Wrinkle-resistant elastic polyester-cotton fabric and production method thereof

A technology of elastic fabric and polyester-cotton, which is applied in the field of wrinkle-resistant polyester-cotton elastic fabric and its production, can solve the problems of poor permanent performance of wrinkle resistance, environmental pollution, environmental pollution of wrinkle-resistant finishing agent, etc., achieve excellent weft elastic performance, and simple process Environmental protection, excellent wrinkle resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Warp: polyester filament A (raw material FDY) 75D twist: 1500T / M finalized

[0026] Cotton Yarn 60S

[0027] Weft yarn: elastic yarn B 75D polyester spandex mechanically covered yarn

[0028] Polyester Cotton Covered Yarn 40S

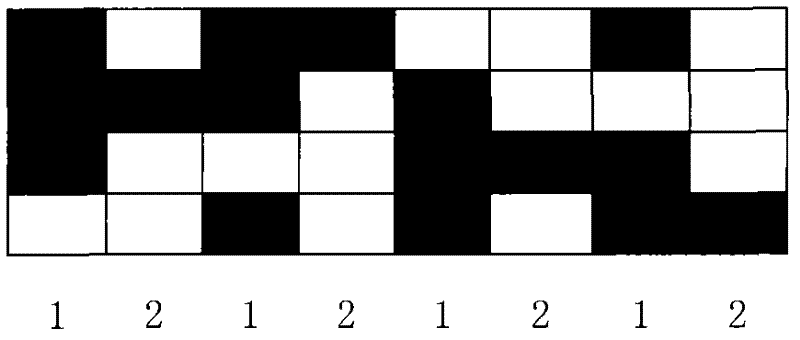

[0029] The polyester filament A and 60S cotton yarn in the warp are arranged in a 1:1 arrangement; the elastic yarn B and the polyester-cotton covered yarn in the weft are arranged in a 1:1 ratio; the warp density is 196 threads / 2.54cm, and the warp yarn surface weave covers The coefficient is 920; the organizational structure is double (see attached figure 1 ), and the polyester filament A is used as the inner warp, the gray cloth obtained by the above design is subjected to general dyeing and finishing projects of cotton fabrics such as gray cloth shaping and scouring, bleaching, singeing, mercerizing, and intermediate shaping, wherein the gray cloth shaping conditions It is: temperature: 160° C., processing time: 40 seconds, wid...

Embodiment 2

[0032] Warp: Polyester filament A (raw material FDY) 100D Twist: 1200T / M

[0033] Polyester-cotton yarn 45S The ratio of polyester-cotton is 65:35

[0034] Warp yarn: elastic yarn B 75D PBT / PET bicomponent elastic yarn

[0035] Cotton covered yarn 40S

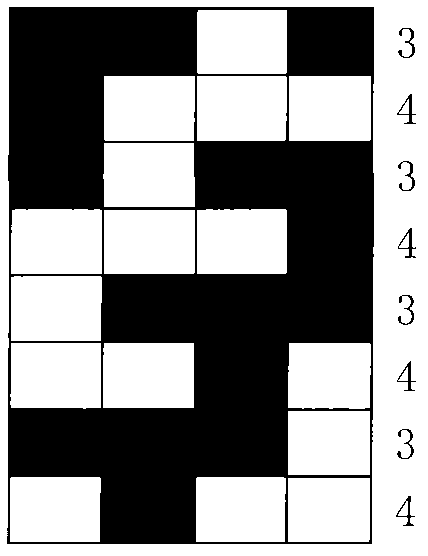

[0036] The polyester filament A and polyester-cotton yarn in the warp are arranged 1:1; the elastic yarn B and the polyester-cotton covered yarn in the weft are arranged in a 1:1 ratio; 1730; the organizational structure is double latitude (see attached figure 2 ), the elastic yarn B is used as the inner weft, and the gray cloth obtained by the above design is processed through general dyeing and finishing projects of cotton fabrics such as gray cloth shaping and scouring, bleaching, singeing, mercerizing, and intermediate shaping, wherein the gray cloth shaping conditions are: Temperature: 160°C, processing time: 31S, width setting: pre-shrink 12% based on the width of gray fabric.

[0037] The warp and weft w...

Embodiment 3

[0039] Warp yarn: polyester filament A (raw material DTY) 50D twist: 2000T / M finalized

[0040] Cotton Yarn 80S

[0041] Weft Yarn: Elastic Yarn B 75D Polyester Spandex Air Core Spun Yarn

[0042] Polyester Cotton Covered Yarn 60S

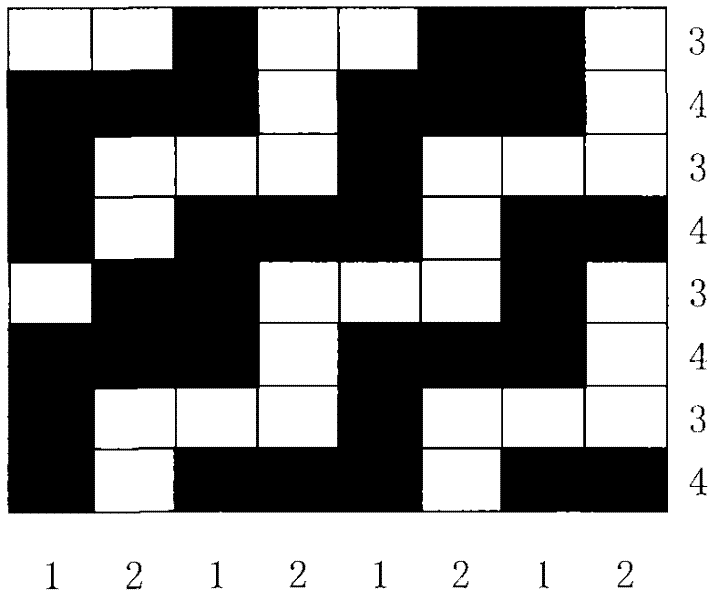

[0043] The polyester filament A and 80S cotton yarn in the warp are arranged in a 1:1 arrangement; the elastic yarn B and the polyester-cotton covered yarn in the weft are arranged in a 1:1 ratio; the warp density is 240 threads / 2.54cm; The coefficient is 1025; the organizational structure is a double-layer organization (see attached image 3 ), and the polyester filament A is used as the inner warp, and the elastic yarn B is used as the inner weft. The gray cloth prepared by the above design is subjected to general dyeing processing of cotton fabrics such as gray cloth shaping and scouring, bleaching, singeing, mercerizing, and intermediate shaping. Finishing project, wherein the conditions for gray cloth shaping are: temperature: 160°C, proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com