Multiple axle driving system for oil-electricity mixed power automobile and method for improving turning radius of automobile by using the system

A hybrid vehicle and drive system technology, which is applied to the arrangement of multiple different prime movers of hybrid vehicles, general power plants, electric vehicles, etc. stability and stability issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

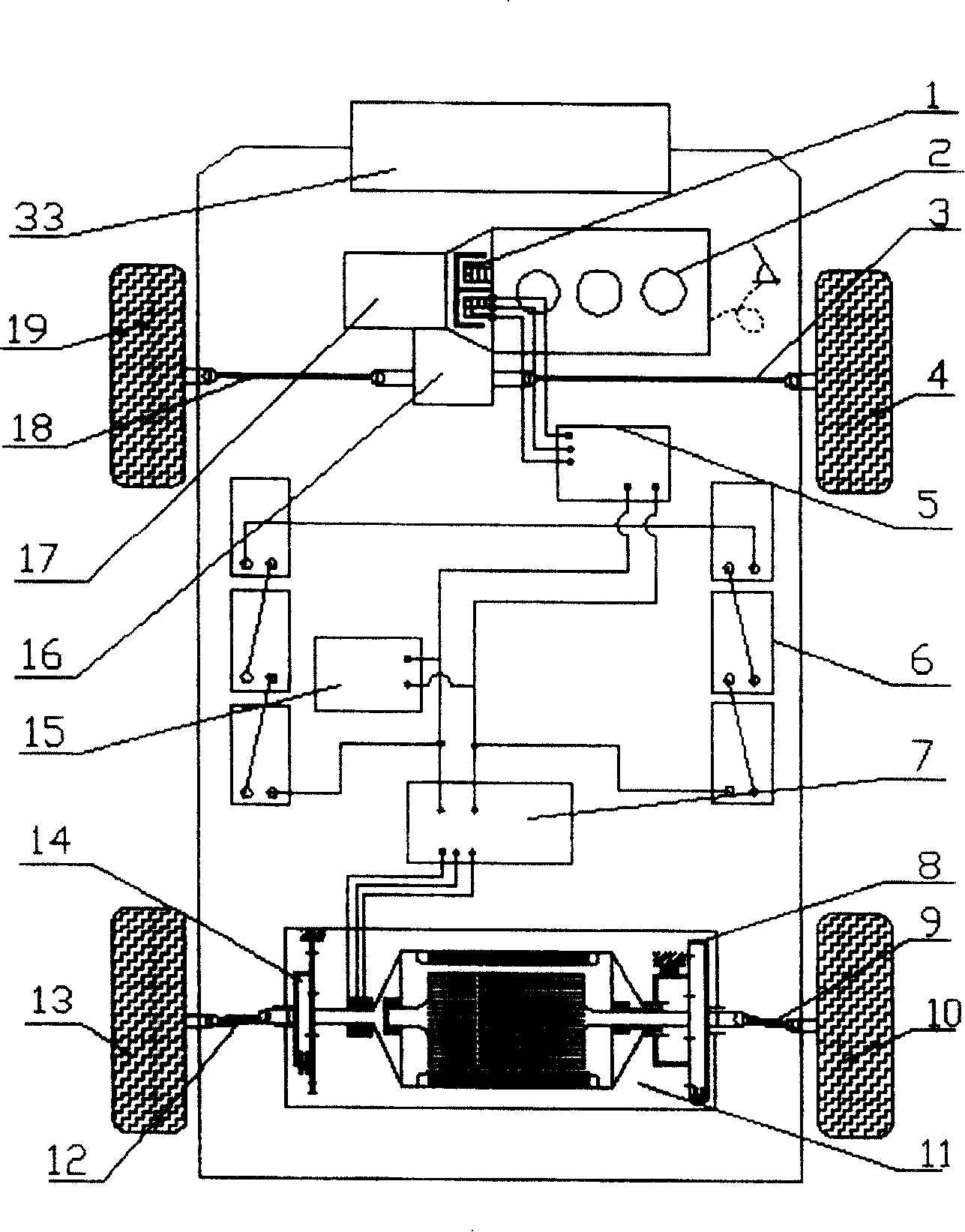

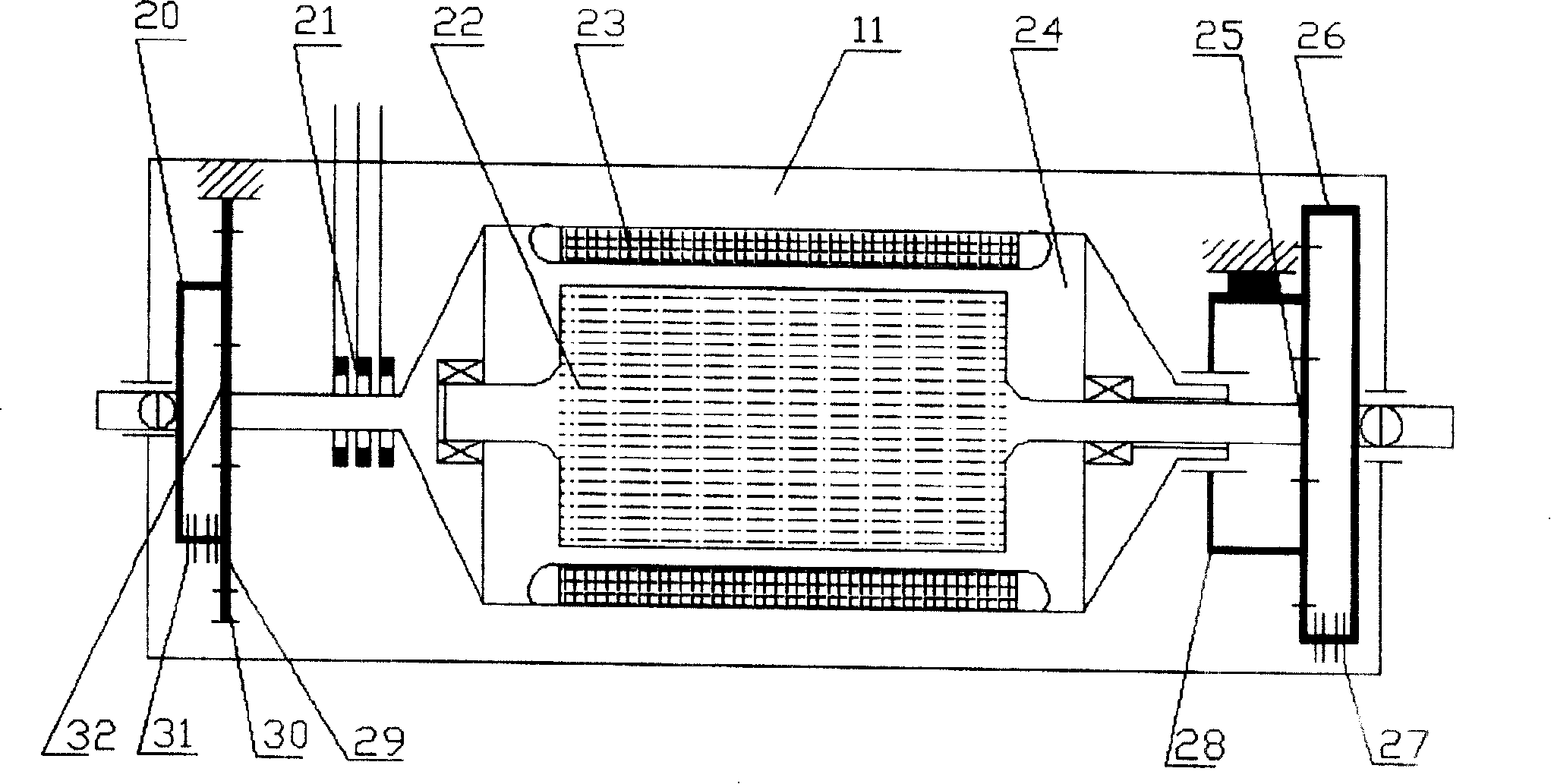

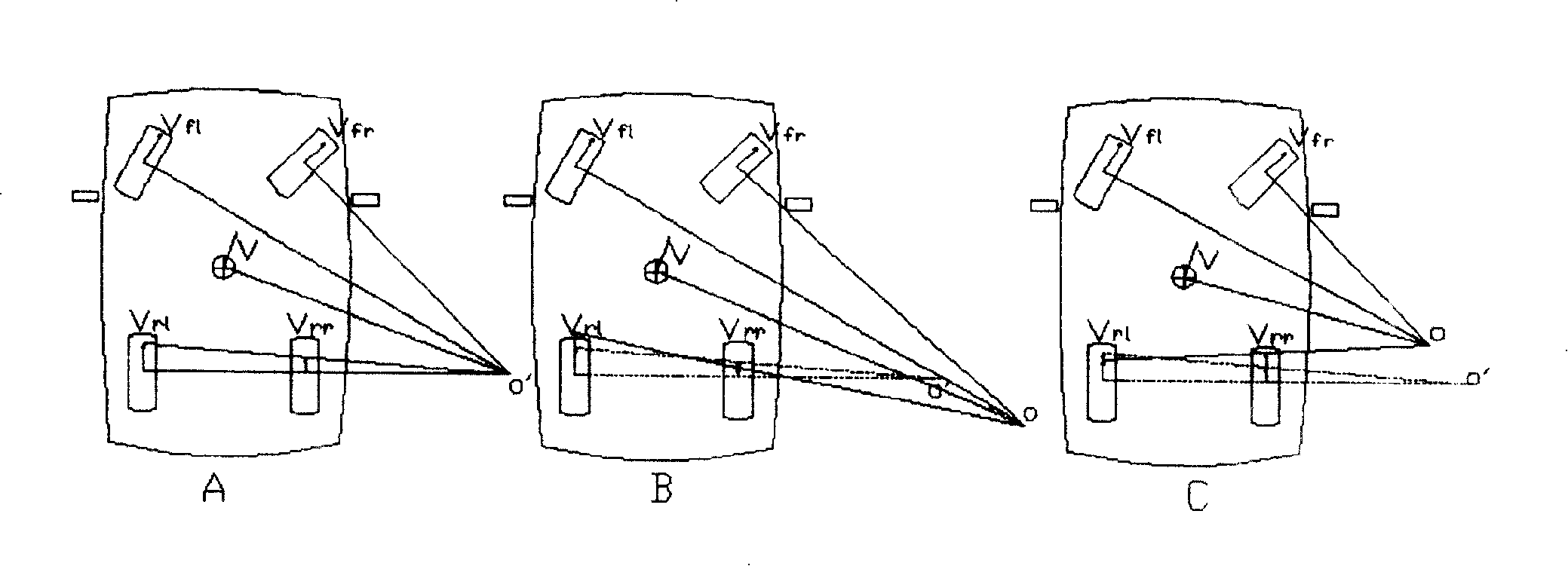

[0059] like figure 1As shown, a multi-axle drive system of an oil-electric hybrid vehicle includes at least one mechanical drive axle subassembly, at least one electric drive axle subassembly, a power supply subassembly, a general controller and a monitoring communication network system. in,

[0060] Mechanical drive axle sub-assembly includes mechanical drive axle and powertrain. The mechanical drive axle is composed of mechanical components such as engine 2 (including fuel tank, electronically controlled accelerator, etc.), transmission 17, transmission shaft, final reducer, differential 16, half shafts 3, 18, hubs 4, 19, brakes, etc. The non-steering conventional axle is used to realize the function of outputting the distributed power according to the torque and speed specified by the control strategy at any time. The transmission 17 can adopt automatic transmissions of types such as hydraulic automatic transmission (AT), electronically controlled mechanical automatic tra...

Embodiment 2

[0080] Figure 4 It is a derivative embodiment of the system for the development of the present invention for vehicles such as buses with rear engines. Example 1.

Embodiment 3

[0082] For the multi-axle automobile driven by three axles, it can be composed of a mechanical drive axle and two electric drive axles, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com