Waterproof socket

A technology of waterproof sockets and sockets, which is applied in the direction of the base/shell, contact parts, etc., and can solve problems such as flowing into the socket shell and poor contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

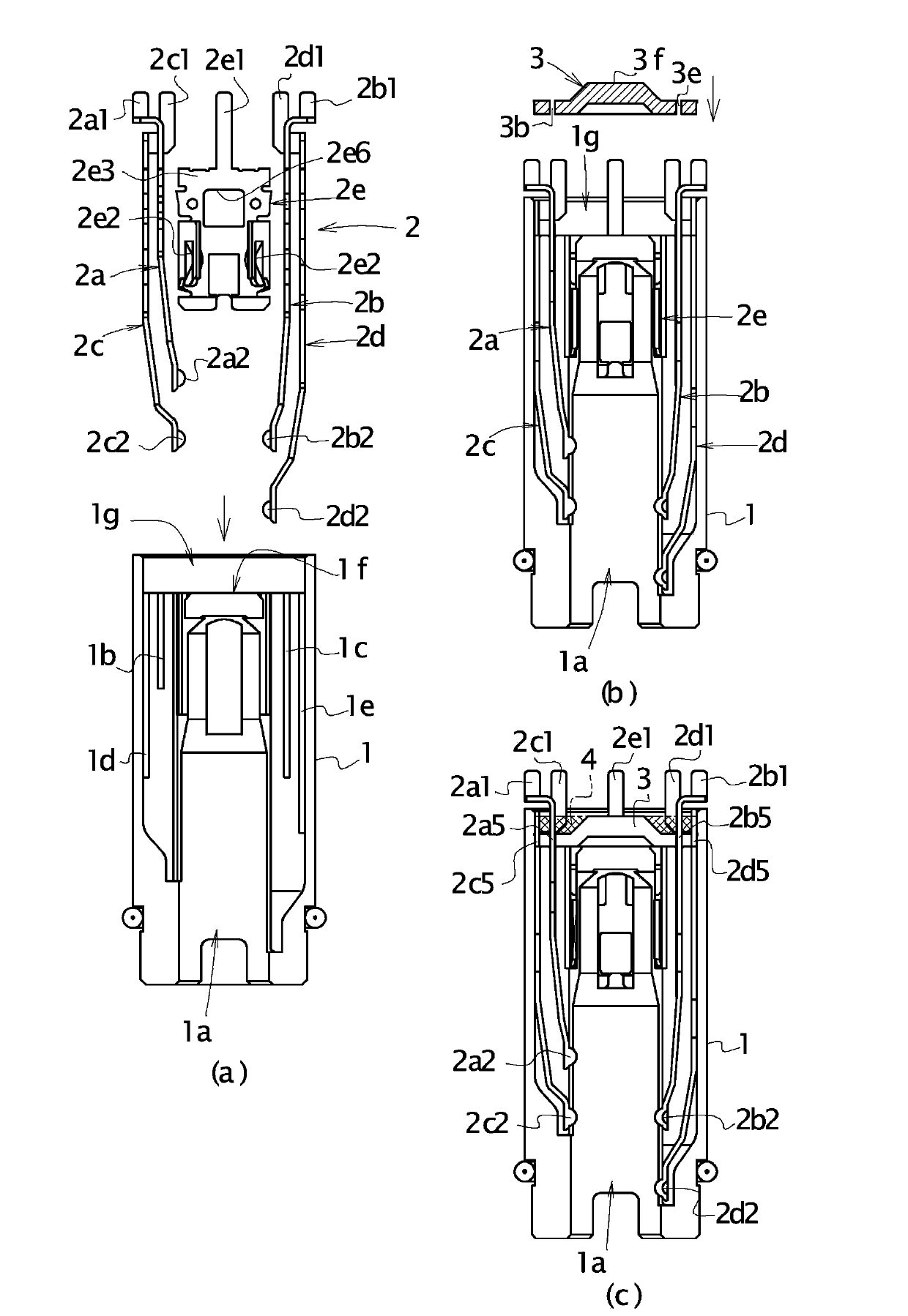

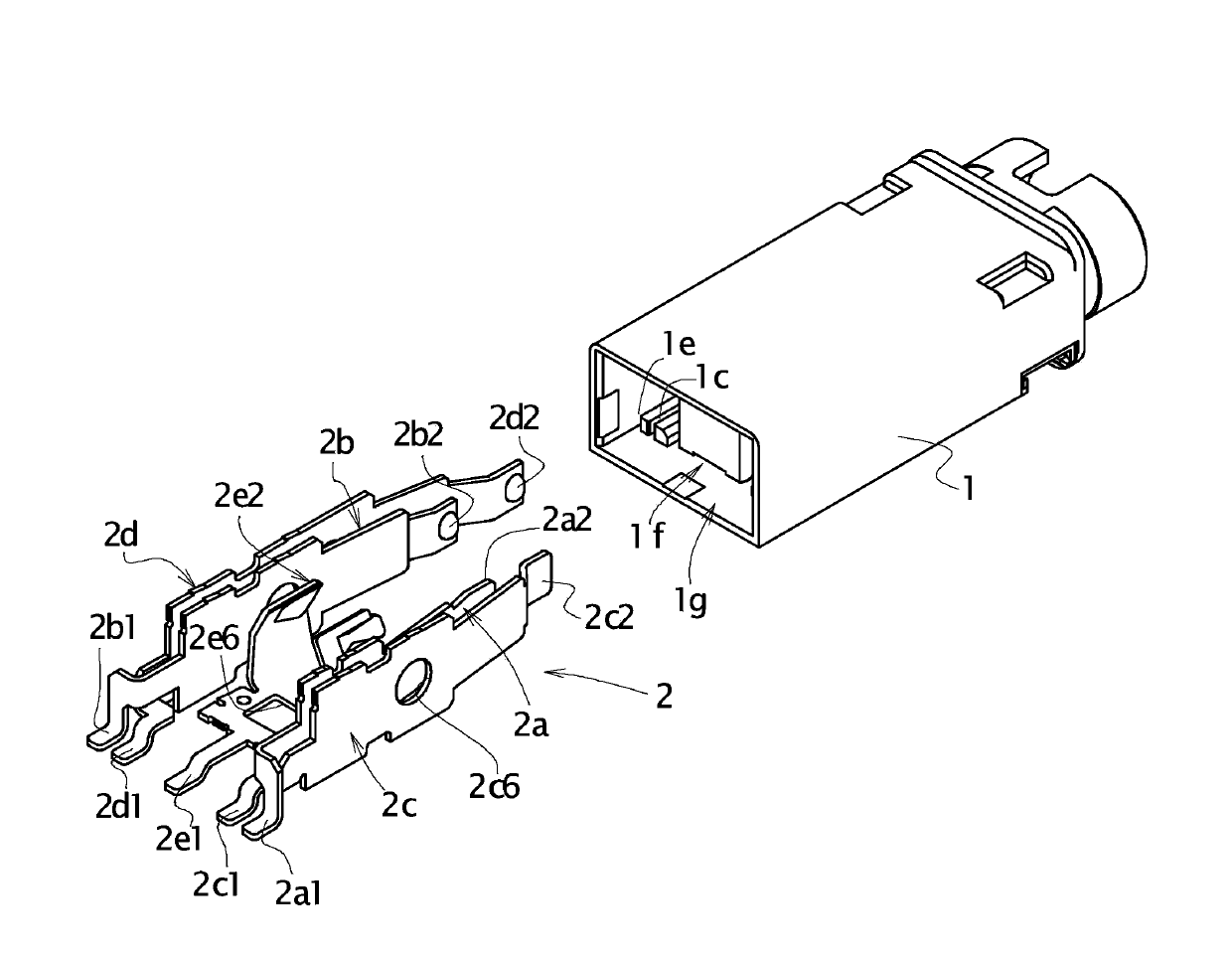

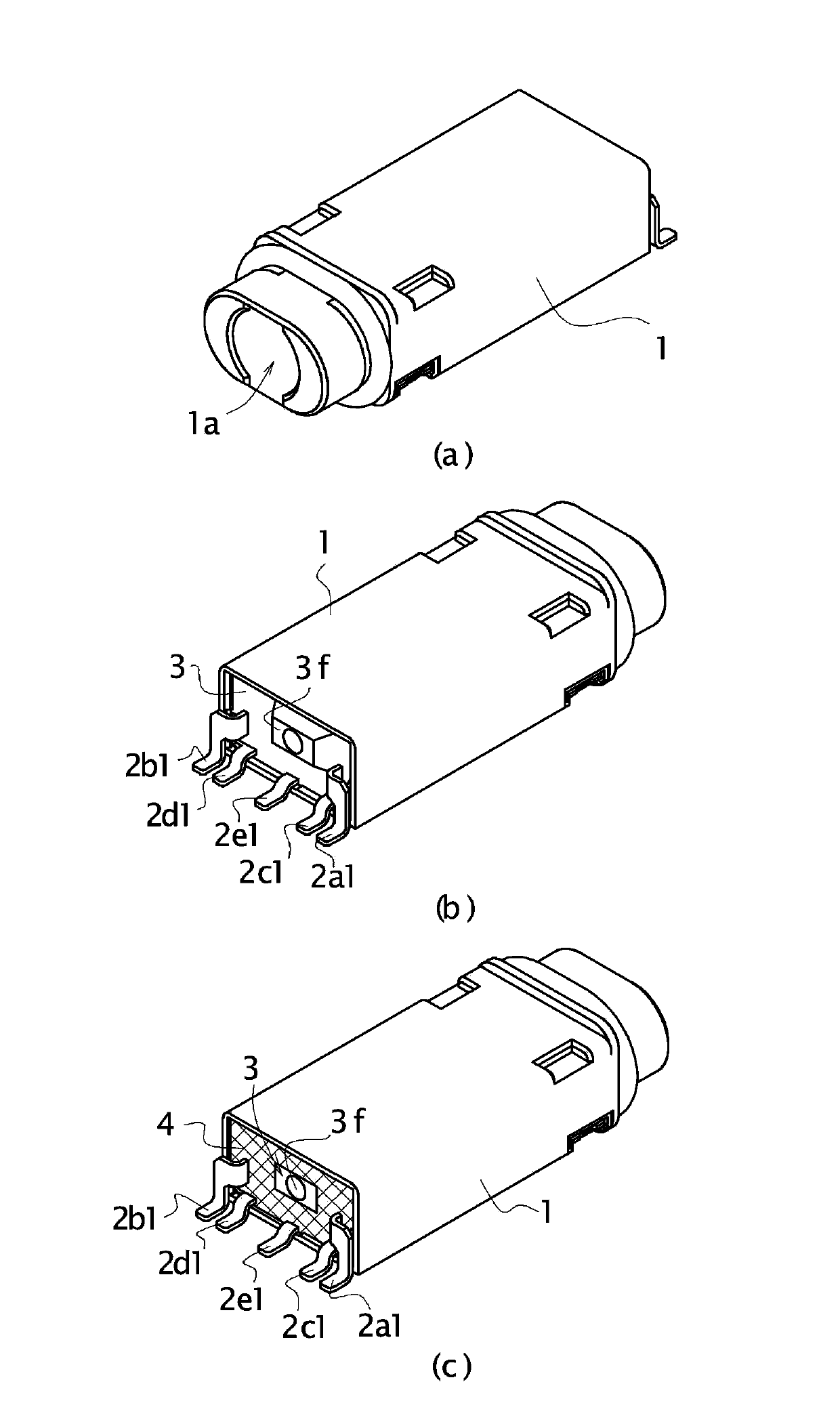

[0037] Hereinafter, based on an Example, the form for implementing this invention is demonstrated in detail, referring drawings.

[0038] like figure 1 (a)~(c), image 3 (c) and Figure 13 As shown in (a) to (d), the waterproof socket of this embodiment is composed of the following components: a socket housing 1 made of insulating plastic material, which has a plug insertion hole 1a, and at a predetermined position around it, as The ring spring (ring spring) 2a of the contact spring 2, the two second sleeve springs (sleeve spring) 2b, 2c, the first sleeve spring 2d and the leaf spring (chip spring) 2e are respectively positioned and fixed in the installation groove (installation Units) 1b, 1c, 1d, 1e, 1f, and the inlet 1g for installing the contact spring 2 in order to install the contact spring into the installation groove 1b, 1c, 1d, 1e, 1f; from the inlet 1g The ring spring 2a, the two second sleeve springs 2b, 2c, the first sleeve spring 2d, and the leaf spring 2e inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com