Plant-based meat product and prepared food

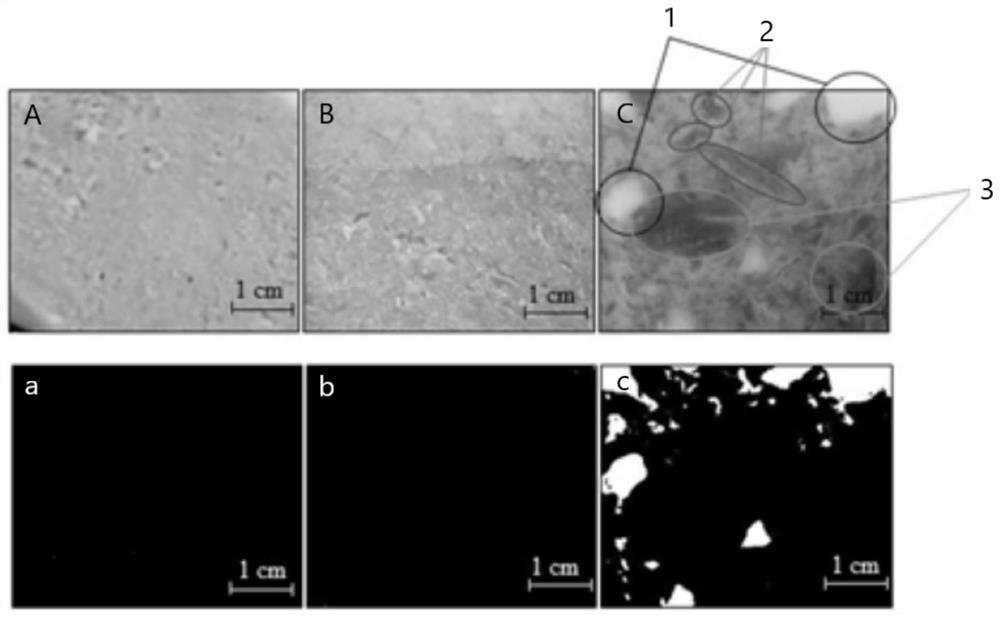

A plant-based meat-based technology, which is applied in food ingredients, protein food processing, plant protein processing, etc., can solve the problems of lack of grainy meat, silky meat, affecting adhesion and molding, and no layering of chewing, etc., to achieve The overall structure of the product is stable, the quality is improved, and the meat is firm and not loose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

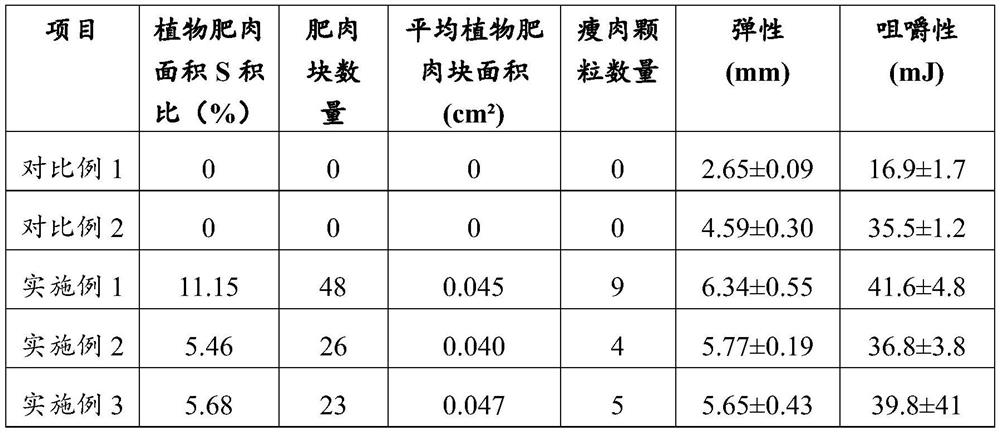

Embodiment 1

[0039] This embodiment provides a plant-based meat product, and the preparation method includes the following steps:

[0040] (1) The making of plant fat: by mass percentage, 55% water, 5% soybean protein isolate, 10% sweet potato starch, 5% konjac flour, 25% coconut oil are added in the blender and emulsified, The speed of the mixer is 3000rpm, the stirring time is 10min, and then it is put into a mold with a fixed shape for cooking and aging. The aging temperature is 75°C and the time is 180min.

[0041] The making of protein chyle: in mass percentage, 64% water, 10% soybean protein isolate, 3% starch, 3% konjac flour, 5% curdlan are added in the mixer and emulsified, and the mixer speed is 1500rpm, stirring time 10min, then add 15% coconut oil for emulsification, at this time, adjust the speed of the mixer to 3000rpm, stirring time 10min, to obtain protein chyle; then season the protein chyle, add salt, monosodium glutamate, yeast extract, etc., spare;

[0042] Production...

Embodiment 2

[0047] This embodiment provides a plant-based meat product, and the preparation method includes the following steps:

[0048] (1) The making of plant fat: by mass percent, 62% water, 4% soybean protein isolate, 5% cornstarch, 4% konjac flour, 25% coconut oil are added in the blender and emulsified, The speed of the mixer is 4500rpm, the stirring time is 10min, and then it is put into a mold with a fixed shape for cooking and aging. The aging temperature is 95°C, and the time is 100min.

[0049] The making of protein chyle: in mass percentage, 72% water, 7% soybean protein isolate, 4% starch, 4% konjac flour, 3% curdlan are added in the mixer and emulsified, and the mixer speed is 1000rpm, stirring time 15min, then add 10% coconut oil for emulsification, at this time, adjust the speed of the mixer to 4000rpm, stirring time 10min, to obtain protein chyle; then season the protein chyle, add salt, monosodium glutamate, yeast extract, etc., spare;

[0050] Production of filamento...

Embodiment 3

[0055] This embodiment provides a plant-based meat product, and the preparation method includes the following steps:

[0056] (1) The making of plant fat: in mass percentage, 70% water, 2% soybean protein isolate, 10% tapioca starch, 3% konjac flour, 15% coconut oil are added in the blender and emulsified, The speed of the mixer is 5000rpm, the stirring time is 10min, and then it is put into a mold with a fixed shape for cooking and aging. The aging temperature is 80°C and the time is 150min.

[0057] The making of protein chyle: in mass percentage, 62% water, 15% soybean protein isolate, 3% starch, 3% konjac flour, 5% curdlan are added in the mixer and emulsified, and the mixer speed is 2000rpm, stirring time 12min, then add 12% coconut oil for emulsification, at this time, adjust the speed of the mixer to 5000rpm, stirring time 10min, to obtain protein chyle; then season the protein chyle, add salt, monosodium glutamate, yeast extract, etc., spare;

[0058] Production of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com