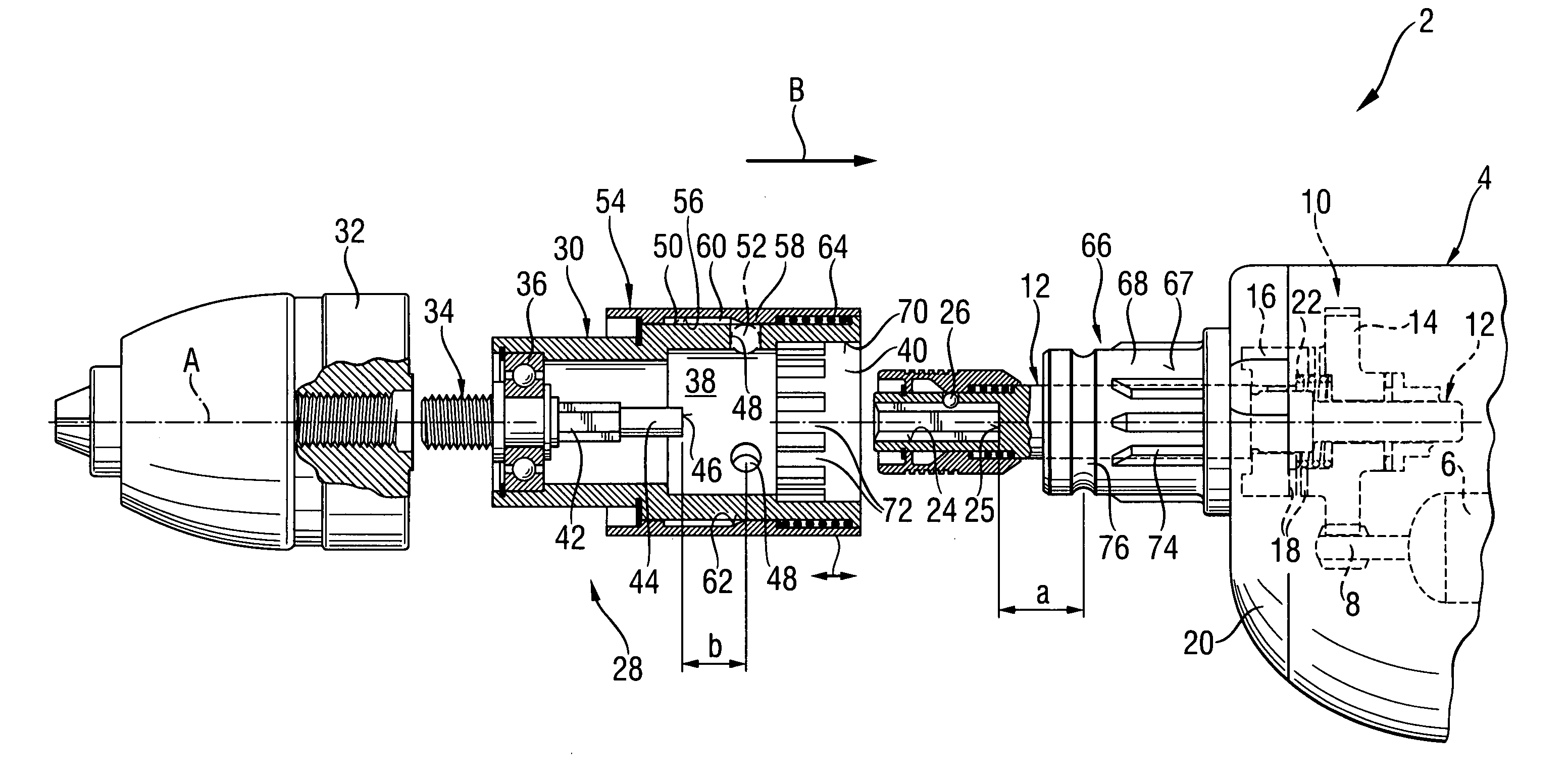

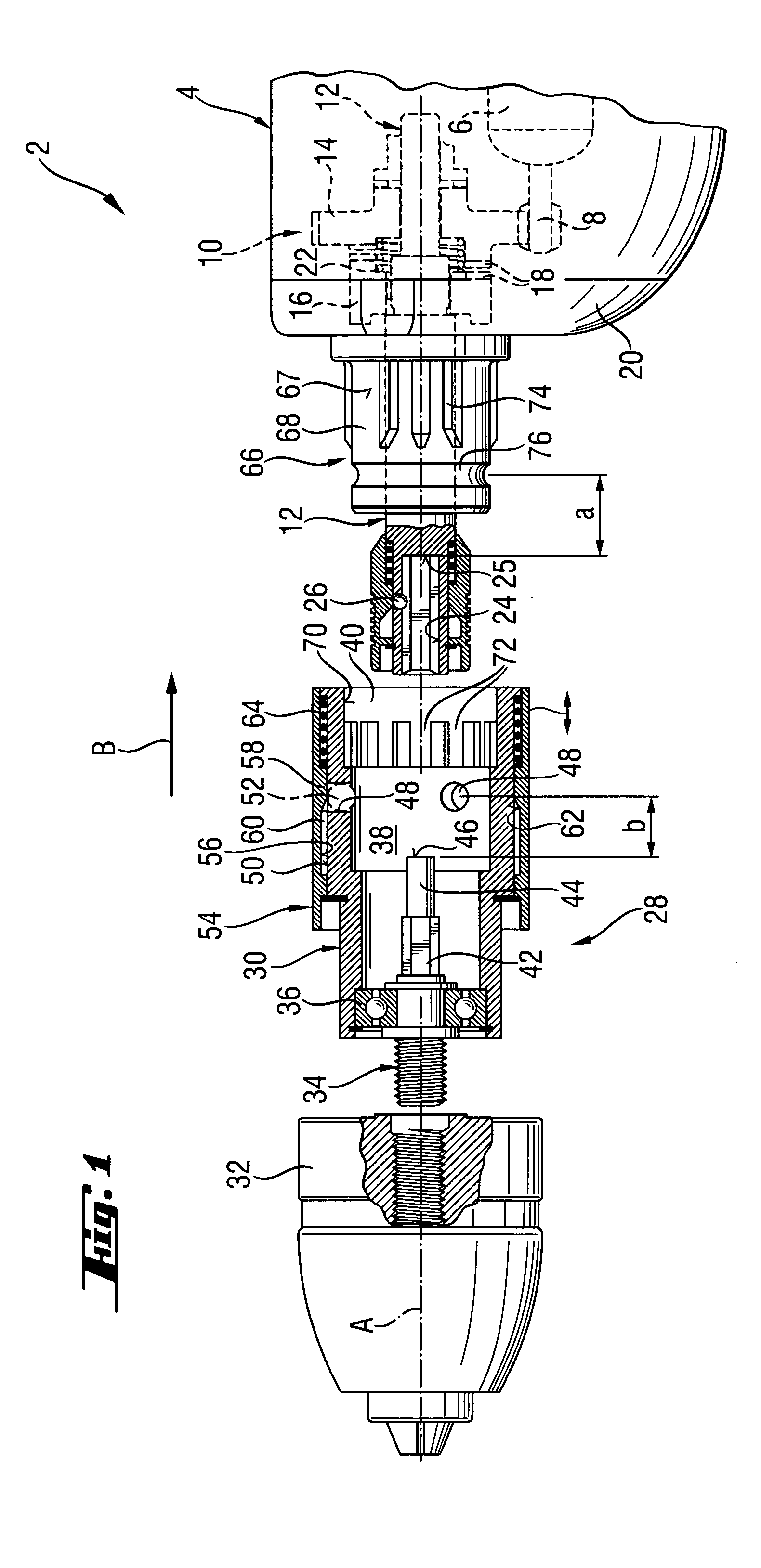

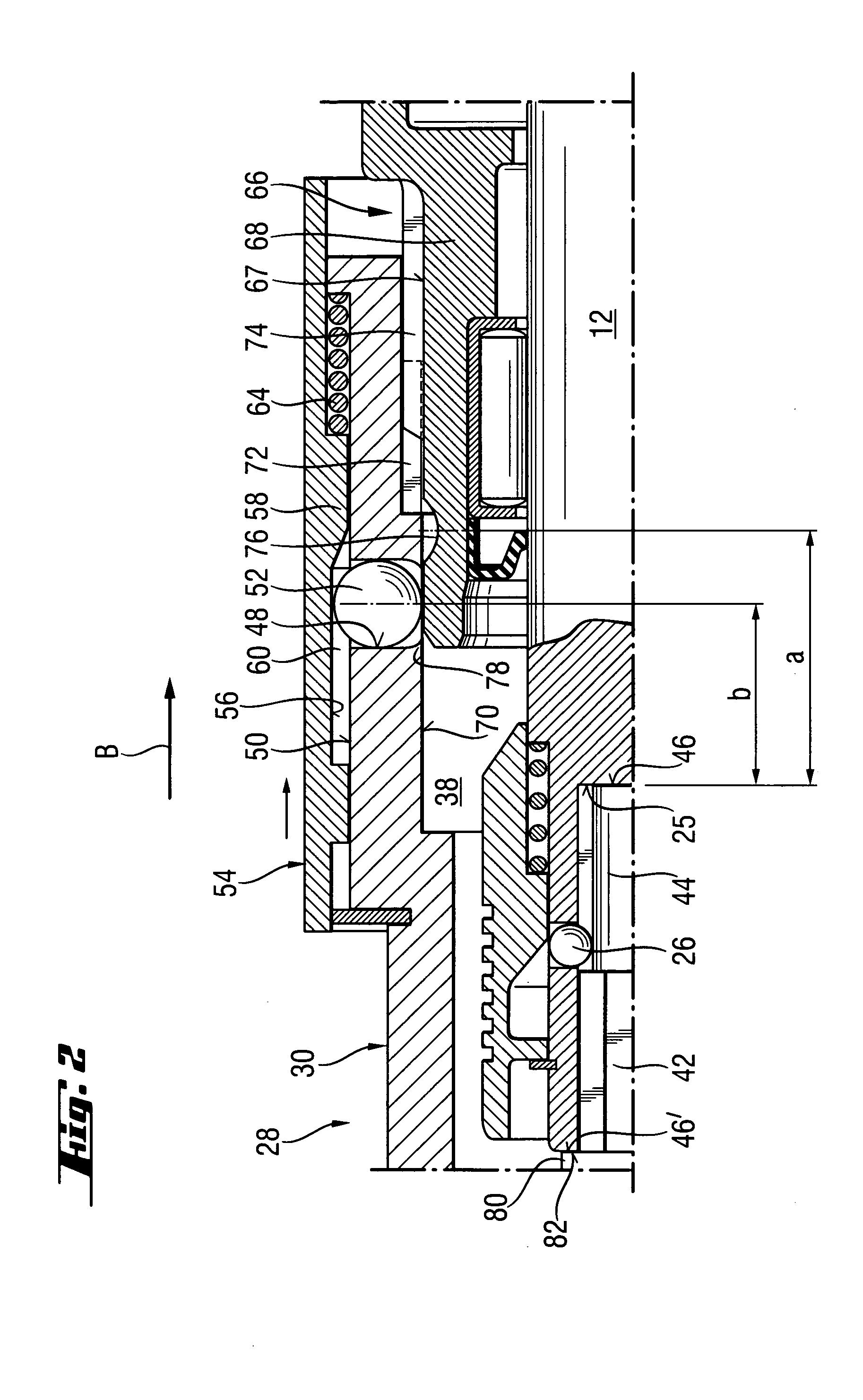

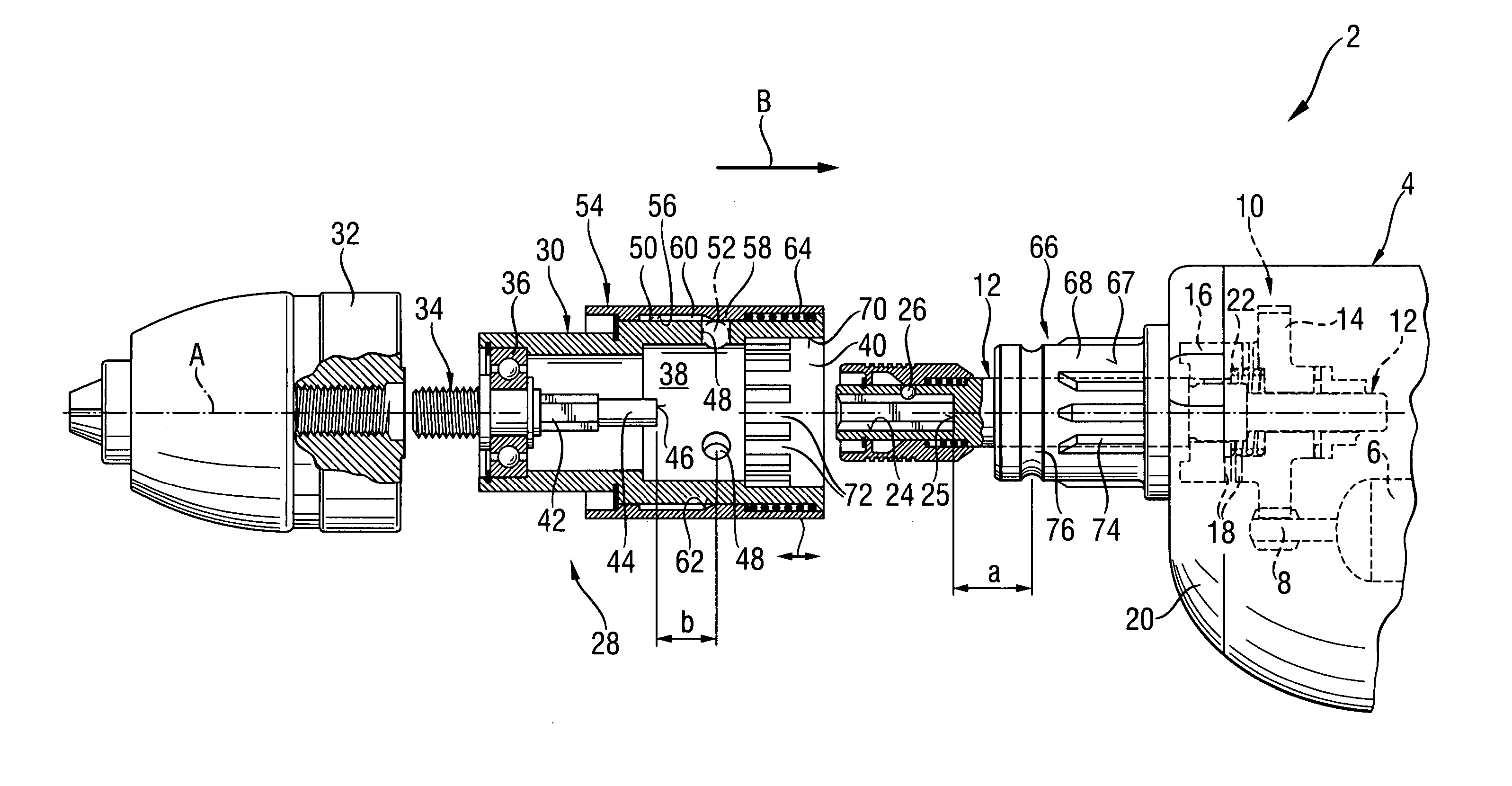

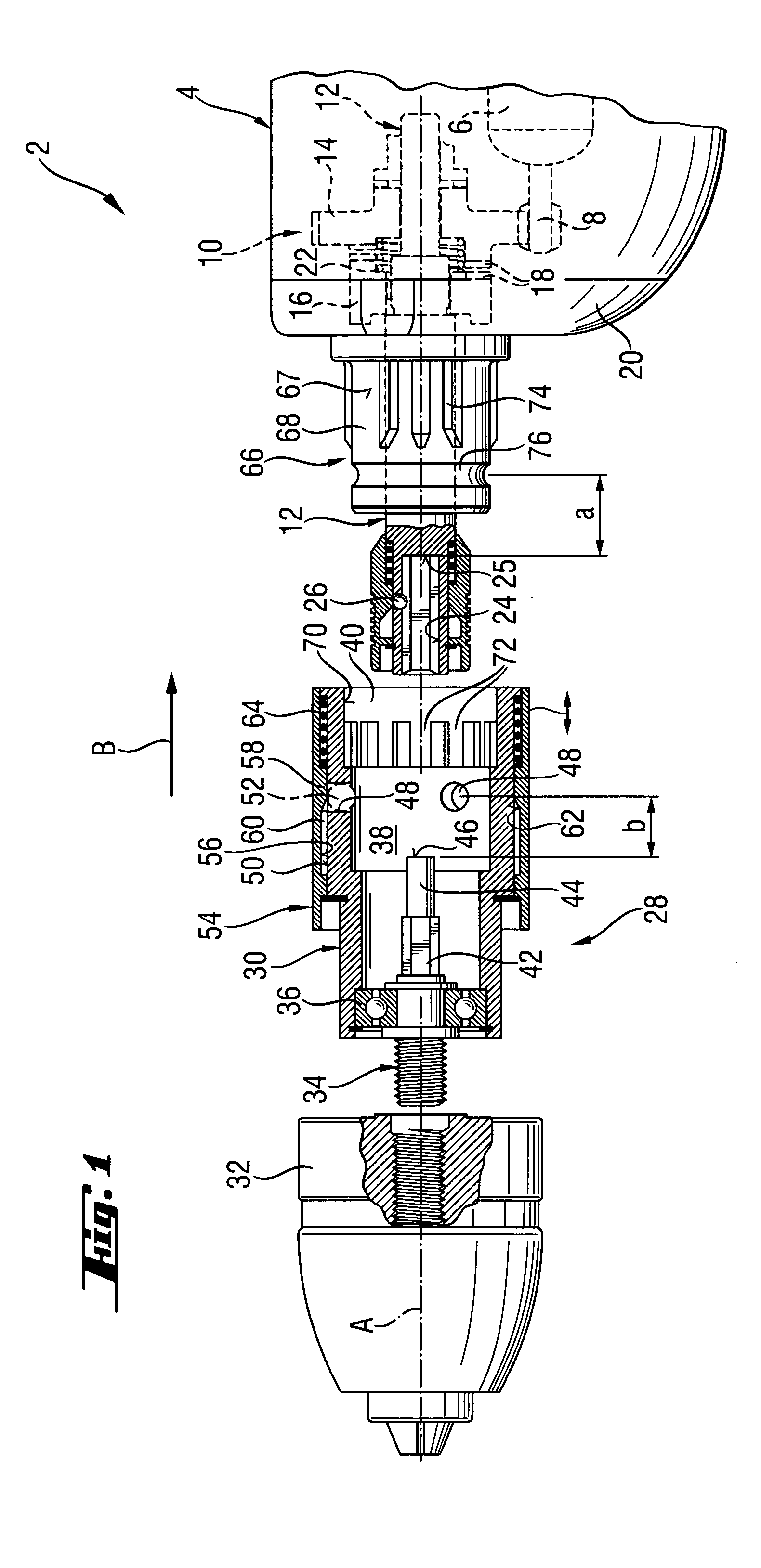

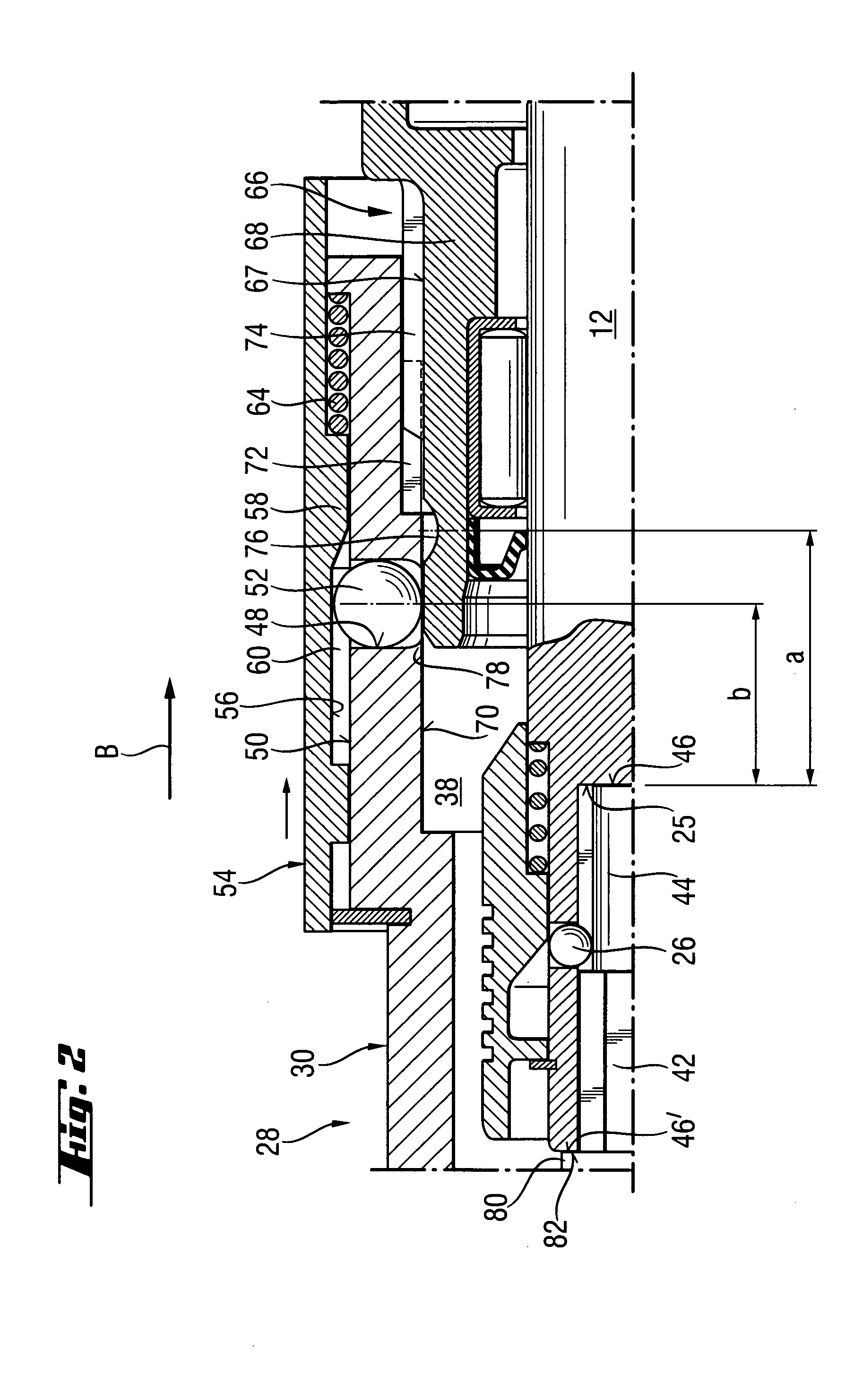

Drill adapter for a power screwdriver

InactiveUS7331738B2Easy to useDrive directlySleeve/socket jointsTransportation and packagingEngineeringClutch

A drill adapter for a power screwdriver and including a locking device for releasably securing the drill adapter (28) on the support region (66) of the screwdriver (4) and having a push-on sleeve (30) supportable on the support region (66) and at least one engagement member (52) for releasably securing the push-on sleeve (30) on the support region, and an element for actuating the drive clutch (10) of the screwdriver (4) via the tool spindle (12) and projecting into a receiving space (38), which is partially limited by the push-on sleeve (30) and is open at one side, and having an axial stop (46) for engaging the tool spindle (12), with the at least one engagement member (52) projecting, in its locking position, beyond an inner surface (70) of the push-on sleeve (30) for establishing an axial formlocking connection between the push-on sleeve (30) and the support region (66) of the screwdriver (4) and which provides for actuation of the drive clutch (10) with actuating element.

Owner:HILTI AG

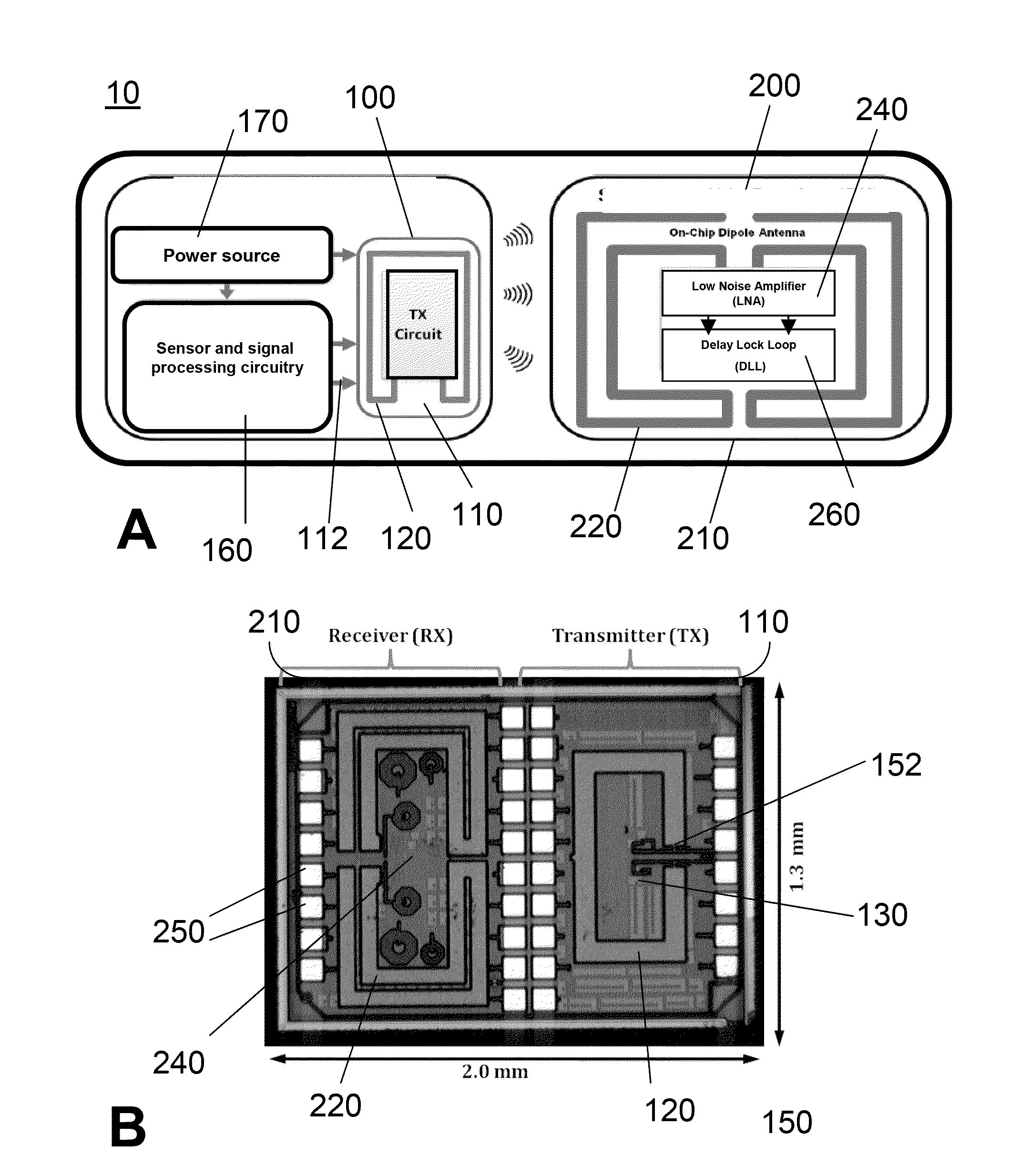

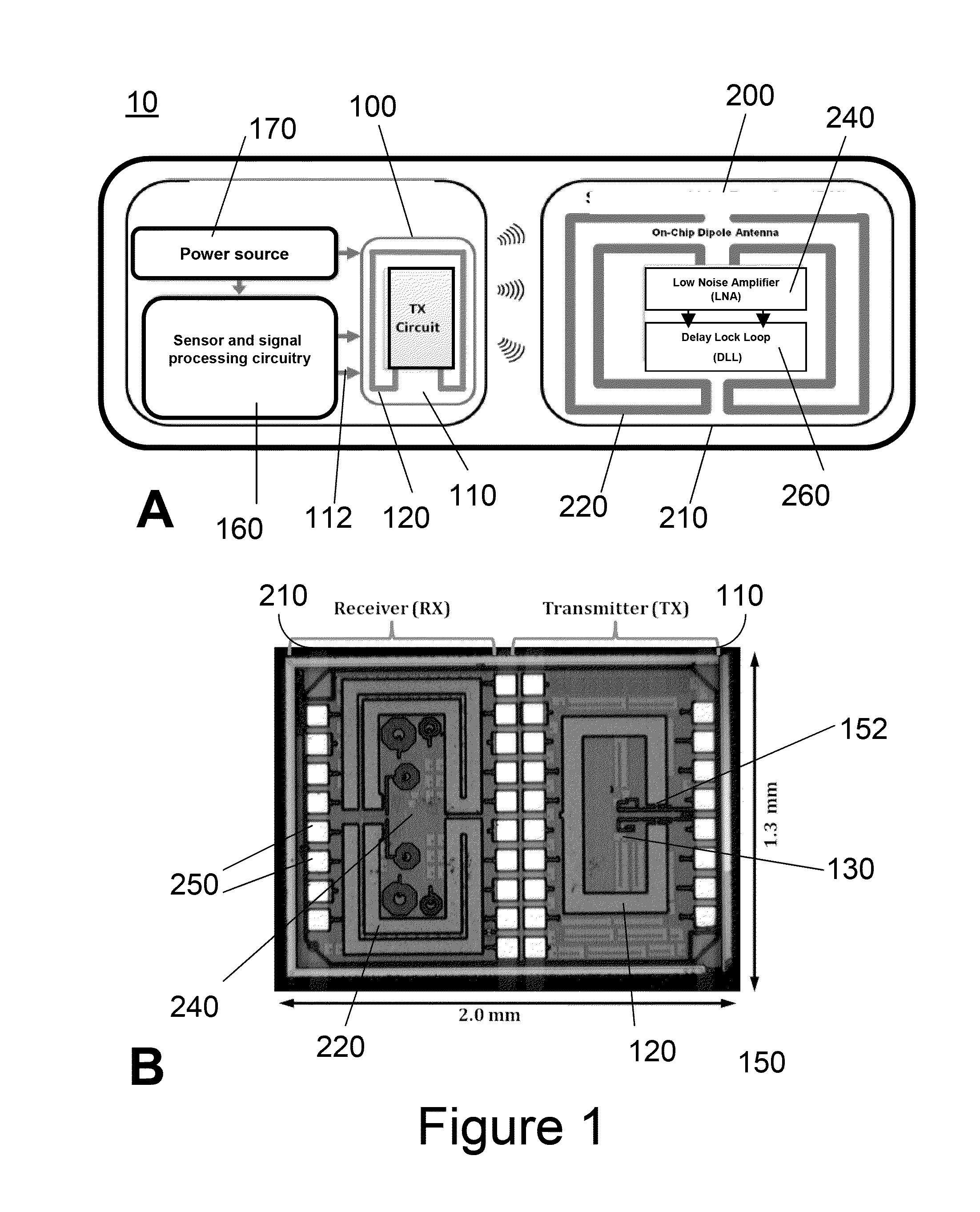

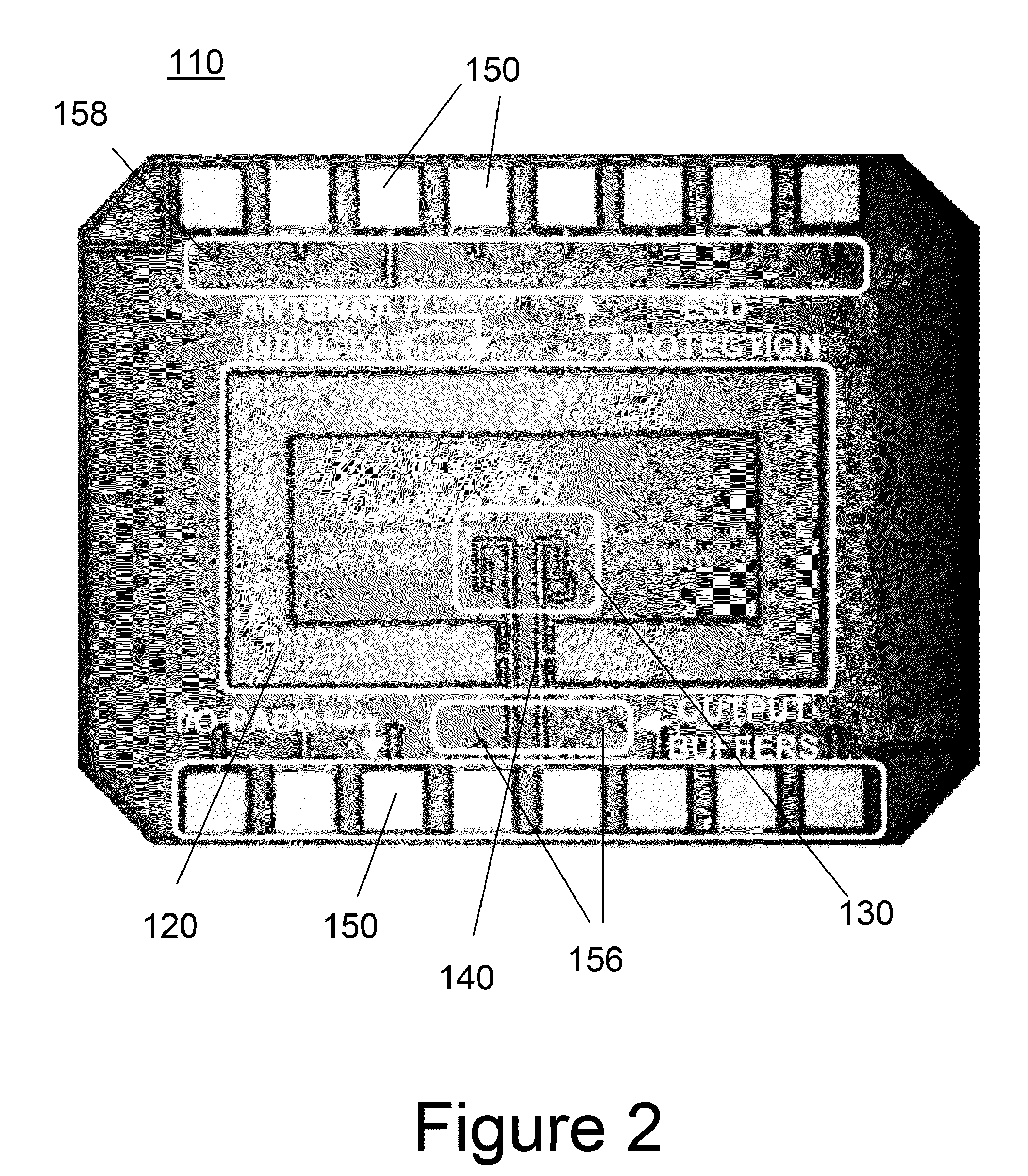

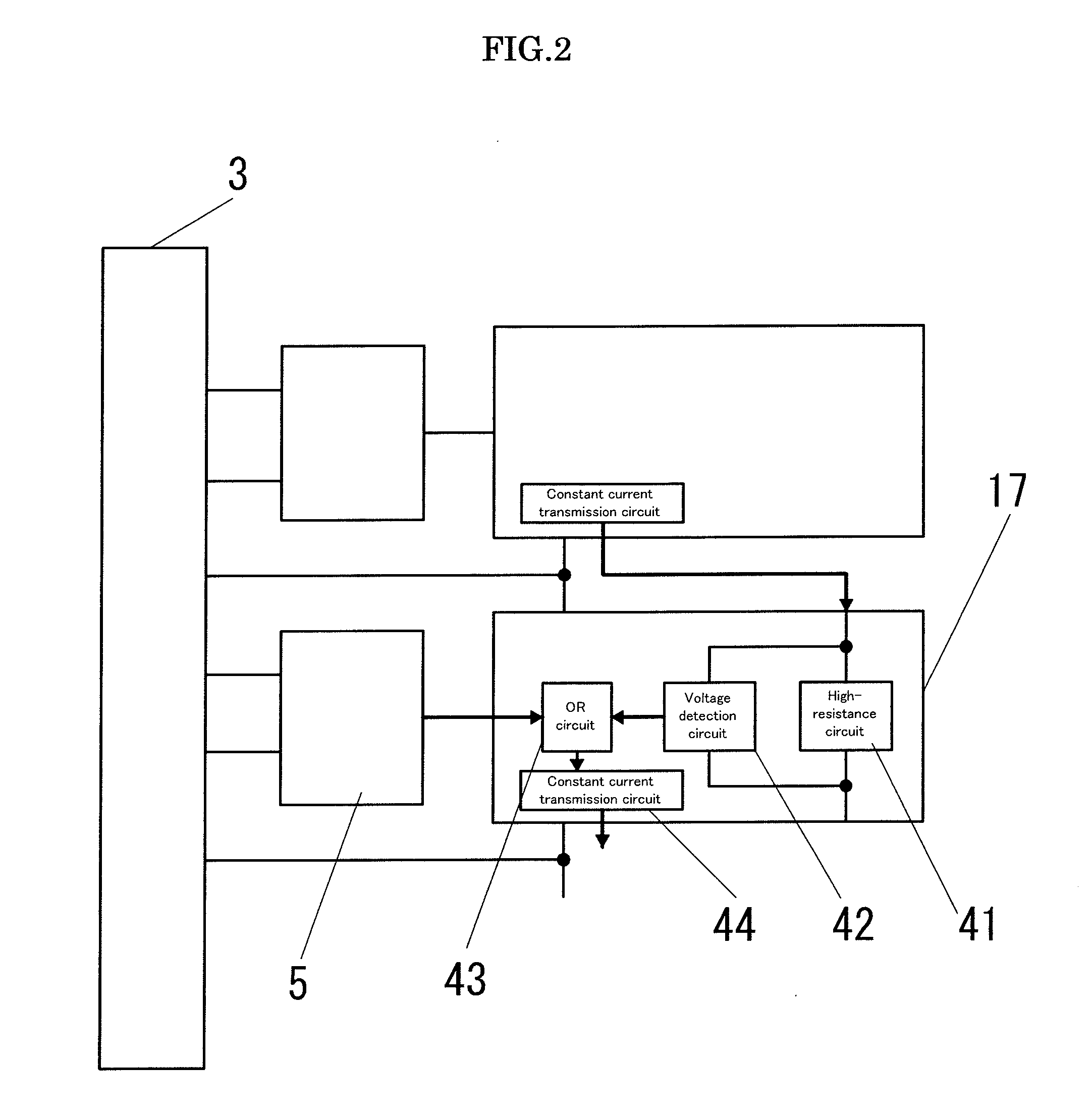

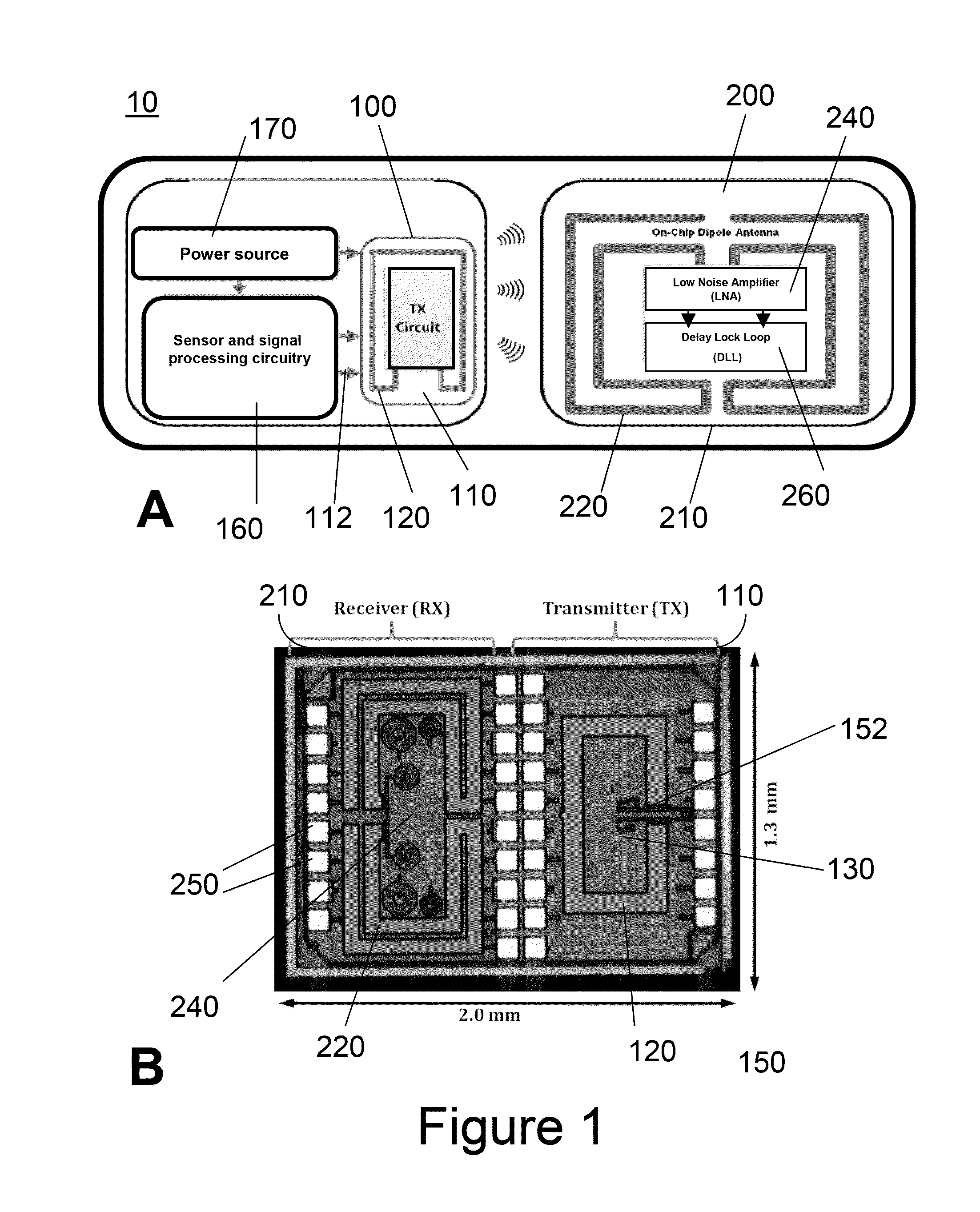

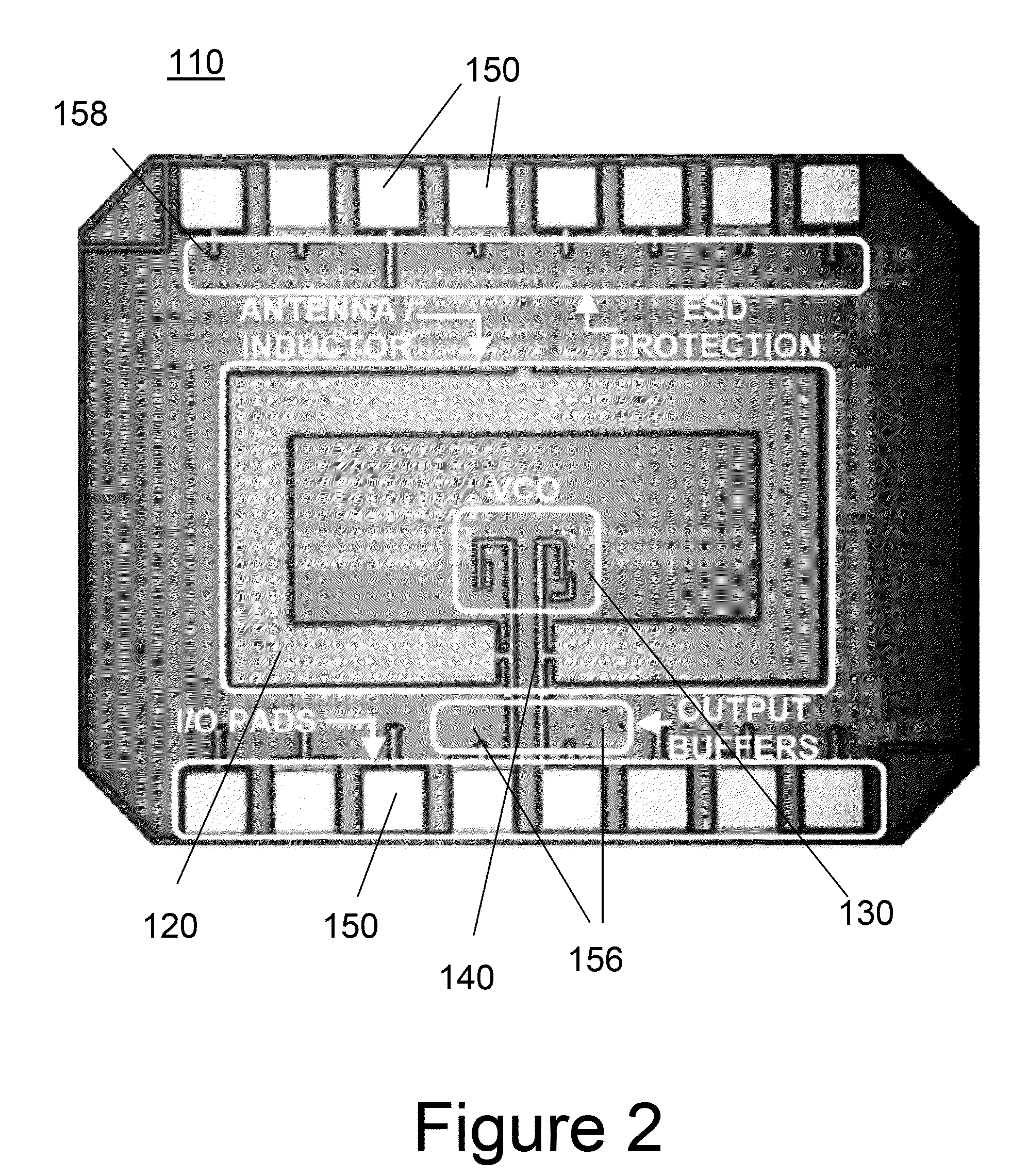

Miniaturized, low power, wireless transmitter and receiver with on-chip antenna, and wireless coupling of on-chip and off-chip antenna

ActiveUS20100099367A1High sensitivityLow resistivityAntenna arraysSolid-state devicesDual modeSoi cmos technology

A miniaturized, low power RF transmitter with a dual mode active on-chip antenna / inductor is disclosed in which antenna also serves as the oscillator inductor. Also disclosed is a miniaturized low power RF receiver with an on-chip antenna; and a RF transmitter system wherein an on-chip antenna is wirelessly coupled to an off chip patch antenna are disclosed. Advantageously, the TX chip is housed in a low loss, e.g. Low Temperature Co-fired Ceramic (LTCC) package with a patch antenna to provide a System-on-Package implementation comprising electromagnetic coupling between a RF TX chip comprising an integrated on-chip antenna and a package antenna. The on-chip antenna feeds the LTCC patch antenna through aperture coupling, thus negating the need for RF buffer amplifiers, matching elements, baluns, bond wires and package transmission lines, and significantly increases the gain and range of the module with respect to the on-chip antenna alone, without deterioration of the circuit performance and power consumption. Exemplary embodiments are disclosed which may be fabricated using standard CMOS technology, for operation in the 5 GHz U-NII band for applications such as miniaturized, low cost, low power wireless devices and sensor systems.

Owner:KING ABDULLAH UNIV OF SCI & TECH

Method of producing, selling, and distributing articles of manufacture

InactiveUS20050283406A1Simple preparation conditionsLess riskHand manipulated computer devicesDiscounts/incentivesElectronic communicationMilestone

There is disclosed a method of selling articles of manufacture. The method comprises an electronic communication system to identify one or more articles of manufacture, from at least one manufacturing entity, which are available for purchase by a plurality of potential purchasers and identify pricing milestones in each of a manufacturing phase and a distribution phase, corresponding to a change in commercial risk. Determining a separate price for each pricing milestone to establish a range of prices for the selected articles of manufacture and making conditional offers for sale to potential purchasers at each pricing milestone, with the conditional offers specifying at least a minimum number of articles which must be ordered in aggregate before the conditional offer becomes binding upon a manufacturing entity. Communicating with potential purchasers and aggregating commercial commitments for each pricing milestone, corresponding to a period of availability, thereby selling one or more articles of manufacture.

Owner:LAKESOUTH HLDG LLC

Drill adapter for a power screwdriver

InactiveUS20050191139A1Wide range of applicationsEasy to handleSleeve/socket jointsTransportation and packagingClutchDrill bit

A drill adapter for a power screwdriver and including a locking device for releasably securing the drill adapter (28) on the support region (66) of the screwdriver (4) and having a push-on sleeve (30) supportable on the support region (66) and at least one engagement member (52) for releasably securing the push-on sleeve (30) on the support region, and an element for actuating the drive clutch (10) of the screwdriver (4) via the tool spindle (12) and projecting into a receiving space (38), which is partially limited by the push-on sleeve (30) and is open at one side, and having an axial stop (46) for engaging the tool spindle (12), with the at least one engagement member (52) projecting, in its locking position, beyond an inner surface (70) of the push-on sleeve (30) for establishing an axial formlocking connection between the push-on sleeve (30) and the support region (66) of the screwdriver (4) and which provides for actuation of the drive clutch (10) with actuating element.

Owner:HILTI AG

Method and apparatus of driving LED and OLED devices

InactiveUS8228001B2Improve versatilityPowerful processingElectrical apparatusStatic indicating devicesDc currentDimmer

A group of novel power conversion concept is developed with this invention for LED and OLED drive applications. The concept utilizes a single power conversion stage to fulfill multiple functions, including Power Factor Correction, DC voltage to DC current conversion, or DC voltage to DC voltage conversion etc. that are necessary for driving LED devices from an AC power input. Multiple dimming control schemes have also been developed to facilitate wide range of application requirements and enable the system to work with different input power format including AC mains power and variable AC voltage from the existing AC dimmer installations.

Owner:SUNTEC ENTERPRISES

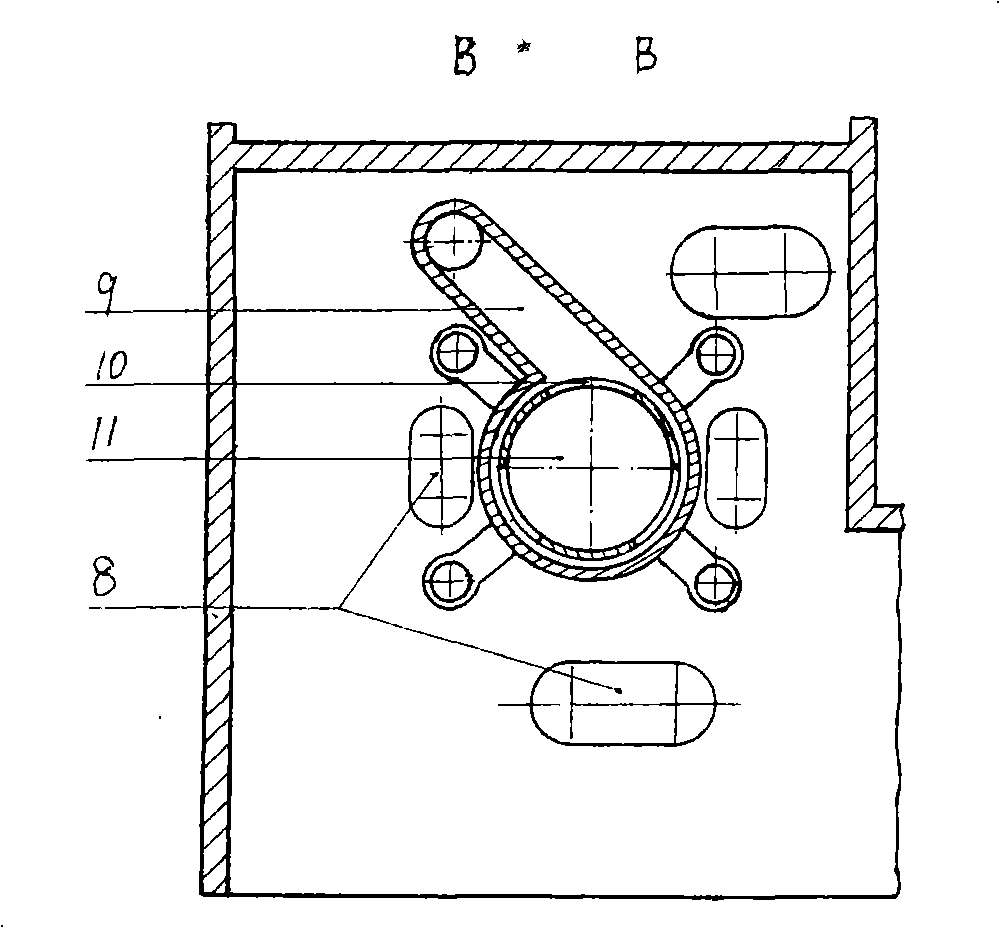

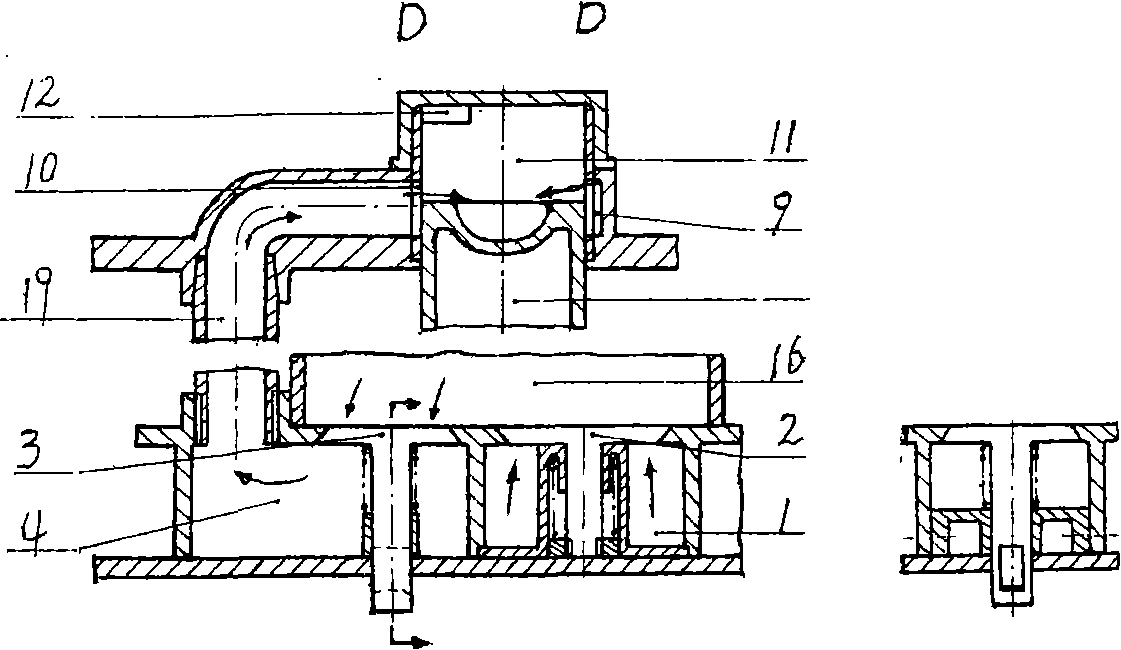

Piston reciprocating internal-combustion engine working substance flow system and its device

InactiveCN101289956AHigh thermal efficiencyEasy to achieve coolingNon-fuel substance addition to fuelInternal combustion piston enginesAir compressionControl set

The invention discloses a working substance flowing system of a piston reciprocating internal combustion engine and regulation and control setting thereof. An upper end of a frame moving up and down along the rotation of a power shaft is connected with an engine cylinder piston [7]; the lower end of the frame is made into a pressure cylinder piston [5]; an air inlet pipe[14], an air inlet check valve[2] and an air compression check valve[3] are arranged on a bottom cover plate of the pressure cylinder; air sucked from the air inlet pipe[14] by the pressure cylinder is sprayed by water mist for intercooling in compression; compressed air is stored in an air storage channel, tangentially supplied to an air inlet[10] of an engine cylinder sleeve; a rod head of the air compression check valve[3] is connected with the compressed air regulating and controlling device. An exhaust port [12] of the engine cylinder is arranged in the rear side of the cylinder top; a pressurized air bypass channel tightly pressed on the lower side of a flashboard-type exhaust valve [21] and an air suction check valve [22] of the upper side of a vent-pipe inlet cool an exhaust system and exhaust air and have the effects of both decontamination and preventing an exhaust gas turbine from surging. The supercharging mechanism has compact structure, indirect transmission, stable pressurization and cooling function; the working substance flowing system is provided with the regulating and controlling device with optimized performance and is convenient to the actualization of a small and medium sized engine.

Owner:肖光宇

Small angle bias measurement mechanism for MEMS instruments

InactiveUS7549334B2Reduce sensitivityError minimizationAcceleration measurement using interia forcesWave based measurement systemsAccelerometerGyroscope

A system and method for separating bias instability of MEMS inertial instruments such as gyroscopes or accelerometers from the instrument signal, in which the inertial measurement instrument has an input axis and an output signal, and the bias instability has a frequency. The instrument is oscillated about an oscillation axis that is orthogonal to the input axis, at a frequency that is greater than the bias instability frequency. The instrument output signal is detected, and demodulated with a phase-sensitive detection method referenced to the instrument rotation.

Owner:MILLI SENSOR & ACTUATOR SYST

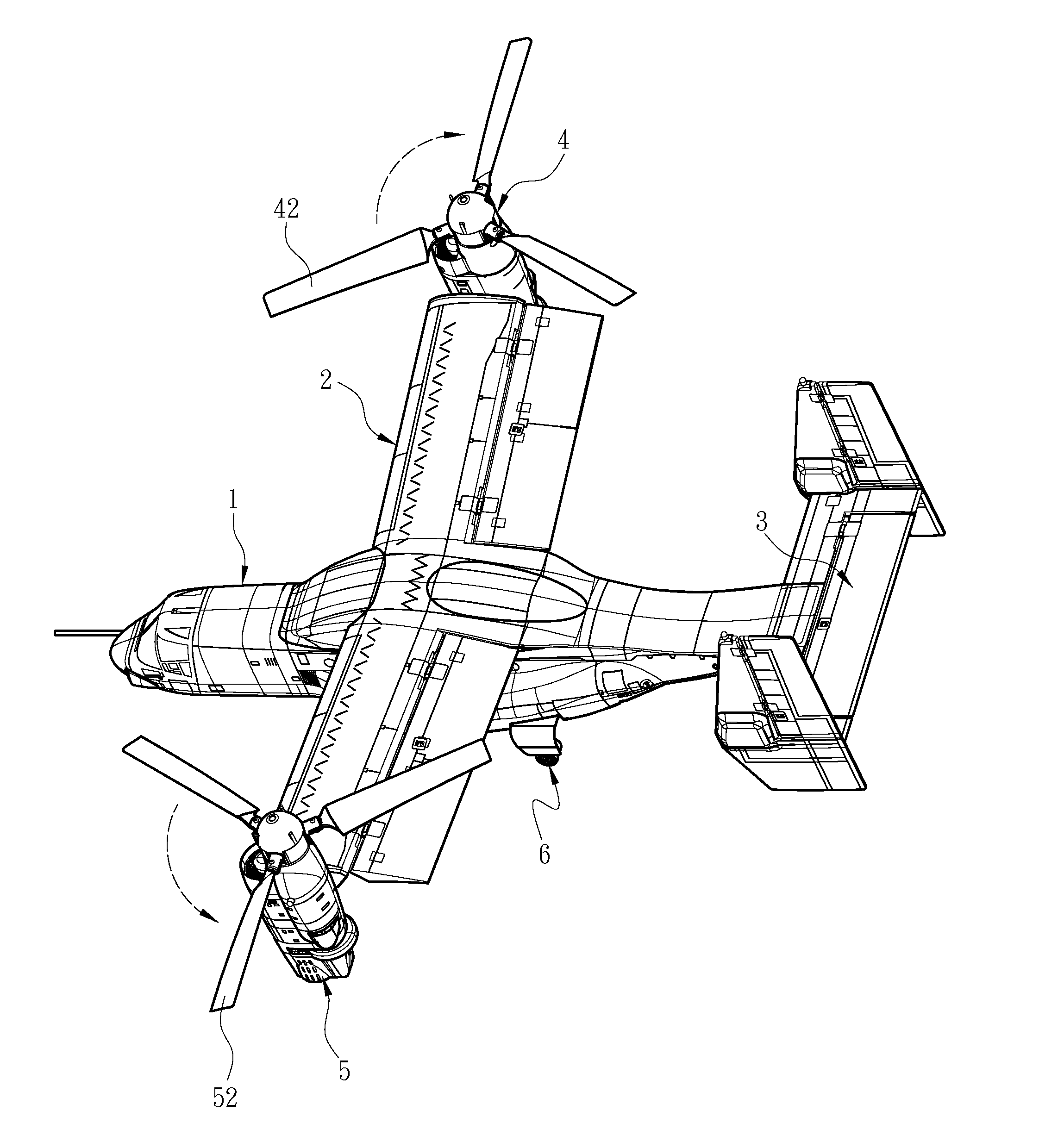

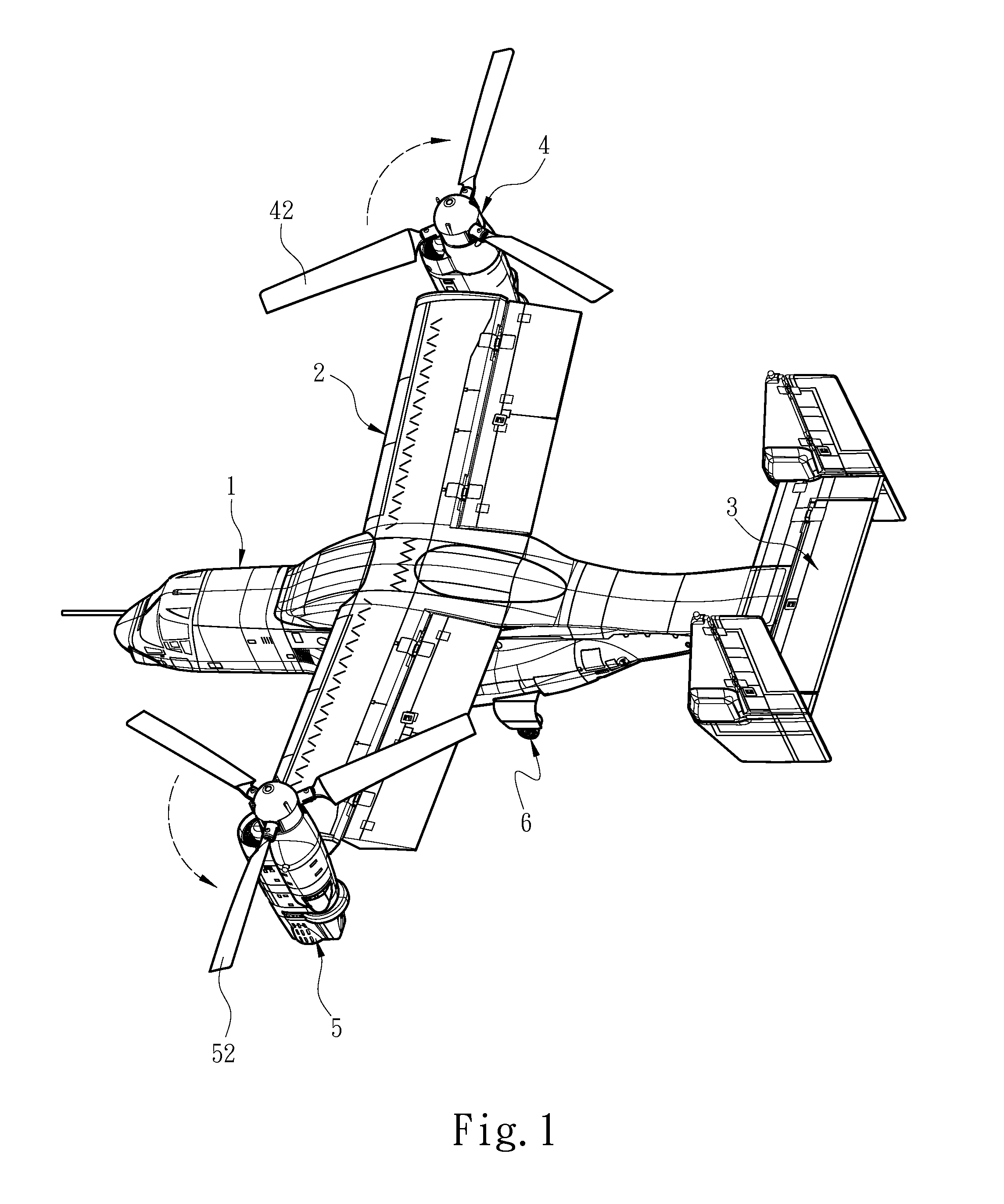

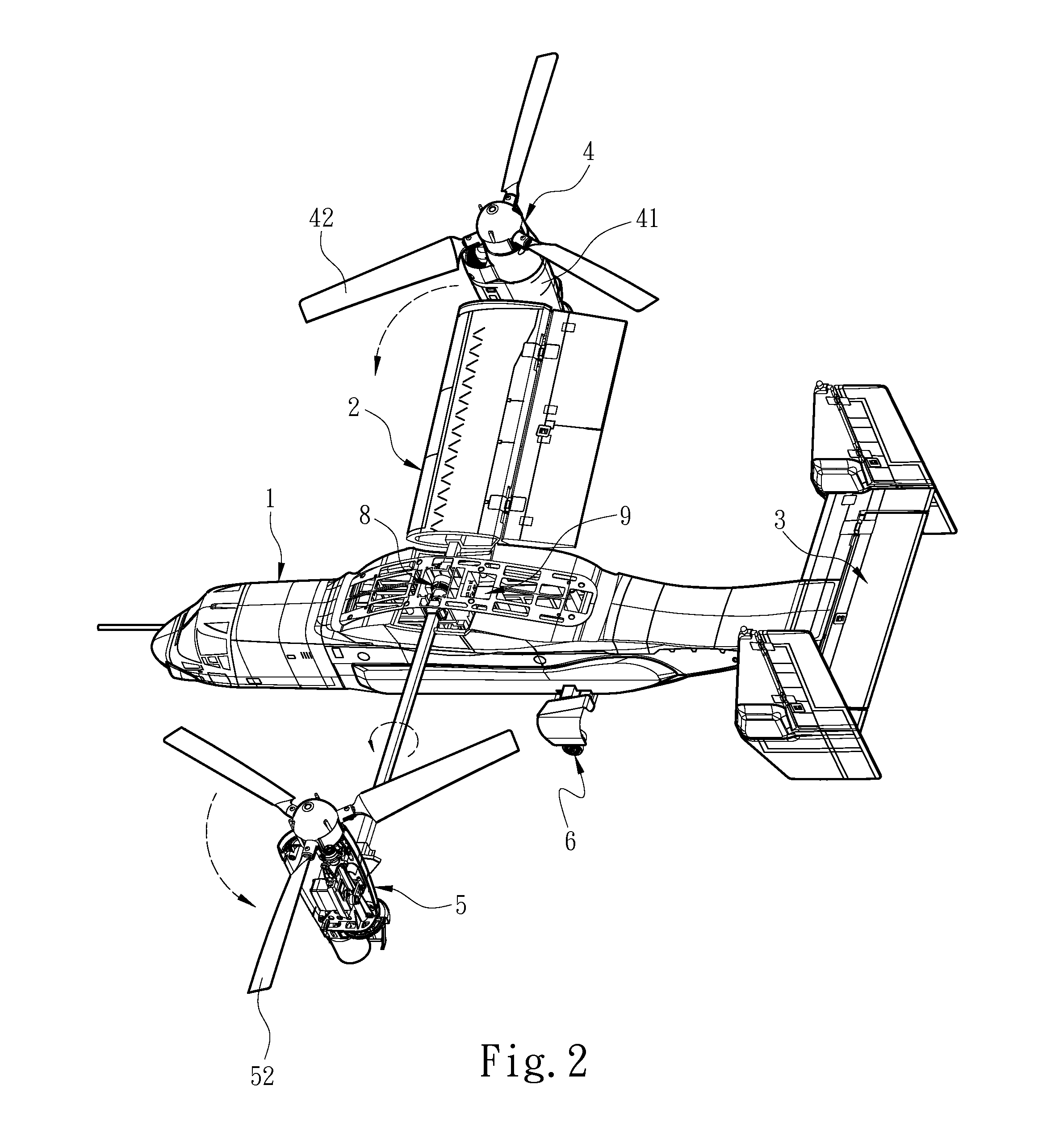

Vtol model aircraft

InactiveUS20110177748A1Simple structureLight weightToy aircraftsVertical landing/take-off aircraftsRotational axisJet aeroplane

A toy model aircraft aims to imitate V-22 Osprey with high emulation by being providing with flight characteristics of V-22 Osprey at a shrunk size of a toy specification. The model aircraft of the invention includes a fuselage, two fixed wings extended outwards from two sides of the fuselage and a tail wing at the tail of the fuselage. Each fixed wing includes a propeller engine installed at a distal end thereof and a rotor. The two rotors of the propeller engines rotating in opposite directions, and the propeller engines are coupled to form an integrated body through a rotary axle mechanism connecting to the wings. The fuselage holds a rotary axle driving means to drive the rotary axle mechanism to rotate and the propeller engines at two ends of the rotary axle mechanism are rotated concurrently between the vertical direction and horizontal direction.

Owner:LUO ZHIHONG

Drive circuit, device, and method for suppressing noise, and use

InactiveUS20050024134A1Good flexibilityReduce circuit costAmplifier modifications to reduce noise influenceMachines/enginesMicrocontrollerNoise suppression

A low-frequency PWM-modulated signal and a high-frequency, unmodulated signal for generating a high-frequency PWM-modulated signal is employed directly for driving an output stage of a device for noise suppression. The low-frequency signal and the high-frequency signal is advantageously provided by a microcontroller which already has an AD converter on the input side. The microcontroller furthermore already makes a PWM output signal with a high bit width available which has the high resolution necessary for driving the loudspeaker.

Owner:CONTINENTAL AUTOMOTIVE GMBH +1

Bias measurement for MEMS gyroscopes and accelerometers

InactiveUS8397568B2Reduce sensitivityError minimizationAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAccelerometerGyroscope

A system and method for separating bias instability of MEMS inertial instruments such as gyroscopes or accelerometers from the instrument signal, in which the inertial measurement instrument has an input axis and an output signal, and the bias instability has a frequency. The instrument is rotated about a rotation axis that is orthogonal to the input axis, at a frequency that is greater than the bias instability frequency. The instrument output signal is detected, and demodulated with a phase-sensitive detection method referenced to the instrument rotation.

Owner:MILLI SENSOR & ACTUATOR SYST

Scale factor measurement for mems gyroscopes and accelerometers

InactiveUS7726188B2Reduce sensitivityError minimizationAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGyroscopeAccelerometer

Owner:MILLI SENSOR & ACTUATOR SYST

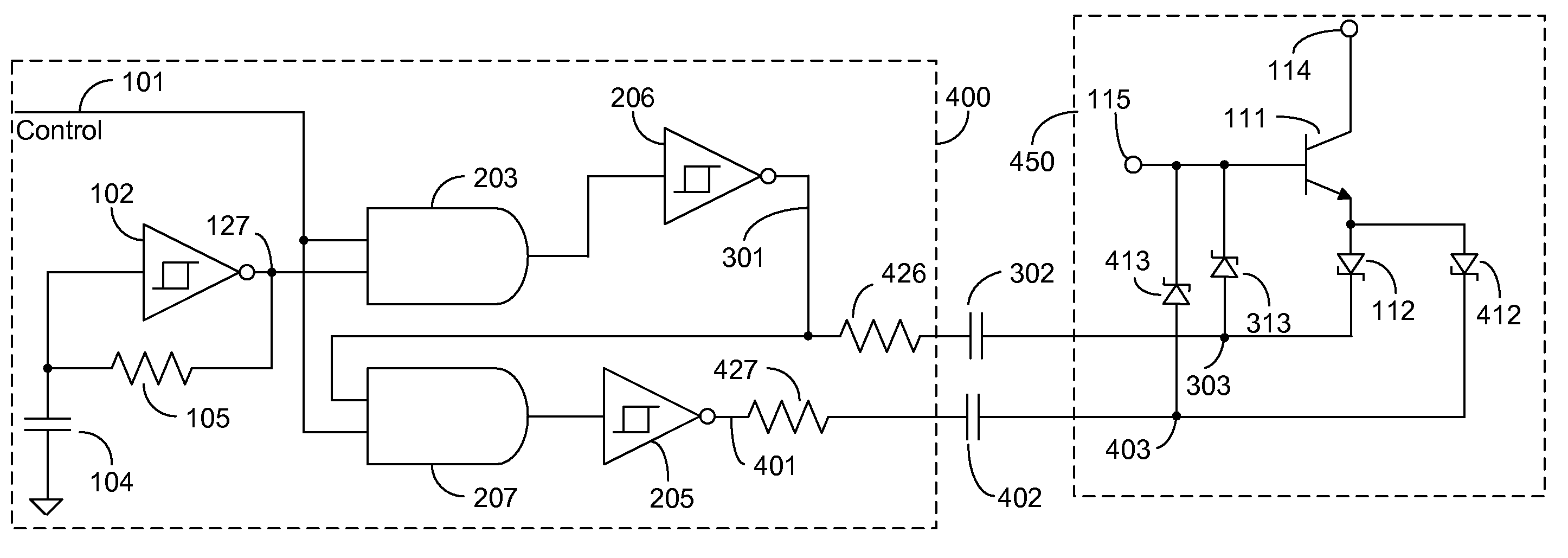

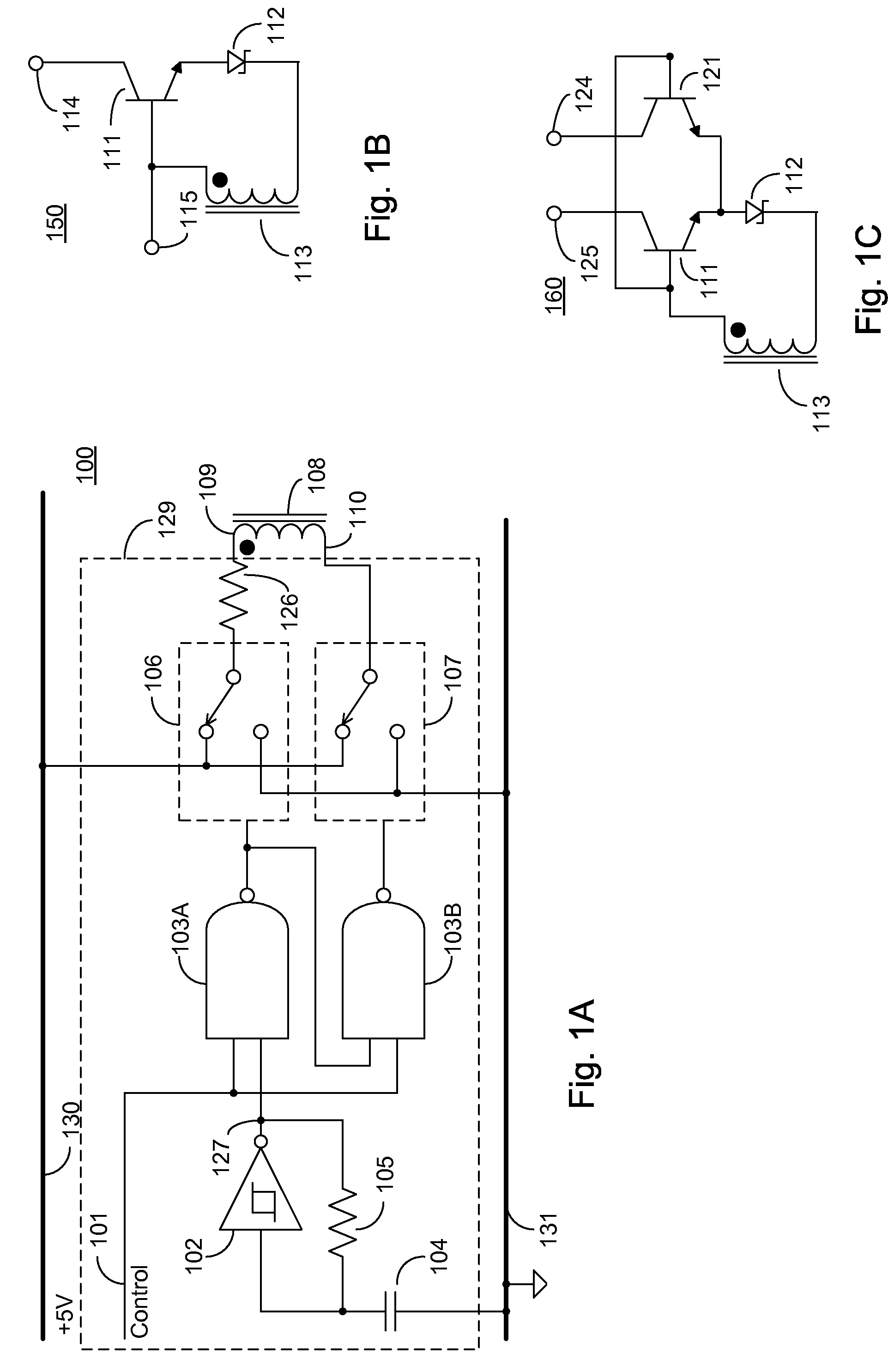

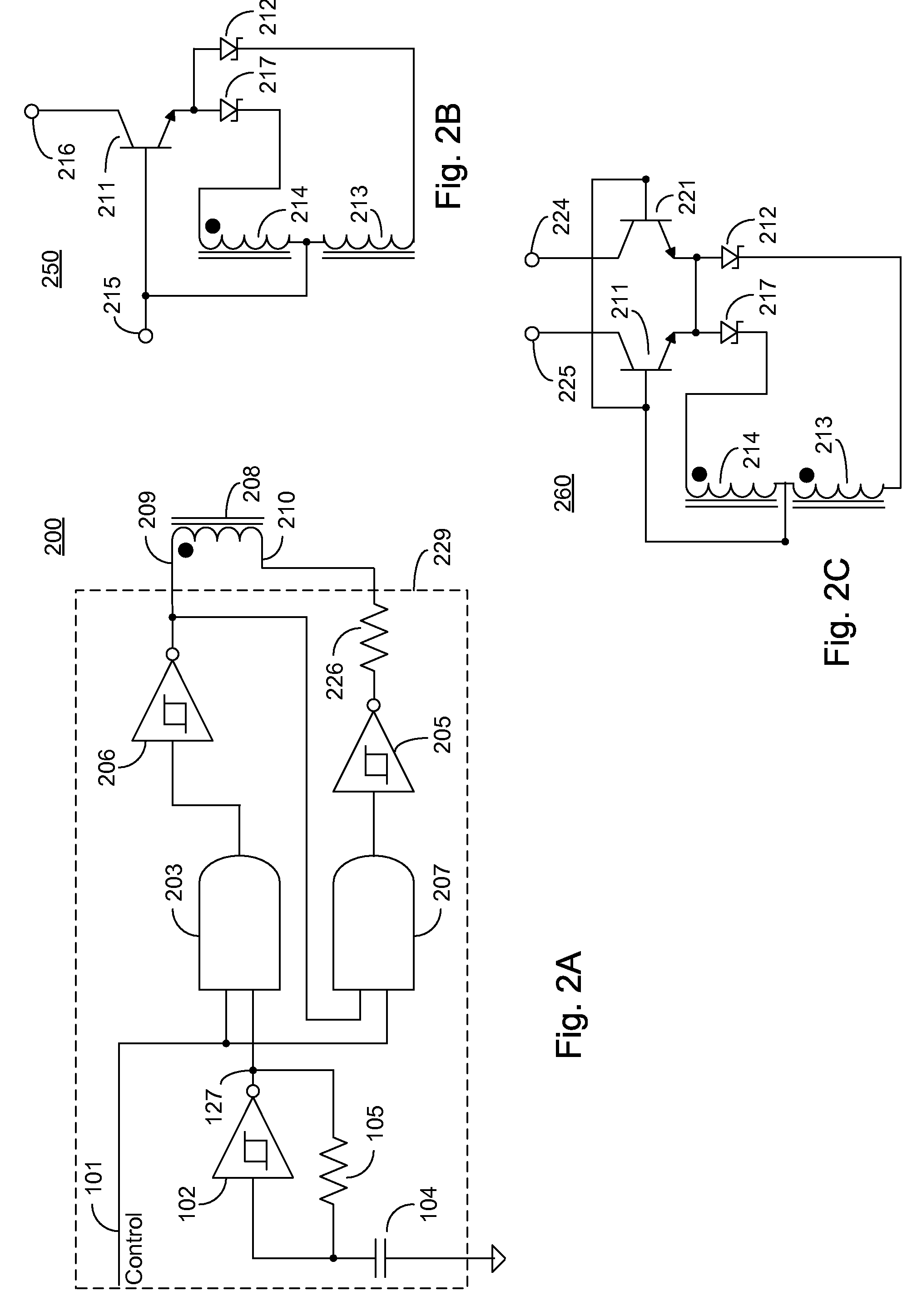

Charge limited high voltage switch circuits

InactiveUS7449841B2Eliminate needDrive directlyContact mechanismsElectronic switchingHigh voltage igbtFull wave

High voltage switches are configured with a junction transistor driven with a transformer coupled AC drive signal in the common base configuration or driven by a capacitor coupled charge pump. The high voltage switches may be configured as half wave or full wave switches wherein the junction transistor is driven during one or both half cycles of the AC drive signal. Bipolar switches that can stand off high DC voltage of either polarity, or that can stand off high AC voltage, are configured from two junction transistors with their bases connected and their emitters connected. These switches may also be driven in full wave or half wave mode, by a transformer or by single or dual capacitive charge pumps. Either NPN or PNP transistors may be used. Example drive circuits, which can be constructed as low voltage integrated circuits, are given for all of the switch types.

Owner:MICROSEMI CORP

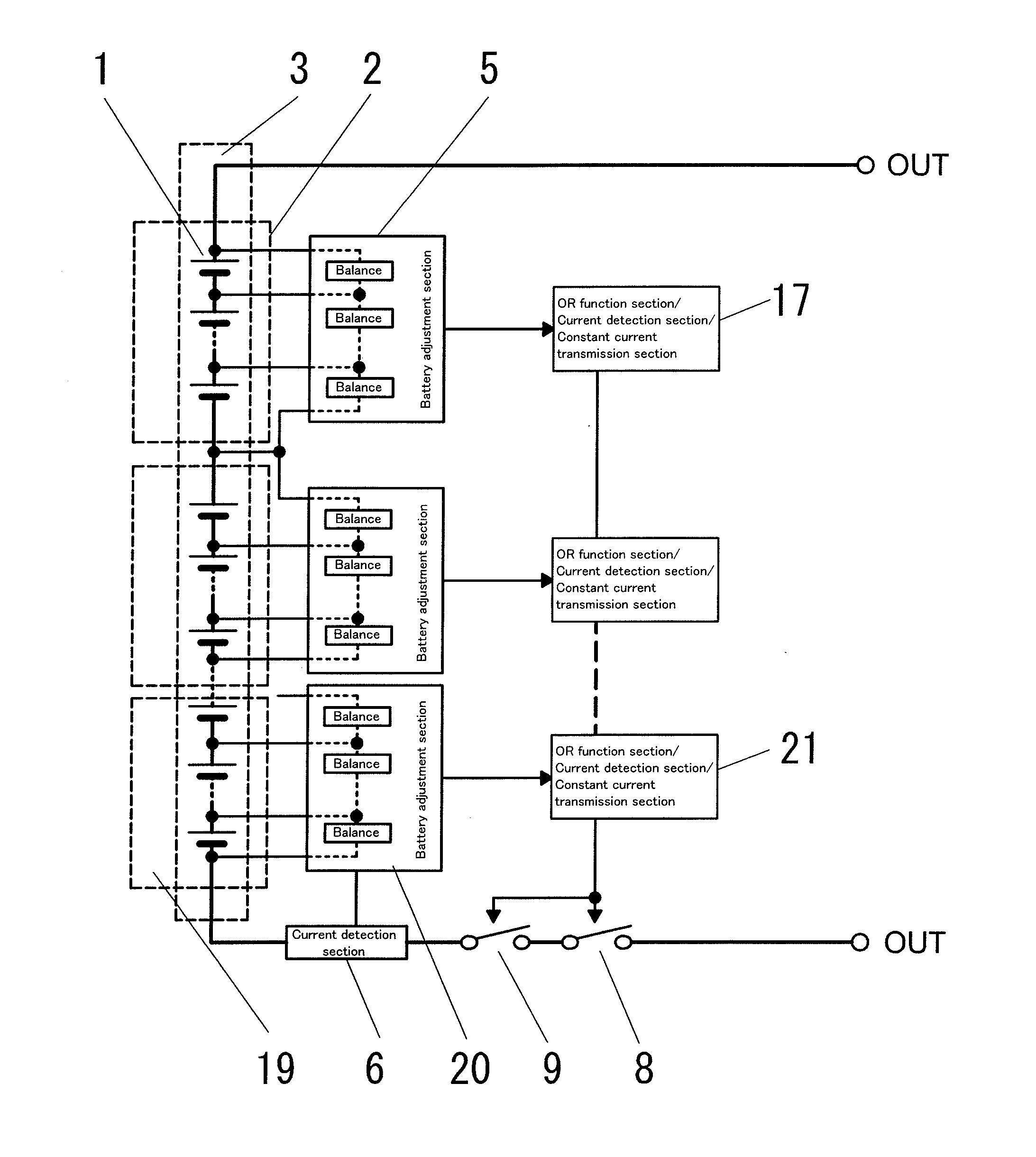

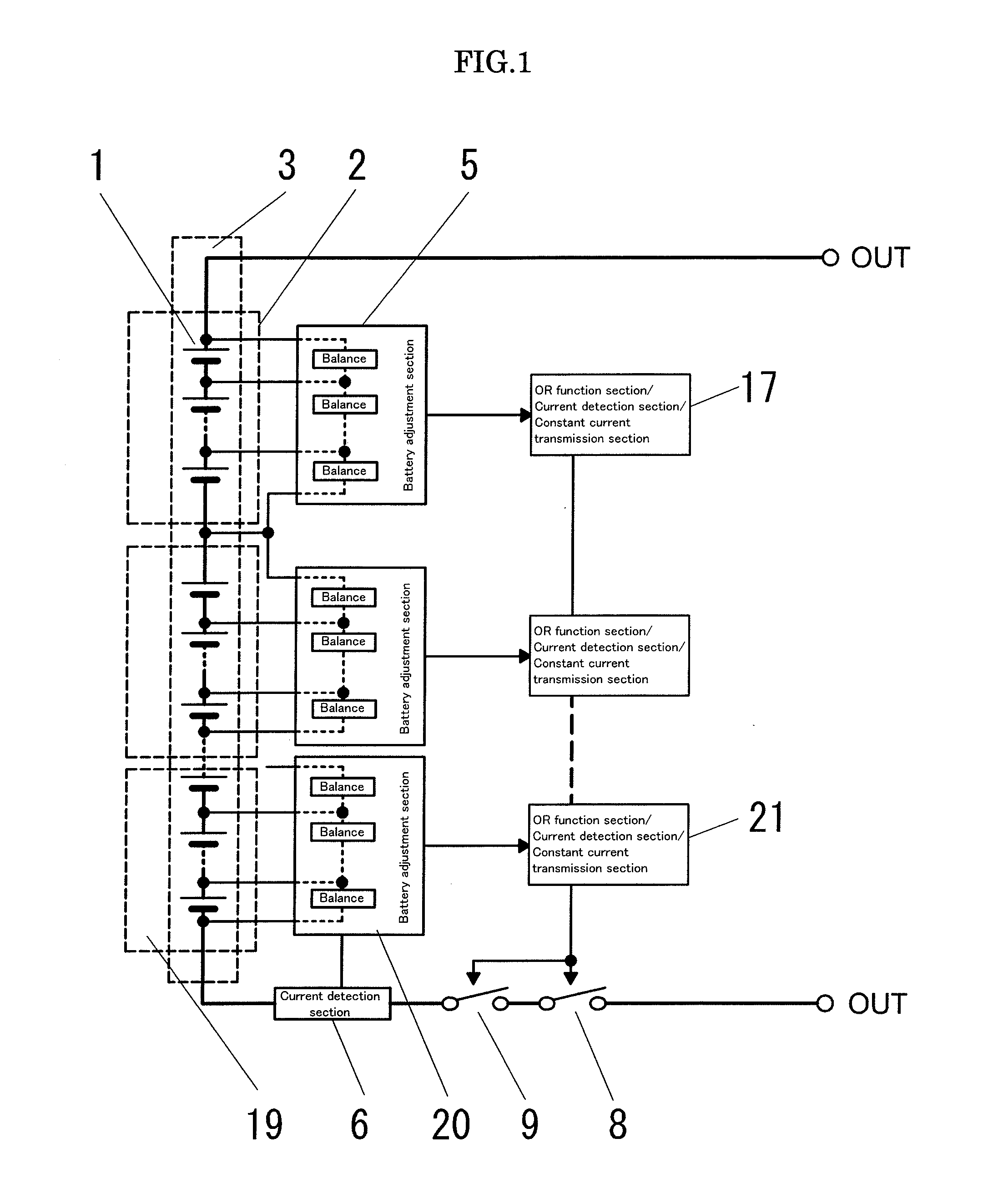

Secondary battery pack

ActiveUS20120025770A1Less operational powerDrive directlyCircuit monitoring/indicationCharge equalisation circuitEngineeringBattery pack

A secondary battery pack of the present invention includes a secondary battery block 3 in which a plurality of unit blocks 2 are connected in series; battery adjustment sections 5 that are each provided for each of the unit blocks 2 and have a function of monitoring the voltage of secondary batteries and a function of adjusting the balance; a charge switch 8; and a discharge switch 9. The secondary battery pack includes transmission sections 17 that receive information from the corresponding battery adjustment sections 5. The transmission sections are connected to the preceding or subsequent transmission sections and are so set that at least either information input from the preceding transmission sections or information input from the battery adjustment sections 5 is output to the subsequent transmission sections. The transmission sections are equipped with a constant current transmission section that transmits with a constant value of current; and a current detection section that can detect the value of the constant current.

Owner:NEC ENERGY DEVICES LTD

Miniaturized, low power, wireless transmitter and receiver with on-chip antenna, and wireless coupling of on-chip and off-chip antenna

ActiveUS8412290B2Simple structureLow powerAntenna arraysSolid-state devicesDual modeSoi cmos technology

Owner:KING ABDULLAH UNIV OF SCI & TECH

Bias measurement for MEMS gyroscopes and accelerometers

InactiveUS20120198934A1Eliminate bias driftSmall sizeSpeed measurement using gyroscopic effectsTesting/calibration of speed/acceleration/shock measurement devicesAccelerometerGyroscope

A system and method for separating bias instability of MEMS inertial instruments such as gyroscopes or accelerometers from the instrument signal, in which the inertial measurement instrument has an input axis and an output signal, and the bias instability has a frequency. The instrument is rotated about a rotation axis that is orthogonal to the input axis, at a frequency that is greater than the bias instability frequency. The instrument output signal is detected, and demodulated with a phase-sensitive detection method referenced to the instrument rotation.

Owner:MILLI SENSOR & ACTUATOR SYST

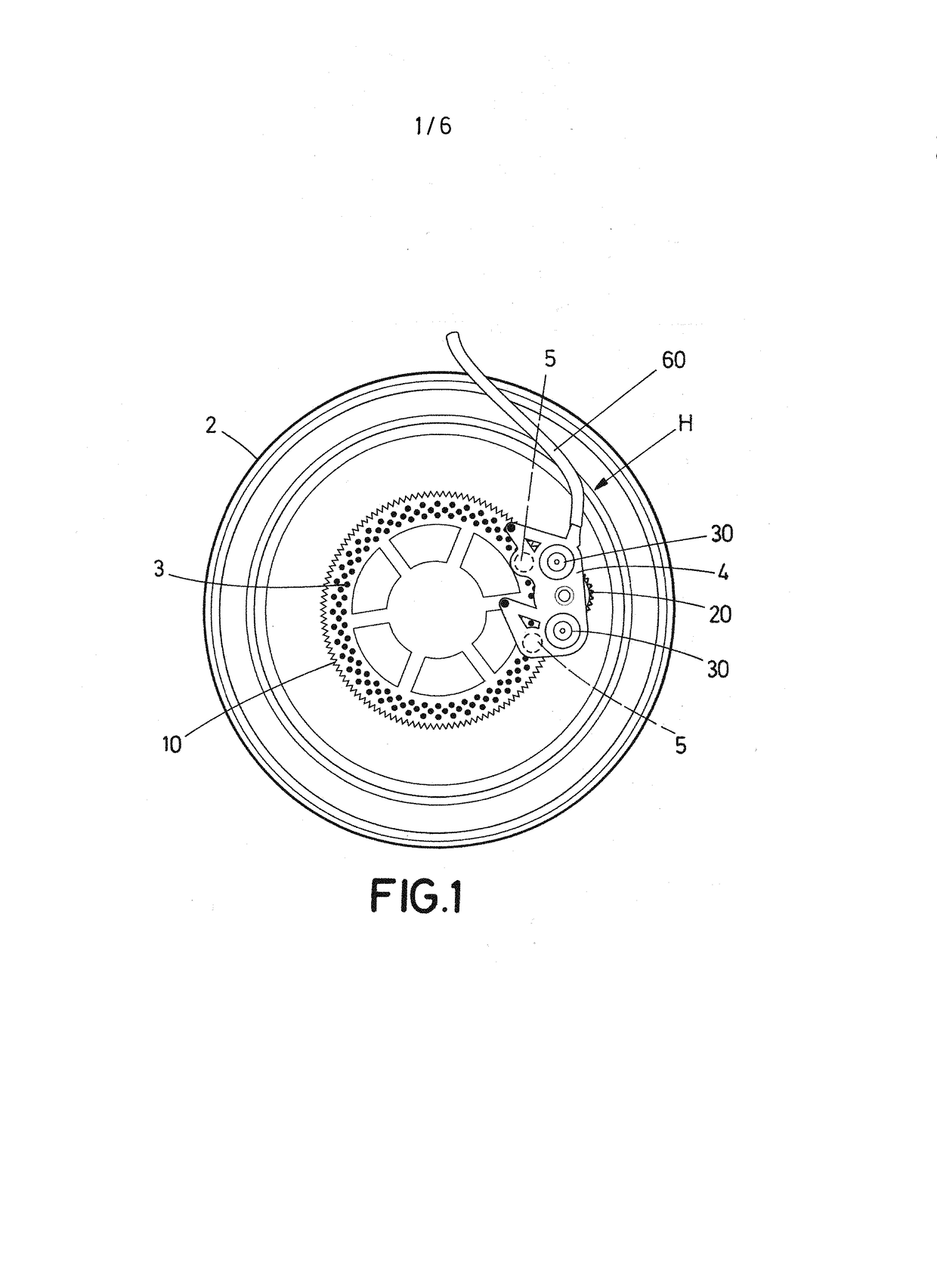

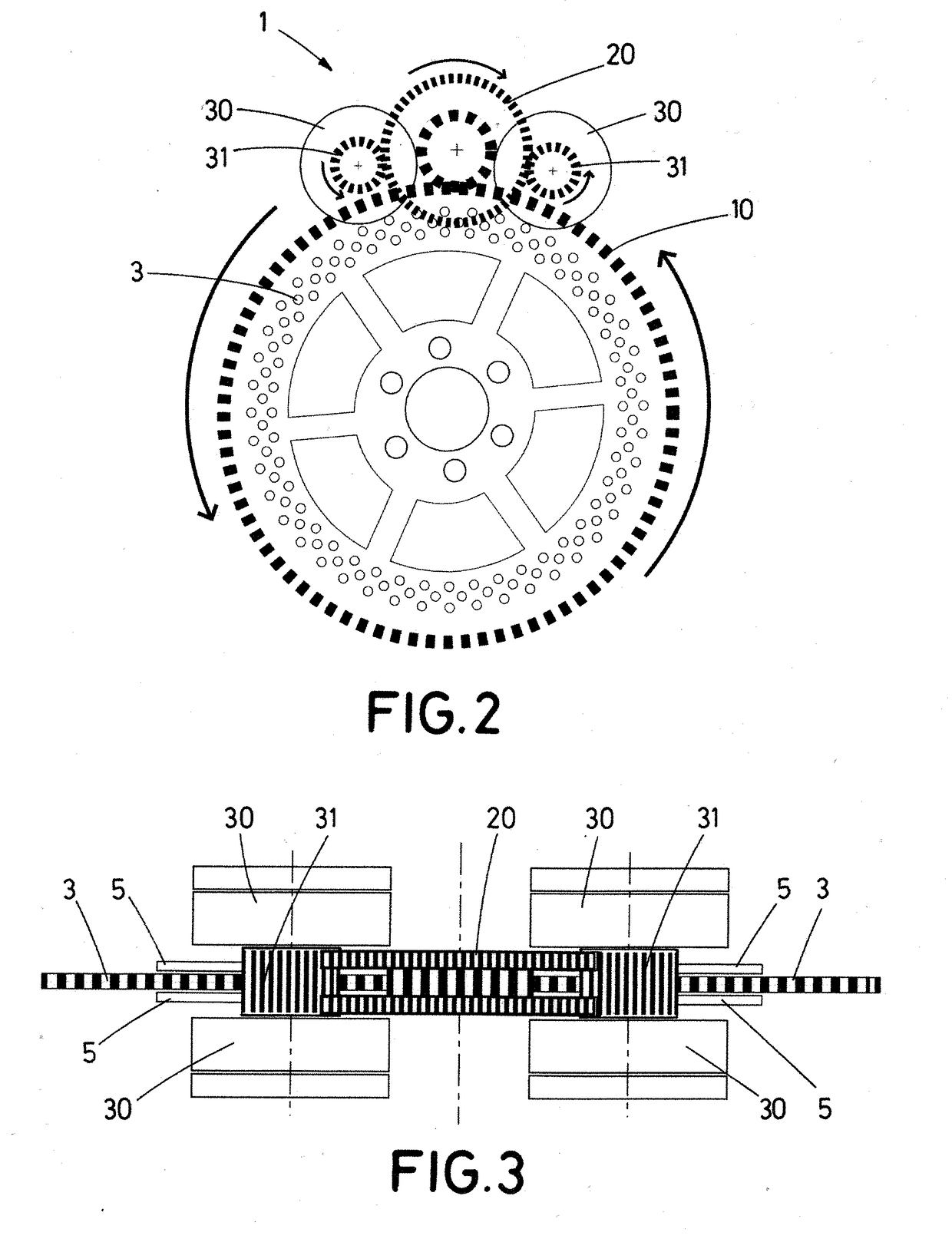

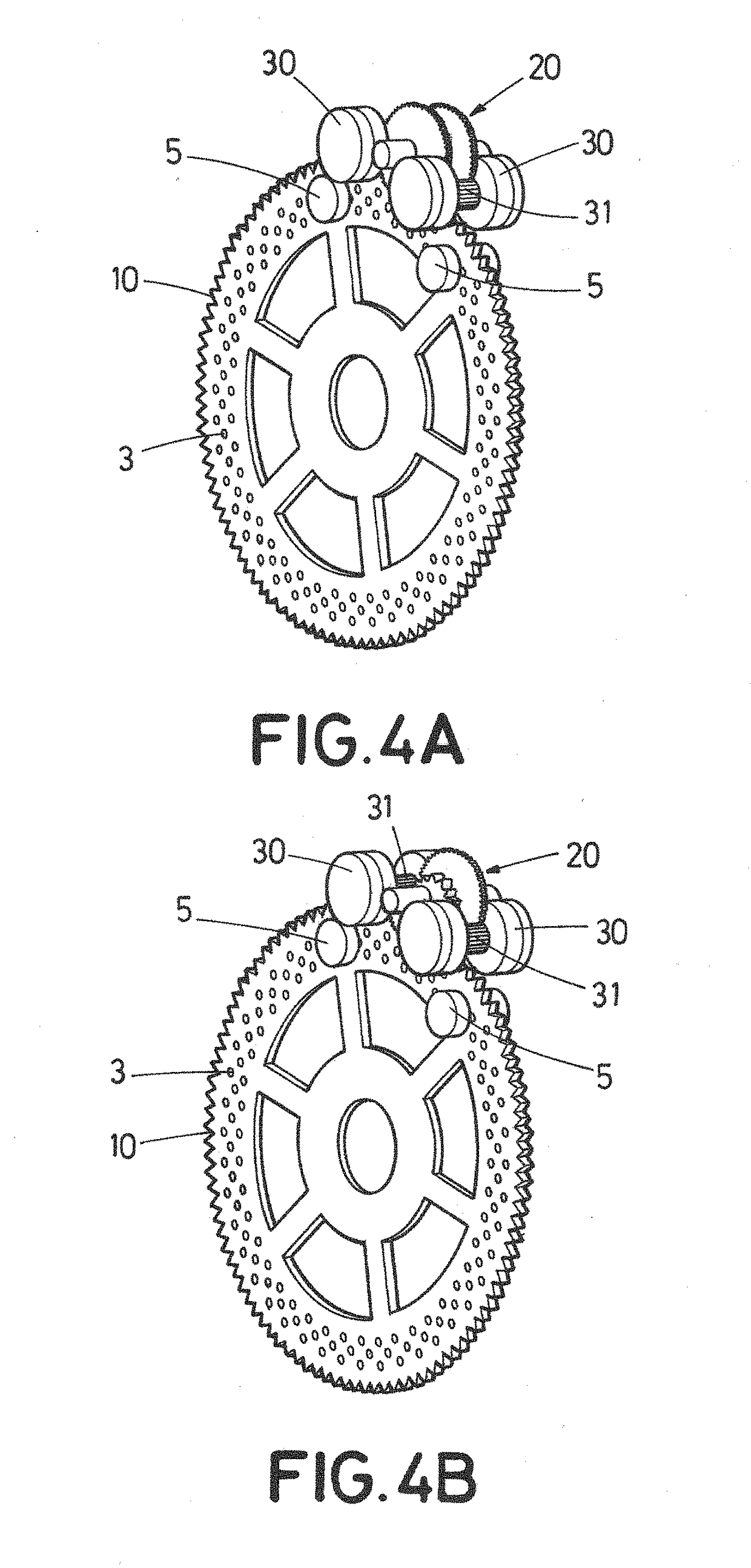

Transmission system for vehicles, and vehicle incorporating said transmission system

InactiveUS20190003534A1Easy to installDrive directlyFluid actuated brakesBraking element arrangementsCalipersRegenerative system

The present invention allows providing a direct drive, which provides drive and traction to the breaking assembly of the vehicle in question, and it further allows the actuation thereof as a regenerative system during braking times, wherein said transmission system (1) comprises: a brake disc (3) having a toothing (10) on its perimetral edge, acting as a main gear; a brake caliper (4) coupled to the brake disc (3) and comprising at least one electric motor (30) assembled on said brake caliper (3); and wherein the at least one electric motor (30) has a secondary gear (31) in turn coupled to the cogging (10) of the brake disc (3) for the operation and / or deceleration thereof. According to another object of the invention, a vehicle incorporating said transmission system (1) is described.

Owner:MOTORDISC ELECTRIC TRANSMISSION SL

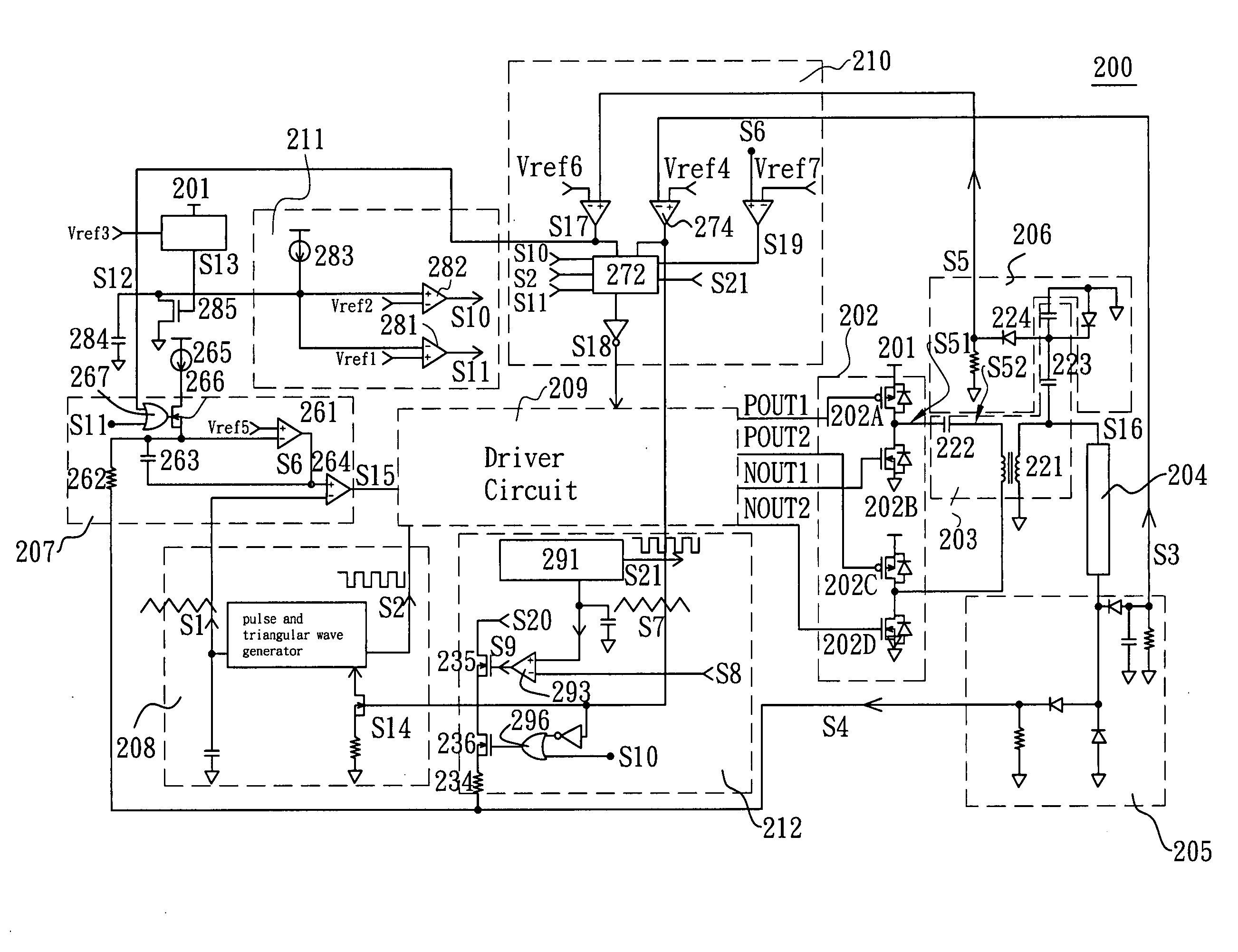

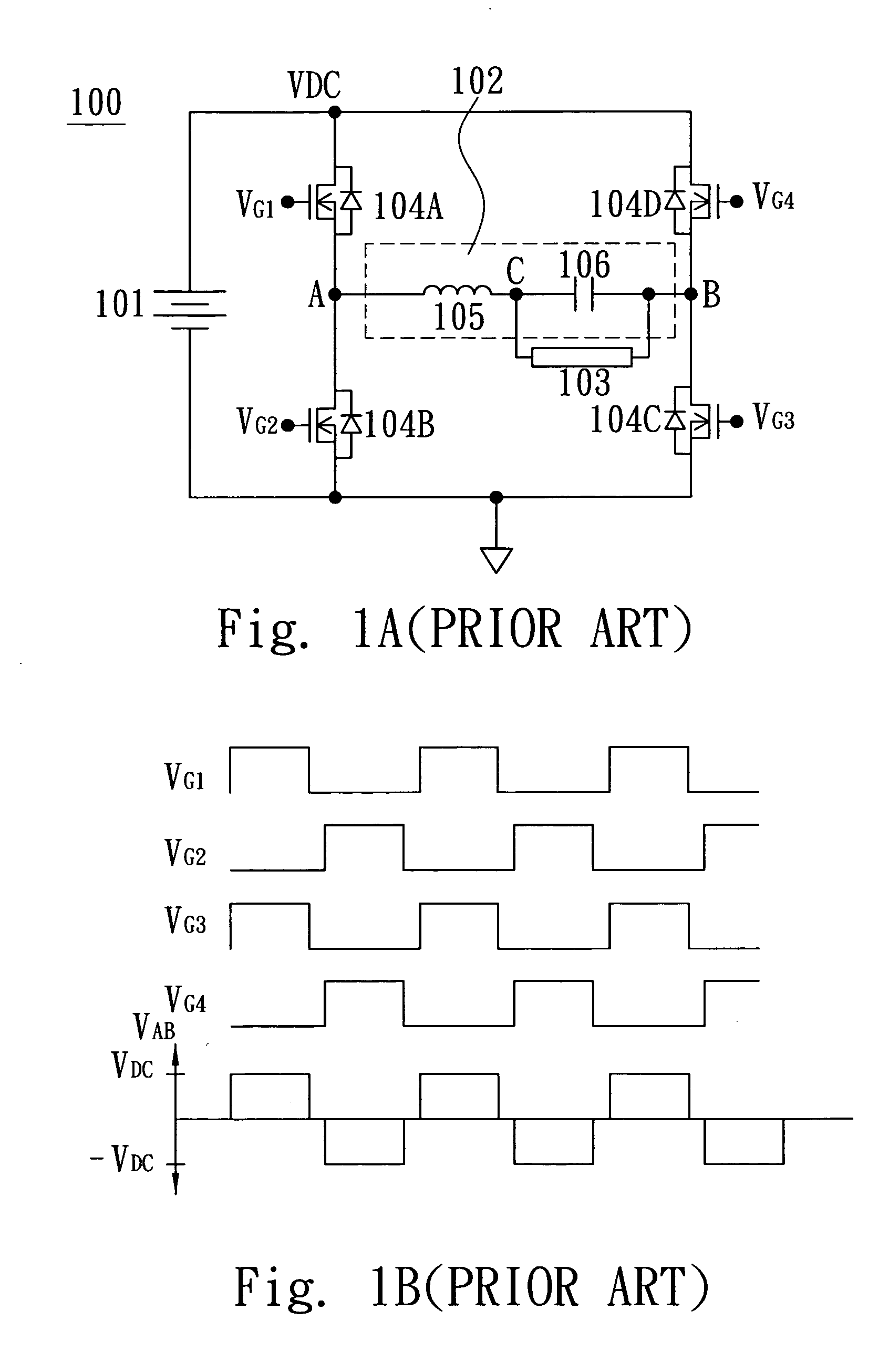

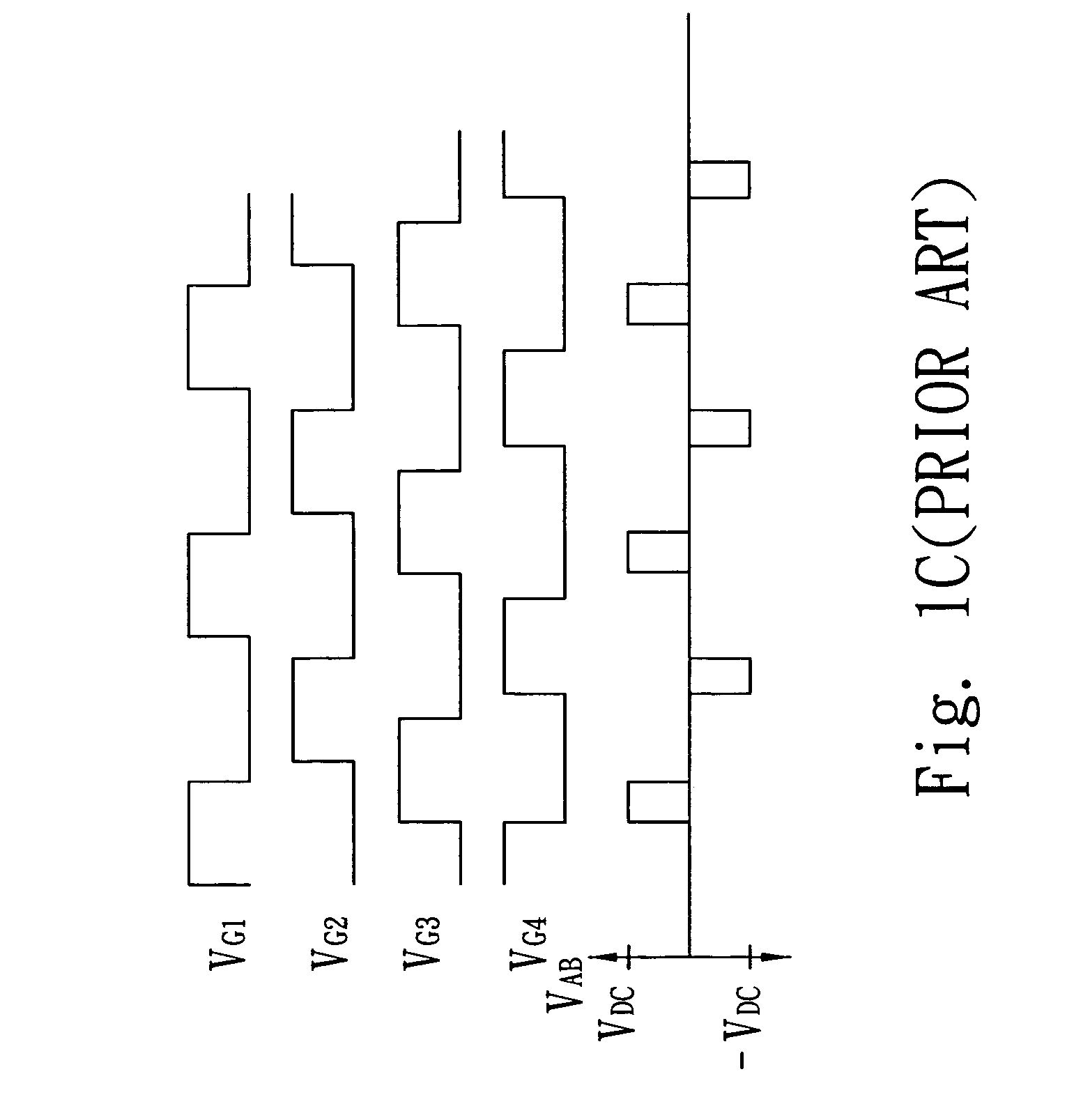

DC/AC inverter

InactiveUS20060203525A1Reduce noiseSimple designEfficient power electronics conversionConversion with intermediate conversion to dcElectricityDriver circuit

Owner:BEYOND INNOVATION TECH

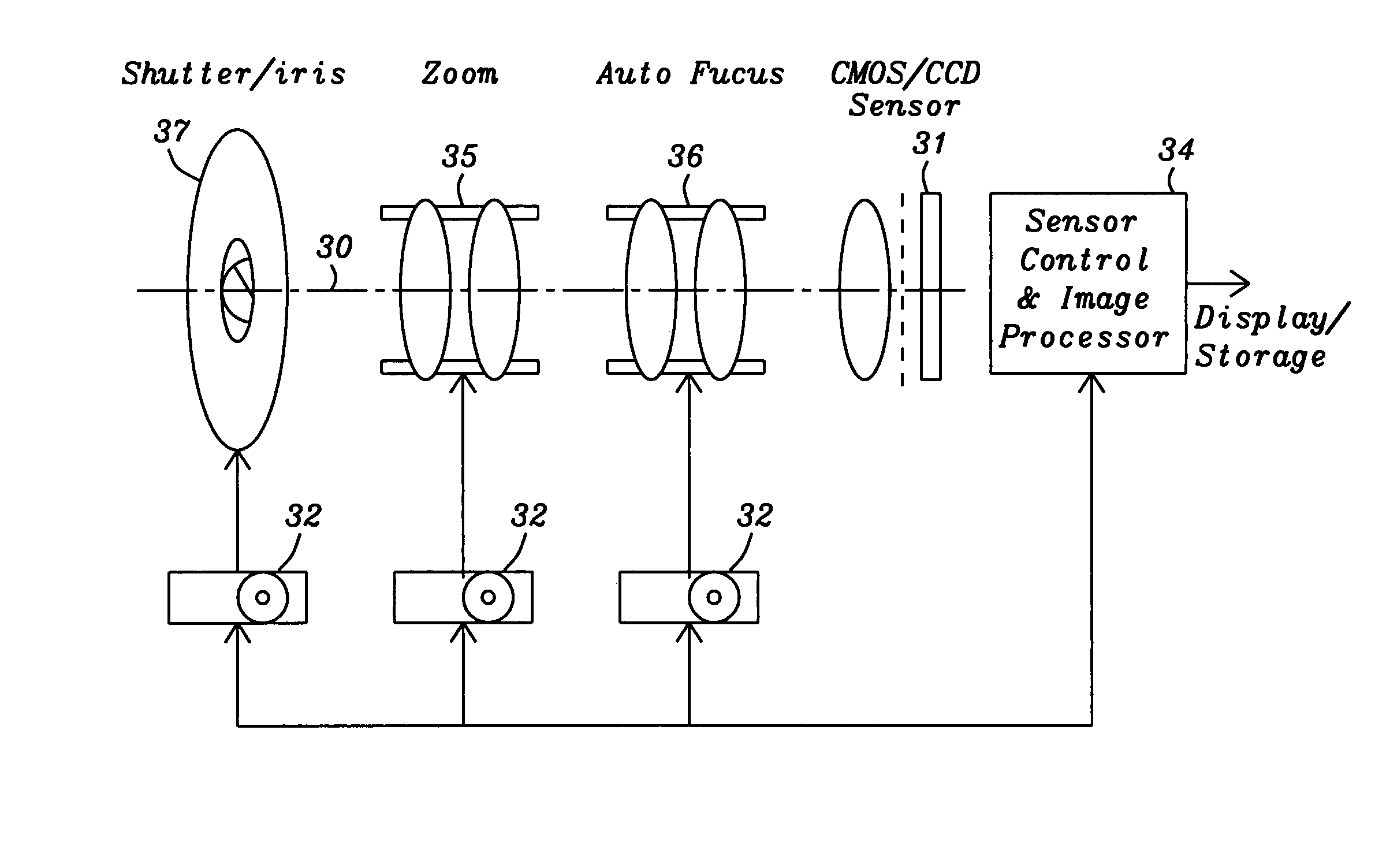

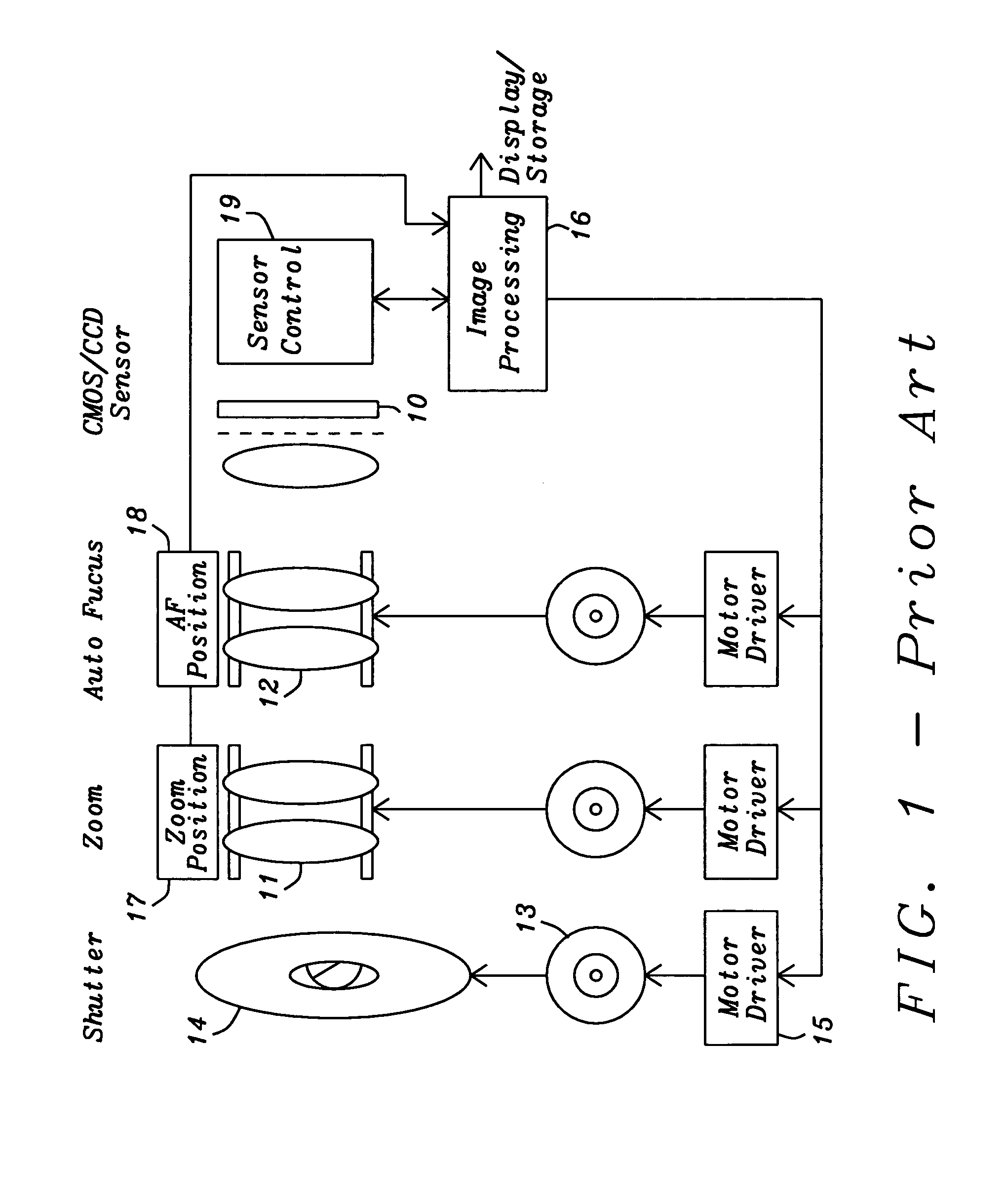

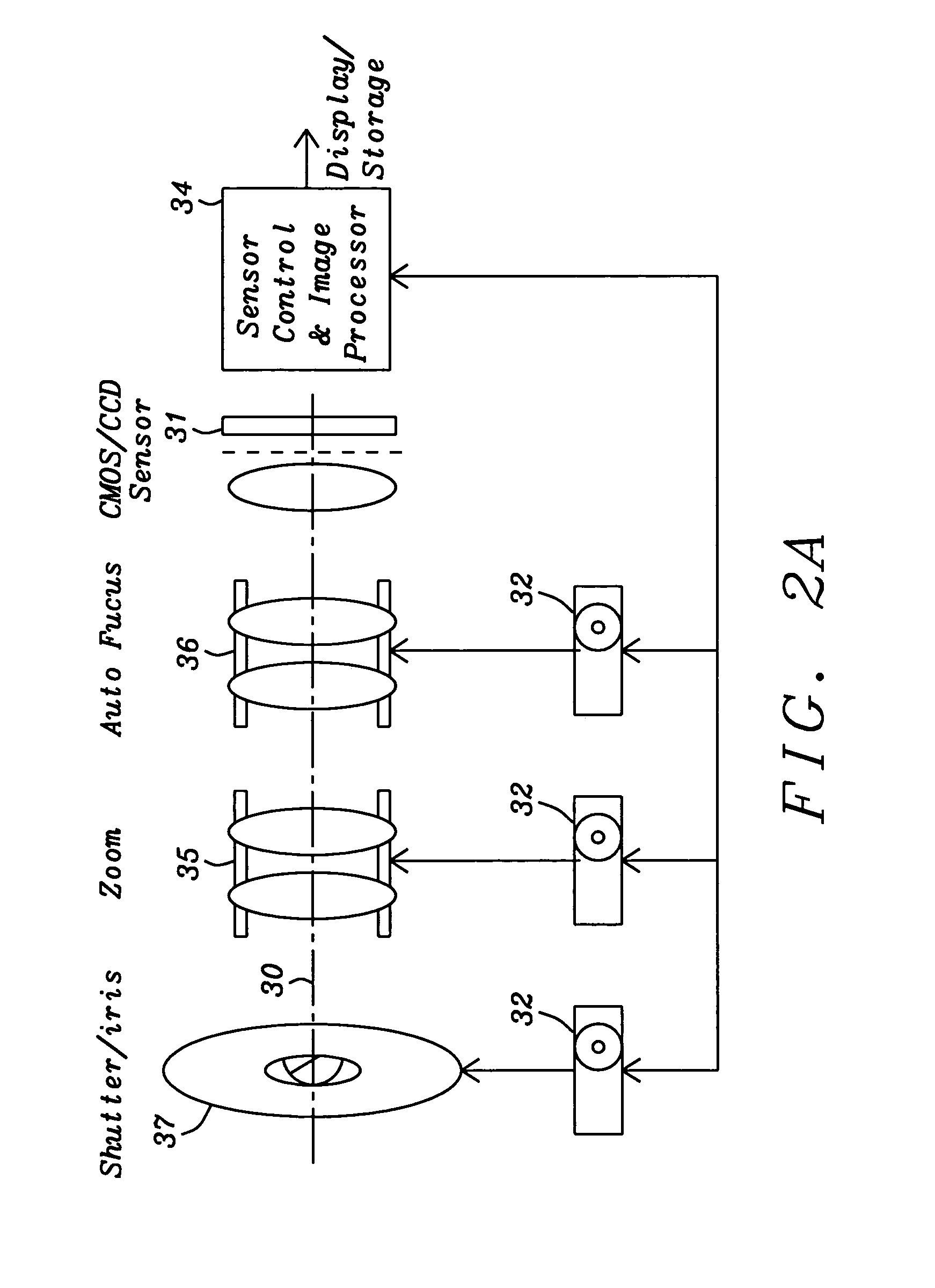

Compact camera modules with Lavet stepping-motors as actuators

InactiveUS20080075446A1Reduce power consumptionExtend battery lifeProjector focusing arrangementCamera focusing arrangementCamera lensEngineering

A horological motor of the Lavet motor concept is used to form an actuator to control movement of a lens system to reduce power consumption in digital camera units used in various electronic equipment, e.g. PDA's, mobile phones, digital still cameras and camcorders, and as a result increase battery life. The coils of the horological motor are driven with CMOS I / O signals eliminating the need for high current motor drivers and allowing the integration of all picture capture functions, including the light sensitive pixel array, into a single chip to form a system on chip implementation. A plurality of actuators is used to control a lens system comprising auto focus, zoom and shutter and iris functions. A gear transmission system is used to allow the motor of the actuator to move in micro step, which allows calibration of the motor against mechanical barriers.

Owner:RPX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com