Tapestry weaving semi-automatic sample weaving machine

A semi-automatic, small prototype technology, applied in small looms, looms, jacquard machines, etc., can solve problems such as low efficiency, low production efficiency, time-consuming and laborious, and achieve the effect of convenient operation, improved production efficiency, and enhanced sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

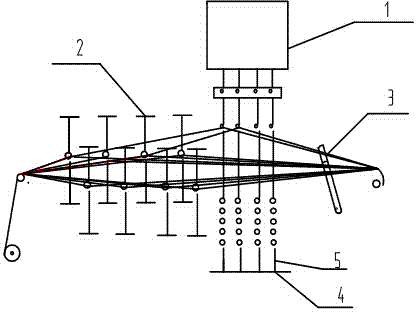

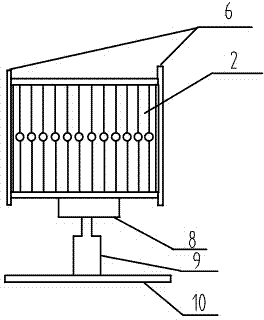

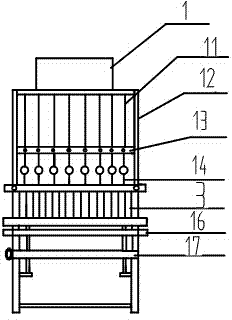

[0026] Such as figure 1 As shown, a semi-automatic mini-prototype device for Kesi, in which an electronic jacquard shedding device 1 is added to the traditional mini-prototype, and the return heddle 5 vertically below is installed on the return heddle spring support 4. During the weaving process, it will be necessary to stir up The flower warps of the electronic jacquard shedding device 1 are inserted into the heddle eyes of the electronic jacquard shedding device 1, the ground warps are penetrated into the heddle eyes of the heald frame 2, and then all of them are threaded into the reed 3 for weaving. The degree of automation of the equipment is further increased, the labor intensity of the operator is reduced, and the production effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com