Method for producing a woven belt strap

A technology of braided belts and restraint belts, which is applied in the weaving field of braided belts, and can solve problems such as discomfort and danger for vehicle occupants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

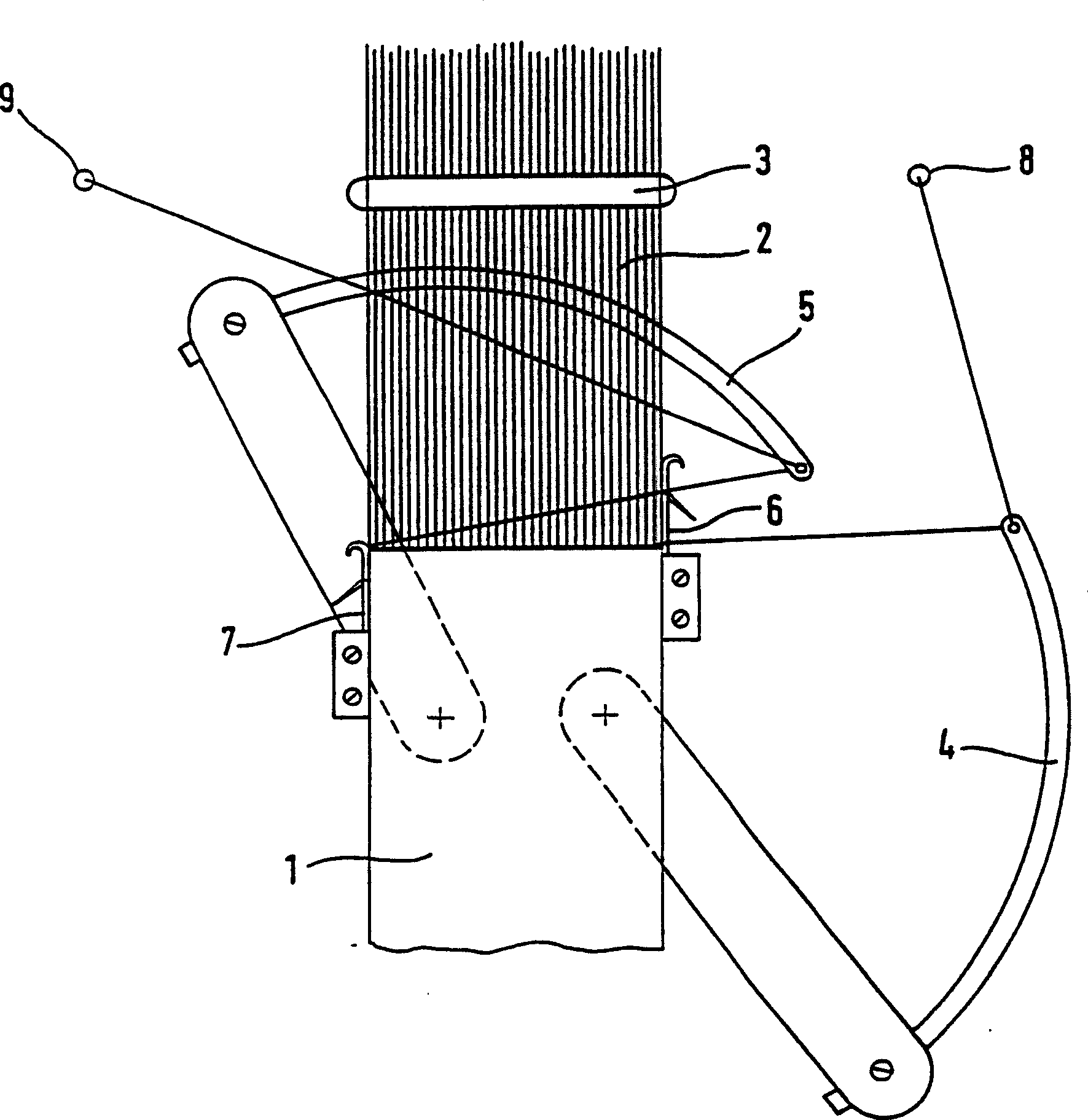

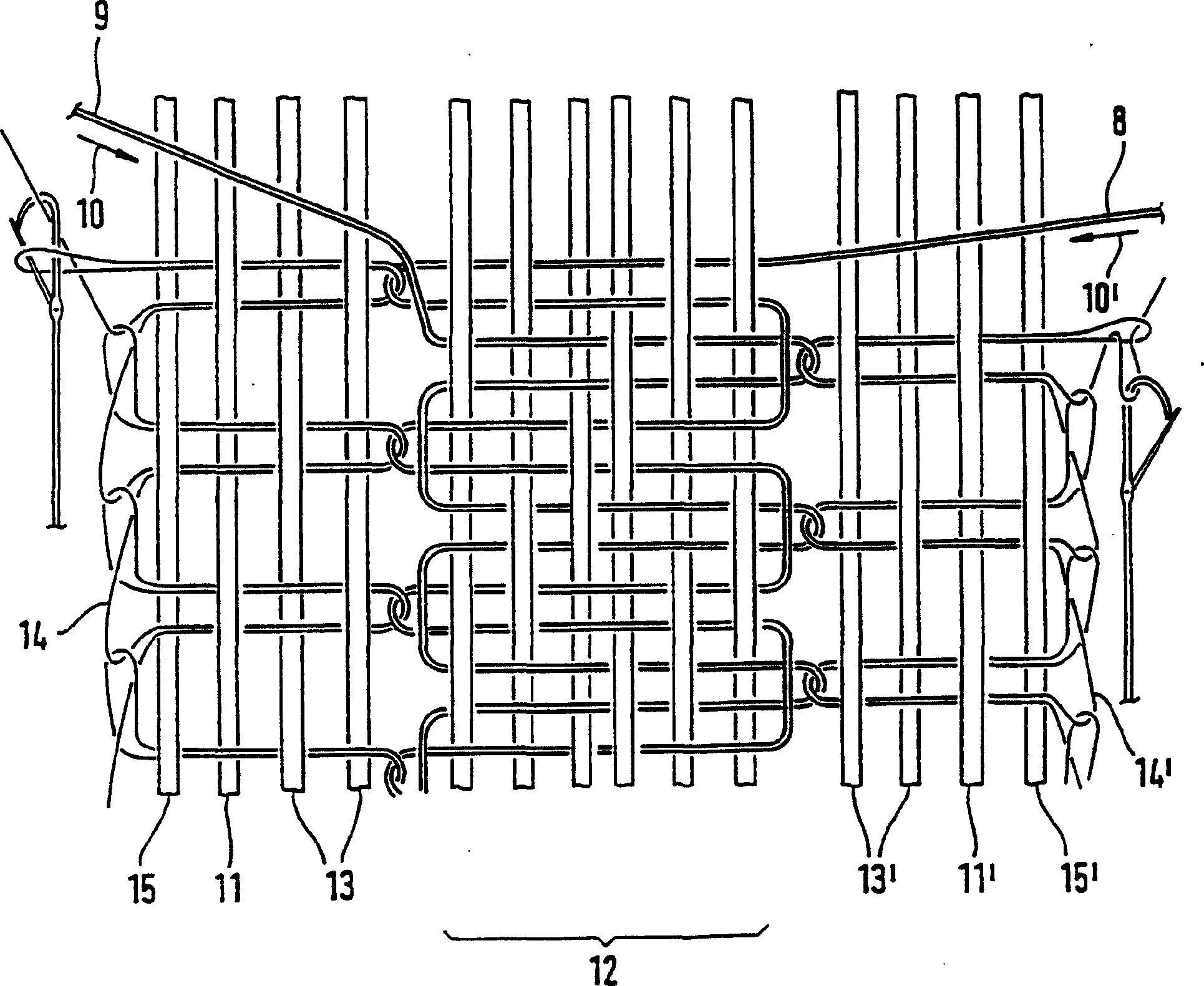

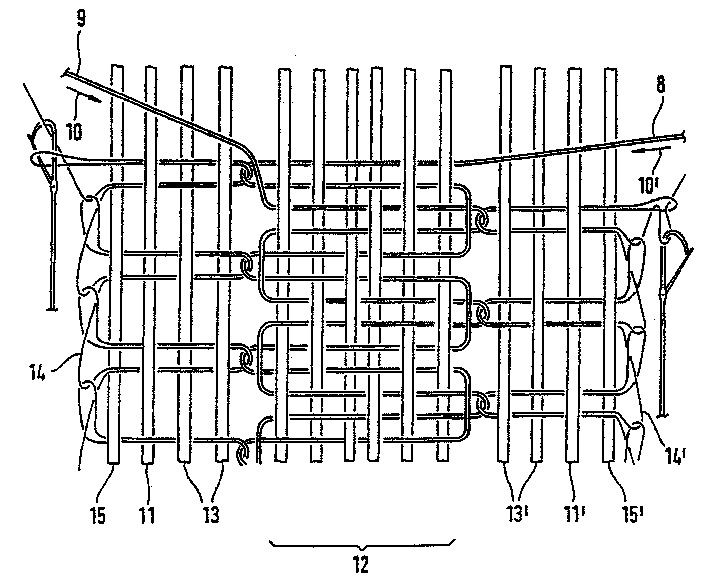

[0015] The sequence of the method according to the invention is as follows, for example:

[0016] The first weft picking:

[0017] In the shed (shed) formed by the warp yarn 2, utilize the weft yarn needle 5 to drop a weft yarn 9 from left to right, and utilize the knitting needle 6 on the right side to make it meet the tuck thread (tuckthread) on the right side edge of the belt ( not shown) interspersed with each other (this particular case is just as described).

[0018] After the weft needle has returned to the left, the weft-inserted yarn is attached to the finished fabric 1 by means of the reed 3 .

[0019] During one revolution of the machine, the weft needle on the left and the knitting needle on the right remain stationary while changing the shed.

[0020] The second weft picking:

[0021] Utilize the right side weft yarn needle 4 to drop weft yarn 8 from the right side in the shed and utilize the left side knitting needle 7 to make it interweave with a tuck yarn. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com