Airbag and method for manufacturing a fabric for an airbag

A technology for airbags and fabrics, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of waste of materials and production costs, and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Since the machines, tools, devices and materials required to perform the method according to the present invention are well known to those skilled in the art, they will not be described or shown in detail below.

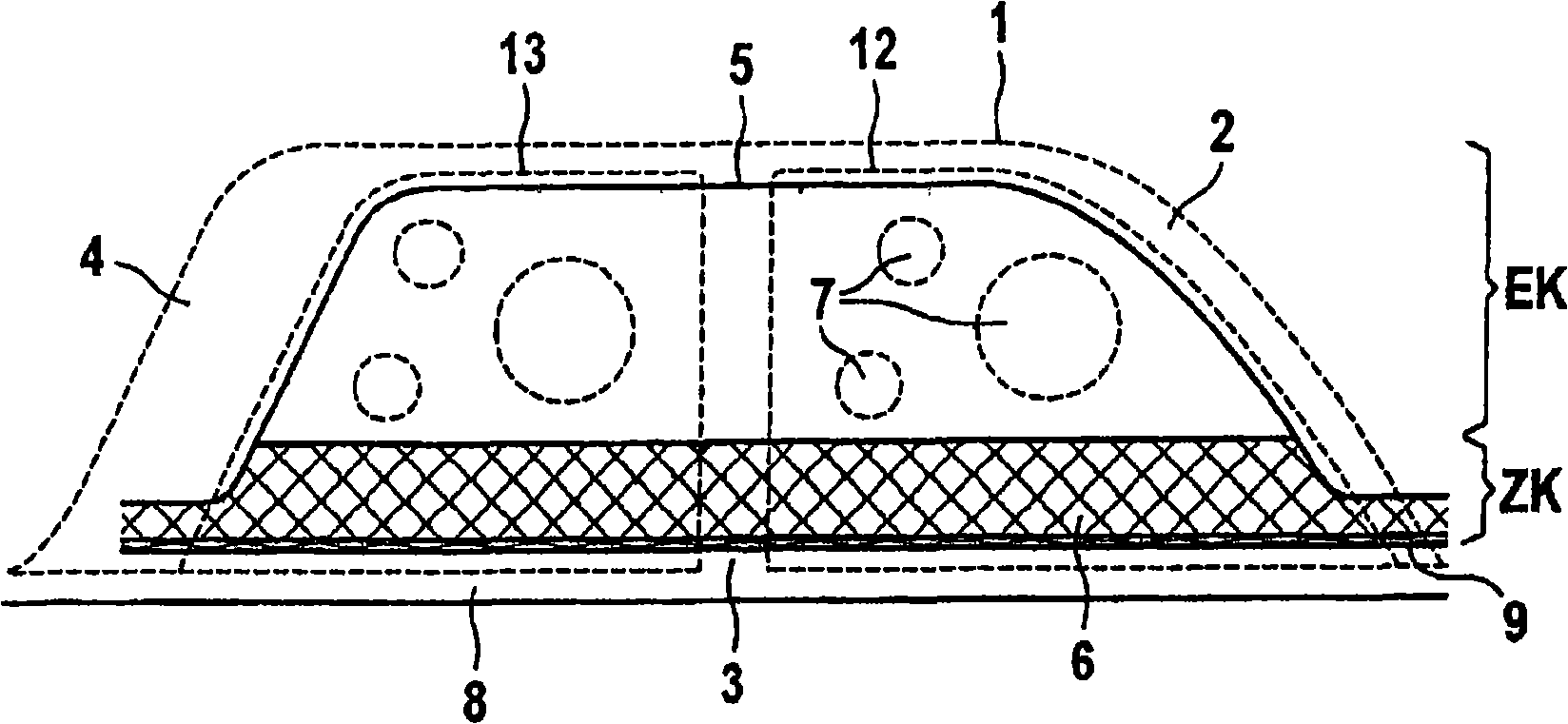

[0026] The invention mainly comprises a method of manufacturing a knitted fabric for an airbag of a vehicle occupant restraint system, which method is characterized by the following steps:

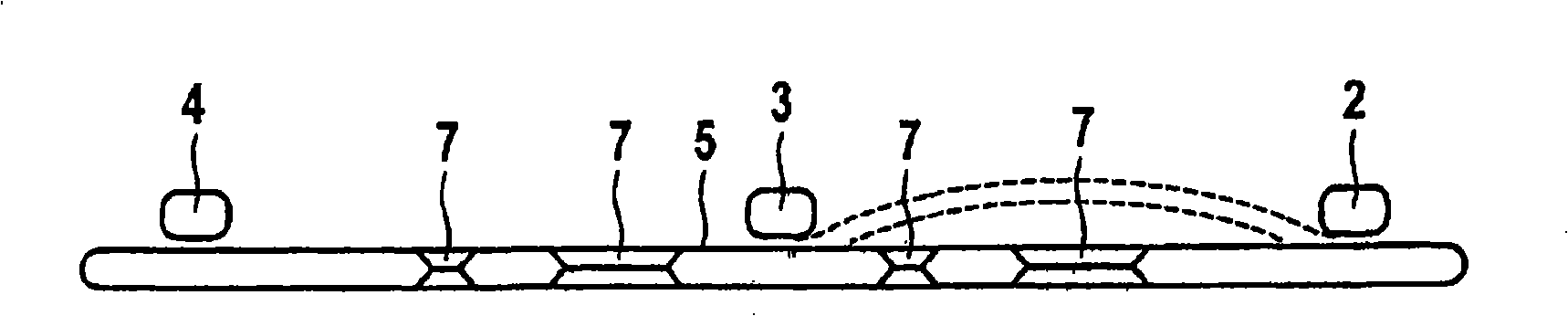

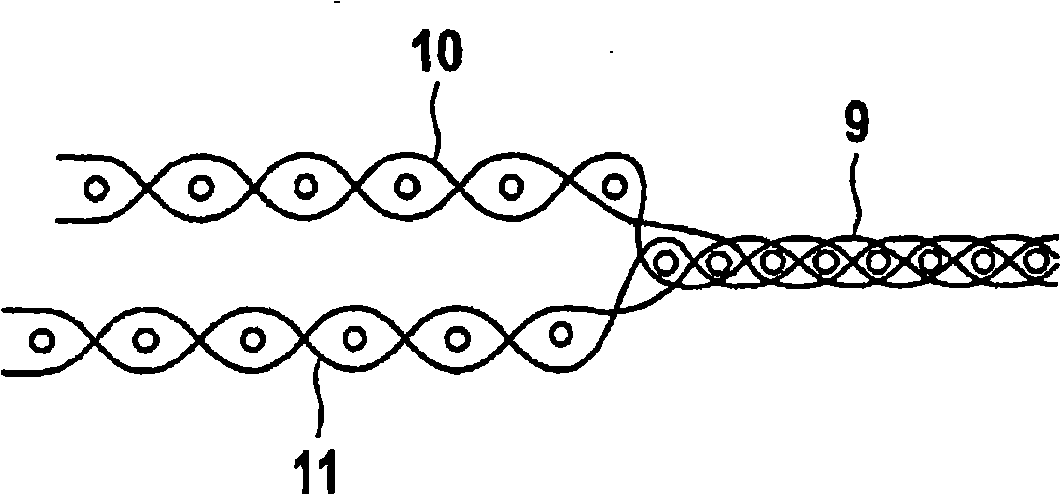

[0027] An array of warp yarns is prepared from warp yarns of different yarn qualities, the array comprising first warp yarns and second warp yarns arranged at selected positions of the warp yarn array comprising mixed yarns comprising first filaments and second filaments. within a given section;

[0028] weaving the fabric with at least one weft quality;

[0029] The fabric is thermally, mechanically or chemically treated to cause the second filaments to lose their filament structure to become amorphous and to interconnect the first filaments to form monofilament-type fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com