Anti-wrinkling fabric and preparation method thereof

A fabric and anti-wrinkle agent technology, applied in the field of garment fabric processing, can solve the problems of insufficiency, difficult wrinkle resistance and comfort, and achieve the effects of avoiding pilling, ensuring warmth and comfort, and having a thick texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The embodiment of the present application also discloses the preparation method of the wrinkle-resistant fabric, comprising the following steps:

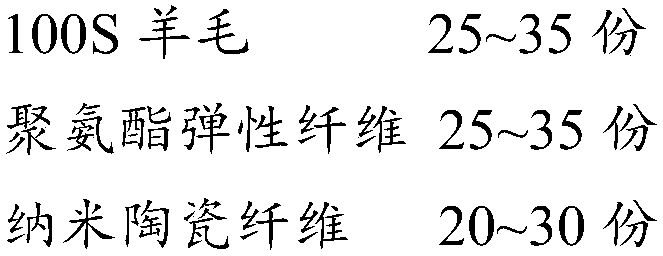

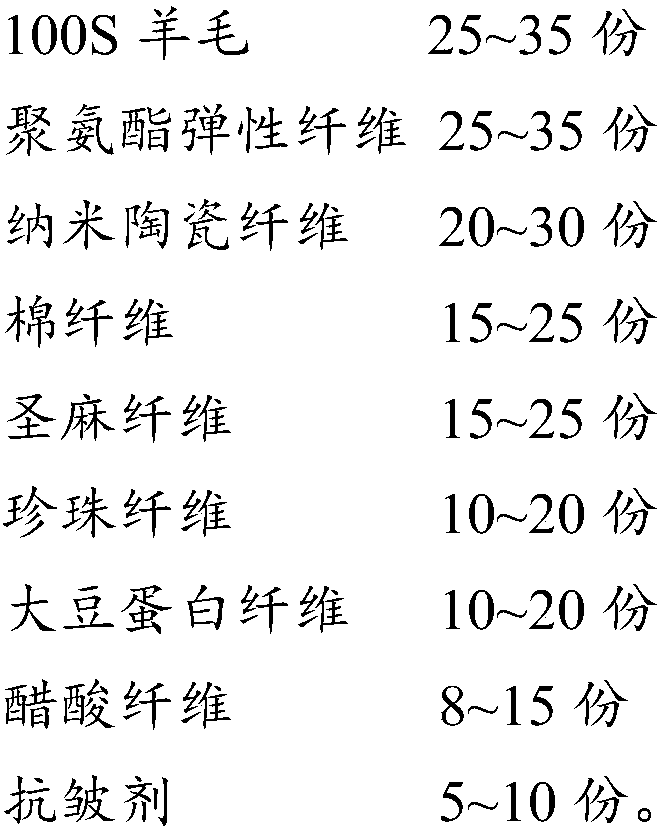

[0032] (1) Material collection process: select 25-35 parts of 100S wool, 25-35 parts of polyurethane elastic fiber, 20-30 parts of nano-ceramic fiber, 15-25 parts of cotton fiber, 15-25 parts of holy hemp fiber, and 10-20 parts of pearl Fiber, 10-20 parts of soybean protein fiber and 8-15 parts of acetate fiber;

[0033] (2) Merging process: 25-35 parts of 100S wool, 25-35 parts of polyurethane elastic fiber, 20-30 parts of nano-ceramic fiber and 15-25 parts of cotton fiber are sent into the doubling machine for yarn intermingling and forming a blend. And warp, send 15-25 parts of holy hemp fiber, 10-20 parts of pearl fiber, 10-20 parts of soybean protein fiber and 8-15 parts of acetate fiber into the doubling machine for yarn interlacing and forming mixed weft yarn;

[0034] (3) Winding and warping process: use the winding ...

Embodiment 1

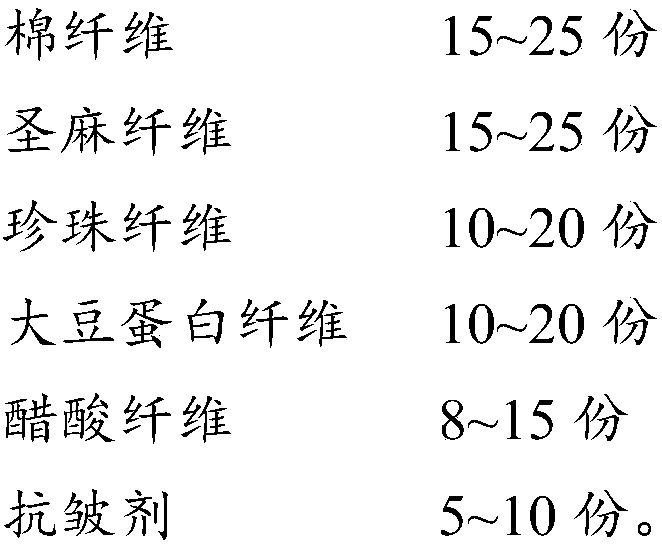

[0045] The anti-wrinkle fabric includes the following raw materials in parts by weight:

[0046]

[0047]

[0048] Wherein, the anti-wrinkle agent is dimethylol vinyl aldehyde.

[0049] (1) Material extraction process: select the above-mentioned raw materials;

[0050] (2) Merging process: 25 parts of 100S wool, 25 parts of polyurethane elastic fiber, 20 parts of nano-ceramic fiber and 25 parts of cotton fiber are sent into the doubling machine for yarn intermingling and forming a mixed warp thread, and 15 parts of Shengma Fiber, 10 parts of pearl fiber, 10 parts of soybean protein fiber and 15 parts of acetate fiber are sent into the doubling machine for yarn crossing and forming mixed weft yarn;

[0051] (3) Winding and warping process: use the winding machine to make the warp and weft into a twisted bobbin, and make the warp and weft on the twisted bobbin into a warp beam through the warping machine according to the requirements of the warping process, and then the w...

Embodiment 2

[0057] The anti-wrinkle fabric includes the following raw materials in parts by weight:

[0058]

[0059]

[0060]Wherein, the anti-wrinkle agent includes dimethylol vinyl aldehyde.

[0061] The embodiment of the present application also discloses the preparation method of the wrinkle-resistant fabric, comprising the following steps:

[0062] (1) Material collection process: select 25-35 parts of 100S wool, 25-35 parts of polyurethane elastic fiber, 20-30 parts of nano-ceramic fiber, 15-25 parts of cotton fiber, 15-25 parts of holy hemp fiber, and 10-20 parts of pearl Fiber, 10-20 parts of soybean protein fiber and 8-15 parts of acetate fiber;

[0063] (2) Merging process: 35 parts of 100S wool, 35 parts of polyurethane elastic fiber, 30 parts of nano-ceramic fiber and 15 parts of cotton fiber are sent into the doubling machine for yarn interlacing and forming a mixed warp thread, and 25 parts of Shengma Fiber, 20 parts of pearl fiber, 20 parts of soybean protein fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com