Electric automobile driving system and electric automobile

A drive system and electric vehicle technology, applied in the automotive field, can solve the problems of single motor function and increase the cost of electric vehicles, and achieve the effect of reducing costs and improving drive flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

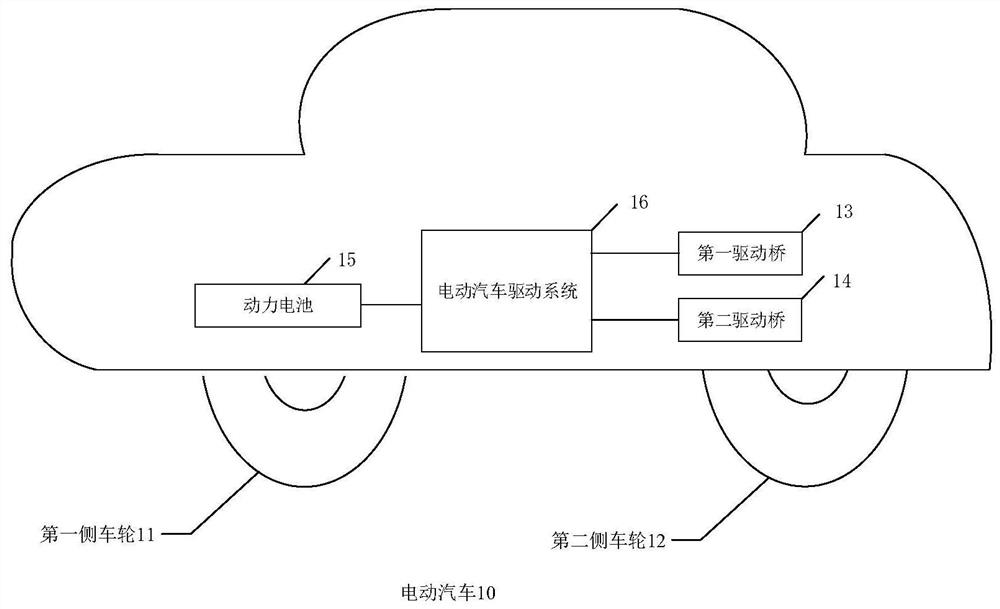

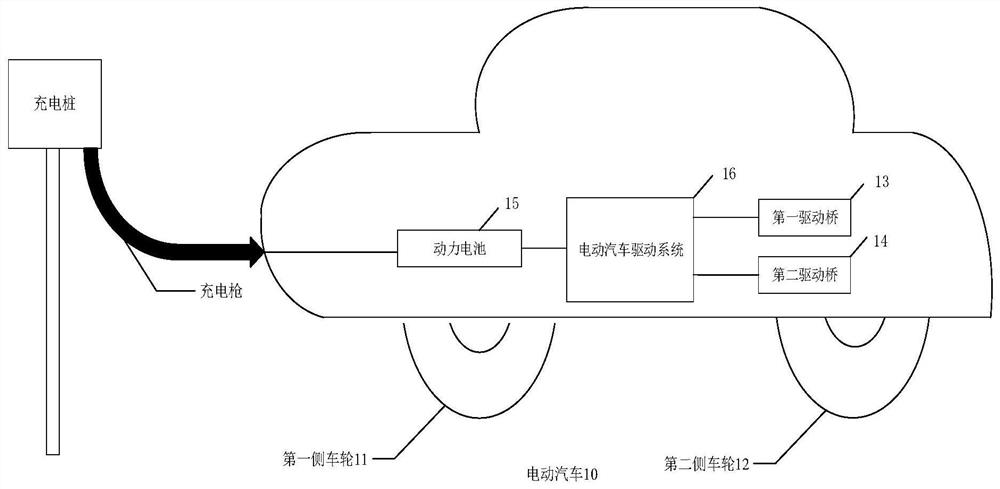

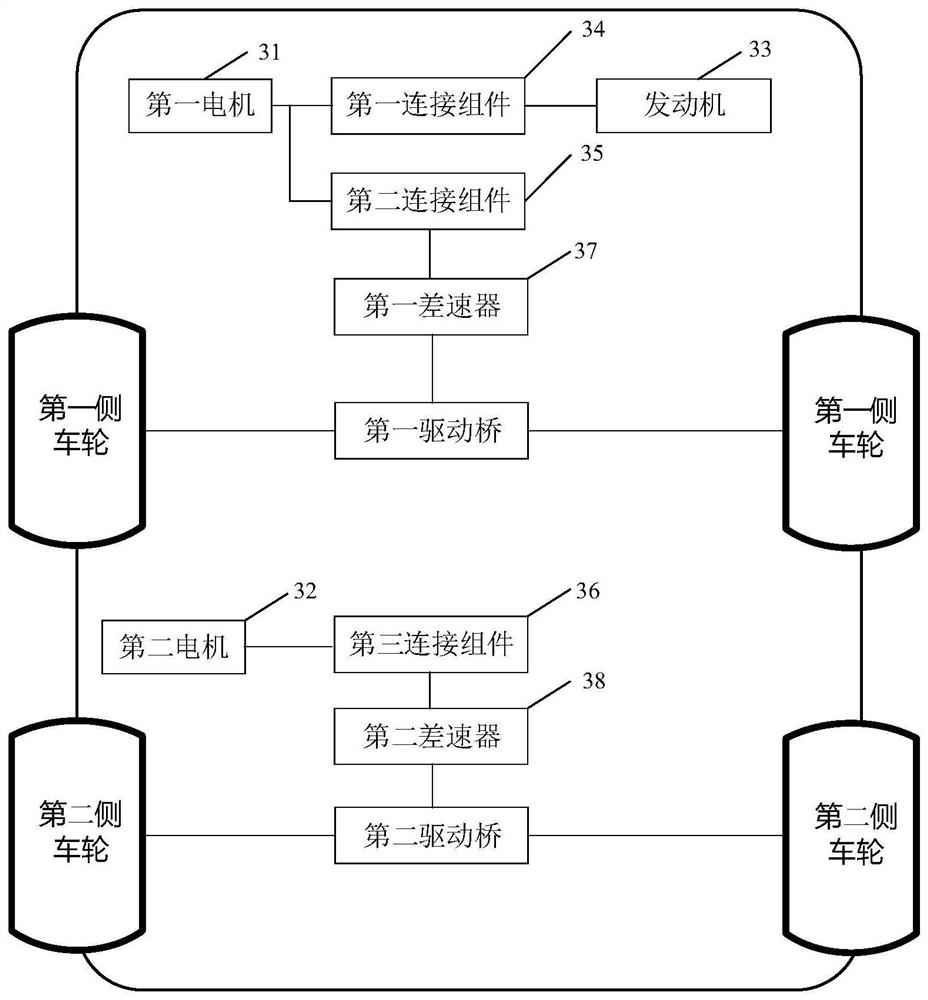

[0108] In the present application embodiment, the electric vehicle drive system includes a first motor 31, a second motor 32, an engine 33, a first connecting assembly 34, a second connection assembly 35, a third connecting assembly 36, a first differential, and The second differential speed 38.

[0109] Wherein, the first connection assembly 34 includes a first linear row 341 and a first clutch 342; the second connection assembly 35 includes a first transmission 351 and a second clutch 352; the third connection assembly 36 includes a seventh transmission 361.

[0110] Wherein, the first transmission 351 can be a reduction, or a glow. It should be noted that the first transmission 351 may be a single-port transmission or a multi-speed transmission. Wherein, the first transmission 351 can be a fixed axis, or a planetary wheel.

[0111] When actually use, the device in the first connection assembly 34 and the second connection assembly 35 has a variety of connection modes, and the s...

example 1

[0113] See Figure 4 As shown, the ring gear of the first line of star row 341 is connected to the engine 33 through the first clutch 342, and the sun gear of the first row star line 341 is connected to the first motor 31; the first stage gear of the first transmission 351 and the first line of star 341 The ring gear is connected, the second stage gear of the first transmission 351 is connected to the first differential speed 37; the second clutch 352 is coupled between the first stage gear and the second stage gear of the first transmission 351; seventh transmission The first stage gear of 361 is connected to the second electrode 32, and the second stage gear of the seventh transmission 361 is connected to the second differential 38.

[0114] It should be understood that when the first clutch 342 is engaged, the engine 33 is connected to the first linear star 341, the power output of the engine 33 can be transmitted to the first motor 31 through the first line of star 341, and thr...

example 2

[0127] See Figure 13 As shown, the planet carrier of the first line of star line 341 is connected by the first clutch 342 engine 33, the sun gear of the first row of star rows 341 is connected to the first motor 31; the first stage gear of the first transmission 351 and the first row of Stars 341 The planet carrier is connected, and the second stage gear of the first transmission 351 is connected to the first differential vehicle 37; the second clutch 352 is connected between the first stage gear and the second stage gear of the first transmission 351; the seventh transmission 361 The first stage gear is connected to the second electrode 32, and the second stage gear of the seventh transmission 361 is connected to the second differential vehicle 38.

[0128] It should be understood that when the first clutch 342 is engaged, the engine 33 is powered by the first row of star line 341, and the power output of the engine 33 can be transmitted to the first motor 31 through the first li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com