Air layer fabric and production method and application thereof

A technology of air layer and fabric, which is applied in application, dyeing, textile and papermaking, etc., to achieve the effect of improving wearing performance, good crease problem, and good resistance to snagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

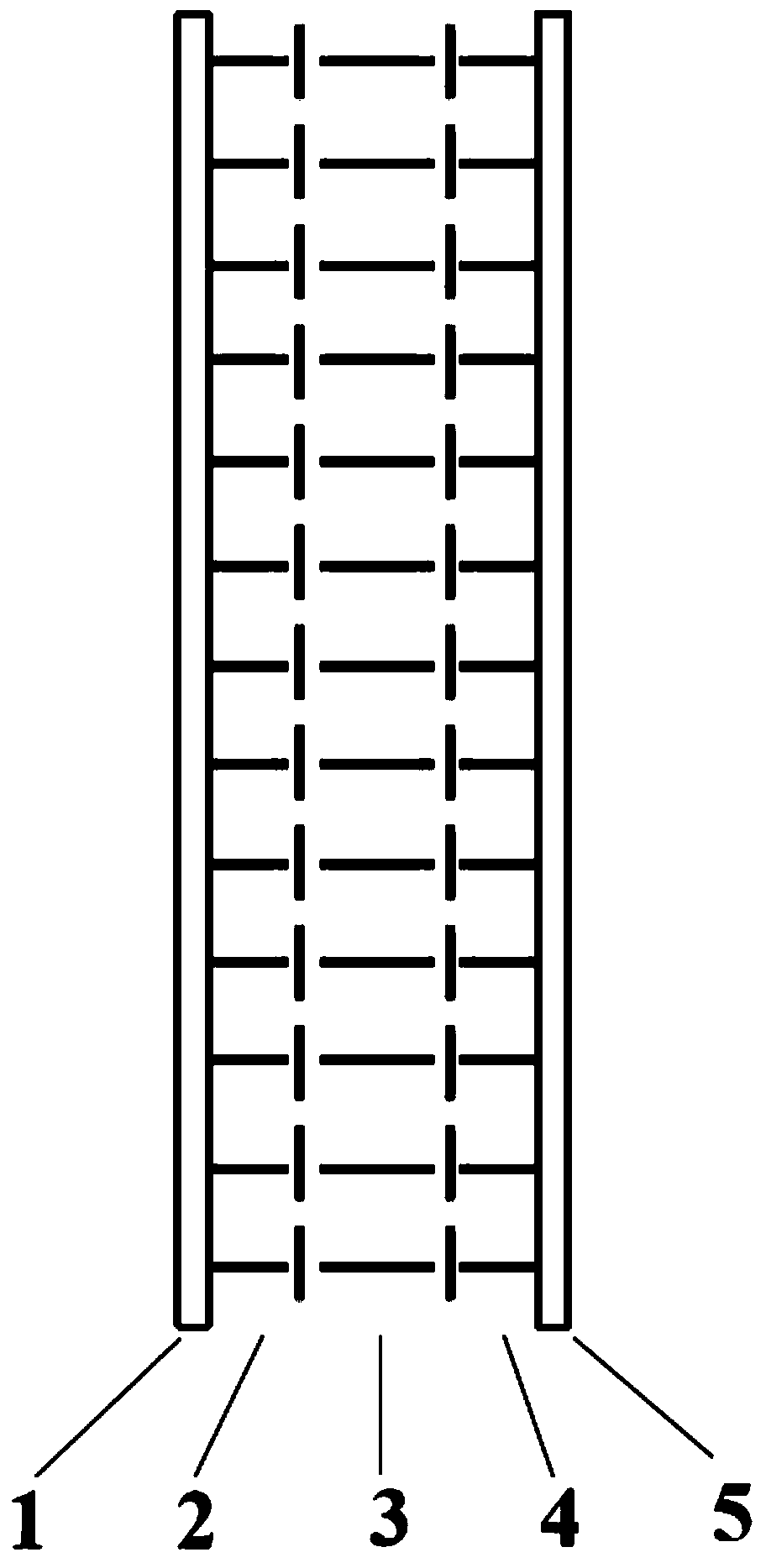

[0030] like figure 1 As shown, an air layer fabric includes: an outer layer 1, a second outer layer 2, an intermediate layer 3, a second inner layer 4 and an inner layer 5, and the outer layer 1 and the inner layer 5 are respectively made of 32S / 1 cotton yarn The knitted weft flat structure, the second outer layer 2 is composed of 30D / 24F polyester low elastic yarn and the coil of the outer layer 1 in the form of tuck connection, and the second inner layer 4 is made of 30D / 24F polyester low elastic The wire and the coil of the inner layer 5 are formed in the form of a tuck connection, and the middle layer 3 is made of 50D / 36F, and the 30D / 24F of the second outer layer 2 and the 30D / 24F of the second inner layer 4 are connected in a tuck manner. set.

[0031] The specific production method steps are as follows:

[0032] (1) Using 32S / 1 refined cotton, 50D / 36F polyester low-stretch yarn, and 30D / 24F polyester low-stretch yarn as raw materials, use 20G34" double-sided large cir...

Embodiment 2

[0041] An air layer fabric, comprising: an outer layer 1, a second outer layer 2, a middle layer 3, a second inner layer 4 and an inner layer 5, and the outer layer 1 and the inner layer 5 are respectively knitted wefts made of 40S / 1 cotton yarn Flat weave structure, the secondary outer layer 2 is composed of 30D / 24F polyester low elastic yarn and the coil of the outer layer 1 in the form of tuck connection, and the secondary inner layer 4 is composed of 30D / 24F polyester low elastic yarn and the coil of the outer layer 1 The coils of the inner layer 5 are formed in the form of tuck connections, and the middle layer 3 is formed by 50D / 36F of 30D / 24F of the second outer layer 2 and 30D / 24F of the second inner layer 4 in a tuck manner. .

[0042] The specific production method steps are as follows:

[0043] (1) Using 40S / 1 refined cotton, 50D / 36F polyester low-stretch yarn, and 30D / 24F polyester low-stretch yarn as raw materials, use 20G34" double-sided large circular machine f...

Embodiment 3

[0052] An air layer fabric, comprising: an outer layer 1, a second outer layer 2, a middle layer 3, a second inner layer 4 and an inner layer 5, and the outer layer 1 and the inner layer 5 are respectively knitted wefts made of 50S / 1 cotton yarn Flat weave structure, the second outer layer 2 is composed of 30D / 24F polyester low elastic yarn and the coil of the outer layer 1 in the form of tuck connection, the second inner layer 4 is made of 30D / 24F and the inner layer 5 The coils are formed in the form of tuck connections, and the middle layer 3 is formed by 50D / 36F connecting 30D / 24F of the second outer layer 2 and 30D / 24F of the second inner layer 4 in a tuck manner.

[0053] The specific production method steps are as follows:

[0054] (1) Using 50S / 1 refined cotton, 50D / 36F polyester low-stretch yarn, and 30D / 24F polyester low-stretch yarn as raw materials, use 20G34" double-sided large circular machine for weaving;

[0055] (2) The outer layer 1 and the inner layer 5 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com