Weft-filled decorative fabrics in three-layer structure and production process thereof

A decorative fabric, three-layer structure technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the effective thickness of fabrics, thermal insulation and decorative discounts, low effective fabric thickness and air content, fabrics lack of elasticity and three-dimensional feeling and other problems, to achieve the effect of smooth, delicate and compact front and back of the structure in the length and width directions, strong three-dimensional flower shape, and good heat insulation and warmth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

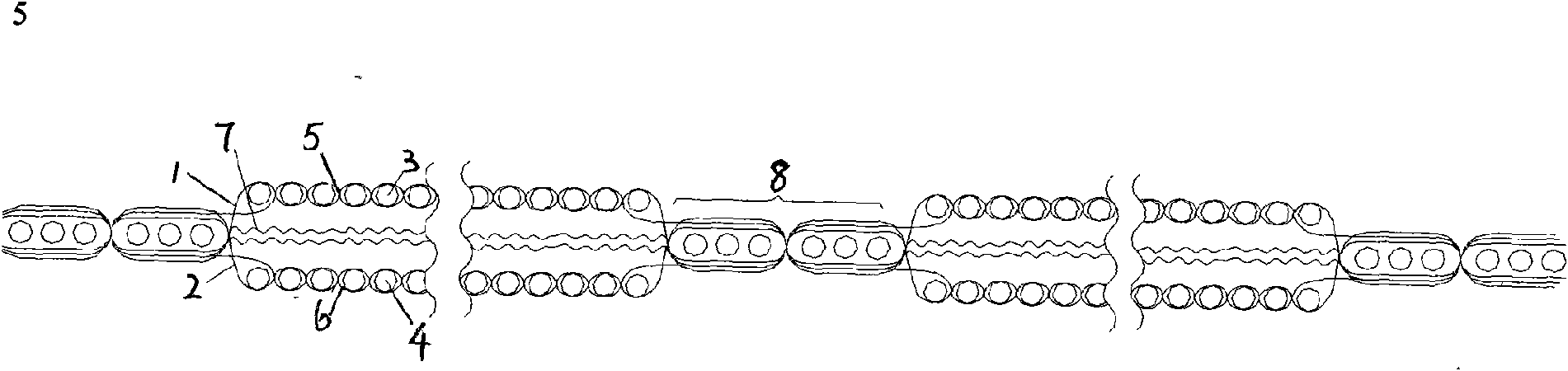

[0017] A weft-filled three-layer structure decorative fabric, the warp and weft of the surface layer and the warp and weft of the inner layer are both made of 40 S / 2-80 S / 2 pure cotton or rayon yarn, or 75D / 48f-200D / 144f cationic polyester FDY; the warp and weft yarns are made of 75D / 48f-200D / 144f ordinary polyester stock solution dyed (black or blue) dark silk FDY; while the core filling weft yarn adopts 200D / 96f-300D / 144f natural color ordinary polyester DTY or 30 S / 2-40 S / 2 Acrylic bulked yarn. The cross-sectional structure of the fabric is as figure 1 shown. Surface weft yarn 1, inner weft yarn 2, surface warp yarn 3, inner warp yarn 4, the outer and inner warp yarns and the outer and inner weft yarns are interwoven into a double-layer fabric, including the surface weave 5 and the inner weave 6; Weave 3 / 3 warp heavy flat and 2 / 2 weft heavy flat weave single-layer lattice inlaid yarn, warp heavy flat inlaid yarn weave as figure 1 As shown in 8, the weft weight fla...

Embodiment 2

[0029] A kind of weft-filled core surface-inside double-layer weave triple-structure decorative fabric, the warp and weft yarns of the surface weave are made of 75D / 48f-200D / 144f cationic polyester FDY, and the warp and weft yarns of the inner weave are made of 75D / 48f-200D / 144f ordinary polyester FDY ;The warp and weft yarns of the inlaid weave in the warp and weft direction adopt 75D / 48f-200D / 144f ordinary polyester dope dyed (black or blue) dark silk FDY; or 30 S / 2-40 S / 2 Acrylic bulked yarn. The cross-sectional structure of the fabric is as figure 1shown. The surface weft yarn 1, the inside weft yarn 2, the surface warp yarn 3, the inside warp yarn 4, the surface and interior warp yarns and the surface and interior weft yarns are interwoven into a double-layer fabric, including the surface weave fabric 5 and the inner weave fabric 6; Weave 3 / 3 of the warp heavy flat and 2 / 2 weft heavy flat weave single-layer lattice inlaid yarns, and the warp heavy flat inlaid yarns ...

Embodiment 3

[0041] A weft-filled three-layer structure decorative fabric, the warp and weft yarns of the surface layer and the warp and weft yarns of the inner layer are all made of (20-30) D / 1f polyester or nylon transparent monofilament; the warp and weft insert yarn is also made of (20-30) ) D / 1f polyester or nylon transparent monofilament. The weft suspension core yarn adopts (200-300) D / 96f dope dyed polyester colored silk DTY or chenille thread fancy braiding thread. The cross-sectional structure of the fabric is as figure 1 shown. The surface weft yarn 1, the inside weft yarn 2, the surface warp yarn 3, the inside warp yarn 4, the surface and interior warp yarns and the surface and interior weft yarns are interwoven into a double-layer fabric, including the surface weave fabric 5 and the inner weave fabric 6; Weave 3 / 3 of the warp heavy flat and 2 / 2 weft heavy flat weave single-layer lattice inlaid yarns, and the warp heavy flat inlaid yarns are as follows: figure 1 As shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com