High-power-density moving-coil type electromagnetic direct-drive hydraulic pump

A high power density, moving coil technology, applied in the field of hydraulic pumps, can solve the problems of restricting the development of linear direct drive hydraulic pump technology, low flow control accuracy, slow response speed, etc., to achieve compact structure, enhanced air gap magnetic field strength, The effect of increased power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

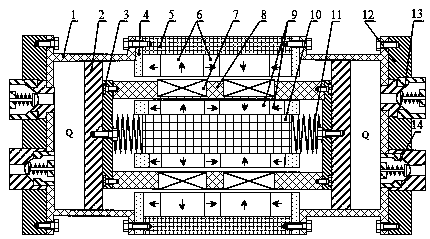

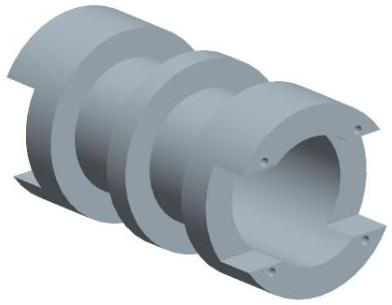

[0023] Such as Figures 1 to 3 As shown, a high power density moving coil electromagnetic direct drive hydraulic pump includes a hydraulic cylinder (1), a piston (2), a connecting plate (3), an end cover (4), an outer yoke (5), an outer Permanent magnet array (6), coil (7), coil bobbin (8), inner permanent magnet array (9), inner yoke (10), centering spring (11), valve body (12), liquid outlet valve ( 13) and the liquid inlet valve (14), the characteristics of which include: the outer permanent magnet array (6) and the inner permanent magnet array (9) are alternately arranged by axially magnetized permanent magnets and radially magnetized permanent magnets The formed Halbach permanent magnet array layer, the inner permanent magnet array (9) and the outer permanent magnet array (6) are respectively surface-attached to the outer side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com