Pneumatic circulation drying system of soft drying machine

A drying system and dryer technology, applied in dryers, drying, progressive dryers, etc., to achieve the effect of avoiding pilling and high-efficiency gas flapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

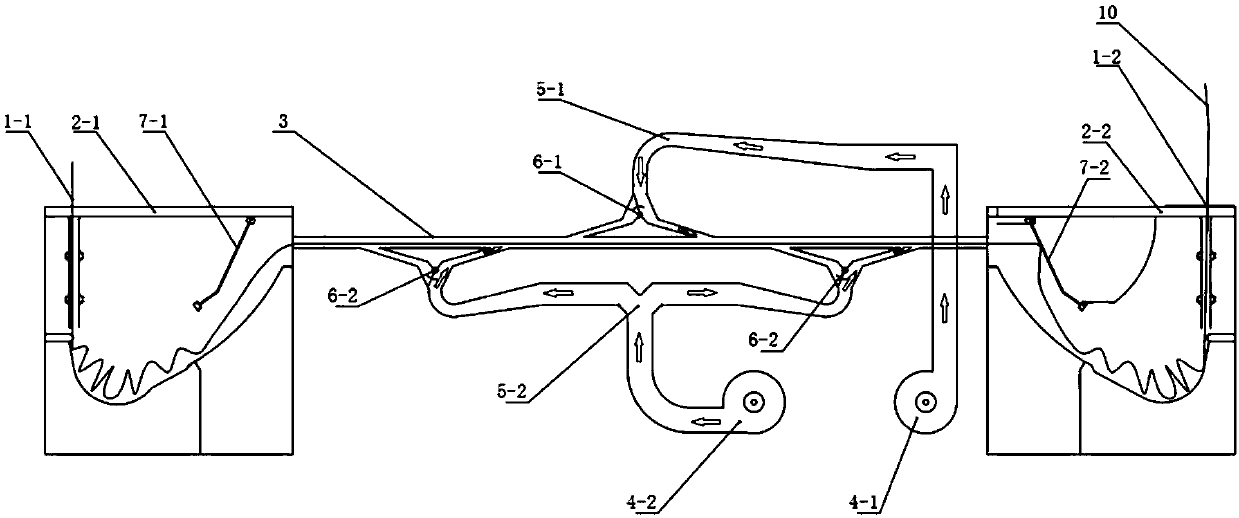

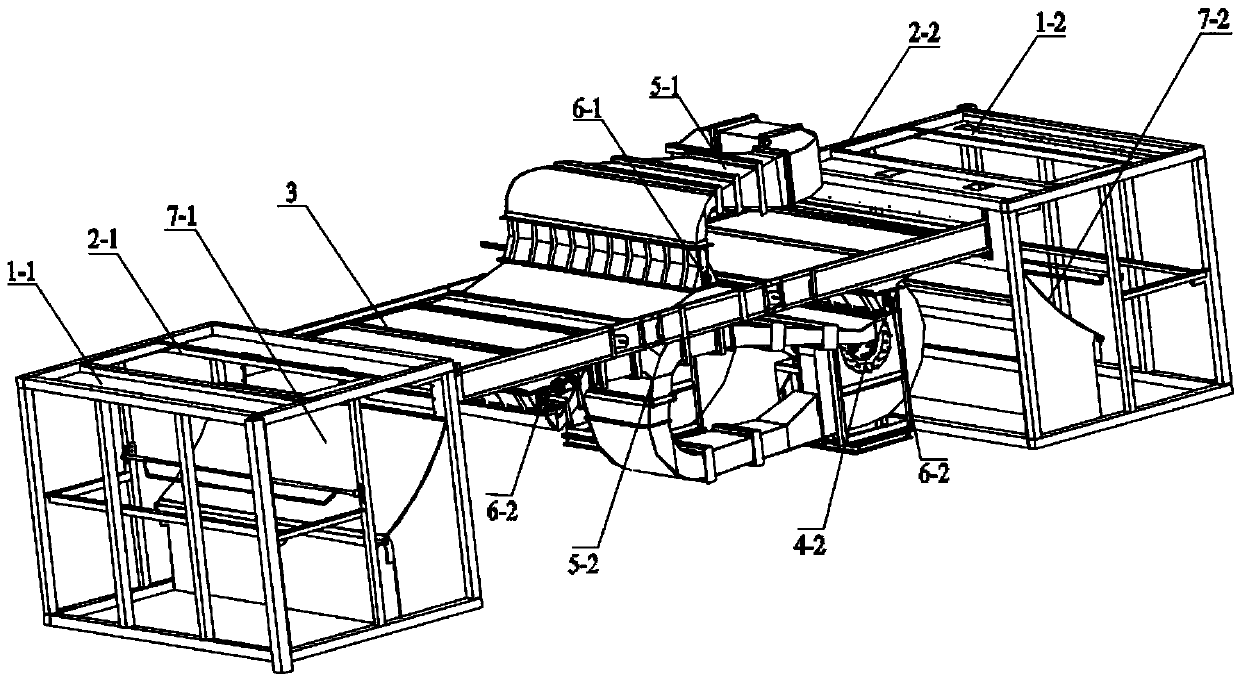

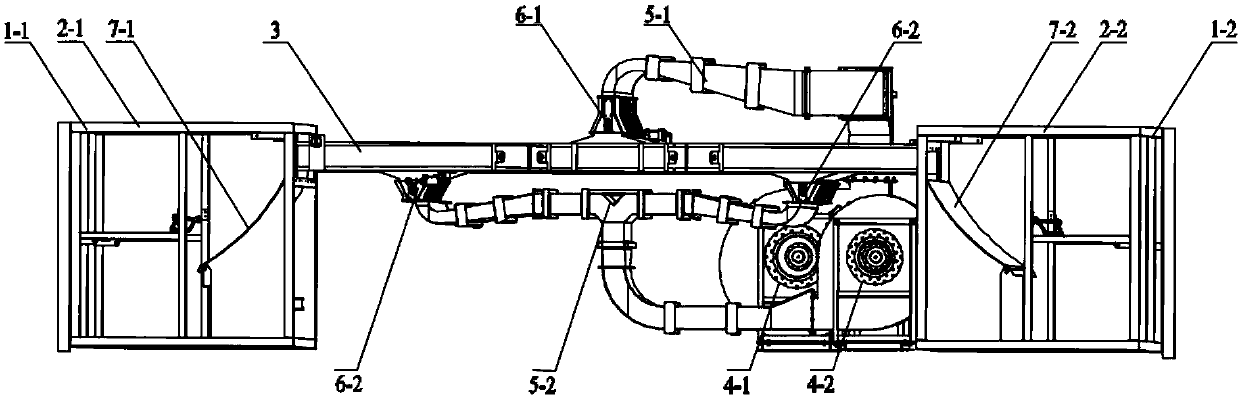

[0016] Such as figure 1 - As shown, this embodiment provides a pneumatic circulation drying system for a judo dryer, including a cloth inlet 1-1 and a first cloth storage box 2-1, a cloth outlet 1-2 and a second cloth storage box 2 -2. Connect the first cloth storage box 2-1 and the second cloth storage box 2-2 with the cloth trough air duct 3, and connect the cloth trough air duct 3 with the fan 4, the fan 4 includes the main fan 4-1 and the auxiliary fan 4 -2, the main fan 4-1 is connected to at least one main air duct 5-1, the main air duct 5-1 is connected to the main air duct reversing valve plate 6-1, and the main air duct reversing valve plate 6-1 is connected to the main air duct There ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com