Spring mattress with edge being not easy to collapse

An edge and difficult technology, applied in the field of improvement of spring cores in spring mattresses, can solve problems such as no better solution, unsightly mattresses, and edge collapse of the spring cores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

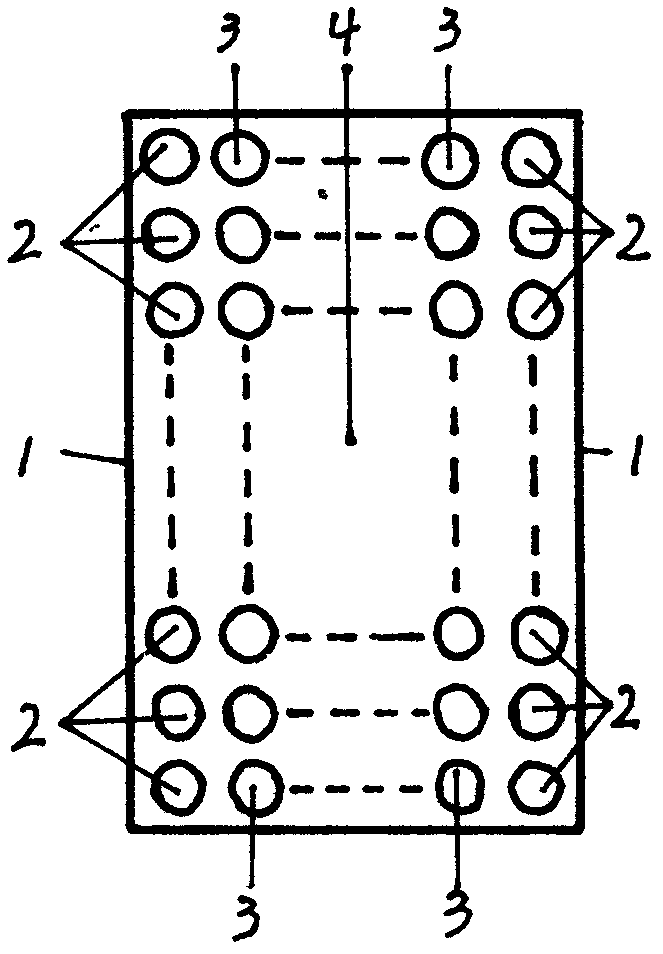

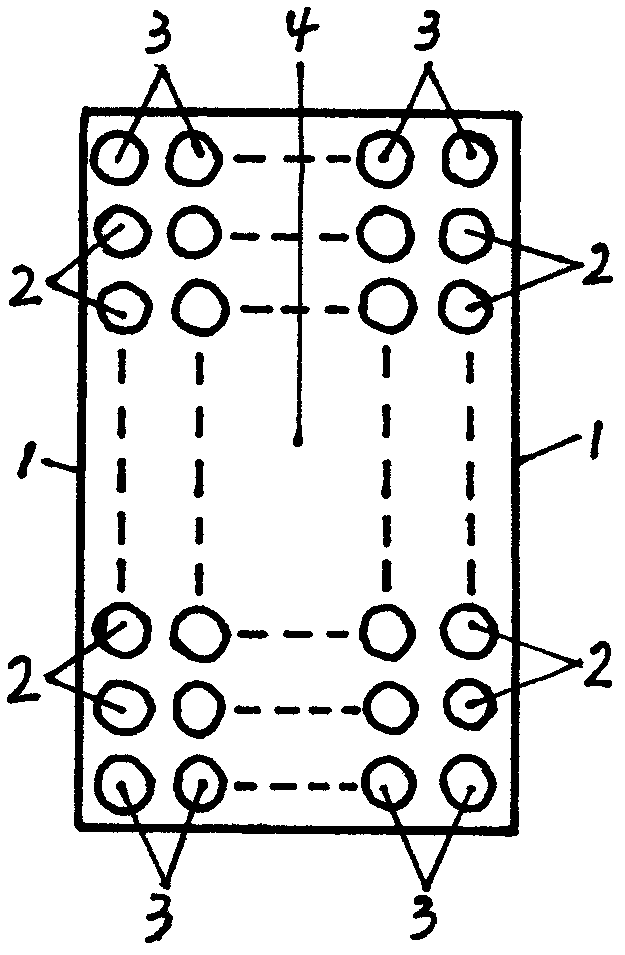

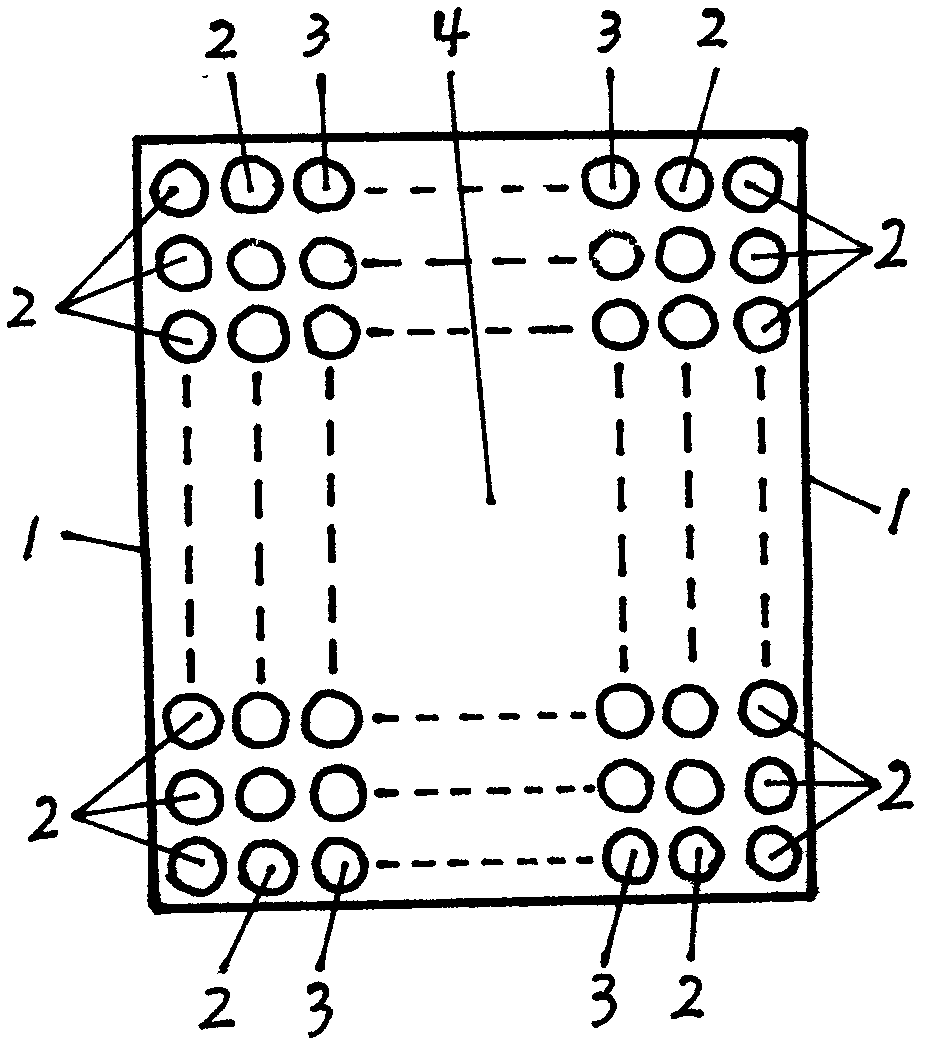

[0023] figure 1 Among them, the spring core 4 is formed by binding the edge spring 2 and the core capsule spring 3 on the positioning steel wire and fixing them together (the positioning steel wire is not shown in the figure), and the edge spring 2 is distributed on the edge 1 on the opposite sides of the spring core 4 , the edge spring 2 is a row of springs distributed along the edge 1 of the spring core 4, and the edge spring 2 is adjacent to the edge 1 of the spring core 4, and the other parts of the spring core 4 are distributed with core bag springs 3, the stiffness of the edge spring 2 Greater than the stiffness of the core spring 3, after a person sits on the edge of the spring mattress, since the stiffness of the edge spring 2 is larger and greater than the stiffness of the core spring 3, the edge spring 2 is not prone to plastic deformation, so that the spring core 4. It is not easy to collapse, which not only maintains the elasticity and comfort of the spring mattres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com