Weft insertion belt knitting machine used for producing belt, especially label belt knitted with conductive fine yarn specifically antenna fine yarn

A technology for knitting belt machines and conductive filaments, which is applied in the field of antenna filaments, and can solve problems such as inability to know

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

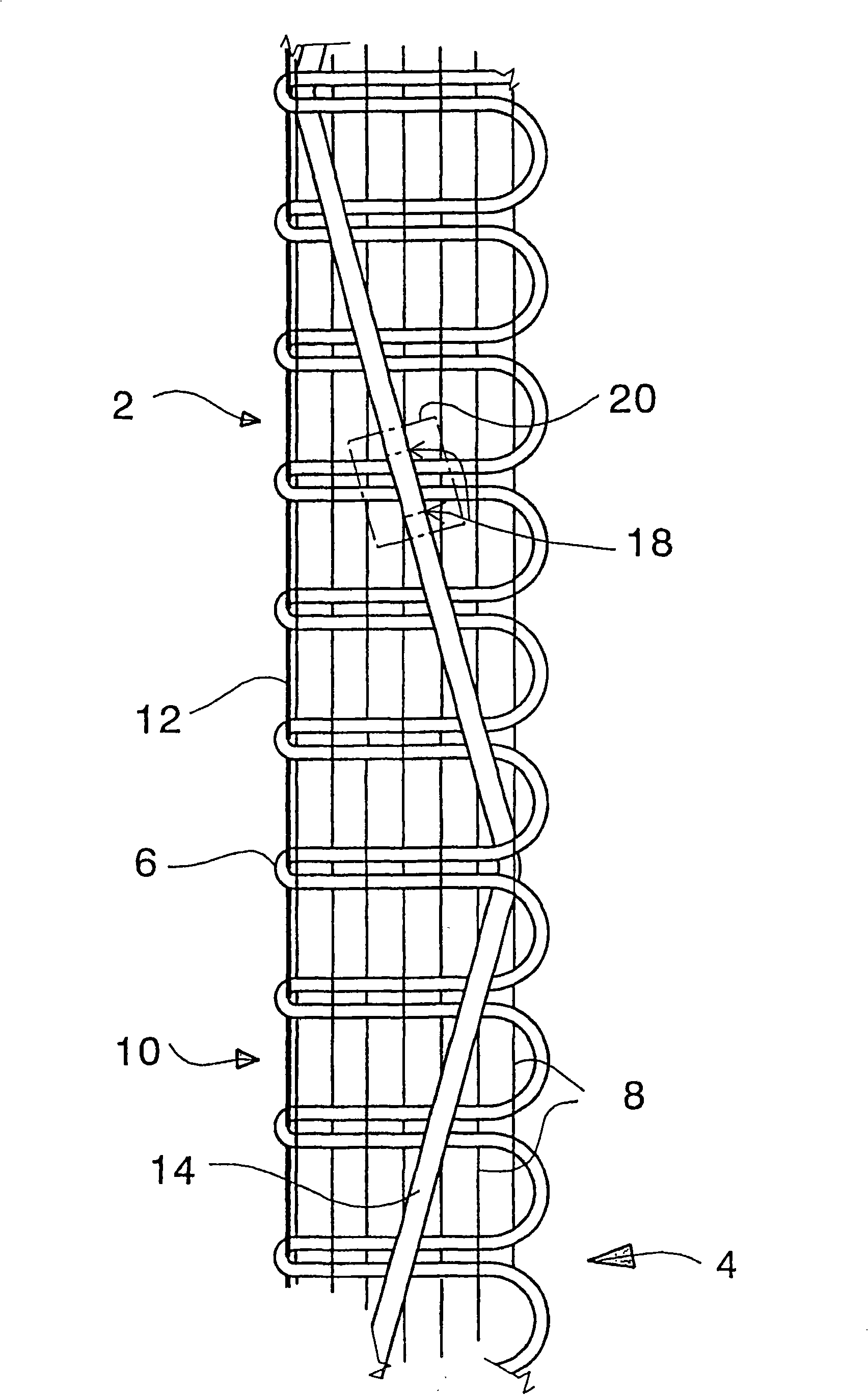

[0019] figure 1 A strip of fabric 2 is shown in which weft thread loops 6 are inserted between warp threads 8 from the insertion side 4 . On the side 10 with the opposite insertion side 4, the weft thread loops 6 are knotted to one another by means of loops 12, schematically represented as a thread. The conductive filaments 14 run in a zigzag on the upper layer of the belt fabric 2 and are knotted in any case at turning points 16 by means of the weft loops 6 . The conductive thread 14 is interrupted at point 18 before the application of the transponder chip 20 as an antenna, said chip being connected to both ends of the conductive thread. Such connections may be accomplished by means such as welding, soldering, bonding with conductive adhesives, and crimping.

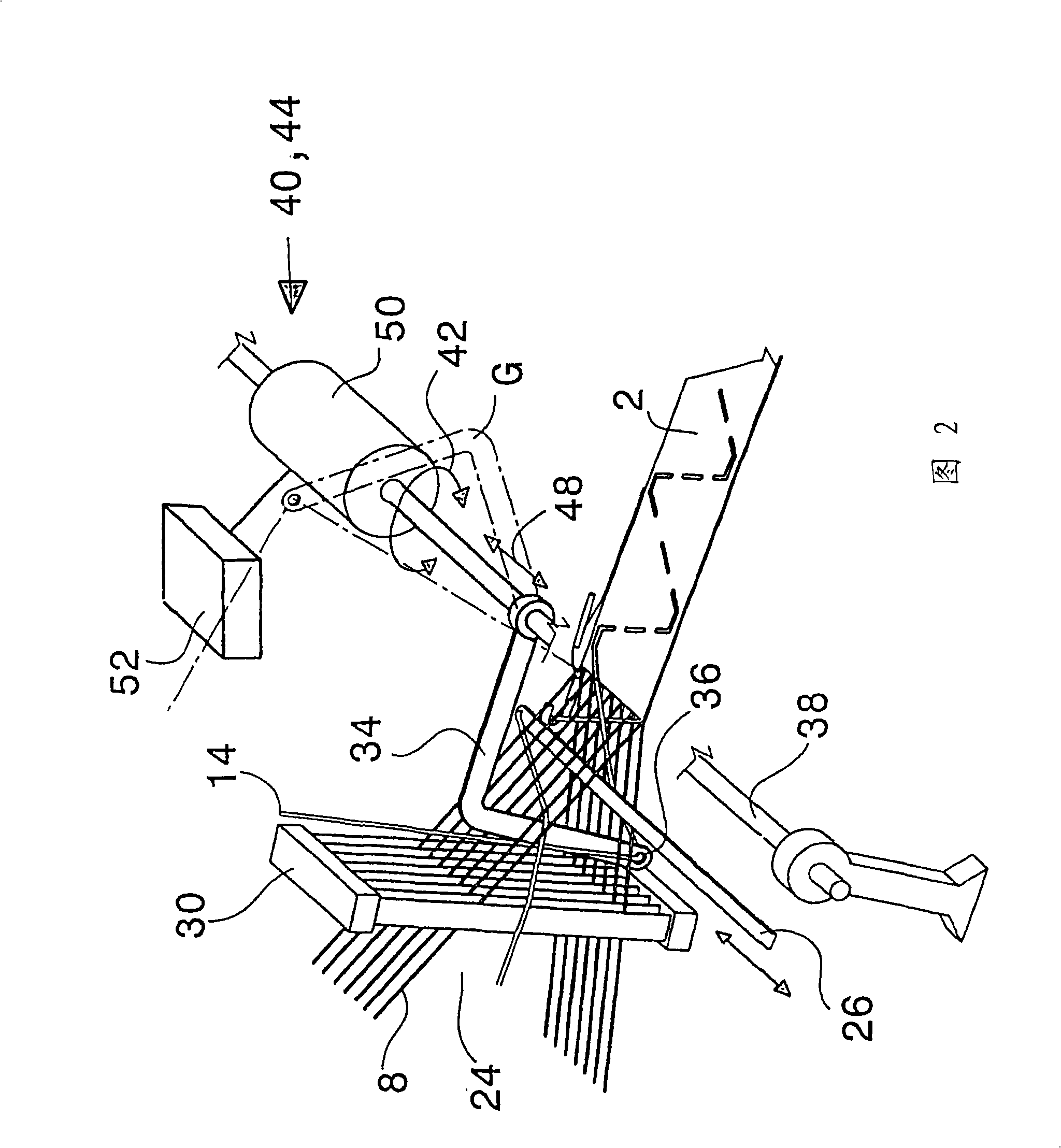

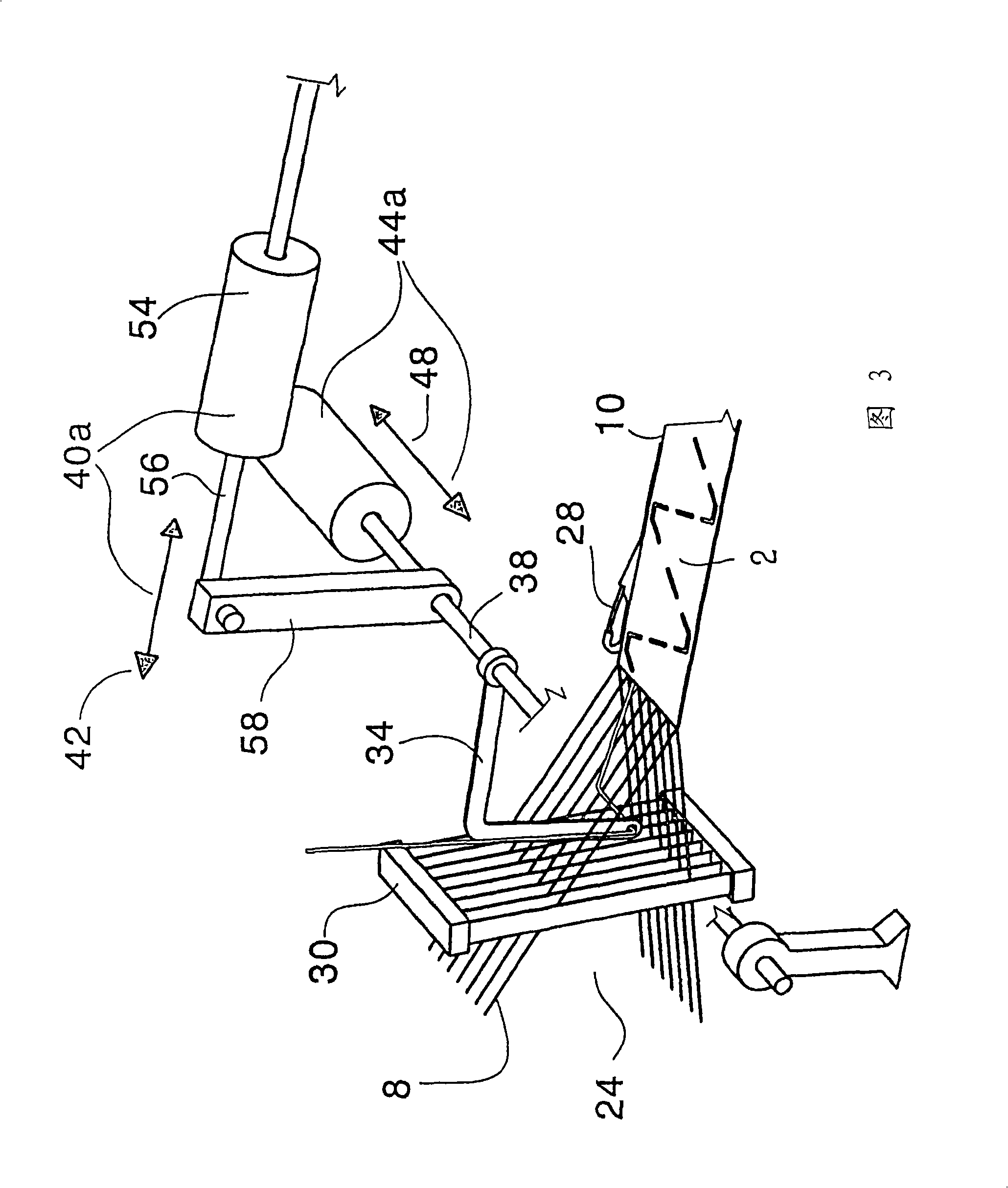

[0020] Fig. 2 schematically shows a weft-introduction knitting machine 22, which is suitable for manufacturing figure 1 A tape fabric 2 with conductive threads 14 without a transponder chip 20. The warp thread 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com