Single-phase power socket

A single-phase power supply and socket technology, applied in circuits, electrical components, fixed/insulated contact components, etc., can solve the problems of low contact pressure, easy loosening, and easy heat generation, and achieve good electrical contact, not easy to heat, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

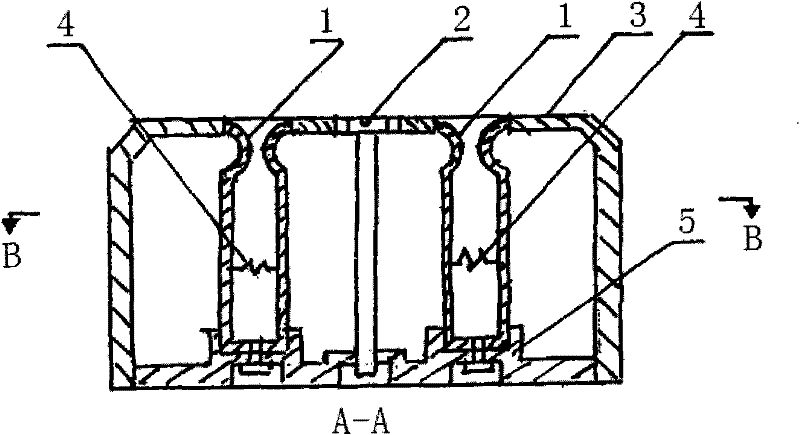

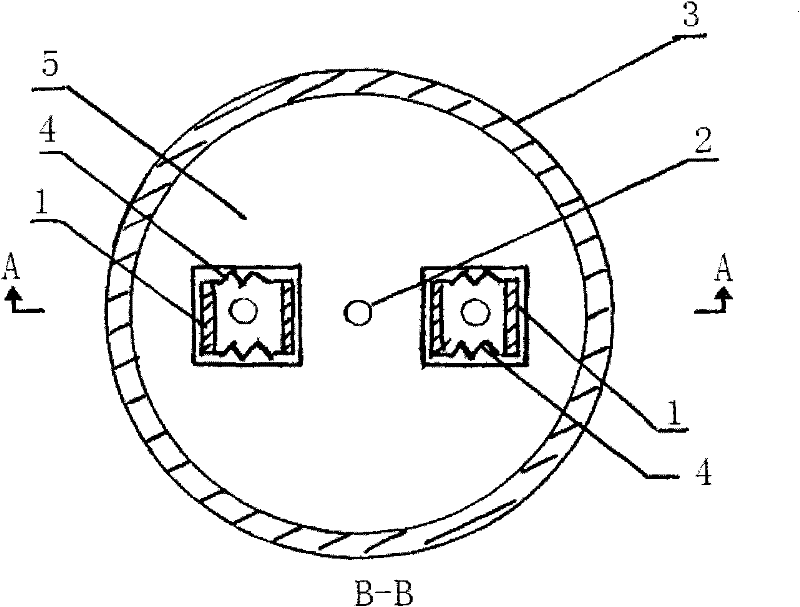

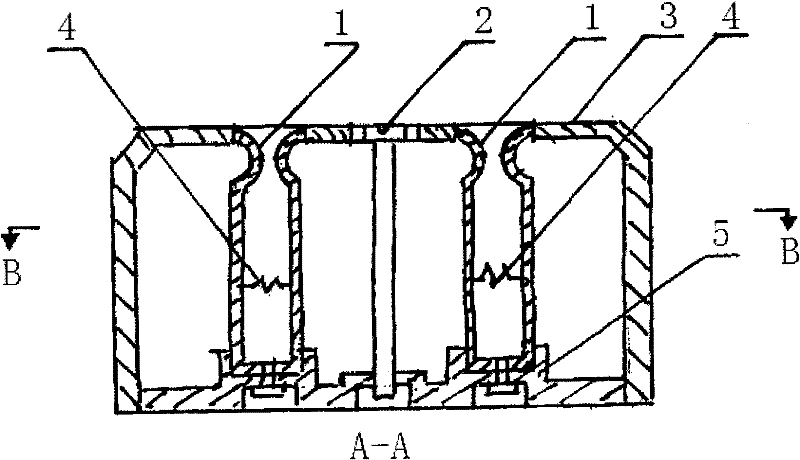

[0012] like Figure 1-2 As shown, a single-phase power socket according to the embodiment of the present invention includes a copper contact piece 1, a cover 3 and a bottom plate 5, and a spring 4 is connected to each of the copper sheets on both sides of the middle section of the two copper contact pieces 1, The two copper contacts 1 and the bottom plate 5 are connected by screws 2, the outer cover 3 is fixed on the bottom plate 5 by screws 2, and the copper contacts 1 rely on the tension of the spring 4 to clamp the copper sheet on the plug, so that the electrical contact is good and it is not easy to generate heat. , but also prolong the service life.

[0013] The invention has good electrical contact, is not easy to generate heat, and has a long service life because the spring will not affect the elastic force when used for a long time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com