Electromagnetic direct-drive linear hydraulic pump based on dissymmetric-flow-pass heat dissipation

An asymmetric, hydraulic pump technology, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, can solve problems such as internal heat dissipation difficulties, electromagnetic direct-drive plunger pump heating, etc., and achieve compact structure, Solve severe fever and enhance the effect of air gap magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

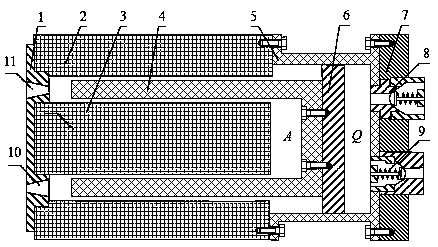

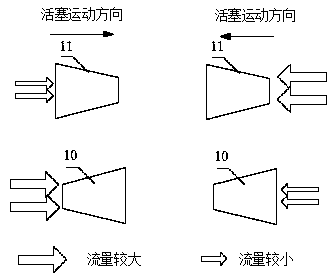

[0019] like Figures 1 to 2 As shown, an electromagnetic direct-drive linear hydraulic pump based on asymmetric flow channel heat dissipation includes an end cover (1), an outer stator of a linear actuator (2), an inner stator of a linear actuator (3), and a mover of a linear actuator ( 4), hydraulic cylinder (5), piston (6), valve body (7), liquid outlet valve (8), liquid inlet valve (9), inlet flow channel (10) and exhaust flow channel (11); Its features include that the outer stator (2) and the inner stator (3) of the linear actuator are coaxially fixed through the end cover (1), and the outer stator (2) and the valve block (7) of the linear actuator are adopted through the cylinder block (5) of the linear actuator. The screws are coaxially fixed and the axial end faces are parallel to each other. The valve body (7) is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com