High-performance polyurethane for biological easily degradable spandex and preparation method of high-performance polyurethane

A biodegradable polyester, high-performance technology, applied in the manufacture of rayon, one-component synthetic polymer rayon, chemical characteristics of fibers, etc., can solve the problems of high price, secondary pollution, high recycling cost, and achieve modified The process is simple, the elongation at break and resilience are improved, and the effect of improving the strength of spandex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

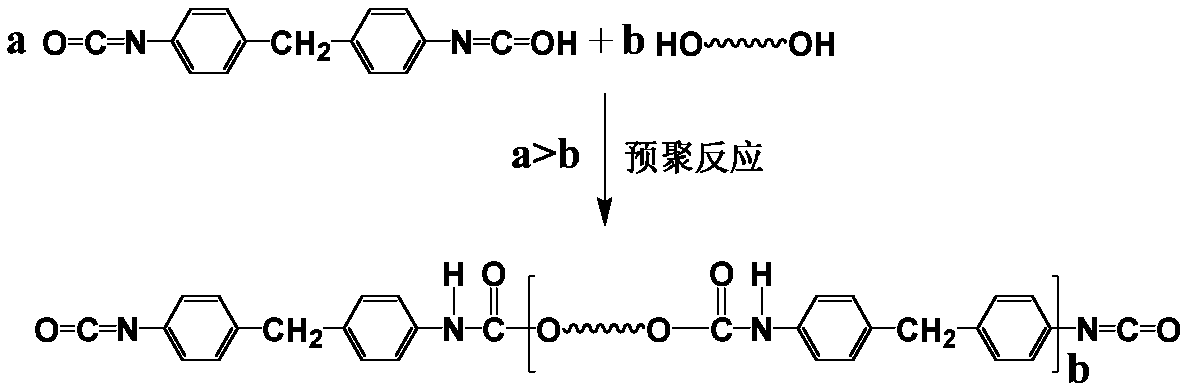

Method used

Image

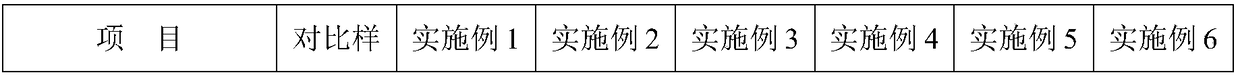

Examples

Embodiment 1

[0025] Step 1: Under nitrogen protection conditions, 169.5g polytetramethylene ether glycol (molecular weight 1810), 2.58g polycaprolactone diol (molecular weight 2000), 39.8g4,4-diphenylmethane diisocyanate Adding it into the reactor, the reaction temperature is 65°C, and the reaction time is 2 hours, to obtain an easily biodegradable polyester polyol modified prepolymer (PP) terminated with a certain mass fraction of -NCO;

[0026] Step 2: Add 494.44 g of DMAC to the prepolymer (PP) prepared in step 1 under the condition of 20°C and nitrogen protection, and stir for 1 hour at a stirring rate of 100 rpm to obtain a uniform prepolymer solution (PPs);

[0027] Step 3: On the basis of step 2, with a stirring rate of 170 rpm, 108g of mixed amine DMAC solution (including 0.22g of propylenediamine, 3.39g of ethylenediamine, 0.56g of diethylamine, and 0.2g of ethanolamine) was slowly added dropwise Add in the above-mentioned homogeneous prepolymer solution (PPs) in a manner, and ad...

Embodiment 2

[0030] Step 1: Under nitrogen protection conditions, 165.7g polytetramethylene ether glycol (molecular weight 1810), 5.16g polycaprolactone diol (molecular weight 2000), 39.8g4,4-diphenylmethane diisocyanate Adding it into the reactor, the reaction temperature is 65°C, and the reaction time is 2 hours, to obtain an easily biodegradable polyester polyol modified prepolymer (PP) terminated with a certain mass fraction of -NCO;

[0031] Step 2: Add 491.56 g of DMAC to the prepolymer (PP) prepared in Step 1 under the condition of 20°C and nitrogen protection, and stir for 1 hour at a stirring rate of 100 rpm to obtain a uniform prepolymer solution (PPs);

[0032] Step 3: On the basis of step 2, with a stirring rate of 170 rpm, 107.5g of mixed amine DMAC solution (including 0.22g of propylenediamine, 3.37g of ethylenediamine, 0.56g of diethylamine, and 0.2g of ethanolamine) was slowly dropped Add the above-mentioned high-performance prepolymer solution (PPs) by adding, and add fun...

Embodiment 3

[0035] Step 1: Under nitrogen protection conditions, 165.3g polytetramethylene ether glycol (molecular weight 1810), 8.70g aliphatic polycarbonate diol (molecular weight 2000), 41g4,4-diphenylmethane diisocyanate Adding it into the reactor, the reaction temperature is 70°C, and the reaction time is 2 hours to obtain an easily biodegradable polyester polyol modified prepolymer (PP) terminated with a certain mass fraction of -NCO;

[0036] Step 2: Add 5001.68 g of DMAC to the prepolymer (PP) prepared in step 1 under the condition of 20°C and nitrogen protection, and stir for 1 hour at a stirring rate of 100 rpm to obtain a uniform prepolymer solution (PPs);

[0037] Step 3: On the basis of step 2, with a stirring rate of 170 rpm, 109.7g of mixed amine DMAC solution (including 0.22g of propylenediamine, 3.44g of ethylenediamine, 0.57g of diethylamine, and 0.2g of ethanolamine) was slowly dropped Add the above-mentioned high-performance prepolymer solution PPs, and add functional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com