Opening device for stereo loom

A technology of shedding devices and looms, applied in other shedding mechanisms, textiles, textiles and papermaking, etc., can solve the problems of difficult three-dimensional woven fabric weaving technology, increased warp and heald wear, and inability to meet various structures, etc., to achieve Excellent control performance, reduced number of healds, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

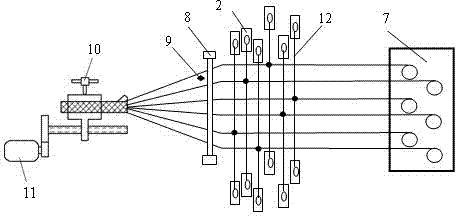

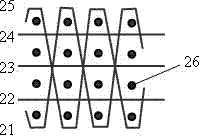

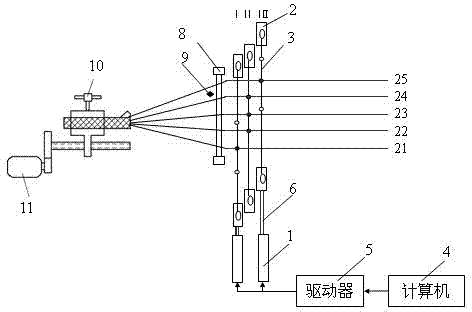

[0026] like figure 2 As shown, it is a three-dimensional orthogonal weave diagram of the fabric in Example 1, the fabric is composed of a first flat warp yarn 22, a second flat warp yarn 23, a third flat warp yarn 24, a first flat yarn 21 and a second flat yarn. 25 and weft yarn 26, using such as image 3 The shown three-dimensional loom opening device for weaving, the three-dimensional loom opening device includes three heald frames 2, and each heald frame 2 is connected with a multi-eye heald 3. The multi-eye brown wire 3 is a three-eye heald (two of which can also be a single-eye heald), wherein the two heald frames 2 are respectively connected to a push rod 6, and the push rod 6 is connected to the servo electric cylinder 1, and the servo electric cylinder 1 is connected to the drive 5, and the drive 5 is connected to the computer 4.

[0027] The first tiling warp yarn 22, the second tiling warp yarn 23 and the third tiling warp yarn 24 respectively penetrate into the 3...

Embodiment 2

[0029] like Figure 5 As shown, it is a three-dimensional full-knot weave three-dimensional fabric diagram in Example 2. The fabric is composed of first and second weft yarns 21 and 25, weft yarns 26, first interlaced warp yarns 32, second interlaced warp yarns 33, and third interlaced weft yarns. The warp 34, the fourth interlaced warp 35, the fifth interlaced warp 36, the sixth interlaced warp 37, the seventh interlaced warp 38, and the eighth interlaced warp 39 are composed. using as Image 6 The shown three-dimensional loom opening device for weaving, the three-dimensional loom opening device includes four heald frames 2, and each heald frame 2 is connected with a multi-eye heald 3. The multi-eye brown wire 3 is a four-eye heald (two of which can also be single-eye heald), each heald frame 2 is connected to a push rod 6, and the push rod 6 is connected to the servo electric cylinder 1, and the servo electric cylinder 1 The drive 5 is connected, and the drive 5 is connect...

Embodiment 3

[0032] like Figure 8 As shown, it is the three-dimensional angle interlocking weave of the three-dimensional fabric in Example 3. The fabric is composed of weft yarns 26, first warp yarns 41, second warp yarns 42, third warp yarns 43, fourth warp yarns 44, fifth warp yarns 45, sixth warp yarns The warp yarn 46, the seventh warp yarn 47, and the eighth warp yarn 48 are composed. using as Figure 9 The shown three-dimensional loom opening device for weaving, the three-dimensional loom opening device includes four heald frames 2, and each heald frame 2 is connected with a multi-eye heald 3. The multi-eye brown wire 3 is a 3-eye heald (two of which can also be single-eye heald), each heald frame 2 is connected to a push rod 6, and the push rod 6 is connected to the servo electric cylinder 1, and the servo electric cylinder 1 The drive 5 is connected, and the drive 5 is connected to the computer 4.

[0033] The second warp yarn 42, the fourth warp yarn 44, and the sixth warp ya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com