Two speed adjustable speed transmission device for tangential and longitudinal flow threshing separating transmission system

A transmission system, threshing separation technology, applied in the direction of multi-ratio transmission, transmission, gear transmission, etc., can solve the problems of lack of overload protection, reduce the operating efficiency of harvesters, and difficult installation of longitudinal axial flow drum shafts, etc., to achieve Improved stability and transmission efficiency, excellent adaptability and versatility, and compact transmission system routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

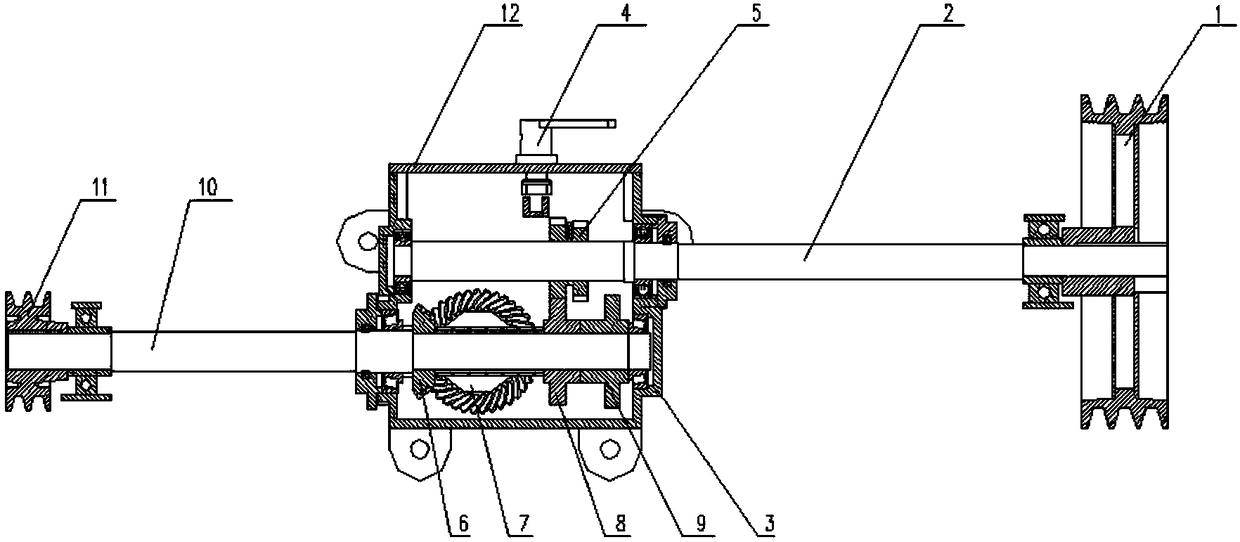

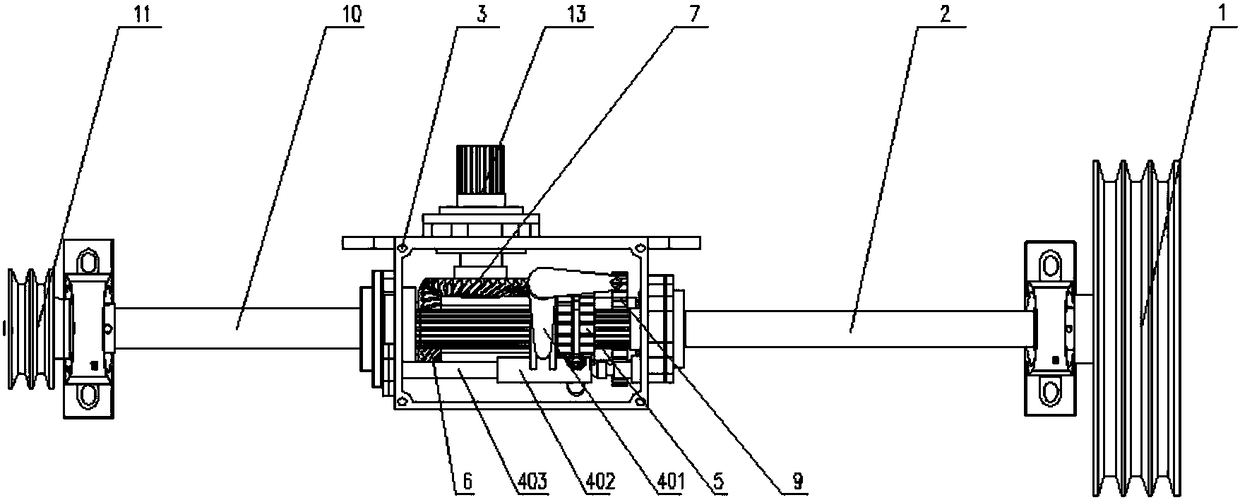

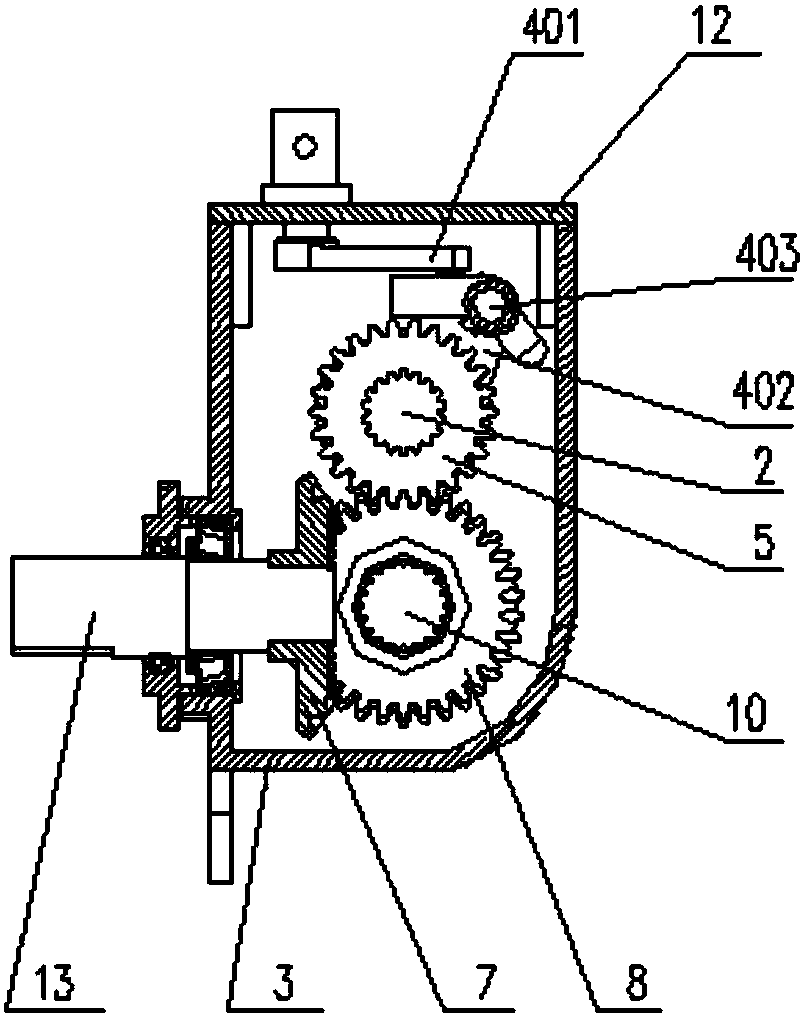

[0039] Such as figure 1 , figure 2 As shown, the two-speed transmission device of the cutting and longitudinal flow threshing separation transmission system of the present invention includes a two-speed gear transmission box body, a shift fork mechanism 4, two pairs of gear shift spur gears, a pair of reversing bevel gears, The input horizontal axis 2, the output horizontal axis 10 and the output vertical axis 13, the axes of the input horizontal axis 2 and the output horizontal axis 10 are parallel and in the same normal plane, and the output horizontal axis 10 is directly below the input horizontal axis 2 The transmission of power is realized between the input cross shaft 2 and the output cross shaft 10 through two pairs of gear shifting spur gears. The combined spur ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com