Rapier looms and corresponding textile methods

A loom and rapier technology, applied in rapier looms and corresponding textile fields, can solve problems such as limited flexibility and achieve the effect of increasing textile speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

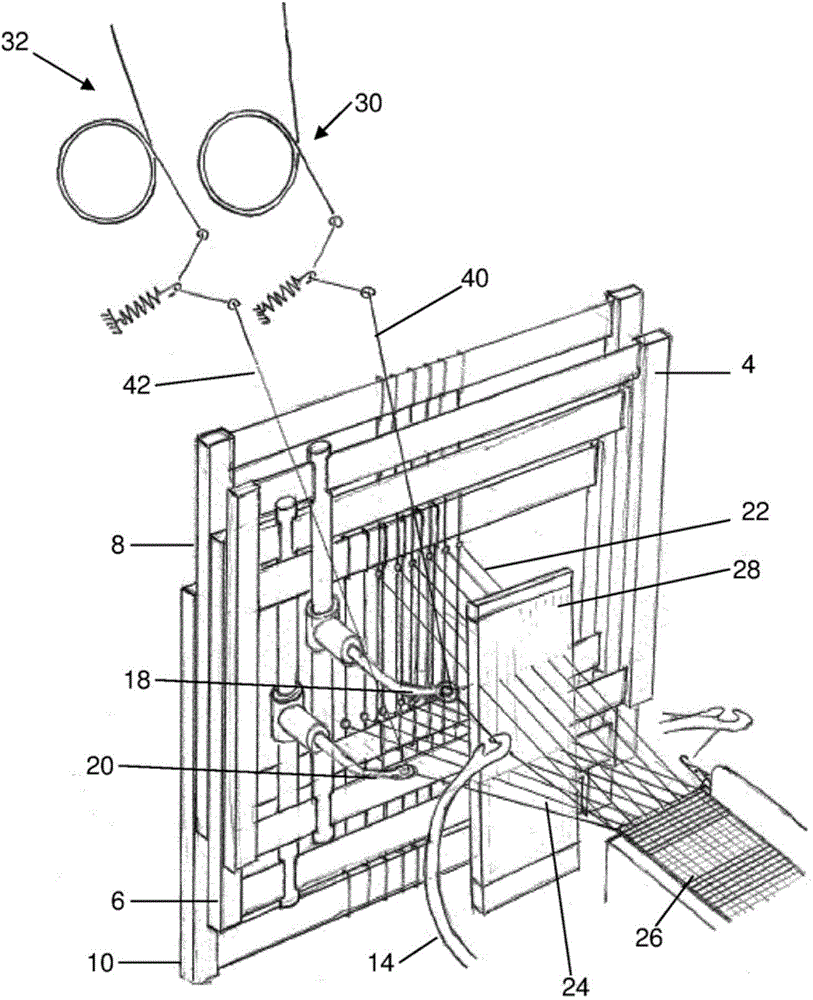

[0021] exist figure 1 A particularly advantageous embodiment of the invention is shown in . here figure 1 Shows the main elements of a rapier loom with a weft insertion device, wherein the respective color control means, in the embodiment shown, a weft selection device 18 for a first color and a weft selection device for a second color The device 20 is assigned correspondingly to the heald frames 4 and 6, the movement of which can control the selective introduction of the respective weft threads. The further heald frames 8 and 10 here conventionally correspond to the structure of the shed. The other elements of the rapier loom, namely the reed 28 and the stopped fabric 26 as well as the warp threads in the upper shed 22 and the warp threads in the lower shed 24 represent here other conventional elements of known rapier looms . This application is only possible if the loom has a control device for controlling the linear motor of the rapier, which is constructed so that at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com