Piston reciprocating internal-combustion engine working substance flow system and its device

A piston and engine technology, applied in the field of piston reciprocating internal combustion engines, can solve the problems of increased engine complexity and manufacturing costs, lack of regulation of pressurized air volume and temperature, and additional power consumption, etc., to achieve compact structure, stable supercharging, Effect of reducing heat transfer loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

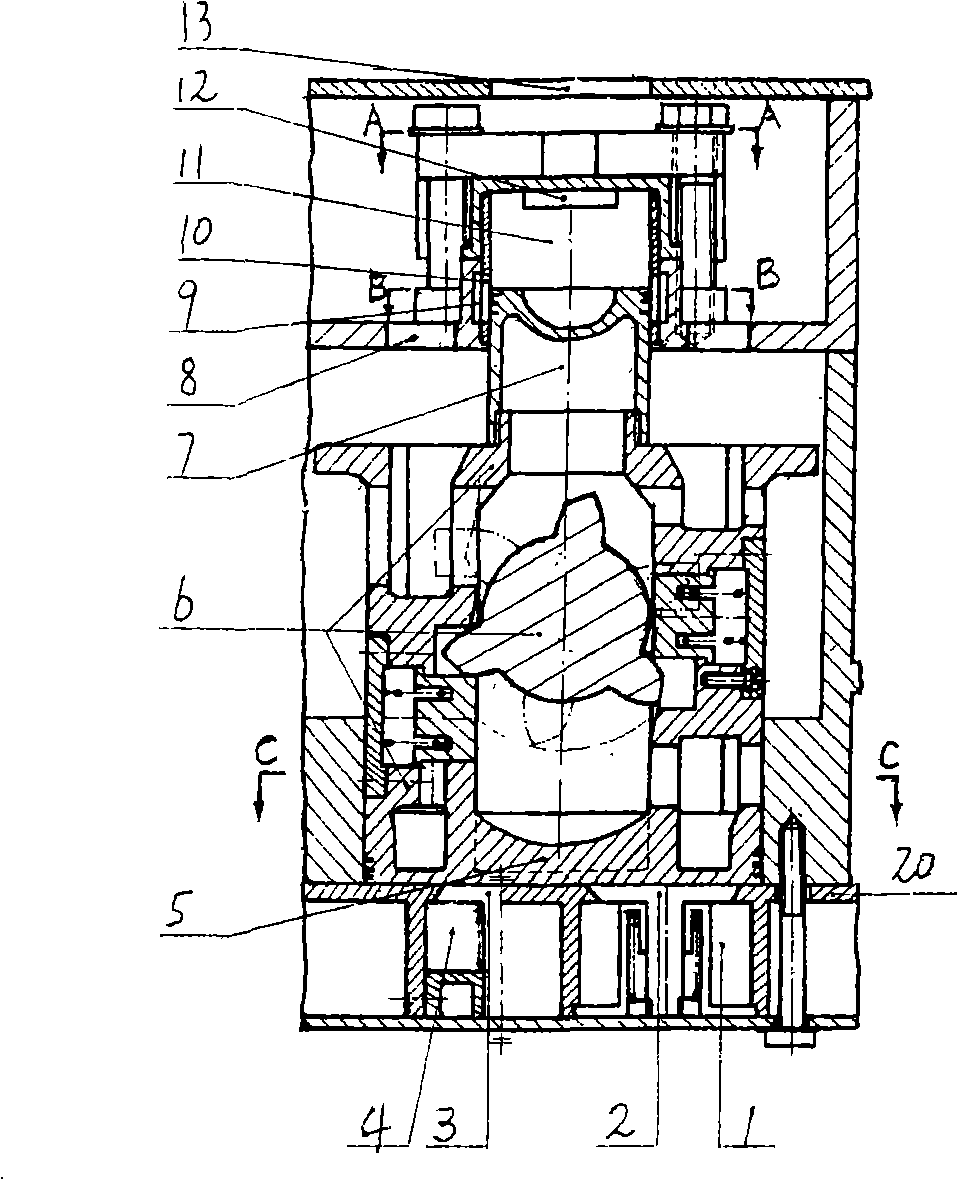

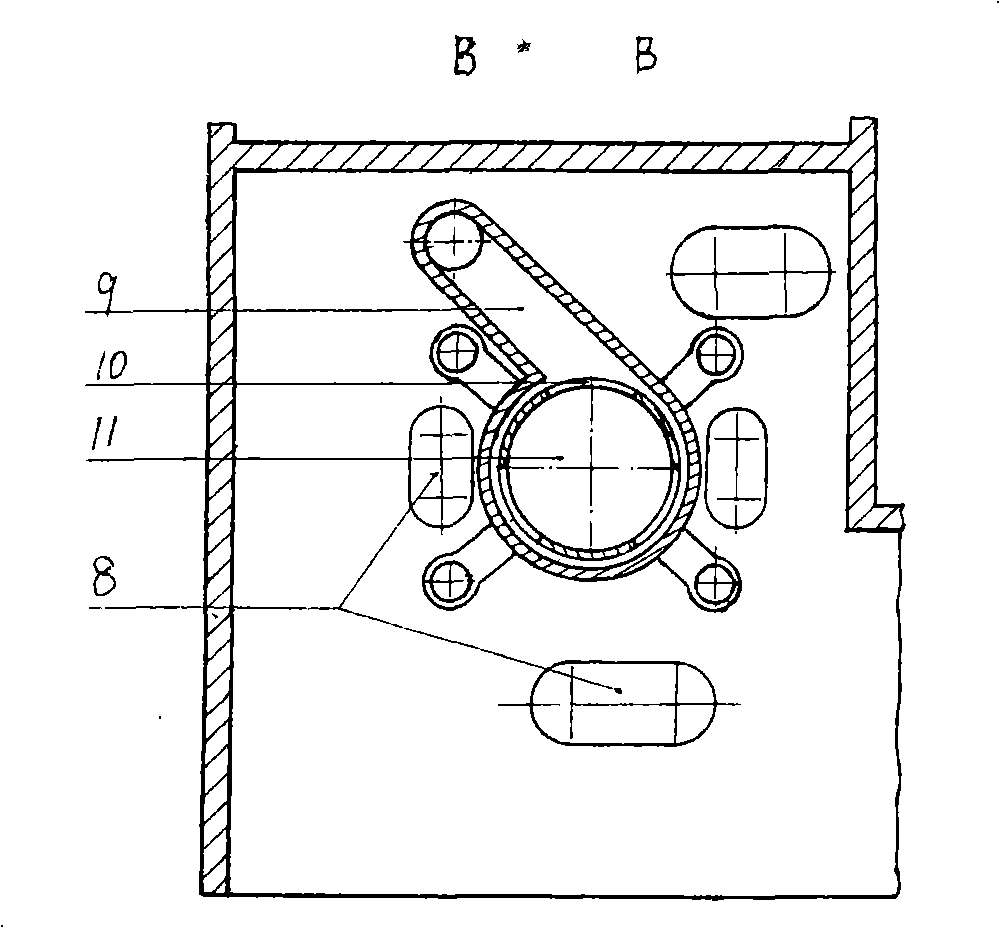

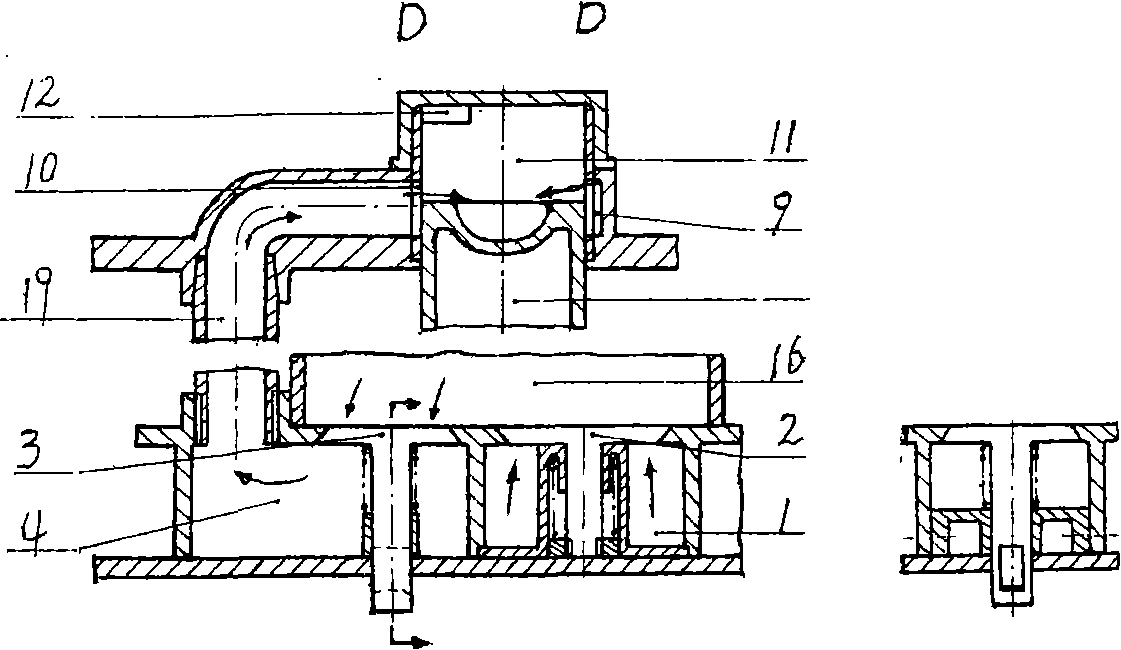

[0012] Specific implementation mode 1: as figure 1 As shown: the application "a rack and pinion mechanism" (application number 200710147446.7) is used for power transmission. The upper horizontal connection part of the rack frame in this mechanism [6] is connected to the engine cylinder piston [7], and the lower horizontal connection part is made booster cylinder piston [5], so the two pistons are synchronous and have the same stroke; the diameter of the booster cylinder piston [5] is more than 2 times the diameter of the starting piston [7], forming an ultra-high booster mechanism, so that the power of the engine is The power of the engine cylinder is more than 5 times when it is not boosted (the specific value depends on the design requirements), the booster cylinder is made under the power output shaft (gear shaft), and the four sides are continuously cast on the body with transverse partitions (as shown in Figure 2.1 ).

[0013] The area inside the booster cylinder bottom...

specific Embodiment approach 2

[0020] Specific implementation mode 2: as Figure 6 Shown: frame [30] upper end connects piston [7] (piston lower mouth makes piston skirt, is connected on the frame [30] with screw), crank shaft [31] passes through frame [30] front and rear middle opening, crank pin [33] is placed in the frame [30] and rotates in the frame [30]. The lower end transverse connection part of framework [30] is made booster cylinder piston [5], the structure and arrangement of booster cylinder [16] and cover plate [20] and other parts are identical with embodiment 1, show and illustrate this in the figure omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com