Table tennis bat with perspective image on surface and manufacturing process thereof

A table tennis racket and manufacturing process technology, applied to rackets, sports accessories, etc., can solve the problems of inability to design images and single colors on the surface of the racket, and achieve the effect of excellent printing quality, rich connotation, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

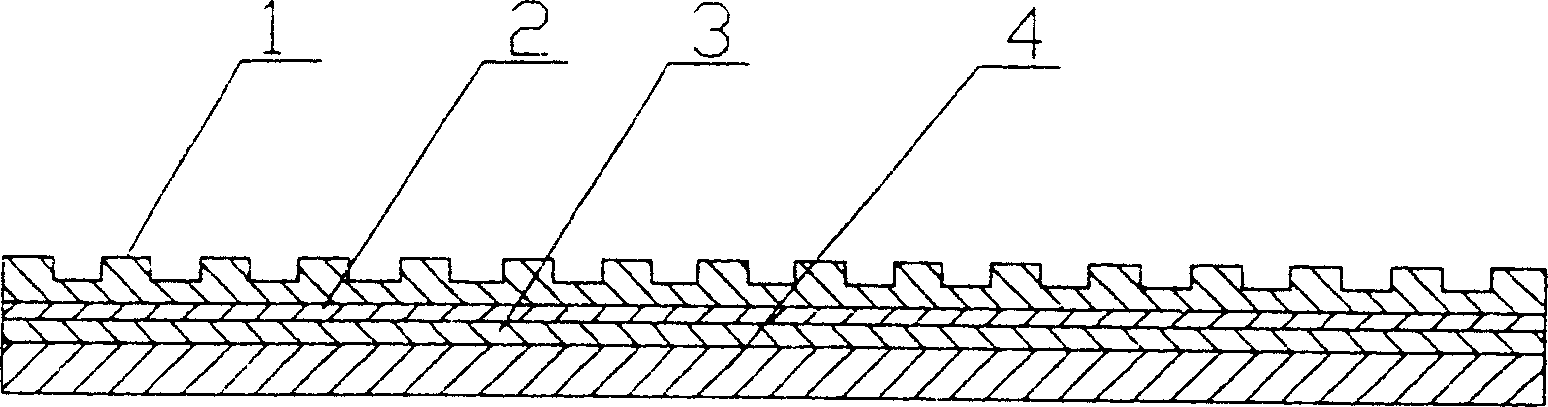

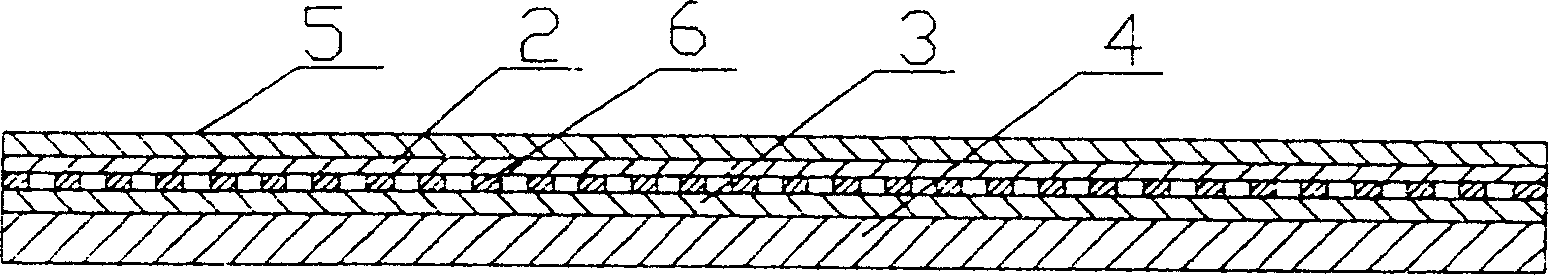

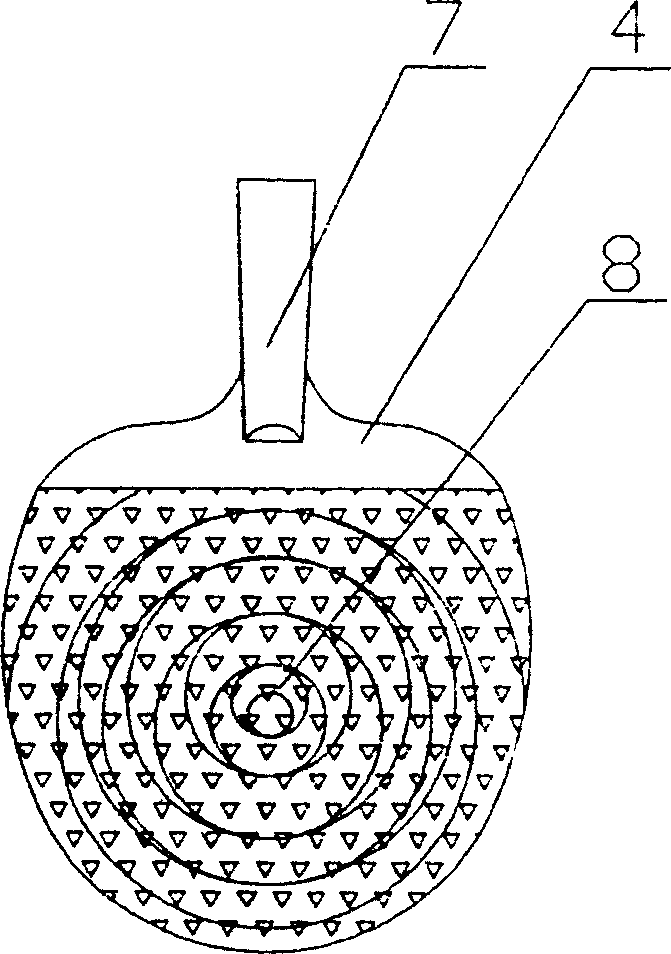

[0017] Embodiment 1: the table tennis racket that bat surface can see through image, it comprises racket base plate 4, handle 7, elastic layer 8 on the racket base plate 4, the elastic layer 8 of described positive rubber racket is provided with transparent colloid layer rubber 1, Image thin layer 2, the transparent rubber layer rubber 1 and the image thin layer 2 are composited to form a positive rubber perspective image rubber, and the elastic layer 8 of the reverse rubber racket is provided with a flat rubber transparent rubber 5, an image thin layer 2, rubber particles Layer 6, the flat glue transparent rubber 5 is combined with the image thin layer 2, and the image thin layer 2 is combined with the rubber particle layer 6 to form a reverse glue perspective image rubber. The positive and reverse glue perspective image rubbers are connected to the racket bottom plate 4 through the middle elastic layer, the perspective image rubber is pasted on the middle elastic layer, the m...

Embodiment 2

[0027] Embodiment 2: The table tennis racket whose racket surface can see through images is that the positive and reverse glue see-through image rubbers described in Embodiment 1 are directly connected to the bottom plate 4 of the racket, and the middle elastic layer is omitted.

[0028] The manufacturing process of the table tennis racket whose racket surface can see through images is as follows: brushing glue on the surface of the racket base plate 4, brushing glue on the back of the rubber of the perspective image, and then bonding the glue surface of the racket base plate 4 with the rubber surface of the perspective image rubber, sticking the rod Rolled evenly, cut along the edge of the racket bottom plate, and pasted along the side of the racket to form the edge protection. Others are identical to the structure and process described in Example 1.

[0029] Embodiment 1, embodiment 2 can be made into rackets of models such as single positive glue, single reverse glue, doubl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com