A countercurrent heat exchanger

A heat exchanger, countercurrent technology, applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of bulky equipment, can not meet the technical requirements of the application field, etc., to increase the tensile strength and creep rupture strength, reasonable velocity distribution, heat transfer enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solution of the present invention will be further described below in combination with specific embodiments.

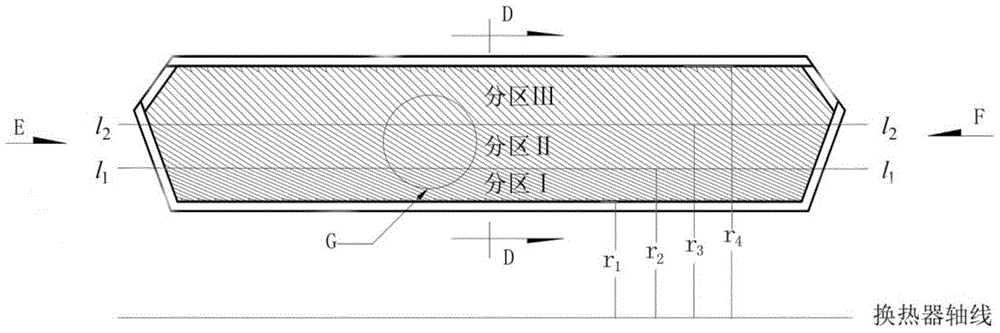

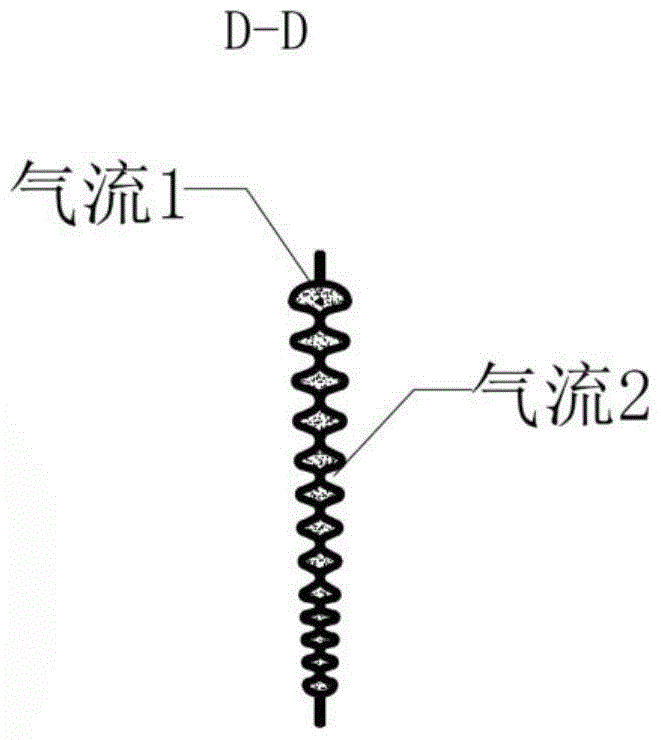

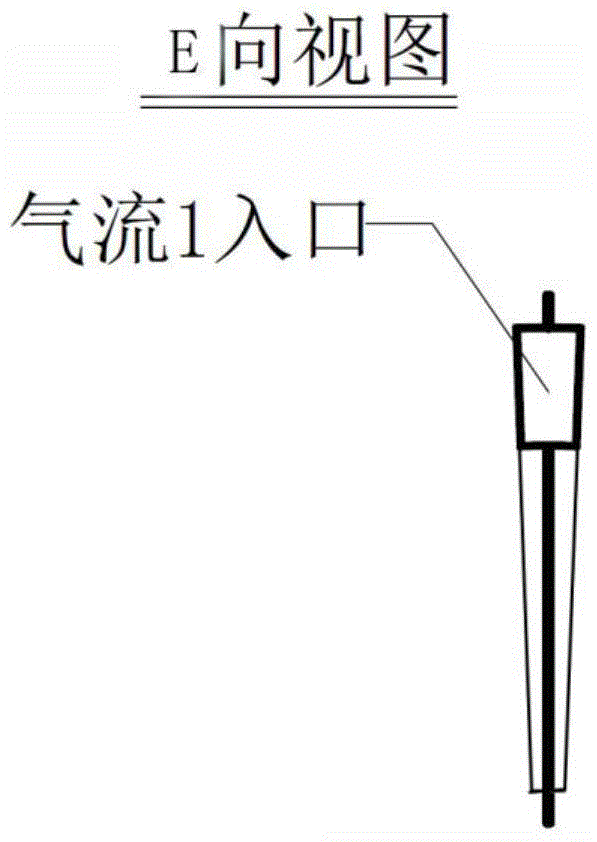

[0051] In this embodiment, the countercurrent heat exchanger of the present invention is a wall-type cold and hot air flow heat exchanger, the two air flows (air flow 1 and air flow 2) do not mix with each other, and the core of the heat exchanger is a circular column body, which is composed of hexagonal heat exchanger core basic units formed in a circular array around the axis of the heat exchanger, which can realize sufficient countercurrent heat exchange effect between the hot and cold air streams, and the microstructure and parameters of the heat exchanger diaphragms have been optimized to obtain high ratio Volumetric heat transfer coefficient, the shell of the heat exchanger is cylindrical, with strong pressure bearing capacity, the heat exchanger is compact in structure, easy to disassemble and maintain, small in size and light in weight, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com