Z-shaped single-mode standing wave linear ultrasonic motor based on multiple vibration modes of piezoelectric ceramics

A technology of piezoelectric ceramics and electric ceramics, which is applied in the field of Z-shaped structure single-mode standing wave linear ultrasonic motors. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

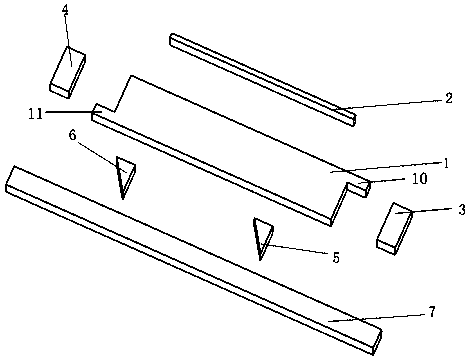

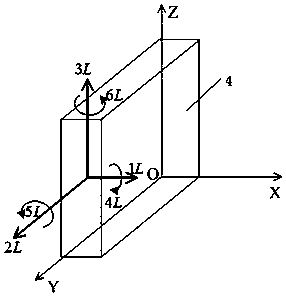

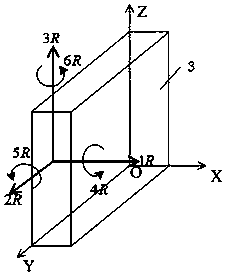

[0032] Such as figure 1 , a Z-structure single-mode standing wave linear ultrasonic motor based on multiple vibration modes of piezoelectric ceramics, including a stator and a mover 7, the stator includes piezoelectric ceramics 2 on the upper surface, piezoelectric ceramics 4 on the left end, and piezoelectric ceramics on the right end 3. The left driving foot 6, the right driving foot 5 and the metal elastic body. The metal elastic body adopts a Z-shaped metal elastic body. The two ends of 1 are respectively provided with protruding right protruding part 10 and left protruding part 11, wherein the right protruding part 10 is close to the upper surface of the metal elastic body, and the left protruding part 11 is close to the lower surface of the metal elastic body , the middle part 1 of the elastic body, the right protruding part 10 and the left protruding part 11 present a Z-shaped structure as a whole, the piezoelectric ceramic 2 on the upper surface is arranged on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com