Dyeing device of elastic fabric and dyeing method using dyeing device

A dyeing device and technology for elastic fabrics, applied in the direction of dyeing, textile material processing, equipment configuration for processing textile materials, etc., can solve problems such as low strength of fabrics, reducing the elasticity of elastic fabrics, and the influence of fabric feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

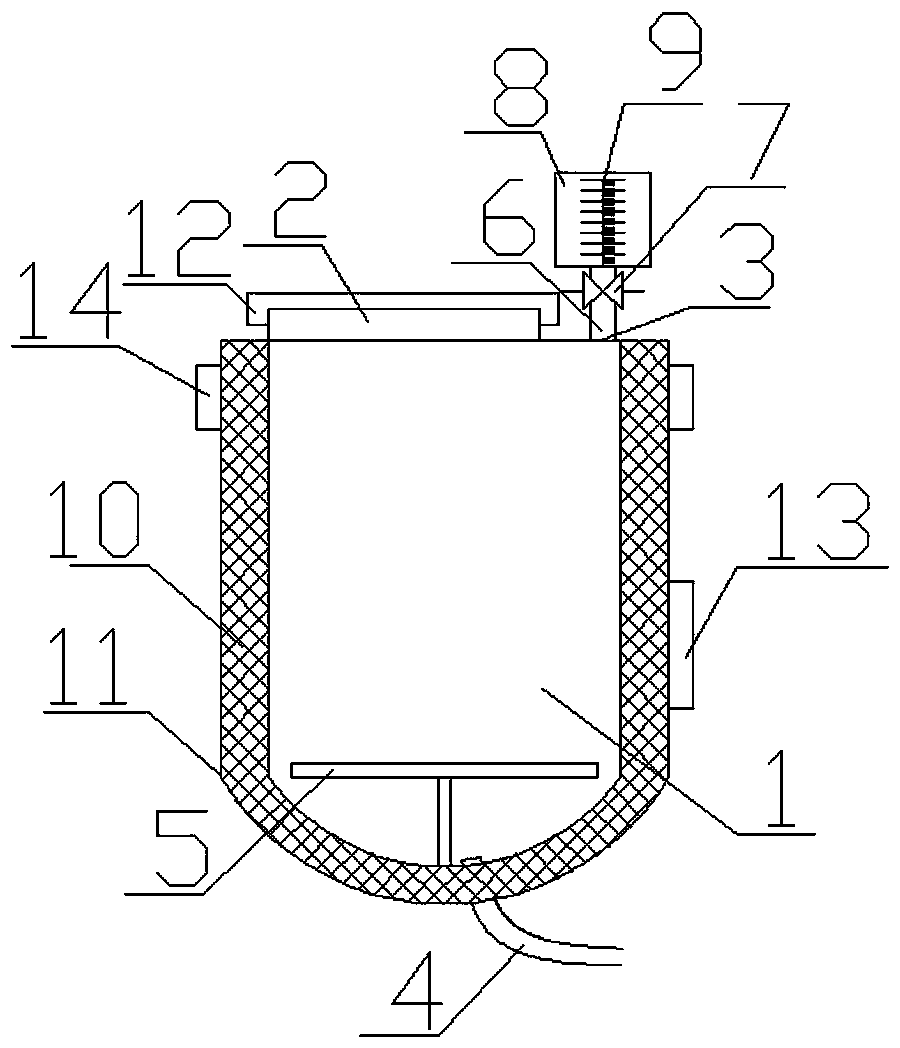

Image

Examples

Embodiment 1

[0041] This embodiment is applied to the dyeing method of the dyeing device of the above-mentioned elastic fabric, and the dyeing method includes the following steps:

[0042] (1) Add dye primer:

[0043] Add dyestuff one in the dyeing vat 1, open valve 7 and enter in the dyeing vat 1 after the dyestuff one is determined volume by measuring cylinder 8, described dyestuff one comprises the epichlorohydrin that volume ratio is 3%, the ferrous sulfate of 2%; Sodium hexametaphosphate; 5% dimethylamine and 25% vegetable dyes, and the rest are water, which is stirred by the stirring device 5 in the dyeing vat 1 to make each material in the dyeing vat 1 fuse evenly;

[0044] (2) Add fusion material:

[0045] Put dye two into the dyeing vat 1, and open the valve 7 after the volume of the dye two is determined by the measuring cylinder 8 to enter the dyeing vat 1. The dye two includes a volume ratio of 2% maleic acid acrylic acid copolymer, 2% isomeric tridecyl alcohol poly Oxyethyle...

Embodiment 2

[0055] This embodiment is applied to the dyeing method of the dyeing device of the above-mentioned elastic fabric, and the dyeing method includes the following steps:

[0056] (1) Add dye primer:

[0057] Add dyestuff one in dye vat 1, dyestuff one is opened valve 7 and enters in the dye vat 1 after measuring cylinder 8 to determine volume, and described dyestuff one comprises epichlorohydrin that volume ratio is 4%, ferrous sulfate of 1.5%; 3% Sodium hexametaphosphate; 4% dimethylamine and 28% vegetable dyes, all the other are water, stir through stirring device 5 in dye vat 1 to make each material in dye vat 1 fuse evenly;

[0058] (2) Add fusion material:

[0059] Put dye two into the dye vat 1, the dye two passes through the measuring cylinder 8 to determine the volume and then opens the valve 7 to enter the dye vat 1. The dye two includes maleic acid acrylic acid copolymer with a volume ratio of 1.5%, isomeric tridecyl alcohol poly Oxyethylene mi phosphoric acid ester, ...

Embodiment 3

[0069] This embodiment is applied to the dyeing method of the dyeing device of the above-mentioned elastic fabric, and the dyeing method includes the following steps:

[0070] (1) Add dye primer:

[0071] Add dyestuff one in dyeing vat 1, dyestuff one is opened valve 7 and enters in the dyeing vat 1 after measuring cylinder 8 to determine volume, and described dyestuff one comprises the epichlorohydrin that volume ratio is 5%, the ferrous sulfate of 1%; 4% Sodium hexametaphosphate; 3% dimethylamine and 30% vegetable dyes, and the rest are water, which is stirred by the stirring device 5 in the dyeing vat 1 to make the fusion of each material in the dyeing vat 1 even;

[0072] (2) Add fusion material:

[0073] Put dye 2 into the dye vat 1, the dye 2 passes through the measuring cylinder 8 to determine the volume and then opens the valve 7 to enter the dye vat 1. The dye 2 includes 1% maleic acid acrylic acid copolymer and 4% isomeric tridecanol poly Oxyethylene mi phosphoric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com