Frame with foldable spare wheel carrier crank support

A technology of spare tire rack and frame, which is applied in the field of frame with foldable spare tire rack crank bracket, and can solve the problems of small crank bracket with no practical effect, waste of materials, and too long distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

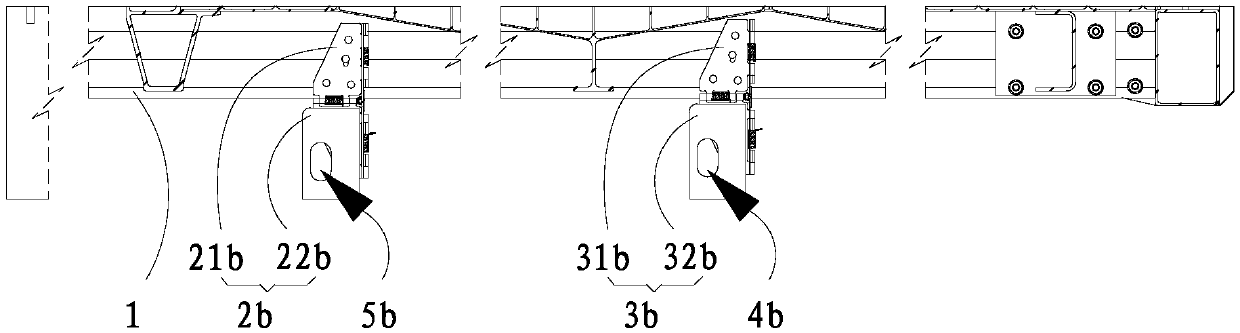

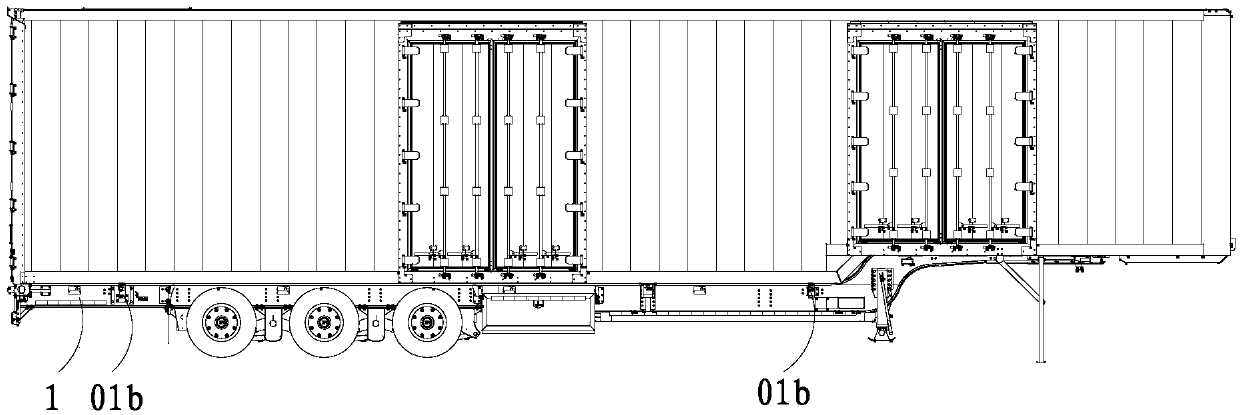

[0022] Please refer to figure 1 , a vehicle frame with a foldable spare tire rack handle bracket, comprising a frame girder 1 and a foldable spare tire rack crank handle bracket located on the vehicle frame girder 1; the vehicle frame girder 1 is two oppositely arranged, the present The application for a vehicle frame with a foldable spare tire rack crank bracket also includes a frame connecting plate arranged between two frame beams 1, and the lower end of the frame connecting plate is provided with a double tire spare tire rack crank Double spare tire carrier with holes, the other end of the bottom of the frame connecting plate is provided with a single tire spare wheel carrier with a hole for the handle of the single tire spare wheel carrier; the foldable spare wheel handle bracket includes a double tire foldable spare wheel carrier Crank bracket 2b, double-tire foldable spare tire rack The crank bracket 2b includes a second mounting plate 21b fixed on the frame frame 1 and...

Embodiment 2

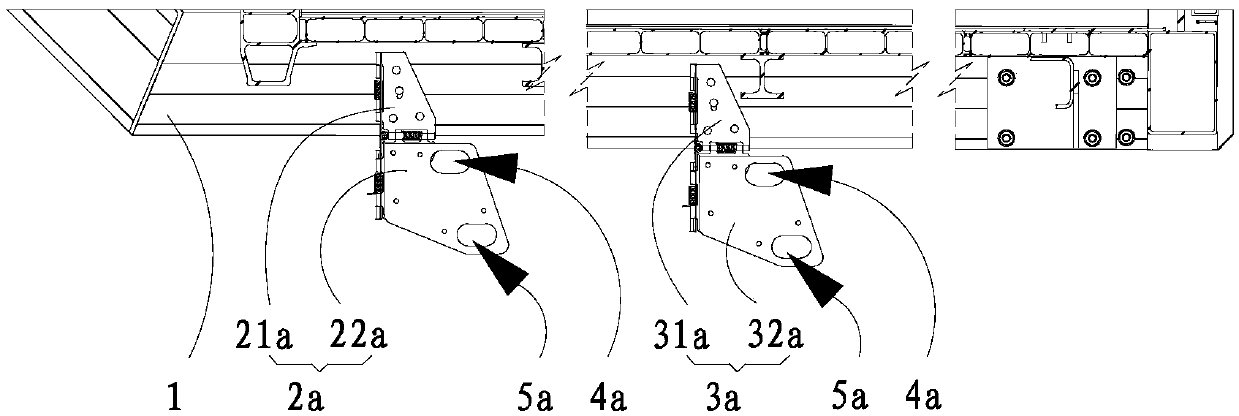

[0025] Please refer to figure 2 , a vehicle frame with a foldable spare tire rack crank bracket, a vehicle frame with a foldable spare tire rack crank bracket, including a frame frame 1 and a foldable spare tire frame crank set on the frame frame 1 Handle brackets; the two frame girders 1 are oppositely arranged, and a vehicle frame with a foldable spare tire rack handle bracket in the present application also includes a frame connecting plate arranged between the two frame girders 1, and the vehicle frame The lower end of the connecting plate is provided with a twin-tire spare tire rack with a handle hole for a twin-tire spare tire rack, and the other end below the frame connecting plate is provided with a single-tire spare tire rack with a handle hole for a single-tire spare tire rack; The foldable spare tire rack crank bracket includes a twin tire foldable spare tire rack crank bracket 2a, and the twin tire foldable spare tire rack crank bracket 2a includes a second mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com