Twisting or micro-moving frictional wear test method and device thereof

A fretting friction and wear test technology, which is applied in the field of friction technology research, can solve the problems of manual control reproduction or simulation difficulties, life loss and trouble, fatigue life reduction, etc., and achieve high control and test accuracy, high degree of automation, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

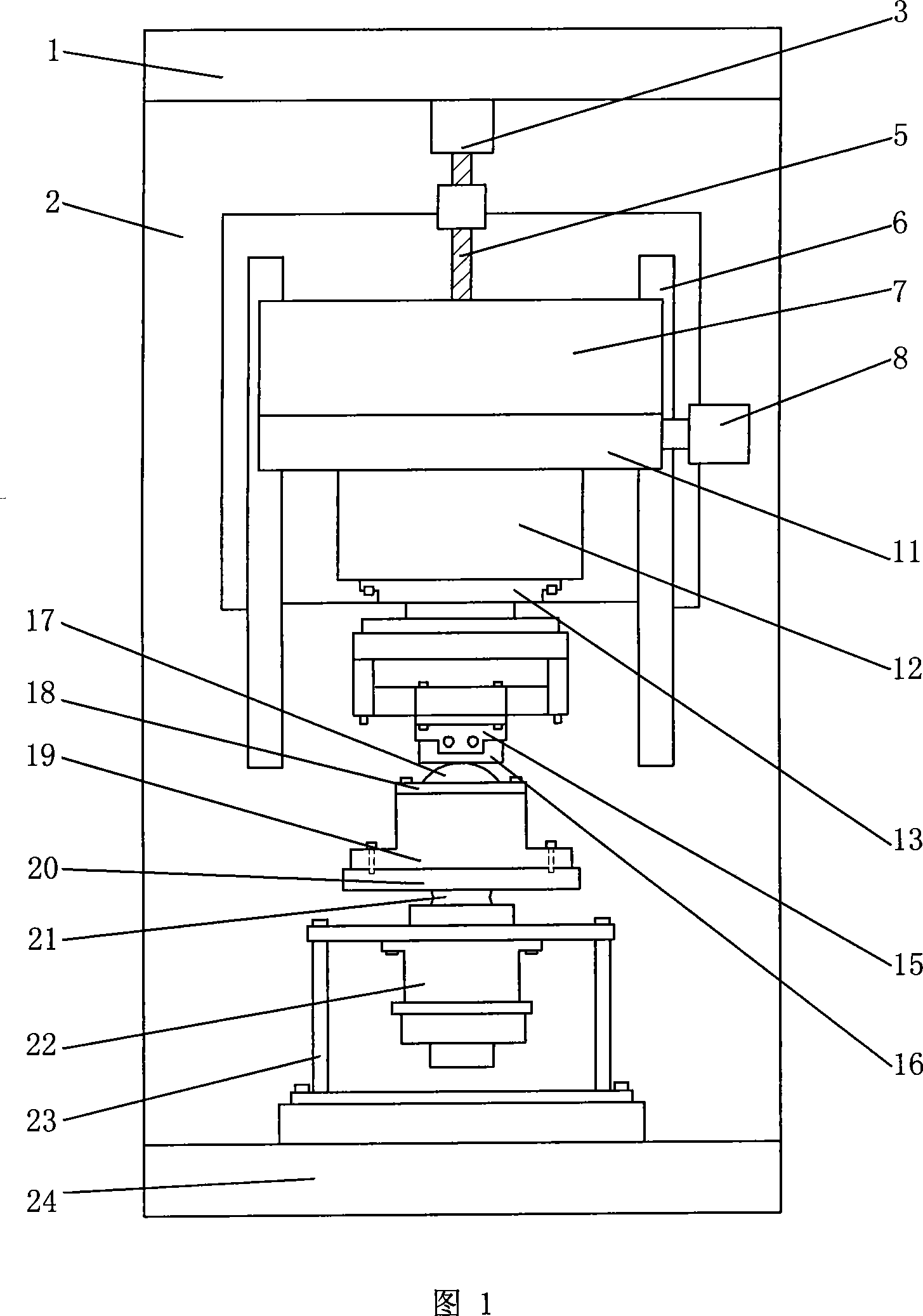

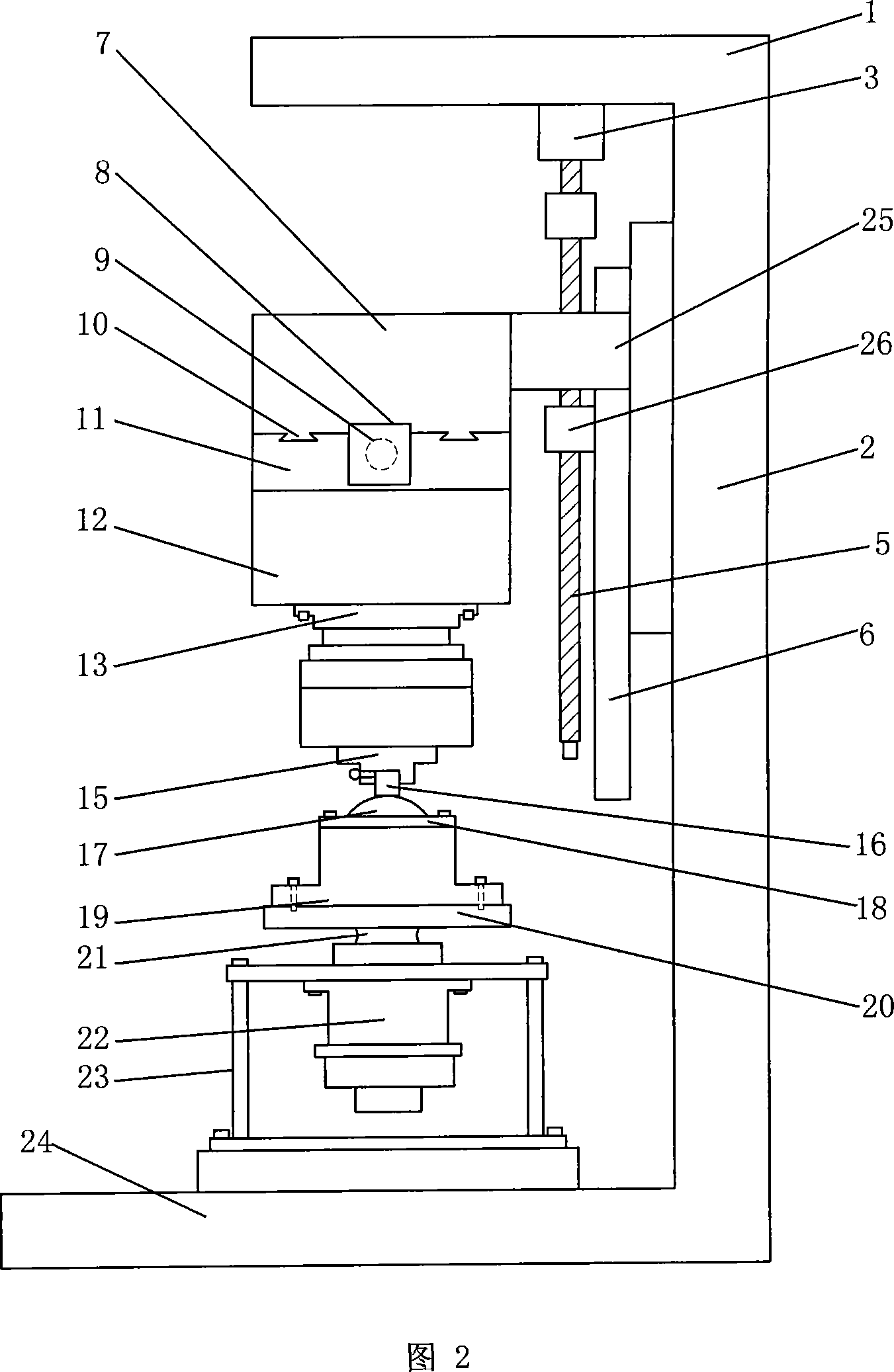

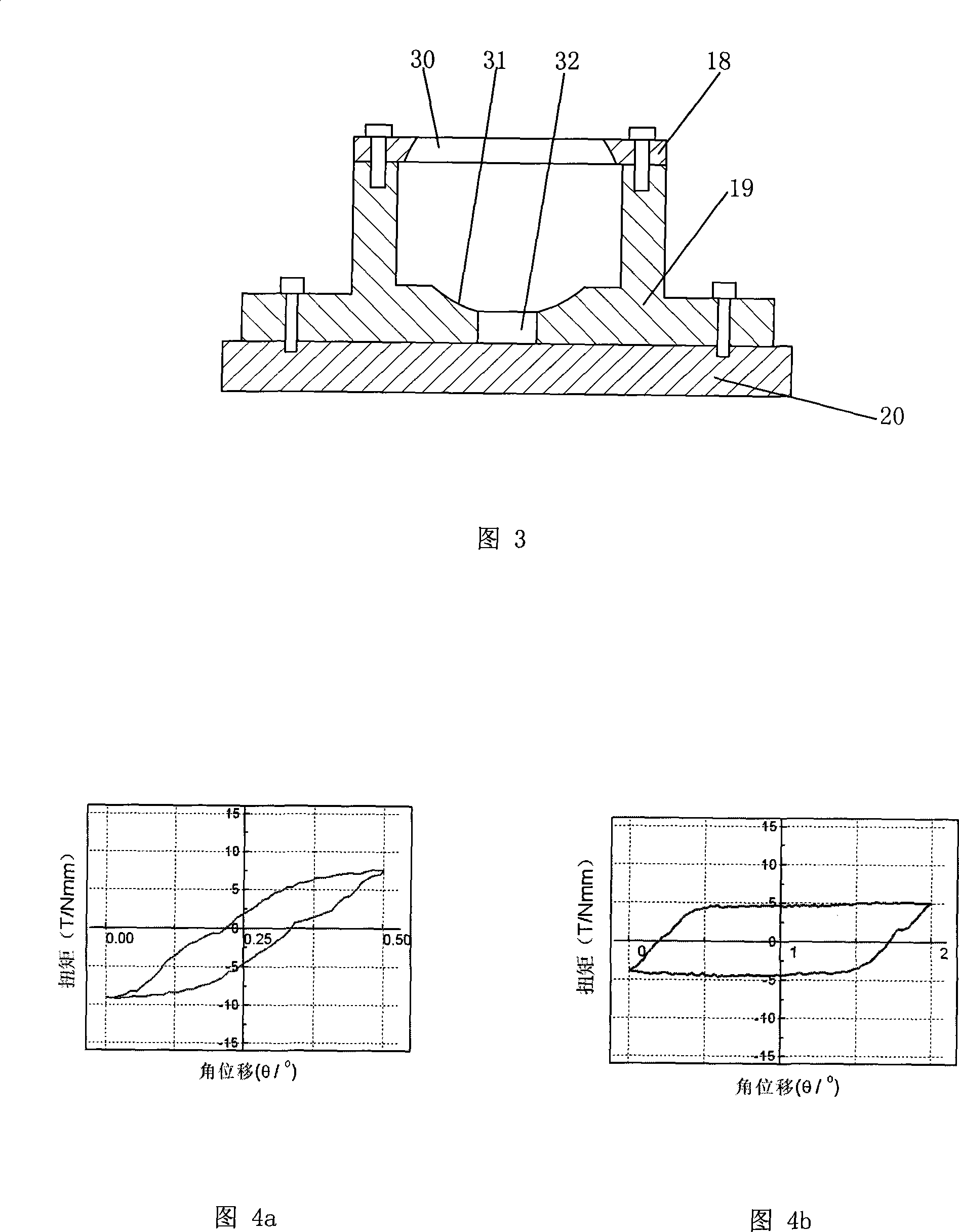

[0045] A kind of specific embodiment of the present invention is, a kind of torsion fretting friction and wear test method, and its practice is:

[0046] a. Clamp the upper specimen on the upper fixture, and then fix the lower fixture and the high-precision low-speed turntable through threads, and the vertical centerline of the clamping cavity of the lower fixture is aligned with the rotation axis of the high-precision low-speed turntable, Clamp the spherical lower test piece with the lower clamp;

[0047] b. Control the up and down movement of the upper fixture through the data acquisition control system, so that the upper and lower specimens are in contact with and apply the set load P, and at the same time, through the control of the data acquisition control system, the lower fixture and the lower specimen held by it are controlled by the data acquisition control system. The reciprocating rotation of the set speed ω, rotation angle θ and reciprocating times N realizes the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com