Vehicular multifunctional electromagnetic differential system

A multi-functional, electromagnetic technology, applied in the field of differential speed and auxiliary braking of motor vehicles, and auxiliary braking of vehicles, it can solve the problems of electronic products being less reliable than mechanical products and expensive to manufacture, so as to shorten the power transmission path and improve the efficiency. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

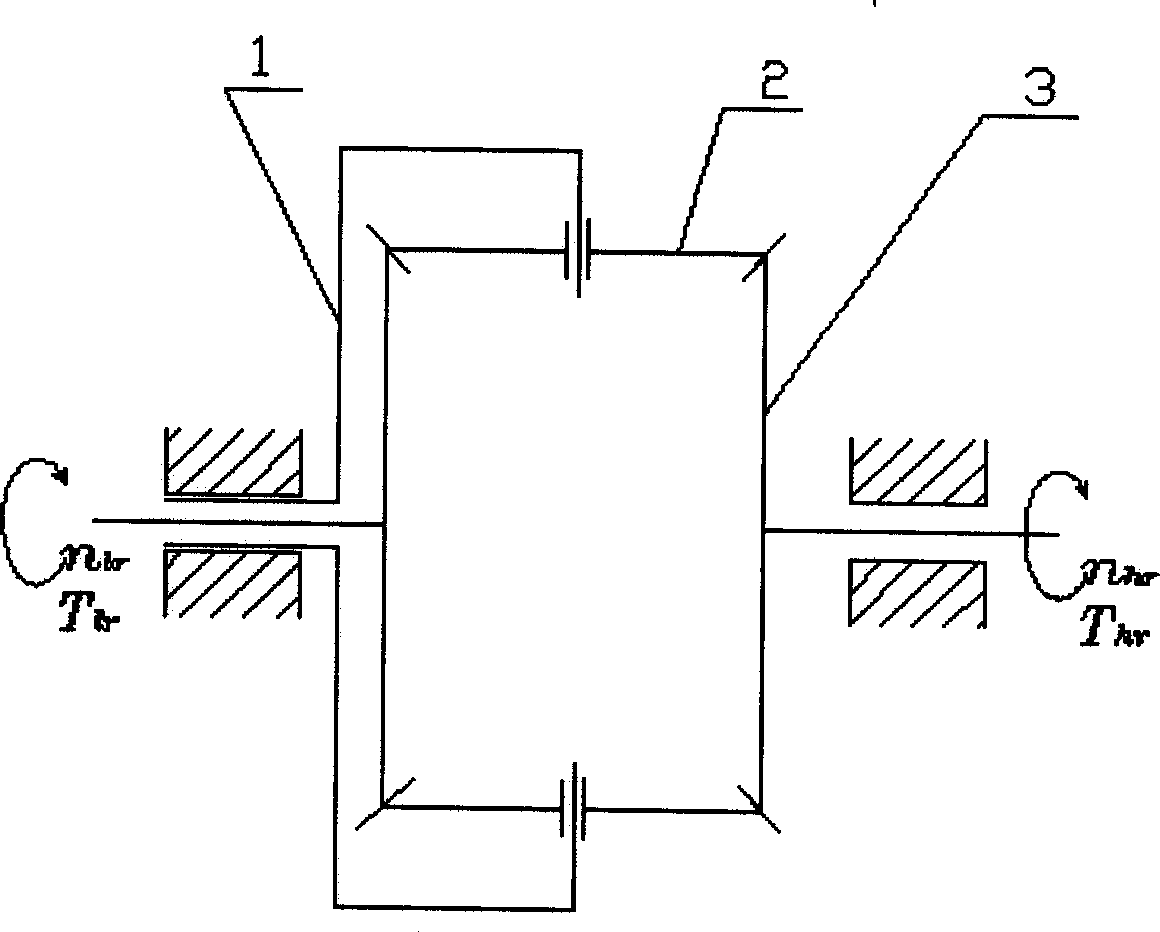

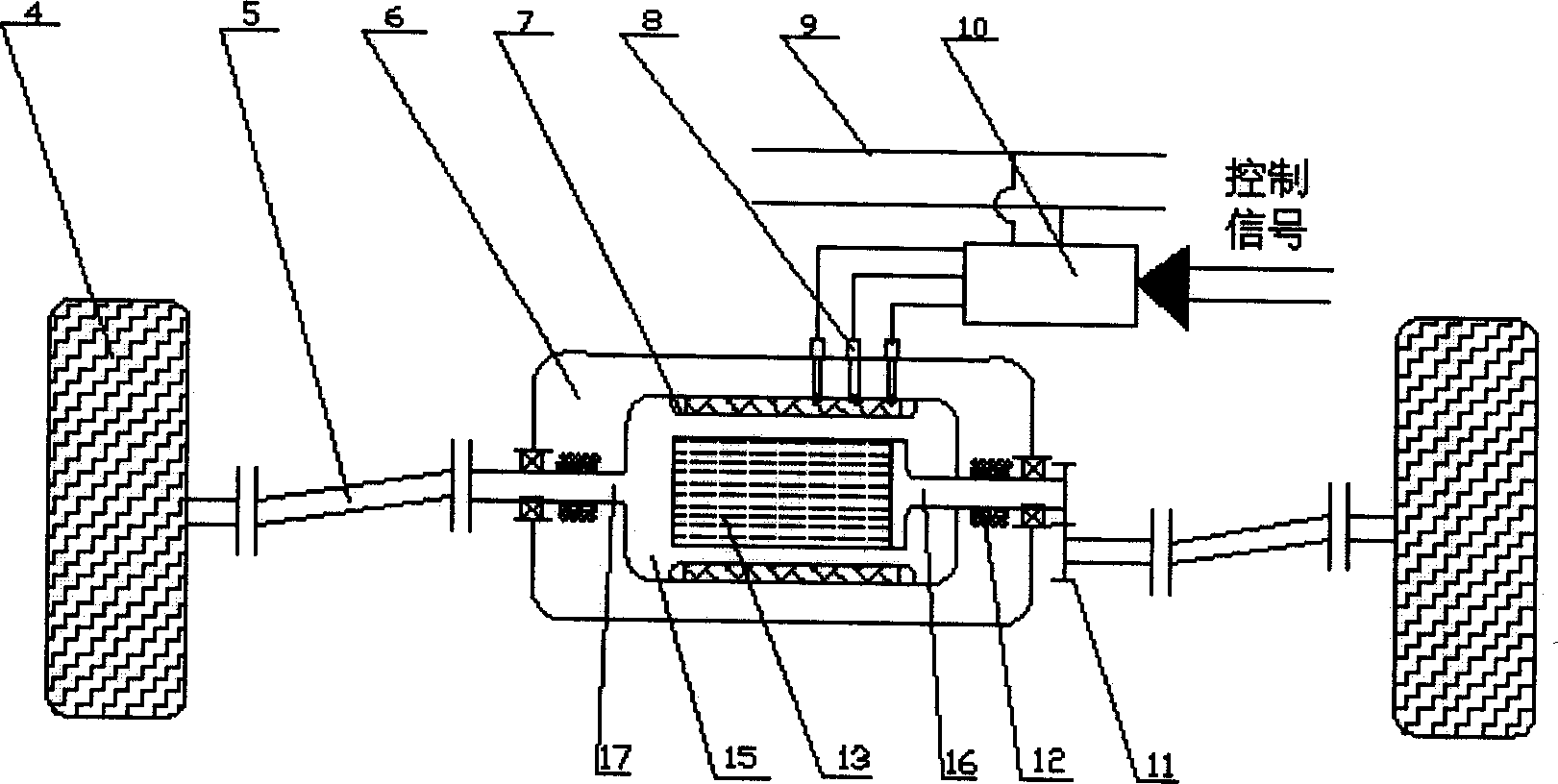

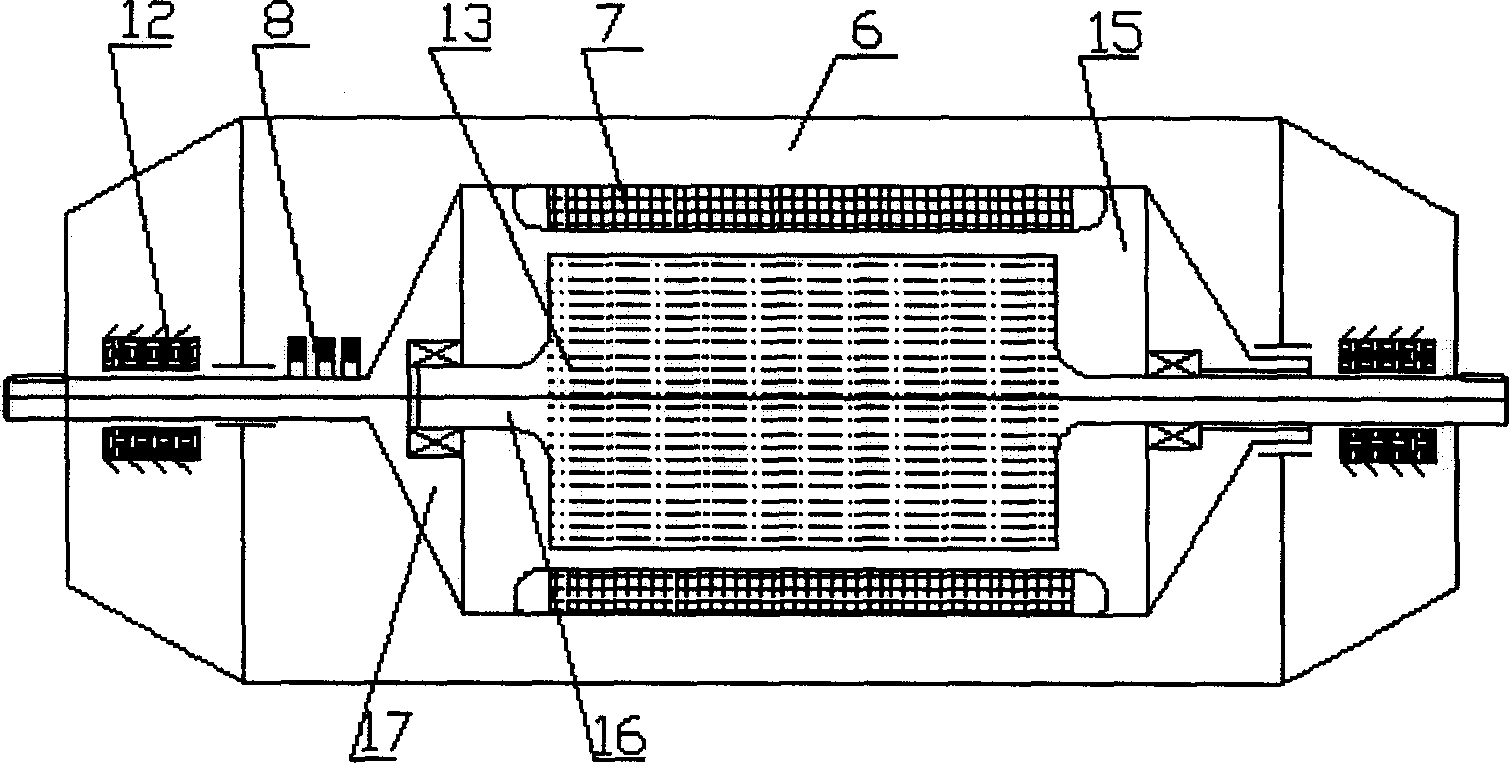

[0022] The vehicle multifunctional electromagnetic differential system is used for the differential. The motor is a squirrel-cage AC asynchronous counter-rotating double-rotor motor. for hybrid vehicles.

[0023] Such as figure 2 , the device of the present invention is made up of counter-rotating towing double-rotor motor 15, differential housing 6, reversing gear 11, left and right constant velocity universal joints 5, motor controller 10, power bus 9, anti-skid electromagnetic brake 12, etc. The counter-rotating dragging dual-rotor motor 15 is composed of an outer rotor 17 wound by an excitation winding and an inner rotor 16. The outer rotor 17 is connected to the wheel 4 on one side through a connecting device, and the inner rotor 16 is connected to the other side wheel 4 through a reversing gear 11 and a connecting device. The wheels 4 are connected; the excitation winding 7 on the outer rotor 17 is connected to the controller 10 through the slip ring mechanism 8 , and...

Embodiment 2

[0053] The vehicle multifunctional electromagnetic differential system is used for the differential. The permanent magnet DC motor is selected as the counter-rotating and dragging dual-rotor motor. for internal combustion engine vehicles.

[0054] Compared with Example 1, the dual-rotor permanent-magnet DC motor with counter-rotating dragging uses permanent magnets instead of excitation windings as a constant magnetic field source, which can improve the volume, weight, loss and heat of the motor, and its structure is simple and easy Easy to process. There are many types of permanent magnet materials used in the motor, such as general-purpose ferrite, aluminum-nickel drill, rare earth permanent magnet, bonded permanent magnet, etc., and this embodiment is ferrite. The shape of the permanent magnet material generally also has ring shape, tile shape, fan shape, square etc., and the present embodiment is tile shape. According to the performance requirements of internal combusti...

Embodiment 3

[0056] The vehicle multifunctional electromagnetic differential system is used for the differential. The series-excited DC motor is selected as the counter-rotating dragging double-rotor motor. For pure electric vehicles.

[0057] Series excited DC motor has the characteristics of high speed, small size, light weight, and convenient speed regulation, so it is used as a power source in many electric tools. The double-rotor motor in this system can also choose this type of motor. However, the series motor is more prone to stall and the armature temperature rises sharply. Therefore, when using series excited motors, relatively high requirements should be put forward in terms of manufacturing quality, and reasonable control strategies and safety protection measures should be used. The motor is controlled by a common DC controller. The structure and working principle of the system are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com