Radix isatidis extract modified terylene fiber and preparation method thereof

A technology of isatis root extract and polyester fiber, applied in the direction of abrasion resistance fiber, fiber type, fiber treatment, etc., can solve the problem of easy pilling of polyester staple fiber, improve anti-melting performance, improve hygroscopicity, and reduce alkalinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

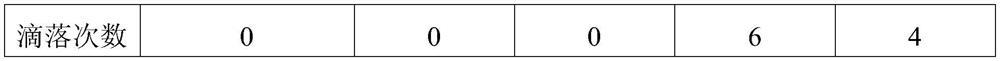

Embodiment 1

[0029] A kind of isatidis root extract modified polyester fiber of the present embodiment, the mass percentage of Radix Radix Radix Radix extract is 0.1%, the mass percentage of Radix Paeoniae Alba extract is 0.1%, the mass percentage of sodium pyrrolidone carboxylate is 0.5%, the mass percentage of melamine phosphate The mass percent is 0.05%, and the mass percent of triethylamine is 0.2%;

[0030] The Radix Isatidis extract and Radix Paeoniae Alba extract are modified as follows:

[0031] (1) Add Radix Radix Radix or Paeoniae Alba Radix Extract into water and stir until completely dissolved, heat the water to 60°C; the mass ratio of Radix Radix Radix Radix Radix Radix Radix or Radix Radix Radix Radix Alba or Radix Paeoniae Alba Extract to water is 1:5, add zeolite powder, The mass ratio of isatidis extract or white peony root extract to zeolite powder is 1:5, stirred evenly and dried at 50°C for 60 minutes to obtain porous nanomaterial wrapping;

[0032] (2) Add long-chain ...

Embodiment 2

[0037] A kind of isatidis root extract modified polyester fiber of the present embodiment, the mass percentage of Radix Radix Radix Radix extract is 2.5%, the mass percentage of Radix Paeoniae Alba extract is 0.5%, the mass percentage of sodium pyrrolidone carboxylate is 0.7%, the mass percentage of melamine phosphate The mass percent is 0.4%, and the mass percent of triethylamine is 0.4%;

[0038] The Radix Isatidis extract and Radix Paeoniae Alba extract are modified as follows:

[0039] (1) Add Radix Radix Radix or Radix Paeoniae Alba Extract to water and stir until completely dissolved, heat the water to 75°C; the mass ratio of Radix Radix Radix Radix Radix Radix or Radix Radix Radix Radix Alba or Radix Paeoniae Alba Extract to water is 1:7.5, add porous nano-SiO 2 Microspheres, Radix Isatidis Extract or Paeoniae Alba Extract with Porous Nano-SiO 2 The mass ratio of microspheres is 1:7.5, stir evenly and dry at 70°C for 30 minutes to obtain porous nanomaterial wrappings; ...

Embodiment 3

[0045] A kind of Radix Radix Radix extract modified polyester fiber of this embodiment, the mass percentage of Radix Radix Radix Radix Radix extract is 5%, the mass percentage of Radix Paeoniae Alba extract is 1%, the mass percentage of sodium pyrrolidone carboxylate is 0.9%, the mass percentage of melamine phosphate The mass percent is 0.8%, and the mass percent of triethylamine is 0.6%;

[0046] The Radix Isatidis extract and Radix Paeoniae Alba extract are modified as follows:

[0047] (1) Add Radix Radix Radix or Radix Paeoniae Alba Extract to water and stir until completely dissolved, heat the water to 90°C, the mass ratio of Radix Radix Radix Radix Radix Radix Radix or Radix Radix Radix Alba or Radix Paeoniae Alba Extract to water is 1:10, add montmorillonite and porous nano-SiO 2 Microspheres, isatidis extract or white peony extract with montmorillonite and porous nano-SiO 2 The total mass ratio of microspheres is 1:10, montmorillonite and porous nano-SiO 2 The mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com