Elastic water-proof damp/air permeable cloth

A waterproof and moisture-permeable fabric technology, applied to fabrics with resilience, manufacturing tools, textiles, etc., can solve problems such as increased man-hours and costs, hard hand feeling, increased thickness and weight of fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following description is only a preferred embodiment of the present invention.

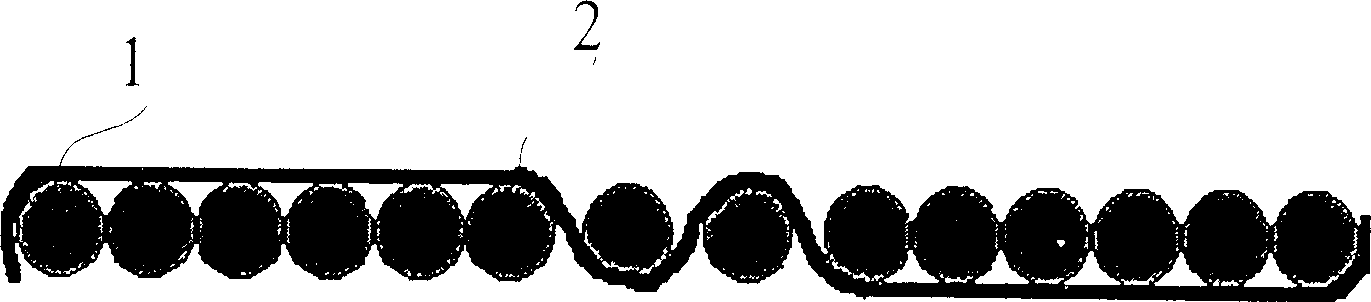

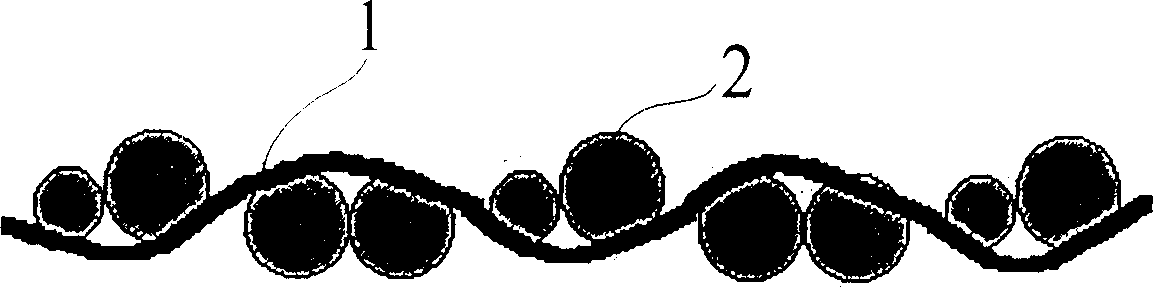

[0018] The present invention weaves warp yarn 1 and weft yarn 2 into gray cloth through warping engineering and weaving engineering. The warping engineering system includes: bobbin—warping—coiling—warp head—sizing—coiling—merging—weaving Cloth head and other steps, and the weaving engineering department includes: weaving head - drawing in heald - machine - insert warp stop piece - set weaving parameters - gray cloth (high-density fabric) and other steps. The density of the gray cloth is controlled by weaving to achieve high coverage, and elastic yarns are added to the warp 1 and weft 2 to make the warp and weft directions of the cloth surface elastic and better extensible, and the gray cloth It is processed through the dyeing and finishing project, which includes: desizing-scouring-presetting-dyeing-drying-post-setting finishing and other steps; or gray cloth setting-desizing-scouring-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com