Electromagnetic linear actuator based on reed valve heat dissipation

A technology of linear actuators and reed valves, applied in the field of actuators, can solve problems such as heating of electromagnetic linear actuators, achieve the effects of solving severe heating, improving power density and working reliability, and strengthening air cooling and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

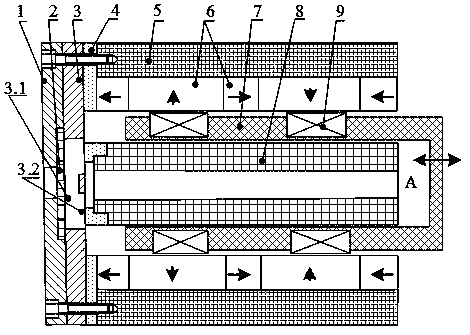

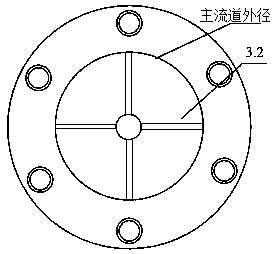

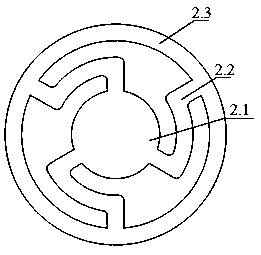

[0021] like Figures 1 to 3 As shown, including reed valve seat (1), reed (2), reed valve cover (3), end cover (4), outer yoke (5), permanent magnet array (6), skeleton (7) , an inner yoke (8), and a coil (9), the features of which include:

[0022] The permanent magnet array (6) is a Halbach permanent magnet array layer composed of axially magnetized permanent magnets and radially magnetized permanent magnets arranged alternately close to each other, and the permanent magnet array (6) is surface-attached to the outer yoke (5) Inside; the inner yoke (8) and the outer yoke (5) are coaxially fixed by the end cover (4), and there is an air gap in between; the outer yoke (5) and the reed valve seat (1), the reed valve cover ( 3), the end cover (4) is coaxially fixed and used as the stator; the coil (9) is wound in the groove of the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com